Optimization Strategies Used for Boosting Piezoelectric Response of Biosensor Based on Flexible Micro-ZnO Composites

Abstract

:1. Introduction

2. Fabrication and Methods of Characterization

2.1. ZnO MRs Synthesis

2.2. ZnO MPs and MRs Based Composites

2.3. Characterization Methods

2.3.1. Morphological Characterization

2.3.2. Mechanical, Dielectric and Piezoelectric Characterizations

3. Results and Discussion

3.1. Morphological Properties of as-Grown ZnO MRs

3.2. Electric Field Distribution Based 2D COMSOL Model

3.3. Optimization of DEP Processing Conditions

3.4. ZnO MPs and MRs Based Composites

3.4.1. DEP Assessment through SEM Image

3.4.2. Mechanical Properties

3.4.3. Dielectric Properties

3.4.4. Piezoelectric Properties

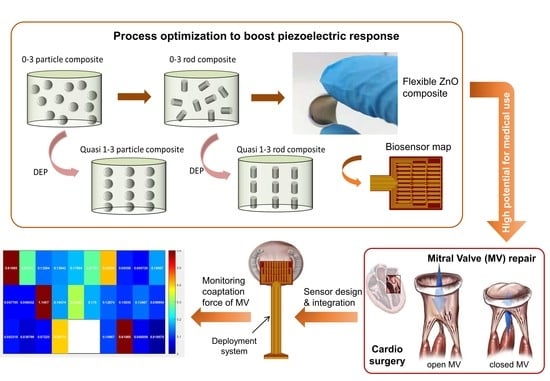

- Enhancing the filler content gives rise to an enhanced piezoelectric response. For instance, increasing the volume fraction of the randomly dispersed MR composite (e.g., from 2% to 8%) leads to a 2.4-fold increase in the d33 value. However, it is challenging to fabricate high-density composites due to agglomeration and high viscosity effects.

- Integrating fillers with a higher AR could perform fewer interconnections between the neighboring phases, which in turn boost the piezoelectric effect. Using MRs instead of MPs allows the enhancement of the piezoelectric sensitivity of around 2.0-fold and 2.6-fold, respectively, for the random and structured composites integrating an 8% fraction vol. of ZnO filler.

- Structuring the filler dispersion via the DEP process leads to significantly enhanced piezoelectric properties. For example, under the same filler’s concentration, size and shape, the d33 value can be boosted even up to 6.0-fold for the 8% MR composites.

4. Potential Application of Piezoelectric Biosensor on Force Measurement of Mitral Valve Coaptation

- High-resolution sensors enable the measurement of pressure inside the MV, with typical amplitude of stress of around 0.1 MPa to 0.7 MPa [79]. The sensors must be no thicker than 200 µm with low stiffness to “mold” to the shape of the MV without interacting with its function.

- A deployment system allows the sensors to be set and manipulated inside of the valve during the measurement period but also to be retrieved outside of the heart after the measurement.

- Acquisition system allows for real-time recording, analyzing and monitoring of the data.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, K.-M.; Zhao, Y.-P.; He, F.-Q.; Liu, D.-Q. Piezoelectricity of ZnO Films Prepared by Sol-Gel Method. Chin. J. Chem. Phys. 2007, 20, 721–726. [Google Scholar] [CrossRef]

- Jiansirisomboon, S.; Songsiri, K.; Watcharapasorn, A.; Tunkasiri, T. Mechanical properties and crack growth behavior in poled ferroelectric PMN–PZT ceramics. Curr. Appl. Phys. 2006, 6, 299–302. [Google Scholar] [CrossRef]

- Grinberg, D.; Siddique, S.; Le, M.-Q.; Liang, R.; Capsal, J.-F.; Cottinet, P.-J. 4D Printing based piezoelectric composite for medical applications. J. Polym. Sci. Part B Polym. Phys. 2019, 57, 109–115. [Google Scholar] [CrossRef]

- Lee, H.; Cooper, R.; Wang, K.; Liang, H. Nano-Scale Characterization of a Piezoelectric Polymer (Polyvinylidene Difluoride, PVDF). Sensors 2008, 8, 7359–7368. [Google Scholar] [CrossRef] [PubMed]

