1. Introduction

Pathogenic bacteria are a major worldwide concern, e.g., in the areas of food and water safety as well as healthcare. Independent of the local setting and level of development, any shortage or even lack of robust, reliable and affordable tests for rapid detection of pathogenic bacteria leads to a possible elevated transmission risk of pathogens, which may subsequently lead to life-threatening illnesses. This is true for some highly developed countries, where the screening of patients regarding colonialization with antimicrobial resistant bacteria is still not carried out routinely due to cost and resource issues. Likewise, bacterial contaminations in food and drinking water pose serious threats to the well-being of people particularly in less-developed countries. The World Health Organization (WHO) declared that 1.1 billion people lack access to an improved drinking water supply [

1]. For people living in regions that have no access to necessary technical and economic resources, microbiological water lab tests in approved laboratories are often practically out of reach.

Independently of the focus and local challenges, the development of novel cheap, rapid, easy to use point of care (POC) bacteria detection methods may contribute to overcome the limitations of conventional methods especially regarding the specific needs for certain application areas and settings. Key to their success are also efficient methods to quantify their performance in order to set proper thresholds for clear readouts.

In this context, there has been growing interest in detection of (pathogenic) bacteria, such as the hygiene marker

Escherichia coli (

E. coli) on-site using simple approaches that can be applied by non-specialists in a non-laboratory setting.

E. coli is by default tested in drinking water or other industrial water resources based on detection of the target enzyme β-Glucuronidase (ß-Gus), an enzyme that is produced in high concentration by 95% of all

E. coli [

2,

3] but also by mammalian cells as a lysosomal enzyme responsible for degradation of glucoronate-containing glycosaminoglycans [

4] as well as in some plants [

5], that as off-target sources obviously do not result in relevant false positives in the β-Gus chromogenic standards method approved for specific

E. coli detection. Conventional methods for detecting and identifying bacteria are based on culturing the microorganism on chromogenic differential nutrient agar plates. These can be also be tailored for the selective growth of a particular bacterial species and thus can provide useful information about the bacteria present in a contaminated sample [

6]. The drawback is that these methods are time-consuming due to the necessary transport to specialized microbiological laboratories in hospitals or research institutes that need to incubate these specific agar plates for at least one up to 4 days for visual detection of bacteria colonies by bare eye. Additionally, there might be challenges with antagonistic organism interference, lack of specificity, or special challenges for slow-growing fastidious microorganisms. Other highly advanced approaches require trained personnel or dedicated and highly complex analytical devices, such as mass spectrometers, flow cytometers that can detect fluorescently labeled individual bacteria in complex media in an automated manner, as well as thermocyclers for polymerase chain reaction (PCR) for detection of short DNA sequences specific for a certain bacterial species [

7,

8].

Hence it is not surprising that a multitude of approaches with novel sensing materials has been reported in recent years. These approaches rely on, among other things, sensing nanoparticles [

9,

10], nanocapsules [

11,

12] and hydrogels [

6,

13,

14,

15,

16,

17,

18]. The adaptation of such bacteria detection approaches with demonstrated feasibility to POC-compatible formats for application in remote settings without controlled temperature and reliable electricity is another challenge. Suitable, but yet unavailable sensor systems, must exhibit pronounced robustness, long shelf-life and high stability, coupled with ease of application and a robust and bias-free detection and analysis.

Due to the worldwide availability of mobile phones, smartphone-based biosensors have already been gaining considerable momentum in this area and opened new avenues towards next-generation POC sensing and biosensing applications, also known as “lab-in-a-phone technology” [

19,

20]. For instance, Kim et al. reported on a smartphone-based sensor for determining blood hematocrit from 10% to 65% with a limit of detection (LOD) of 0.1%. In their study the hematocrit concentration was determined from the red, green and blue components of images captured under white light illumination in a microfluidic device using a smartphone camera [

21,

22]. Liu et al. [

23] proposed a smartphone sensor to measure concentrations of the antibiotic streptomycin in different food products. The detection of changes in absorbance ratio due to streptomycin binding to aptamer-conjugated Au nanoparticles was realized by a smartphone camera [

21,

23]. Likewise the concentrations of proteins (bovine serum albumin, BSA), enzymes (catalase) and carbohydrates were determined using an analysis of the average brightness of smartphone-acquired images, which were obtained by converting the image pixels to HSV (hue, saturation, value) color space [

21,

24].

