3D Concentric Electrodes-Based Alternating Current Electrohydrodynamics: Design, Simulation, Fabrication, and Potential Applications for Bioassays

Abstract

:1. Introduction

2. Materials and Methods

2.1. Design and Fabrication of Microdevices

2.2. Ac-EHD Experiments Setup

2.3. Electric Field Simulations

2.4. Electrochemical Measurements

3. Results and Discussion

3.1. 2D Ac-EHD Devices

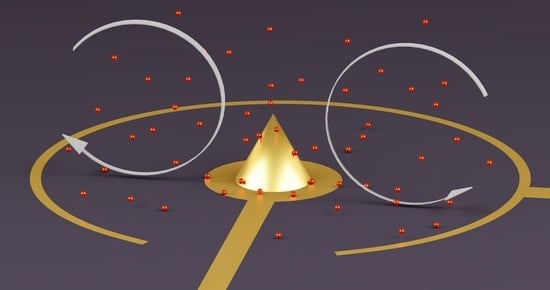

3.2. 3D Ac-EHD Device

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ateya, D.A.; Erickson, J.S.; Howell, P.B.; Hilliard, L.R.; Golden, J.P.; Ligler, F.S. The good, the bad, and the tiny: A review of microflow cytometry. Anal. Bioanal. Chem. 2008, 391, 1485–1498. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lion, N.; Rohner, T.C.; Dayon, L.; Arnaud, I.L.; Damoc, E.; Youhnovski, N.; Wu, Z.Y.; Roussel, C.; Josserand, J.; Jensen, H.; et al. Microfluidic systems in proteomics. Electrophoresis 2003, 24, 3533–3562. [Google Scholar] [CrossRef] [PubMed]

- Barry, R.; Ivanov, D. Microfluidics in biotechnology. J. Nanobiotechnol. 2004, 2, 2. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhao, C.X.; He, L.Z.; Qiao, S.Z.; Middelberg, A.P.J. Nanoparticle synthesis in microreactors. Chem. Eng. Sci. 2011, 66, 1463–1479. [Google Scholar] [CrossRef]

- Shui, L.; Pennathur, S.; Eijkel, J.C.T.; van den Berg, A. Multiphase flow in lab on chip devices: A real tool for the future. Lab Chip 2008, 8, 1010–1014. [Google Scholar] [CrossRef]

- Jung, W.E.; Han, J.; Choi, J.W.; Ahn, C.H. Point-of-care testing (POCT) diagnostic systems using microfluidic lab-on-a-chip technologies. Microelectron. Eng. 2015, 132, 46–57. [Google Scholar] [CrossRef]

- Cardoso, R.M.; dos Santos, R.O.; Munoz, R.A.A.; Garcia, C.D.; Blanes, L. A Multi-Pump Magnetohydrodynamics Lab-On-A-Chip Device for Automated Flow Control and Analyte Delivery. Sensors 2020, 20, 4909. [Google Scholar] [CrossRef]

- Urbanski, J.P.; Thorsen, T.; Levitan, J.A.; Bazant, M.Z. Fast AC electro-osmotic micropumps with nonplanar electrodes. Appl. Phys. Lett. 2006, 89, 143598. [Google Scholar] [CrossRef]

- Kim, D.; Sonker, M.; Ros, A. Dielectrophoresis: From Molecular to Micrometer-Scale Analytes. Anal. Chem. 2019, 91, 277–295. [Google Scholar] [CrossRef]

- Vaidyanathan, R.; Dey, S.; Carrascosa, L.G.; Shiddiky, M.J.A.; Trau, M. Alternating current electrohydrodynamics in microsystems: Pushing biomolecules and cells around on surfaces. Biomicrofluidics 2015, 9, 061501. [Google Scholar] [CrossRef] [Green Version]

- Sheehan, P.E.; Whitman, L.J. Detection limits for nanoscale biosensors. Nano Lett. 2005, 5, 803–807. [Google Scholar] [CrossRef] [PubMed]

- Wuethrich, A.; Ibn Sina, A.; Ahmed, M.; Lin, T.Y.; Carrascosa, L.G.; Trau, M. Interfacial nano-mixing in a miniaturised platform enables signal enhancement and in situ detection of cancer biomarkers. Nanoscale 2018, 10, 10884–10890. [Google Scholar] [CrossRef] [PubMed]

- Wu, J.; Ben, Y.X.; Chang, H.C. Particle detection by electrical impedance spectroscopy with asymmetric-polarization AC electroosmotic trapping. Microfluid. Nanofluidics 2005, 1, 161–167. [Google Scholar] [CrossRef]

- Hart, R.; Lec, R.; Noh, H. Enhancement of heterogeneous immunoassays using AC electroosmosis. Sen. Actuators B Chem. 2010, 147, 366–375. [Google Scholar] [CrossRef]

- Reza, K.K.; Wang, J.; Vaidyanathan, R.; Dey, S.; Wang, Y.L.; Trau, M. Electrohydrodynamic-Induced SERS Immunoassay for Extensive Multiplexed Biomarker Sensing. Small 2017, 13, 1602902. [Google Scholar] [CrossRef]