- Carbone, C.; Benwadih, M.; D’Ambrogio, G.; LE, M.-Q.; Capsal, J.-F.; Cottinet, P.-J. Influence of Matrix and Surfactant on Piezoelectric and Dielectric Properties of Screen-Printed BaTiO3/PVDF Composites. Polymers 2021, 13, 2166. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Yang, R.; Yu, M.; Bai, F.; Li, C.; Wang, Z.L. Cellular Level Biocompatibility and Biosafety of ZnO Nanowires. J. Phys. Chem. C 2008, 112, 20114–20117. [Google Scholar] [CrossRef] [Green Version]

- Chawich, J.; Hassen, W.M.; Elie-Caille, C.; Leblois, T.; Dubowski, J.J. Regenerable ZnO/GaAs Bulk Acoustic Wave Biosensor for Detection of Escherichia coli in “Complex” Biological Medium. Biosensors 2021, 11, 145. [Google Scholar] [CrossRef]

- Wang, Z.L. Zinc oxide nanostructures: Growth, properties and applications. J. Phys. Condens. Matter 2004, 16, R829. [Google Scholar] [CrossRef]

- Yang, R.; Qin, Y.; Li, C.; Zhu, G.; Wang, Z.L. Converting Biomechanical Energy into Electricity by a Muscle-Movement-Driven Nanogenerator. Nano Lett. 2009, 9, 1201–1205. [Google Scholar] [CrossRef]

- Mao, Y.; Zhu, Y.; Zhao, T.; Jia, C.; Bian, M.; Li, X.; Liu, Y.; Liu, B. A Portable and Flexible Self-Powered Multifunctional Sensor for Real-Time Monitoring in Swimming. Biosensors 2021, 11, 147. [Google Scholar] [CrossRef]

- Li, Z.; Zhu, G.; Yang, R.; Wang, A.C.; Wang, Z.L. Muscle-Driven In Vivo Nanogenerator. Adv. Mater. 2010, 22, 2534–2537. [Google Scholar] [CrossRef] [PubMed]

- D’Ambrogio, G.; Zahhaf, O.; Bordet, M.; Le, M.Q.; Della Schiava, N.; Liang, R.; Cottinet, P.-J.; Capsal, J.-F. Structuring BaTiO3/PDMS Nanocomposite via Dielectrophoresis for Fractional Flow Reserve Measurement. Adv. Eng. Mater. 2021, 23, 2100341. [Google Scholar] [CrossRef]

- Lee, S.; Hinchet, R.; Lee, Y.; Yang, Y.; Lin, Z.-H.; Ardila, G.; Montès, L.; Mouis, M.; Wang, Z.L. Ultrathin Nanogenerators as Self-Powered/Active Skin Sensors for Tracking Eye Ball Motion. Adv. Funct. Mater. 2013, 24, 1163–1168. [Google Scholar] [CrossRef]

- Mao, Y.; Yue, W.; Zhao, T.; Shen, M.L.; Liu, B.; Chen, S. A Self-Powered Biosensor for Monitoring Maximal Lactate Steady State in Sport Training. Biosensors 2020, 10, 75. [Google Scholar] [CrossRef]

- Cottinet, P.-J.; Guyomar, D.; Guiffard, B.; Lebrun, L.; Putson, C. Electrostrictive polymer composite for energy harvesters and actuators. J. Polym. Eng. 2011, 31, 133–140. [Google Scholar] [CrossRef]

- Xiang, Z.; Ducharne, B.; Della Schiava, N.; Capsal, J.-F.; Cottinet, P.-J.; Coativy, G.; Lermusiaux, P.; Le, M.Q. Induction heating-based low-frequency alternating magnetic field: High potential of ferromagnetic composites for medical applications. Mater. Des. 2019, 174, 107804. [Google Scholar] [CrossRef]