The combination of lab-in-a phone technology with smart interface or nanochemistry technologies for bioanalytical applications has raised hope in particular for applications in remote and resource-poor settings [

19,

25]. As carriers for the reporting units, paper and paper-based microfluidic devices have been developed for applications in areas such as health diagnostics, food safety, and environmental monitoring [

26]. Paper eliminates the need for pumps, since the wicking mechanism allows for passive transport via capillary action. Moreover, paper is also compatible with a variety of chemicals and biomaterials (biological inertness) and eliminates problems associated with bubbles [

27,

28].

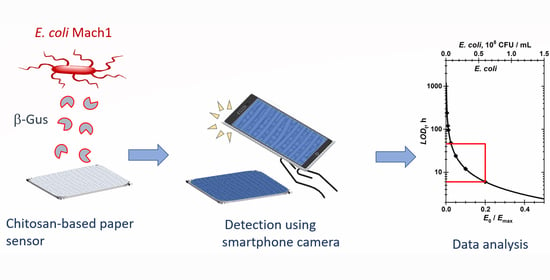

Hence a promising strategy is the combination of feasible bacteria detection approaches with a paper-based carrier system that was investigated here for the

E. coli marker enzyme β-glucuronidase (ß-Gus) and the non-pathogenic

E. coli Mach1 lab strain as a model organism (

Figure 1) with smartphone-based detection, readout and quantitative data analysis. Previously, chitosan hydrogels equipped with different fluorogenic or chromogenic substrates were shown to rapidly, selectively and sensitively detect and differentiate among different strains of bacteria with LOD for the enzymes in several cases <1 nM after 1 h observation time [

16,

29]. As we report here, chitosan-based autonomously self-reporting hydrogels were successfully adapted to this paper carrier-based format to detect and quantify concentrations of bacterial enzymes. In particular, the robust and complete analysis of images, captured with a conventional smartphone camera, affords quantitative values for the limit of detection. This new approach that was demonstrated for the detection of

E. coli can be adapted for use in other sensing systems that rely on color changes.

3. Discussion

The contact angle values (

Figure S1) showed that the hydrophilic paper was coated with the much more hydrophobic chitosan. The successful deposition was also concluded from FESEM images (

Figure S3) and was in agreement with the literature, where it was observed that the chitosan solution filled the micropores of uncoated paper and formed a layer on the surface [

31]. The increasing values of the static water contact angle with increasing number of coating steps may indicate a thicker or less defective chitosan layer. Since paper with larger mean pore size exhibited larger values of the contact angle, the data are consistent with a chitosan covered cellulose paper that retained its microscopic structure. This interpretation is supported by morphological observations made by FESEM (

Figure S3) and the analysis of the chemical composition of the surface by XPS (

Figure 2a–c and

Figure S2). As there was no nitrogen found in the paper used (

Figure S2) and since XPS provides compositional information up to a maximum information depth of 8–10 nm under the conditions employed, one may conclude from the N1s signal observed only after coating with nitrogen containing chitosan (

Figure 2) that the deposition was successful. Hence after coating the paper with chitosan, the characteristic N1s signal indicates the presence of chitosan in the top 8–10 nm of the sample surface. Furthermore, the element scan shown in

Figure 2 corroborate that the chemical environment of the observed carbon and oxygen is consistent with chitosan. On the other hand, the not perfectly compensated charging make a quantitative analysis difficult.

The ATR-FTIR spectra (

Figure 2d) were in agreement with previously published data [

13], which showed that the chromogenic substrate X-Gluc was successfully immobilized on the chitosan layer coating of the filter paper. After modification with X-Gluc, the primary amine peak in chitosan chain at 1599 cm

−1 disappeared, while the amide I and II vibrations at 1641 cm

−1 and 1557 cm

−1, respectively, became stronger.

The presence of the substrate residuals was also observed in enzymatic reaction under various conditions. Both in PBS and LB medium the neat enzyme solutions caused a characteristic blue color (

Figure 3 and

Figure S4), which did not leach from the paper. No blue color was observed outside hydrogel-coated paper, in agreement with previous report [

17]. With increasing reaction time, the color became more intense. Qualitatively similar observation in

E. coli suspension indicates the presence of the enzyme also in the LB medium (

Figure 4), in agreement with previously published work [

29]. The quantitative analysis of the photographs and the enzymatic reaction kinetics is key for an application of related sensors in the future. Bare eye visual detection possesses inherently lower LOD values [

17] and is also hampered by possible observer bias as well as color weakness and blindness issues of the observer. The analysis mandates first a closer look at the fundamentals of the reaction kinetics involved.