- Vaidyanathan, R.; Rauf, S.; Grewal, Y.S.; Spadafora, L.J.; Shiddiky, M.J.A.; Cangelosi, G.A.; Trau, M. Enhancing Protein Capture Using a Combination of Nanoyeast Single-Chain Fragment Affinity Reagents and Alternating Current Electrohydrodynamic Forces. Anal. Chem. 2015, 87, 11673–11681. [Google Scholar] [CrossRef]

- Vaidyanathan, R.; van Leeuwen, L.M.; Rauf, S.; Shiddiky, M.J.A.; Trau, M. A Multiplexed Device Based on Tunable Nanoshearing for Specific Detection of Multiple Protein Biomarkers in Serum. Sci. Rep. 2015, 5, 9756. [Google Scholar] [CrossRef] [Green Version]

- Rauf, S.; Shiddiky, M.J.A.; Trau, M. Electrohydrodynamic removal of non-specific colloidal adsorption at electrode interfaces. Chem. Commun. 2014, 50, 4813–4815. [Google Scholar] [CrossRef] [Green Version]

- Cotton, J.S.; Robinson, A.J.; Shoukri, M.; Chang, J.S. AC voltage induced electrohydrodynamic two-phase convective boiling heat transfer in horizontal annular channels. Exp. Therm. Fluid Sci. 2012, 41, 31–42. [Google Scholar] [CrossRef]

- Cotton, J.S. Electrohydrodynamic Condensation Heat Transfer Modulation under dc and ac Applied Voltages in a Horizontal Annular Channel. IEEE Trans. Dielectr. Electr. Insul. 2009, 16, 495–503. [Google Scholar] [CrossRef]

- Song, M.G.; Bishop, K.J.M.; Pinchuk, A.O.; Kowalczyk, B.; Grzybowski, B.A. Formation of Dense Nanoparticle Monolayers Mediated by Alternating Current Electric Fields and Electrohydrodynamic Flows. J. Phys. Chem. C 2010, 114, 8800–8805. [Google Scholar] [CrossRef]

- Lee, K.H.; Yang, G.L.Z.; Wyslouzil, B.E.; Winter, J.O. Electrohydrodynamic Mixing-Mediated Nanoprecipitation for Polymer Nanoparticle Synthesis. ACS Appl. Polym. Mater. 2019, 1, 691–700. [Google Scholar] [CrossRef]

- Thrift, W.J.; Nguyen, C.Q.; Darvishzadeh-Varcheie, M.; Zare, S.; Sharac, N.; Sanderson, R.N.; Dupper, T.J.; Hochbaum, A.I.; Capolino, F.; Qomi, M.J.A.; et al. Driving Chemical Reactions in Plasmonic Nanogaps with Electrohydrodynamic Flow. Acs Nano 2017, 11, 11317–11329. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ramos, A.; Gonzalez, A.; Castellanos, A.; Green, N.G.; Morgan, H. Pumping of liquids with ac voltages applied to asymmetric pairs of microelectrodes. Phys. Rev. E 2003, 67, 056302. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ajdari, A. Pumping liquids using asymmetric electrode arrays. Phys. Rev. E 2000, 61, R45–R48. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, J.; Shanmugasundaram, K.B.; Yeo, B.L.D.; Moeller, A.; Wuethrich, A.; Lin, L.L.; Trau, M. Tracking Drug-Induced Epithelial-Mesenchymal Transition in Breast Cancer by a Microfluidic Surface-Enhanced Raman Spectroscopy Immunoassay. Small 2020, 16, 1905614. [Google Scholar] [CrossRef]

- Raftery, L.J.; Howard, C.B.; Grewal, Y.S.; Vaidyanathan, R.; Jones, M.L.; Anderson, W.; Korbie, D.; Duarte, T.; Cao, M.D.; Nguyen, S.H.; et al. Retooling phage display with electrohydrodynamic nanomixing and nanopore sequencing. Lab Chip 2019, 19, 4083–4092. [Google Scholar] [CrossRef] [PubMed]

- Sun, H.T.; Zhu, J.; Baumann, D.; Peng, L.L.; Xu, Y.X.; Shakir, I.; Huang, Y.; Duan, X.F. Hierarchical 3D electrodes for electrochemical energy storage. Nat. Rev. Mater. 2019, 4, 45–60. [Google Scholar] [CrossRef]

- Kim, B.J.; Kuo, J.T.W.; Hara, S.A.; Lee, C.D.; Yu, L.; Gutierrez, C.A.; Hoang, T.Q.; Pikov, V.; Meng, E. 3D Parylene sheath neural probe for chronic recordings. J. Neural. Eng. 2013, 10, 045002. [Google Scholar] [CrossRef] [Green Version]

- Hemanth, S.; Halder, A.; Caviglia, C.; Chi, Q.J.; Keller, S.S. 3D Carbon Microelectrodes with Bio-Functionalized Graphene for Electrochemical Biosensing. Biosensors 2018, 8, 70. [Google Scholar] [CrossRef] [Green Version]