- Zhang, X.; Le, M.-Q.; Zahhaf, O.; Capsal, J.-F.; Cottinet, P.-J.; Petit, L. Enhancing dielectric and piezoelectric properties of micro-ZnO/PDMS composite-based dielectrophoresis. Mater. Des. 2020, 192, 108783. [Google Scholar] [CrossRef]

- Zhang, X.; Le, M.-Q.; Nguyen, V.-C.; Mogniotte, J.-F.; Capsal, J.-F.; Grinberg, D.; Cottinet, P.-J.; Petit, L. Characterization of micro-ZnO/PDMS Composite Structured via Dielectrophoresis—Toward medical application. Mater. Des. 2021, 208, 109912. [Google Scholar] [CrossRef]

- Newnham, R.E.; Skinner, D.P.; Cross, L.E. Connectivity and piezoelectric-pyroelectric composites. Mater. Res. Bull. 1978, 13, 525–536. [Google Scholar] [CrossRef]

- Wang, D.Y.; Li, K.; Chan, H.L.W. High frequency 1–3 composite transducer fabricated using sol–gel derived lead-free BNBT fibers. Sens. Actuators A Phys. 2004, 114, 1–6. [Google Scholar] [CrossRef]

- Abrar, A.; Zhang, D.; Su, B.; Button, T.W.; Kirk, K.J.; Cochran, S. 1–3 connectivity piezoelectric ceramic–polymer composite transducers made with viscous polymer processing for high frequency ultrasound. Ultramicroscopy 2004, 42, 479–484. [Google Scholar] [CrossRef] [PubMed]

- Pohl, H.A.; Crane, J.S. Dielectrophoresis of Cells. Biophys. J. 1971, 11, 711–727. [Google Scholar] [CrossRef] [Green Version]

- Zhang, X.; Minh-Quyen, L.E.; Mogniotte, J.-F.; Capsal, J.-F.; Cottinet, P.-J.; Petit, L. Effect of dielectrophoretic structuring on dielectric and piezoelectric behaviors of ZnO/PDMS microcomposite. In Electroactive Polymer Actuators and Devices (EAPAD) XXIII; International Society for Optics and Photonics: Bellingham, WA, USA, 2021; Volume 11587, p. 41. [Google Scholar] [CrossRef]

- Van den Ende, D.; Bory, B.F.; Groen, W.A.; van der Zwaag, S. Improving the d33 and g33 properties of 0–3 piezoelectric composites by dielectrophoresis. J. Appl. Phys. 2010, 107, 024107. [Google Scholar] [CrossRef]

- D’Ambrogio, G.; Zahhaf, O.; Hebrard, Y.; Le, M.Q.; Cottinet, P.; Capsal, J. Micro-Structuration of Piezoelectric Composites Using Dielectrophoresis: Toward Application in Condition Monitoring of Bearings. Adv. Eng. Mater. 2021, 23, 2000773. [Google Scholar] [CrossRef]

- Chen, L.; Liu, X.; Zheng, X.; Zhang, X.; Yang, J.; Tian, T.; Liao, Y. Dielectrophoretic Separation of Particles Using Microfluidic Chip with Composite Three-Dimensional Electrode. Micromachines 2020, 11, 700. [Google Scholar] [CrossRef] [PubMed]

- Khaliq, J.; Hoeks, T.; Groen, P. Fabrication of Piezoelectric Composites Using High-Temperature Dielectrophoresis. J. Manuf. Mater. Process. 2019, 3, 77. [Google Scholar] [CrossRef] [Green Version]

- Xiang, Z.; Nguyen, V.C.; Ducharne, B.; Della Schiava, N.; Capsal, J.F.; Cottinet, P.J.; Le, M.Q. 3D Printing of Flexible Composites via Magnetophoresis: Toward Medical Application Based on Low-Frequency Induction Heating Effect. Macromol. Mater. Eng. 2021, 306, 2100211. [Google Scholar] [CrossRef]

- Zahhaf, O.; D’Ambrogio, G.; Le, M.-Q.; Coativy, G.; Grasland, F.; Cottinet, P.-J.; Capsal, J.-F. Dielectrophoretic alignment of Al2O3/PDMS composites: Enhancement of thermal and dielectric properties through structural sedimentation analysis. Mater. Des. 2021, 211, 110134. [Google Scholar] [CrossRef]