3.1. Reaction Kinetics

The overall enzymatic reaction of substrate molecules in solution is classically described by the Michaelis–Menten kinetic scheme [

32,

33]:

Here

E denotes the enzyme,

S is the substrate and

P is the primary reaction product,

(in s

−1) denotes the reaction rate constant,

(in M) is the equilibrium constant of the dissociation of the enzyme-substrate complex

. A somewhat different substrate-conserving model is suggested for two phase reactions at solid substrates [

34]:

Although this micro-kinetic scheme gives the same initial rate of product formation as that of Scheme (1), this reaction does not slow down at higher degrees of substrate conversion and finally yields infinite amounts of P. In addition, the scheme is oversimplified due to an irreversible catalytic second stage. In the present study this problem has been solved by a fast irreversible aerobic oxidation of the colorless P to the indigo-like dimer , which is observed owing to its deep blue color

In the experiments, the enzymatic cleavage of chitosan-g-X-Gluc by ß-Gus leads to the primary product

P, 5-bromo-4-chloro-3-hydroxyindole, and finally by reaction (3) to an insoluble final product

, 5,5’-dibromo-4,4’-dichloro-indigo, with a stoichiometric coefficient

b = 1/2. The amount of reaction product at time

t is estimated by a Samsung SM-G950W color digital image sensor having three primary red-green-blue (

RGB) bands with maxima at 470, 540 and 620 nm, respectively [

35]. The final reaction product, i.e., the blue pigment

, possesses strong absorption in the

R-channel and practically no absorption both in the

G-channel and in the

B-channel, see

Figure 5.

Hence, the

R-channel is optimal for the detection of

. The experimental intensities

were estimated as integral intensities in the

RGB-channels, followed by the splitting of the measured images with ImageJ software. Because these

RGB chromatic intensities are just reflected light intensities, they can be used for this purpose in a similar manner as a measure for

in the form of the Beer’s law. The amount of

is given by the relative color intensity at time

t and that at time zero

, where

is an effective natural molar absorption coefficient of

over the red spectral range. Then for a given time

t the pigment

and amount of primary product formed in (1) equals

. Taking into account that the value of

normalized to initial (

t = 0) substrate amount

, the experimental value of the remaining substrate fraction,

, can be evaluated as:

Reaction scheme (1), similar to reference [

36], gives for the total enzyme concentration

the integrated enzyme kinetics:

3.2. Chromatic Intensity Kinetics at Different Enzyme Concentrations

The typical kinetics of

for the enzymatic reaction of chitosan-g-X-Gluc with ß-Gus in PBS and in LB at 25 °C as well as in the presence of

E. coli Mach1 strain in LB at 20 °C, respectively, is shown in

Figure 6.

The chroma red exhibits a gradual decrease with reaction time for the chitosan film both in the enzymatic and in bacterial suspension solution, and clear tendency to level off at long reaction times. This is due to the absorption of red light by the blue pigment

, a product of reactions (1) and (3). The hydrolysis kinetics in all these three cases is well described by the Michaelis reaction scheme (1), as is shown by the solid line calculated with Equation (5) for all kinetic curves at different enzyme or bacterial suspension concentrations. Of course, the pigment

formation is slower at lower

and at a higher dilution factor:

where

is the enzyme concentration in the stock bacterial suspension. The thermodynamic and kinetic parameters of (5),

and

, are strongly correlated to each other. For almost equivalent fit quality, characterized by sum of squared residuals (SSR), several sets of kinetic and thermodynamic parameters

and

can be used, keeping the

ratio practically constant. From the data in

Table 1 one can see that even when these parameters change within at least one order of magnitude (cf.

= 1000 and 10,000 for enzymatic substrate hydrolysis in PBS and LB as well as

= 1 and 10 nM

−1h

−1 for bacterial substrate hydrolysis) the

ratio changes only by 0.1%, 0.1% and 20%, respectively, so that the fit quality SSR remains practically constant within 0.06%.

