Bias Tunable Photocurrent in Metal-Insulator-Semiconductor Heterostructures with Photoresponse Enhanced by Carbon Nanotubes

Abstract

:1. Introduction

2. Materials and Methods

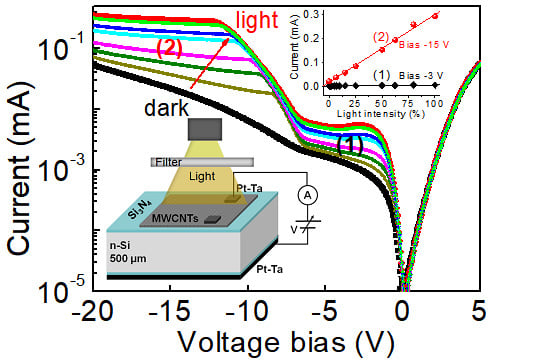

3. Results and Discussion

Band Model

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Zaporotskova, I.V.; Boroznina, N.P.; Parkhomenko, Y.N.; Kozhitov, L.V. Carbon nanotubes: Sensor properties. A review. Mod. Electron. Mater. 2016, 2, 95–105. [Google Scholar] [CrossRef]

- Poudel, Y.R.; Li, W. Synthesis, properties, and applications of carbon nanotubes filled with foreign materials: A review. Mater. Today Phys. 2018, 7, 7–34. [Google Scholar] [CrossRef]

- Belin, T.; Epron, F. Characterization methods of carbon nanotubes: A review. Mater. Sci. Eng. B 2005, 119, 105–118. [Google Scholar] [CrossRef]

- Lamura, G.; Andreone, A.; Yang, Y.; Barbara, P.; Vigolo, B.; Hérold, C.; Marêché, J.-F.; Lagrange, P.; Cazayous, M.; Sacuto, A.; et al. High-Crystalline Single- and Double-Walled Carbon Nanotube Mats Grown by Chemical Vapor Deposition. J. Phys. Chem. C 2007, 111, 15154–15159. [Google Scholar] [CrossRef]

- Dekker, C. How we made the carbon nanotube transistor. Nat. Electron. 2018, 1, 518. [Google Scholar] [CrossRef]

- Artukovic, E.; Kaempgen, M.; Hecht, D.S.; Roth, S.; Grüner, G. Transparent and Flexible Carbon Nanotube Transistors. Nano Lett. 2005, 5, 757–760. [Google Scholar] [CrossRef] [PubMed]

- Di Bartolomeo, A.; Rinzan, M.; Boyd, A.K.; Yang, Y.; Guadagno, L.; Giubileo, F.; Barbara, P. Electrical properties and memory effects of field-effect transistors from networks of single- and double-walled carbon nanotubes. Nanotechnology 2010, 21, 115204. [Google Scholar] [CrossRef] [PubMed]

- Romeo, F.; Citro, R.; Di Bartolomeo, A. Effect of impurities on Fabry-P’erot physics of ballistic carbon nanotubes. Phys. Rev. B 2011, 84, 153408. [Google Scholar] [CrossRef]

- Lee, J.U.; Gipp, P.P.; Heller, C.M. Carbon nanotube p-n junction diodes. Appl. Phys. Lett. 2004, 85, 145–147. [Google Scholar] [CrossRef]

- Manohara, H.M.; Wong, E.W.; Schlecht, E.; Hunt, B.D.; Siegel, P.H. Carbon Nanotube Schottky Diodes Using Ti−Schottky and Pt−Ohmic Contacts for High Frequency Applications. Nano Lett. 2005, 5, 1469–1474. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.; Wang, B.-W.; Hou, P.-X.; Liu, C.; Fang, L.-L.; Tan, J.; Sun, D.-M.; Cheng, H.-M. A carbon nanotube non-volatile memory device using a photoresist gate dielectric. Carbon 2017, 124, 700–707. [Google Scholar] [CrossRef]

- Di Bartolomeo, A.; Yang, Y.; Rinzan, M.B.M.; Boyd, A.K.; Barbara, P. Record Endurance for Single-Walled Carbon Nanotube–Based Memory Cell. Nanoscale Res. Lett. 2010, 5, 1852–1855. [Google Scholar] [CrossRef] [PubMed]