- Gascoyne, P.R.C.; Vykoukal, J. Particle Separation by Dielectrophoresis. Electrophoresis 2002, 23, 1973–1983. [Google Scholar] [CrossRef]

- Bowen, C.P.; Newnham, R.E.; Randall, C.A. Dielectric properties of dielectrophoretically assembled particulate-polymer composites. J. Mater. Res. 1998, 13, 205–210. [Google Scholar] [CrossRef]

- D’Ambrogio, G.; Zahhaf, O.; Le, M.-Q.; Capsal, J.-F.; Cottinet, P.-J. Dielectrophoresis Structurization of PZT/PDMS Micro-Composite for Elastronic Function: Towards Dielectric and Piezoelectric Enhancement. Materials 2021, 14, 4071. [Google Scholar] [CrossRef] [PubMed]

- Van den Ende, D.A.; Van Kempen, S.E.; Wu, X.; Groen, P.; Randall, C.A.; Van Der Zwaag, S. Dielectrophoretically structured piezoelectric composites with high aspect ratio piezoelectric particles inclusions. J. Appl. Phys. 2012, 111, 124107. [Google Scholar] [CrossRef] [Green Version]

- Nguyen, T.H.L.; Laffont, L.; Capsal, J.-F.; Cottinet, P.-J.; Lonjon, A.; Dantras, E.; Lacabanne, C. Magnetoelectric properties of nickel nanowires-P(VDF–TrFE) composites. Mater. Chem. Phys. 2015, 153, 195–201. [Google Scholar] [CrossRef] [Green Version]

- Al Masud, M.A.; Ounaies, Z. Dielectric Properties of Dielectrophoretically Aligned ZNO-PDMS Composites. In Proceedings of the ASME 2016 Conference on Smart Materials, Adaptive Structures and Intelligent Systems, SMASIS 2016; Stowe, VT, USA, 28–30 September 2016, American Society of Mechanical Engineers: New York, NY, USA, 2016; Volume 1, 8p. [Google Scholar] [CrossRef]

- Del Gobbo, S.; Poolwong, J.; D’Elia, V. In-Suspension Growth of ZnO Nanorods with Tunable Length and Diameter Using Polymorphic Seeds. Cryst. Growth Des. 2019, 19, 6792–6800. [Google Scholar] [CrossRef]

- Del Gobbo, S.; Poolwong, J.; D’Elia, V.; Ogawa, M. Simultaneous Controlled Seeded-Growth and Doping of ZnO Nanorods with Aluminum and Cerium: Feasibility Assessment and Effect on Photocatalytic Activity. Cryst. Growth Des. 2020, 20, 5508–5525. [Google Scholar] [CrossRef]

- Villafuerte, J.; Donatini, F.; Kioseoglou, J.; Sarigiannidou, E.; Chaix-Pluchery, O.; Pernot, J.; Consonni, V. Zinc Vacancy–Hydrogen Complexes as Major Defects in ZnO Nanowires Grown by Chemical Bath Deposition. J. Phys. Chem. C 2020, 124, 16652–16662. [Google Scholar] [CrossRef]

- Villafuerte, J.; Chaix-Pluchery, O.; Kioseoglou, J.; Donatini, F.; Sarigiannidou, E.; Pernot, J.; Consonni, V. Engineering nitrogen- and hydrogen-related defects in ZnO nanowires using thermal annealing. Phys. Rev. Mater. 2021, 5, 056001. [Google Scholar] [CrossRef]

- Zhang, X.; Villafuerte, J.; Consonni, V.; Capsal, J.-F.; Cottinet, P.-J.; Petit, L.; Le, M.-Q. Characterizing and Optimizing Piezoelectric Response of ZnO Nanowire/PMMA Composite-Based Sensor. Nanomaterials 2021, 11, 1712. [Google Scholar] [CrossRef]