While the thermodynamic equilibrium constant

appears in the left side of (5), the kinetic rate constant

and analytical enzyme concentration

are present only on the right side as a product. In this case the roots

of (5)

vs. unitless time

form a universal global line for all enzymatic kinetics in a series with different

or

. The results of such a global fit for enzymatic reactions in PBS, LB and bacterial suspension shown in

Figure 7 and

Table 2 allow one to conclude that the enzymatic reaction of chitosan-g-X-Gluc in a complete set of analytical enzyme concentrations can be quantitatively described by the Michaelis–Menten reaction scheme (1) with only two generalized constants: (i) the thermodynamic equilibrium constant

and (ii) the reaction rate constant

. In these figures, the experimental data

scaled with the factor

to an attained substrate conversion

are plotted against the unitless time

or

. Taking the practically straightforward correlation of

and

into account, see

Table 1, the latter is assumed to be equal to 1 nM

−1h

−1.

The constant value of

for different

implies a constant substrate amount

at each

in a series. This means in turn equal amounts of substrate, which are converted finally to the pigment

in equal amounts at the end of reaction, i.e., equal amplitude factors

. Although variation of

is not so strong in series, some substantial deviations, such as 0.82 and 0.56, in comparison to 1.28 ± 0.16 for ß-Gus in PBS (

Figure 7a), 0.58 in comparison to 1.00 ± 0.12 for ß-Gus in LB (

Figure 7b) and 0.843, 0.459 and 0.793 in comparison to 0.232 ± 0.048 for

E. coli Mach1 suspension in LB (

Figure 7c) are probably caused by inhomogeneous light scattering in these samples.

While the constants

and

are a function of substrate amount, their ratio

is independent from

for enzymatic solutions and proportional to the enzyme concentration in stock bacterial suspension

for bacteria mediated cleavage. When the small temperature difference is neglected, the ratio of this value for stock (

= 1) suspension (

,

Table 2) to an averaged value of

= 0.86 pM

−1h

−1 for the model system with the same substrate and enzyme in the same LB (

Table 2) gives an estimation of

for stock

E. coli Mach1 suspension in LB.

3.3. Limit of Detection ()

With the results obtained, the minimum detectable pigment fraction

) value can be determined from the correlation of experimental values of

vs. calculated values of

shown in

Figure 7 by the following relation [

37,

38]:

Here

is root-mean-square deviation of

from

and

is the slope, which is ≈1. The calculated

values are collected in

Table 2. The minimal reaction conversion degree to smartphone-based detection of the enzymatic reaction is rather high, 0.089–0.25, probably due to substantial scattering in the experimental chromatic intensity.

The minimal reaction time (

) required to reach the conversion

at a certain enzyme concentration according to Equation (5) is inversely proportional to enzyme concentration:

The lowest

values in

Table 2 calculated from the best fit from 100 to 440 nM h means that in order to detect β-Gus in LB at a low concentration of 1 nM, one needs 4–18 days to reach the minimal detectable pigment amount. The

reaches a few (1–5) hours at 100 nM of enzyme. The concentration plot of

in the entire range of studied

is shown in

Figure 8.

Optical biosensors that rely on the detection of absorbed ultraviolet–visible (UV–Vis) light [

14,

15,

16,

17,

24,

39,

40,

41,

42] possess usually lower sensitivity than those based on fluorescence [

13,

16,

18,

19]. This is also true for UV–Vis detection of indigo derivatives [

14,

17,

39]. Employing a Lowry protein assay, the absorption of a copper (I) complex at 660 nm measured by a smartphone camera enabled the detection of catalase with a rather high LOD of 5 µM [

24]. Rarely the values of the LOD for photometric detection is lower than that for fluorometric detection [

15]: LOD values of 20 and 45 nM were found for the hydrolysis of a chromogenic substrate by elastase and a fluorogenic substrate by α-glucosidase, respectively. This fact might be caused by different substrates used and variation of enzyme activity. In general, the LOD strongly depends on the quality of optical path and sample. Detection of β-Gus and β-galactosidase by formation of indigo-derivatives in transparent chitosan film was noted to possess LOD values of 3–5 nM for detection with an absorption spectrometer and around 30–60 nM for bare eye visual detection [

17]. It was shown that with reporter-hydrogel coated glass 40 nM of β-Gus in solution can be detected within 5 min employing high-quality research-grade absorption spectrometers [

14]. Here it is reported that for the same biochemical system, simple smartphone-based paper biosensors are shown to also reach this level, albeit with a 13 times longer incubation time of 1.6 h for the neat enzyme in PBS, which is comparable to the results reported before using a reporter-hydrogel coated glass fiber [

14]. For neat enzyme in LB and

E. coli bacterial suspension with a concentration of 5.8 × 10

7 CFU/mL the incubation time for the smart phone approach required longer incubation time of 5–6 h (

Table 2).