- Baker, B.A.; Zhang, H.; Cha, T.-G.; Choi, J.H. 9-Carbon nanotube solar cells. In Carbon Nanotubes and Graphene for Photonic Applications; Yamashita, S., Saito, Y., Choi, J.H., Eds.; Woodhead Publishing: Sawston, Cambridge, UK, 2013; pp. 241–269. ISBN 978-0-85709-417-9. [Google Scholar]

- Hu, X.; Hou, P.; Liu, C.; Cheng, H. Carbon nanotube/silicon heterojunctions for photovoltaic applications. Nano Mater. Sci. 2019, 1, 156. [Google Scholar] [CrossRef]

- Zhang, S.; Cai, L.; Wang, T.; Miao, J.; Sepúlveda, N.; Wang, C. Fully printed flexible carbon nanotube photodetectors. Appl. Phys. Lett. 2017, 110, 123105. [Google Scholar] [CrossRef]

- Camilli, L.; Passacantando, M. Advances on Sensors Based on Carbon Nanotubes. Chemosensors 2018, 6, 62. [Google Scholar] [CrossRef]

- Boscarino, S.; Filice, S.; Sciuto, A.; Libertino, S.; Scuderi, M.; Galati, C.; Scalese, S. Investigation of ZnO-decorated CNTs for UV Light Detection Applications. Nanomaterials 2019, 9, 1099. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.; Liu, L.; Zhao, D.; Duan, Q.; Ji, J.; Jian, A.; Zhang, W.; Sang, S. Highly Sensitive and Stretchable Strain Sensor Based on Ag@CNTs. Nanomaterials 2017, 7, 424. [Google Scholar] [CrossRef] [PubMed]

- Schroeder, V.; Savagatrup, S.; He, M.; Lin, S.; Swager, T.M. Carbon Nanotube Chemical Sensors. Chem. Rev. 2019, 119, 599–663. [Google Scholar] [CrossRef] [PubMed]

- Giordano, C.; Filatrella, G.; Sarno, M.; Bartolomeo, A.D. Multi-walled carbon nanotube films for the measurement of the alcoholic concentration. Micro Nano Lett. 2019, 14, 304–308. [Google Scholar] [CrossRef]

- Di Bartolomeo, A.; Sarno, M.; Giubileo, F.; Altavilla, C.; Iemmo, L.; Piano, S.; Bobba, F.; Longobardi, M.; Scarfato, A.; Sannino, D.; et al. Multiwalled carbon nanotube films as small-sized temperature sensors. J. Appl. Phys. 2009, 105, 064518. [Google Scholar] [CrossRef]

- Wang, Z.; Wu, S.; Wang, J.; Yu, A.; Wei, G. Carbon Nanofiber-Based Functional Nanomaterials for Sensor Applications. Nanomaterials 2019, 9, 1045. [Google Scholar] [CrossRef] [PubMed]

- Passacantando, M.; Bussolotti, F.; Santucci, S.; Di Bartolomeo, A.; Giubileo, F.; Iemmo, L.; Cucolo, A.M. Field emission from a selected multiwall carbon nanotube. Nanotechnology 2008, 19, 395701. [Google Scholar] [CrossRef] [PubMed]

- Giubileo, F.; Bartolomeo, A.D.; Scarfato, A.; Iemmo, L.; Bobba, F.; Passacantando, M.; Santucci, S.; Cucolo, A.M. Local probing of the field emission stability of vertically aligned multi-walled carbon nanotubes. Carbon 2009, 47, 1074–1080. [Google Scholar] [CrossRef]

- Giubileo, F.; Iemmo, L.; Luongo, G.; Martucciello, N.; Raimondo, M.; Guadagno, L.; Passacantando, M.; Lafdi, K.; Di Bartolomeo, A. Transport and field emission properties of buckypapers obtained from aligned carbon nanotubes. J. Mater. Sci. 2017, 52, 6459–6468. [Google Scholar] [CrossRef]

- Di Bartolomeo, A.; Scarfato, A.; Giubileo, F.; Bobba, F.; Biasiucci, M.; Cucolo, A.M.; Santucci, S.; Passacantando, M. A local field emission study of partially aligned carbon-nanotubes by atomic force microscope probe. Carbon 2007, 45, 2957–2971. [Google Scholar] [CrossRef]

- Melisi, D.; Nitti, M.A.; Valentini, M.; Valentini, A.; Ligonzo, T.; De Pascali, G.; Ambrico, M. Photodetectors based on carbon nanotubes deposited by using a spray technique on semi-insulating gallium arsenide. Beilstein J. Nanotechnol. 2014, 5, 1999–2006. [Google Scholar] [CrossRef] [PubMed]