- Cuscó, R.; Alarcón-Lladó, E.; Ibáñez, J.; Artús, L.; Jiménez, J.; Wang, B.; Callahan, M.J. Temperature dependence of Raman scattering in ZnO. Phys. Rev. B 2007, 75, 165202. [Google Scholar] [CrossRef]

- Bundesmann, C.; Ashkenov, N.; Schubert, M.; Spemann, D.; Butz, T.; Kaidashev, E.M.; Lorenz, M.; Grundmann, M. Raman scattering in ZnO thin films doped with Fe, Sb, Al, Ga, and Li. Appl. Phys. Lett. 2003, 83, 1974–1976. [Google Scholar] [CrossRef]

- Gaffuri, P.; Appert, E.; Chaix-Pluchery, O.; Rapenne, L.; Salaün, M.; Consonni, V. The Path of Gallium from Chemical Bath into ZnO Nanowires: Mechanisms of Formation and Incorporation. Inorg. Chem. 2019, 58, 10269–10279. [Google Scholar] [CrossRef] [PubMed]

- Verrier, C.; Appert, E.; Chaix-Pluchery, O.; Rapenne, L.; Rafhay, Q.; Kaminski-Cachopo, A.; Consonni, V. Effects of the pH on the Formation and Doping Mechanisms of ZnO Nanowires Using Aluminum Nitrate and Ammonia. Inorg. Chem. 2017, 56, 13111–13122. [Google Scholar] [CrossRef] [PubMed]

- Verrier, C.; Appert, E.; Chaix-Pluchery, O.; Rapenne, L.; Rafhay, Q.; Kaminski-Cachopo, A.; Consonni, V. Tunable Morphology and Doping of ZnO Nanowires by Chemical Bath Deposition Using Aluminum Nitrate. J. Phys. Chem. C 2017, 121, 3573–3583. [Google Scholar] [CrossRef]

- Nickel, N.H.; Fleischer, K. Hydrogen Local Vibrational Modes in Zinc Oxide. Phys. Rev. Lett. 2003, 90, 197402. [Google Scholar] [CrossRef] [PubMed]

- Reynolds, J.G.; Reynolds, C.L., Jr.; Mohanta, A.; Muth, J.F.; Rowe, J.E.; Everitt, H.O.; Aspnes, D.E. Shallow acceptor complexes in p-type ZnO. Appl. Phys. Lett. 2013, 102, 152114. [Google Scholar] [CrossRef]

- Hu, J.; He, H.Y.; Pan, B.C. Hydrogen diffusion behavior in N doped ZnO: First-principles study. J. Appl. Phys. 2008, 103, 113706. [Google Scholar] [CrossRef]

- Lavrov, E.V.; Weber, J.; Börrnert, F.; Van de Walle, C.G.; Helbig, R. Hydrogen-related defects in ZnO studied by infrared absorption spectroscopy. Phys. Rev. B 2002, 66, 165205. [Google Scholar] [CrossRef]

- Lavrov, E.V.; Börrnert, F.; Weber, J. Dominant hydrogen-oxygen complex in hydrothermally grown ZnO. Phys. Rev. B 2005, 71, 035205. [Google Scholar] [CrossRef]

- Lyons, J.L.; Varley, J.B.; Steiauf, D.; Janotti, A.; Van De Walle, C.G. First-principles characterization of native-defect-related optical transitions in ZnO. J. Appl. Phys. 2017, 122, 035704. [Google Scholar] [CrossRef]

- Herklotz, F.; Hupfer, A.; Johansen, K.M.; Svensson, B.G.; Koch, S.G.; Lavrov, E.V. Infrared absorption on a complex comprising three equivalent hydrogen atoms in ZnO. Phys. Rev. B 2015, 92, 155203. [Google Scholar] [CrossRef]

- Lavrov, E.V. Infrared absorption spectroscopy of hydrogen-related defects in ZnO. Phys. B Condens. Matter 2003, 340-342, 195–200. [Google Scholar] [CrossRef]

- Lavrov, E.V.; Herklotz, F.; Weber, J. Identification of two hydrogen donors in ZnO. Phys. Rev. B 2009, 79, 165210. [Google Scholar] [CrossRef]