These data compared favorably to literature data. In an attempt to distinguish among

E. coli serotypes exhibiting different phenotypes regarding production of the enzyme β-Gus, a multilayered paper sensor with two different indigo pigments duplex coloration was proposed by Kim et al. [

39]. Without an additional cultivation step of

E. coli but extra centrifugation and bacteria lysis steps, an LOD of ~10

7 CFU/mL was found by colorimetric analysis with a commercial scanner or bare eye visual detection. A paper-based colorimetric β-lactamase biosensor that relies on the cleavage of nitrocefin showed a LOD of 3.8 × 10

6 CFU/mL for

E. coli, employing an absorption spectrophothometer [

41]. While smartphone detection by absorption of 4-nitrophenol on paper exhibited low values of the LOD of 2, 13 and 100 nM for β-glucosidase, β-galactosidase and β-Gus, respectively, the triggering bacteria

Enterococcus faecalis was found only at a high concentration of 1 × 10

9 CFU/mL without pre-enrichment via culturing [

42]. Thus, the simple sensor system presented here is comparable regarding its LOD values to other sensoric systems based on enzyme chromogenic substrates that are under development, but does not require any extra lysis step or sensitive reagents.

Nevertheless our POC bacterial detection approach needs to be further optimized for specific application to meet the sensitivity required to indicate the relevant harmful concentrations thresholds for E. coli, as used here as a model system, or other bacteria. Therefore, further developments towards applications should be focused on suppressing unwanted reflections, increasing the sensitivity by increasing the specific surface area e.g., by nanostructuring and by increasing the substrate loading as well as by implementing added features. This may refer to the integration of a bacteria lysis step and/or concentration of bacteria or target enzymes for instance via an initial filtration step. We emphasize that this work has to be classified as a proof of concept for chromogenic reporter hydrogel based E. coli detection integrated in a POC approach compatible smart phone signal read out that might be used in the long term upon further development as a POC test for bacterial contamination.

5. Materials and Methods

5.1. Materials

Chitosan (medium molar mass, 190–310 kDa, 75–85% deacetylated), phosphate buffered saline (PBS) tablets, 5-bromo-4-chloro-3-indolyl-β-D-glucuronide (X-Gluc),

N-(3-dimethylaminopropyl)-

N-ethylcarbodiimide hydrochloride (EDC·HCl),

N-hydroxy succinimide (NHS), β-glucuronidase (ß-Gus) purified from

E. coli (694.3 units/mg, E.C. 3.2.1.31; type IX-A), dimethyl sulfoxide (DMSO, 99%), pyridine (anhydrous, 99.8%) were purchased from Sigma-Aldrich. Indigo (Carl Roth) and acetic acid (glacial, J. T. Baker), Dulbecco’s phosphate saline buffer (DPBS, 10 ×, 95 mM (PO

4) without Mg

2+ and Ca

2+, Lonza), Lysogeny broth (LB, Luria/Miller: 10 g/L tryptone, 5 g/L yeast extract, 10 g/L NaCl, pH 7.0 ± 0.2, Carl Roth GmbH, Germany), qualitative filter paper (5–12 µm and 12–15 µm pore size, VWR, France) were purchased from the listed suppliers. Milli-Q water was drawn from a Millipore Direct Q8 system with a resistivity 18.2 MΩ cm (Millipore advantage A10 system, Schwalbach, with Millimark Express 40 filter, Merck, Germany), sterilized PBS solution (10 mM, pH 7.4) was prepared by dissolving one tablet of phosphate buffered saline in 200 mL of Milli-Q water followed by autoclaving at 121 °C and 100.1 kPa vapor pressure in an autoclave (Systec VB-150, Systec GmbH, Linden, Germany). Only for the data shown in

Figure S4, PBS was obtained through the dilution of DPBS with Milli-Q water and volume ratio of DPBS and Milli-Q water was 1:9.

5.2. Bacteria

As a test organism we used the nonpathogenic

Escherichia coli W (ATCC9637) derivative Mach1™ (T1 Phage-resistant, chemical competent, purchased form Invitrogen, USA) [

43].