- Salvato, M.; Scagliotti, M.; De Crescenzi, M.; Boscardin, M.; Attanasio, C.; Avallone, G.; Cirillo, C.; Prosposito, P.; De Matteis, F.; Messi, R.; et al. Time response in carbon nanotube/Si based photodetectors. Sens. Actuators A Phys. 2019, 292, 71–76. [Google Scholar] [CrossRef]

- Soares, J.S.; Jorio, A. Study of Carbon Nanotube-Substrate Interaction. J. Nanotechnol. 2012, 2012, 512738. [Google Scholar] [CrossRef]

- Grace, T.; Yu, L.; Gibson, C.; Tune, D.; Alturaif, H.; Al Othman, Z.; Shapter, J. Investigating the Effect of Carbon Nanotube Diameter and Wall Number in Carbon Nanotube/Silicon Heterojunction Solar Cells. Nanomaterials 2016, 6, 52. [Google Scholar] [CrossRef] [PubMed]

- Passacantando, M.; Bussolotti, F.; Grossi, V.; Santucci, S.; Ambrosio, A.; Ambrosio, M.; Ambrosone, G.; Carillo, V.; Coscia, U.; Maddalena, P.; et al. Photoconductivity in defective carbon nanotube sheets under ultraviolet–visible–near infrared radiation. Appl. Phys. Lett. 2008, 93, 051911. [Google Scholar] [CrossRef]

- Ambrosio, A.; Aramo, C.; Battiston, R.; Castrucci, P.; Cilmo, M.; Crescenzi, M.D.; Fiandrini, E.; Grossi, V.; Guarino, F.; Maddalena, P.; et al. Innovative carbon nanotube-silicon large area photodetector. J. Instrum. 2012, 7, P08013. [Google Scholar] [CrossRef]

- Ambrosio, A.; Ambrosio, M.; Ambrosone, G.; Carillo, V.; Coscia, U.; Grossi, V.; Maddalena, P.; Passacantando, M.; Perillo, E.; Raulo, A.; et al. A new radiation detector made of multi-walled carbon nanotubes. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometersdetectors Assoc. Equip. 2008, 589, 398–403. [Google Scholar] [CrossRef] [Green Version]

- Ambrosio, M.; Ambrosio, A.; Ambrosone, G.; Campajola, L.; Cantele, G.; Carillo, V.; Coscia, U.; Iadonisi, G.; Ninno, D.; Maddalena, P.; et al. Nanotechnology: A new era for photodetection? Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometersdetectors Assoc. Equip. 2009, 610, 1–10. [Google Scholar] [CrossRef]

- Scagliotti, M.; Salvato, M.; De Crescenzi, M.; Boscardin, M.; Castrucci, P. Influence of the contact geometry on single-walled carbon nanotube/Si photodetector response. Appl. Nanosci. 2018, 8, 1053–1058. [Google Scholar] [CrossRef]

- Salvato, M.; Scagliotti, M.; De Crescenzi, M.; Crivellari, M.; Messi, R.; Castrucci, P. Increasing Efficiency in Single-Walled Carbon Nanotube/n-Si Photodetectors by Voltage Doping. IEEE Trans. Nanotechnol. 2018, 17, 837–840. [Google Scholar] [CrossRef]

- Salvato, M.; Scagliotti, M.; De Crescenzi, M.; Crivellari, M.; Prosposito, P.; Cacciotti, I.; Castrucci, P. Single walled carbon nanotube/Si heterojunctions for high responsivity photodetectors. Nanotechnology 2017, 28, 435201. [Google Scholar] [CrossRef] [PubMed]

- Wu, Z.; Chen, Z.; Du, X.; Logan, J.M.; Sippel, J.; Nikolou, M.; Kamaras, K.; Reynolds, J.R.; Tanner, D.B.; Hebard, A.F.; et al. Transparent, Conductive Carbon Nanotube Films. Science 2004, 305, 1273. [Google Scholar] [CrossRef] [PubMed]

- Yu, L.; Shearer, C.; Shapter, J. Recent Development of Carbon Nanotube Transparent Conductive Films. Chem. Rev. 2016, 116, 13413–13453. [Google Scholar] [CrossRef] [PubMed]

- Del Gobbo, S.; Castrucci, P.; Scarselli, M.; Camilli, L.; De Crescenzi, M.; Mariucci, L.; Valletta, A.; Minotti, A.; Fortunato, G. Carbon nanotube semitransparent electrodes for amorphous silicon based photovoltaic devices. Appl. Phys. Lett. 2011, 98, 183113. [Google Scholar] [CrossRef]