- Heinhold, R.; Neiman, A.; Kennedy, J.V.; Markwitz, A.; Reeves, R.J.; Allen, M.W. Hydrogen-related excitons and their excited-state transitions in ZnO. Phys. Rev. B 2017, 95, 054120. [Google Scholar] [CrossRef]

- Meyer, B.K.; Alves, H.; Hofmann, D.M.; Kriegseis, W.; Forster, D.; Bertram, F.; Christen, J.; Hoffmann, A.; Straßburg, M.; Dworzak, M.; et al. Bound exciton and donor–acceptor pair recombinations in ZnO. Phys. Status Solidi (B) 2004, 241, 231–260. [Google Scholar] [CrossRef]

- Sun, J.W.; Lu, Y.M.; Liu, Y.C.; Shen, D.Z.; Zhang, Z.Z.; Yao, B.; Li, B.H.; Zhang, J.Y.; Zhao, D.X.; Fan, X.W. Nitrogen-related recombination mechanisms in p-type ZnO films grown by plasma-assisted molecular beam epitaxy. J. Appl. Phys. 2007, 102, 043522. [Google Scholar] [CrossRef]

- Rommeluère, J.F.; Svob, L.; Jomard, F.; Mimila-Arroyo, J.; Lusson, A.; Sallet, V.; Marfaing, Y. Electrical activity of nitrogen acceptors in ZnO films grown by metalorganic vapor phase epitaxy. Appl. Phys. Lett. 2003, 83, 287–289. [Google Scholar] [CrossRef]

- Pfisterer, D.; Sann, J.; Hofmann, D.M.; Plana, M.; Neumann, A.; Lerch, M.; Meyer, B.K. Incorporation of nitrogen acceptors in ZnO powder. Phys. Status Solidi (B) 2006, 243, R1–R3. [Google Scholar] [CrossRef]

- Zhang, B.P.; Binh, N.T.; Segawa, Y.; Wakatsuki, K.; Usami, N. Optical properties of ZnO rods formed by metalorganic chemical vapor deposition. Appl. Phys. Lett. 2003, 83, 1635–1637. [Google Scholar] [CrossRef]

- Souissi, H.; Jabri, S.; Souissi, A.; Amiri, G.; Gemeiner, P.; Lusson, A.; Galtier, P.; Dkhil, B.; Sallet, V.; Oueslati, M.; et al. Activation of B1 silent Raman modes and its potential origin as source for phonon-assisted replicas in photoluminescence response in N-doped ZnO nanowires. J. Appl. Phys. 2018, 123, 025705. [Google Scholar] [CrossRef]

- Wong, C.K.; Shin, F.G. Effect of electrical conductivity on poling and the dielectric, pyroelectric and piezoelectric properties of ferroelectric 0–3 composites. Front. Ferroelectr. 2007, 229–249. [Google Scholar] [CrossRef]

- Or, Y.T.; Wong, C.K.; Ploss, B.; Shin, F.G. Modeling of poling, piezoelectric, and pyroelectric properties of ferroelectric 0–3 composites. J. Appl. Phys. 2003, 94, 3319–3325. [Google Scholar] [CrossRef] [Green Version]

- Renxin, X.; Wen, C.; Jing, Z.; Yueming, L.; Huajun, S. Dielectric and piezoelectric properties of 0-3 PZT/PVDF composite doped with polyaniline. J. Wuhan Univ. Technol. Sci. Ed. 2006, 21, 84–87. [Google Scholar] [CrossRef]

- Liu, C.-Y.; Bard, A.J. Pressure-induced insulator–conductor transition in a photoconducting organic liquid-crystal film. Nature 2002, 418, 162–164. [Google Scholar] [CrossRef] [PubMed]

- Ahmad, H.; Haddad, A.; Griffiths, H.; Robson, S.; Nishimura, T.; Tsukamoto, N. Electrical characterisation of ZnO microvaristor materials and compounds. In Proceedings of the 2015 IEEE Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), Ann Arbor, MI, USA, 18–21 October 2015; pp. 688–692. [Google Scholar]