5.3. Preparation of Chitosan-Coated Paper

100 µL of 1.5 wt% chitosan in 1 wt% acetic acid solution was deposited on paper substrates (0.8 × 1.0 cm2) and dried these overnight. The two-time deposition of chitosan was done by adding 100 µL of chitosan solution on dried pre-deposited paper substrate followed by overnight drying in a flow hood.

5.4. Contact Angle Measurements

The contact angle measurements were taken using a Data Physics Instruments (Filderstadt, Germany) Contact Angle System OCA-15, equipped with a video measuring system with high-resolution charged coupled device (CCD) camera. SCA 20 software was used for data acquisition. Chitosan coated papers were fixed on a glass slide and were kept flat throughout the analysis. The static contact angle was measured by the sessile drop method by gently placing a droplet of 2 μL of Milli-Q water, and the values were collected 5 times.

5.5. Attenuated Total Internal Reflection-Fourier Transform Infared (ATR-FTIR) Spectroscopy

A Tensor 27 Bruker Optik GmbH (Ettlingen, Germany) FTIR spectrometer was used for ATR-FTIR analysis. The chitosan coated paper was fixed on a holder and subsequently placed in the chamber of the instrument. The measurements were performed in absorbance mode in the spectral range 4000 to 400 cm−1 and a spectral resolution of 4 cm−1. The background spectra were obtained by using air.

5.6. Field-Emission Scanning Electron Microscopy (FESEM) Analysis

The dried samples were sputtered with a thin gold layer (8–10 nm) in a sputter coater (S150B BOC Edwards, West Sussex, UK) at a pressure of 0.2 mbar in argon atmosphere for 2 min at a voltage of 1.0 kV and then placed in a sample holder in the FESEM sample chamber. The data were acquired on a FESEM (Zeiss Ultra 55cv, Oberkochen, Germany) with 30 kV maximum operating voltage formed with an operating voltage of 10 kV with the in-lens secondary electron detector.

5.7. X-ray Photoelectron Spectroscopy (XPS) Analysis

The surface chemical composition of the films was analyzed by X-ray photoelectron spectroscopy (S-probe ESCA SSX-100s, Surface Science Instruments, Mountain View, USA) with an Al Kα radiation of 200 W. Survey spectra were measured from 0 to 1200 eV with a resolution of 1 eV (spot size: 800 µm2) and high resolution spectra with a resolution of 0.1 eV (spot size: 300 µm2).

5.8. Modification with 5-Bromo-4-Chloro-3-Indole-β-D-Glucuronide Sodium Salt (X-Gluc)

Chitosan-g-X-Gluc paper substrate was prepared using EDC/NHS chemistry according to the reference [

16]. Briefly, 4.5 mM of X-Gluc was prepared in PBS (pH 7.4), followed by addition of EDC (6.7 mol/mol of X-Gluc) and NHS (6.7 mol/mol of X-Gluc). Then the solution was stirred for 1 h. Each chitosan sample was then immersed in 2 mL of this modification solution for 6h under shaking (rate 60 Hz), followed by washing with Milli-Q water for 2 h under shaking, with subsequent exchange of Milli-Q water after each 30 min. Then the samples were dried overnight in a flow hood.

5.9. Enzymatic Reaction with β-Glucuronidase

20 µM stock enzyme solution of ß-Gus was prepared in sterilized PBS (pH 7.4) and the desired enzyme concentrations were prepared by further dilutions in PBS (pH 7.4) and LB (pH 7.0). 100 µL of the enzyme solutions tested were deposited on the paper sensors and incubated at 25 °C. Pictures were taken at different time intervals with a Samsung Galaxy S8 camera in a standardized position on a black box with integrated illumination, designed and produced by the workshop of the University of Siegen (see

Figure S5). The illumination was done with a LIVARNO LUX light-emitting diode (LED) light strip (100–240 V, 50/60 Hz) fixed within the black box.

5.10. Detection of E. coli Cultures

For studying enzymatic cleavage via ß-Gus produced by E. coli Mach1, overnight culture was prepared by taking 1 colony from an agar plate prepared in 5 mL LB and incubation at 37 °C for 18 h with shaking at 200 rpm. The OD600 nm of overnight culture was set to 0.5 referring to a bacteria concentration of (3 ± 0.2) × 108 CFU/mL. Then the desired dilutions of bacteria suspension were prepared in LB. We deposited 100 µL of each dilution of bacteria solution on the paper sensors for the experiment. All the experimental steps were performed at 20 °C.