- Tune, D.; Shapter, J. Effect of Nanotube Film Thickness on the Performance of Nanotube-Silicon Hybrid Solar Cells. Nanomaterials 2013, 3, 655–673. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Choi, J.; Kim, J. Defective carbon nanotube-silicon heterojunctions for photodetector and chemical sensor with improved responses. J. Micromechanics Microengineering 2015, 25, 115004. [Google Scholar] [CrossRef]

- Li, X.; Mariano, M.; McMillon-Brown, L.; Huang, J.-S.; Sfeir, M.Y.; Reed, M.A.; Jung, Y.; Taylor, A.D. Charge Transfer from Carbon Nanotubes to Silicon in Flexible Carbon Nanotube/Silicon Solar Cells. Small 2017, 13, 1702387. [Google Scholar] [CrossRef] [PubMed]

- Cox, N.D.; Cress, C.D.; Rossi, J.E.; Puchades, I.; Merrill, A.; Franklin, A.D.; Landi, B.J. Modification of Silver/Single-Wall Carbon Nanotube Electrical Contact Interfaces via Ion Irradiation. Acs Appl. Mater. Interfaces 2017, 9, 7406–7411. [Google Scholar] [CrossRef] [PubMed]

- An, Y.; Behnam, A.; Pop, E.; Ural, A. Metal-semiconductor-metal photodetectors based on graphene/p-type silicon Schottky junctions. Appl. Phys. Lett. 2013, 102, 013110. [Google Scholar] [CrossRef] [Green Version]

- Passacantando, M.; Grossi, V.; Santucci, S. High photocurrent from planar strips of vertical and horizontal aligned multi wall carbon nanotubes. Appl. Phys. Lett. 2012, 100, 163119. [Google Scholar] [CrossRef]

- Di Bartolomeo, A. Graphene Schottky diodes: An experimental review of the rectifying graphene/semiconductor heterojunction. Phys. Rep. 2016, 606, 1–58. [Google Scholar] [CrossRef] [Green Version]

- Giubileo, F.; Di Bartolomeo, A. The role of contact resistance in graphene field-effect devices. Prog. Surf. Sci. 2017, 92, 143–175. [Google Scholar] [CrossRef] [Green Version]

- Niu, G.; Capellini, G.; Hatami, F.; Di Bartolomeo, A.; Niermann, T.; Hussein, E.H.; Schubert, M.A.; Krause, H.M.; Zaumseil, P.; Skibitzki, O.; et al. Selective Epitaxy of InP on Si and Rectification in Graphene/InP/Si Hybrid Structure. Acs Appl. Mater. Interfaces 2016, 8, 26948–26955. [Google Scholar] [CrossRef] [PubMed]

- Speight, J.G. Lange’s Handbook of Chemistry; MC Graw Hill Education: New York, NY, USA, 2017; ISBN 978-1-259-58609-5. [Google Scholar]

- Zhang, L.C.; Jin, H.Y.; Gao, Y.Z.; Zhang, H.; Huang, W.; Lu, J.Z. The characteristics of Ni (Pt) Si /Si Schottky barrier diode with deep trench. In Proceedings of the Proceedings, 7th International Conference on Solid-State and Integrated Circuits Technology, Beijing, China, 18–21 October 2004; IEEE: Beijing, China, 2004; Volume 1, pp. 460–463. [Google Scholar]

- Ocak, Y.S.; Genisel, M.F.; Kılıçoğlu, T. Ta/Si Schottky diodes fabricated by magnetron sputtering technique. Microelectron. Eng. 2010, 87, 2338–2342. [Google Scholar] [CrossRef]

- Sze, S.M.; Gibbons, G. Avalanche breakdown voltages of abrupt and linearly graded p‐n junctions IN Ge, Si, GaAs, and GaP. Appl. Phys. Lett. 1966, 8, 111–113. [Google Scholar] [CrossRef]

- Grillo, A.; Giubileo, F.; Iemmo, L.; Luongo, G.; Urban, F.; Di Bartolomeo, A. Space charge limited current photoconductive effect in few-layer MoS2. J. Phys. Conf. Ser. 2019, 1226, 012013. [Google Scholar] [CrossRef]