- Pedroli, F.; Flocchini, A.; Marrani, A.; Le, M.-Q.; Sanseau, O.; Cottinet, P.-J.; Capsal, J.-F. Boosted energy-storage efficiency by controlling conduction loss of multilayered polymeric capacitors. Mater. Des. 2020, 192, 108712. [Google Scholar] [CrossRef]

- Pedroli, F.; Marrani, A.; Le, M.-Q.; Froidefond, C.; Cottinet, P.-J.; Capsal, J.-F. Processing optimization: A way to improve the ionic conductivity and dielectric loss of electroactive polymers. J. Polym. Sci. Part B Polym. Phys. 2018, 56, 1164–1173. [Google Scholar] [CrossRef]

- Wang, Z.; Nelson, J.K.; Miao, J.; Linhardt, R.J.; Schadler, L.S.; Hillborg, H.; Zhao, S. Effect of high aspect ratio filler on dielectric properties of polymer composites: A study on barium titanate fibers and graphene platelets. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 960–967. [Google Scholar] [CrossRef] [Green Version]

- Kandpal, M.; Sharan, C.; Poddar, P.; Prashanthi, K.; Apte, P.R.; Ramgopal Rao, V. Photopatternable nano-composite (SU-8/ZnO) thin films for piezo-electric applications. Appl. Phys. Lett. 2012, 101, 104102. [Google Scholar] [CrossRef]

- Chirdon, W.M.; O’Brien, W.J.; Robertson, R.E. Diffuse reflectance of short-fiber-reinforced composites aligned by an electric field. Dent. Mater. 2006, 22, 57–62. [Google Scholar] [CrossRef]

- Wilson, S.A.; Maistros, G.M.; Whatmore, R.W. Structure modification of 0–3 piezoelectric ceramic/polymer composites through dielectrophoresis. J. Phys. D Appl. Phys. 2005, 38, 175–182. [Google Scholar] [CrossRef]

- Grinberg, D.; Le, M.-Q.; Kwon, Y.J.; Fernandez, M.A.; Audigier, D.; Ganet, F.; Capsal, J.-F.; Obadia, J.F.; Cottinet, P.-J. Mitral valve repair based on intraoperative objective measurement. Sci. Rep. 2019, 9, 4677. [Google Scholar] [CrossRef]

- Grinberg, D.; Cottinet, P.-J.; Thivolet, S.; Audigier, D.; Capsal, J.-F.; Le, M.-Q.; Obadia, J.-F. Measuring chordae tension during transapical neochordae implantation: Toward understanding objective consequences of mitral valve repair. J. Thorac. Cardiovasc. Surg. 2019, 158, 746–755. [Google Scholar] [CrossRef] [PubMed]

- Sorajja, P.; Vemulapalli, S.; Feldman, T.; Mack, M.; Holmes, D.R.; Stebbins, A.; Kar, S.; Thourani, V.; Ailawadi, G. Outcomes With Transcatheter Mitral Valve Repair in the United States: An STS/ACC TVT Registry Report. J. Am. Coll. Cardiol. 2017, 70, 2315–2327. [Google Scholar] [CrossRef] [PubMed]

- Grinberg, D.; Bruhat, A.; Cottinet, P.-J.; Le, M.Q.; Adams, D.H.; Costa, A. Mitral valve repair based on physical characterization of coaptation forces. J. Thorac. Cardiovasc. Surg. 2020, 159, e181–e183. [Google Scholar] [CrossRef] [PubMed]

- Wei, D.; Han, J.; Zhang, H.; Li, Y.; Xu, C.; Meng, X. The correlation between the coaptation height of mitral valve and mitral regurgitation after mitral valve repair. J. Cardiothorac. Surg. 2017, 12, 120. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Carpentier, A.; Adams, D.H.; Filsoufi, F. Carpentier’s Reconstructive Valve Surgery; Elsevier Health Sciences: Saunders, GA, USA, 2011; ISBN 978-1-4557-1077-5. [Google Scholar]