- Wong, P.K.; Chen, C.Y.; Wang, T.H.; Ho, C.M. Electrokinetic bioprocessor for concentrating cells and molecules. Anal. Chem. 2004, 76, 6908–6914. [Google Scholar] [CrossRef] [PubMed]

- Azmayesh-Fard, S.M.; Decorby, R.G. Lab on a chip for measurement of particulate flow velocity using a single detector. Meas. Sci. Technol. 2018, 29, 095013. [Google Scholar] [CrossRef]

- Wuethrich, A.; Howard, C.B.; Trau, M. Geometric optimisation of electrohydrodynamic fluid flows for enhanced biosensing. Microchem. J. 2018, 137, 231–237. [Google Scholar] [CrossRef] [Green Version]

- Tinevez, J.Y.; Perry, N.; Schindelin, J.; Hoopes, G.M.; Reynolds, G.D.; Laplantine, E.; Bednarek, S.Y.; Shorte, S.L.; Eliceiri, K.W. TrackMate: An open and extensible platform for single-particle tracking. Methods 2017, 115, 80–90. [Google Scholar] [CrossRef]

- Wirde, M.; Gelius, U.; Nyholm, L. Self-assembled monolayers of cystamine and cysteamine on gold studied by XPS and voltammetry. Langmuir 1999, 15, 6370–6378. [Google Scholar] [CrossRef]

- Chen, L.; Dong, M.; Bagci, H. Modeling Floating Potential Conductors Using Discontinuous Galerkin Method. IEEE Access 2020, 8, 7531–7538. [Google Scholar] [CrossRef]

- Chen, L.; Dong, M.; Li, P.; Bagci, H. A hybridizable discontinuous Galerkin method for simulation of electrostatic problems with floating potential conductors. Int. J. Numer. Model. 2021, 34, e2804. [Google Scholar] [CrossRef]

- Chen, L.; Bagci, H. Steady-State Simulation of Semiconductor Devices Using Discontinuous Galerkin Methods. IEEE Access 2020, 8, 16203–16215. [Google Scholar] [CrossRef]

- Koo, K.M.; Dey, S.; Trau, M. A Sample-to-Targeted Gene Analysis Biochip for Nanofluidic Manipulation of Solid-Phase Circulating Tumor Nucleic Acid Amplification in Liquid Biopsies. ACS Sens. 2018, 3, 2597–2603. [Google Scholar] [CrossRef]

- Hakoda, M.; Shiragami, N. Separation of dead cells from culture broth by using dielectrophoresis. Prog. Biotechnol. 2000, 16, 53–58. [Google Scholar] [CrossRef]

- Ramos, A.; Morgan, H.; Green, N.G.; Castellanos, A. Ac electrokinetics: A review of forces in microelectrode structures. J. Phys. D Appl. Phys. 1998, 31, 2338–2353. [Google Scholar] [CrossRef] [Green Version]

- Vaidyanathan, R.; Shiddiky, M.J.A.; Raul, S.; Dray, E.; Tay, Z.; Trau, M. Tunable “Nano-Shearing”: A Physical Mechanism to Displace Nonspecific Cell Adhesion During Rare Cell Detection. Anal. Chem. 2014, 86, 2042–2049. [Google Scholar] [CrossRef] [PubMed]

- Rauf, S.; Mani, V.; Lahcen, A.A.; Yuvaraja, S.; Beduk, T.; Salama, K.N. Binary transition metal oxide modified laser-scribed graphene electrochemical aptasensor for the accurate and sensitive screening of acute myocardial infarction. Electrochim. Acta 2021, 386, 138489. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Silva, R.K.S.; Rauf, S.; Dong, M.; Chen, L.; Bagci, H.; Salama, K.N. 3D Concentric Electrodes-Based Alternating Current Electrohydrodynamics: Design, Simulation, Fabrication, and Potential Applications for Bioassays. Biosensors 2022, 12, 215. https://doi.org/10.3390/bios12040215

Silva RKS, Rauf S, Dong M, Chen L, Bagci H, Salama KN. 3D Concentric Electrodes-Based Alternating Current Electrohydrodynamics: Design, Simulation, Fabrication, and Potential Applications for Bioassays. Biosensors. 2022; 12(4):215. https://doi.org/10.3390/bios12040215

Chicago/Turabian StyleSilva, Raphaela K. S., Sakandar Rauf, Ming Dong, Liang Chen, Hakan Bagci, and Khaled N. Salama. 2022. "3D Concentric Electrodes-Based Alternating Current Electrohydrodynamics: Design, Simulation, Fabrication, and Potential Applications for Bioassays" Biosensors 12, no. 4: 215. https://doi.org/10.3390/bios12040215

APA StyleSilva, R. K. S., Rauf, S., Dong, M., Chen, L., Bagci, H., & Salama, K. N. (2022). 3D Concentric Electrodes-Based Alternating Current Electrohydrodynamics: Design, Simulation, Fabrication, and Potential Applications for Bioassays. Biosensors, 12(4), 215. https://doi.org/10.3390/bios12040215