- Di Bartolomeo, A.; Luongo, G.; Iemmo, L.; Urban, F.; Giubileo, F. Graphene–Silicon Schottky Diodes for Photodetection. IEEE Trans. Nanotechnol. 2018, 17, 1133–1137. [Google Scholar] [CrossRef] [Green Version]

- Luongo, G.; Giubileo, F.; Genovese, L.; Iemmo, L.; Martucciello, N.; Di Bartolomeo, A. I-V and C-V Characterization of a High-Responsivity Graphene/Silicon Photodiode with Embedded MOS Capacitor. Nanomaterials 2017, 7, 158. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Di Bartolomeo, A.; Grillo, A.; Urban, F.; Iemmo, L.; Giubileo, F.; Luongo, G.; Amato, G.; Croin, L.; Sun, L.; Liang, S.-J.; et al. Asymmetric Schottky Contacts in Bilayer MoS2 Field Effect Transistors. Adv. Funct. Mater. 2018, 28, 1800657. [Google Scholar] [CrossRef] [Green Version]

- Sze, S.M.; Ng, K.K. Physics of Semiconductor Devices: Sze/Physics; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2006; ISBN 978-0-470-06832-8. [Google Scholar]

- Lin, C.H.; Liu, C.W. Metal-Insulator-Semiconductor Photodetectors. Sensors 2010, 10, 8797–8826. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hashimoto, H.; Yamada, R.; Hirokane, T.; Arima, K.; Uchikoshi, J.; Morita, M. Photodetective Characteristics of Metal–Oxide–Semiconductor Tunneling Structure with Aluminum Grid Gate. Jpn. J. Appl. Phys. 2007, 46, 2467–2470. [Google Scholar] [CrossRef]

- Yim, C.; McEvoy, N.; Kim, H.Y.; Rezvani, E.; Duesberg, G.S. Investigation of the Interfaces in Schottky Diodes Using Equivalent Circuit Models. Acs Appl. Mater. Interfaces 2013, 5, 6951–6958. [Google Scholar] [CrossRef] [PubMed]

- Di Bartolomeo, A.; Giubileo, F.; Luongo, G.; Iemmo, L.; Martucciello, N.; Niu, G.; Fraschke, M.; Skibitzki, O.; Schroeder, T.; Lupina, G. Tunable Schottky barrier and high responsivity in graphene/Si-nanotip optoelectronic device. 2d Mater. 2016, 4, 015024. [Google Scholar] [CrossRef] [Green Version]

- Hsu, B.C.; Liu, C.W.; Liu, W.T.; Lin, C.H. A PMOS tunneling photodetector. IEEE Trans. Electron Devices 2001, 48, 1747–1749. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Di Bartolomeo, A.; Giubileo, F.; Grillo, A.; Luongo, G.; Iemmo, L.; Urban, F.; Lozzi, L.; Capista, D.; Nardone, M.; Passacantando, M. Bias Tunable Photocurrent in Metal-Insulator-Semiconductor Heterostructures with Photoresponse Enhanced by Carbon Nanotubes. Nanomaterials 2019, 9, 1598. https://doi.org/10.3390/nano9111598

Di Bartolomeo A, Giubileo F, Grillo A, Luongo G, Iemmo L, Urban F, Lozzi L, Capista D, Nardone M, Passacantando M. Bias Tunable Photocurrent in Metal-Insulator-Semiconductor Heterostructures with Photoresponse Enhanced by Carbon Nanotubes. Nanomaterials. 2019; 9(11):1598. https://doi.org/10.3390/nano9111598

Chicago/Turabian StyleDi Bartolomeo, Antonio, Filippo Giubileo, Alessandro Grillo, Giuseppe Luongo, Laura Iemmo, Francesca Urban, Luca Lozzi, Daniele Capista, Michele Nardone, and Maurizio Passacantando. 2019. "Bias Tunable Photocurrent in Metal-Insulator-Semiconductor Heterostructures with Photoresponse Enhanced by Carbon Nanotubes" Nanomaterials 9, no. 11: 1598. https://doi.org/10.3390/nano9111598

APA StyleDi Bartolomeo, A., Giubileo, F., Grillo, A., Luongo, G., Iemmo, L., Urban, F., Lozzi, L., Capista, D., Nardone, M., & Passacantando, M. (2019). Bias Tunable Photocurrent in Metal-Insulator-Semiconductor Heterostructures with Photoresponse Enhanced by Carbon Nanotubes. Nanomaterials, 9(11), 1598. https://doi.org/10.3390/nano9111598