- Rim, Y.; McPherson, D.D.; Kim, H. Effect of leaflet-to-chordae contact interaction on computational mitral valve evaluation. Biomed. Eng. Online 2014, 13, 31. [Google Scholar] [CrossRef] [Green Version]

- Le, M.Q.; Ganet, F.; Audigier, D.; Capsal, J.-F.; Cottinet, P.-J. Printing of microstructure strain sensor for structural health monitoring. Appl. Phys. A 2017, 123, 354. [Google Scholar] [CrossRef]

- DeGraff, J.; Liang, R.; Le, M.Q.; Capsal, J.-F.; Ganet, F.; Cottinet, P.-J. Printable low-cost and flexible carbon nanotube buckypaper motion sensors. Mater. Des. 2017, 133, 47–53. [Google Scholar] [CrossRef]

- Nguyen, V.-C.; Le, M.-Q.; Fimbel, A.; Bernadet, S.; Hebrard, Y.; Mogniotte, J.-F.; Capsal, J.-F.; Cottinet, P.-J. Printing smart coating of piezoelectric composite for application in condition monitoring of bearings. Mater. Des. 2022, 215, 110529. [Google Scholar] [CrossRef]

- Liu, Q.; Le, M.Q.; Richard, C.; Liang, R.; Cottinet, P.-J.; Capsal, J.-F. Enhanced pseudo-piezoelectric dynamic force sensors based on inkjet-printed electrostrictive terpolymer. Org. Electron. 2019, 67, 259–271. [Google Scholar] [CrossRef]

- Chung, S.Y.; Lee, H.-J.; Lee, T.I.; Kim, Y.S. A wearable piezoelectric bending motion sensor for simultaneous detection of bending curvature and speed. RSC Adv. 2017, 7, 2520–2526. [Google Scholar] [CrossRef] [Green Version]

- Deng, W.; Yang, T.; Jin, L.; Yan, C.; Huang, H.; Chu, X.; Wang, Z.; Xiong, D.; Tian, G.; Gao, Y.; et al. Cowpea-structured PVDF/ZnO nanofibers based flexible self-powered piezoelectric bending motion sensor towards remote control of gestures. Nano Energy 2019, 55, 516–525. [Google Scholar] [CrossRef]

- Richards, J.M.; Farrar, E.J.; Kornreich, B.G.; Moïse, N.S.; Butcher, J.T. The mechanobiology of mitral valve function, degeneration, and repair. J. Vet.-Cardiol. 2012, 14, 47–58. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Della Schiava, N.; Pedroli, F.; Thetpraphi, K.; Flocchini, A.; Le, M.-Q.; Lermusiaux, P.; Capsal, J.-F.; Cottinet, P.-J. Effect of beta-based sterilization on P(VDF-TrFE-CFE) terpolymer for medical applications. Sci. Rep. 2020, 10, 8805. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Villafuerte, J.; Consonni, V.; Sarigiannidou, E.; Capsal, J.-F.; Bruhat, A.; Grinberg, D.; Petit, L.; Cottinet, P.-J.; Le, M.-Q. Optimization Strategies Used for Boosting Piezoelectric Response of Biosensor Based on Flexible Micro-ZnO Composites. Biosensors 2022, 12, 245. https://doi.org/10.3390/bios12040245

Zhang X, Villafuerte J, Consonni V, Sarigiannidou E, Capsal J-F, Bruhat A, Grinberg D, Petit L, Cottinet P-J, Le M-Q. Optimization Strategies Used for Boosting Piezoelectric Response of Biosensor Based on Flexible Micro-ZnO Composites. Biosensors. 2022; 12(4):245. https://doi.org/10.3390/bios12040245

Chicago/Turabian StyleZhang, Xiaoting, Jose Villafuerte, Vincent Consonni, Eirini Sarigiannidou, Jean-Fabien Capsal, Alexis Bruhat, Daniel Grinberg, Lionel Petit, Pierre-Jean Cottinet, and Minh-Quyen Le. 2022. "Optimization Strategies Used for Boosting Piezoelectric Response of Biosensor Based on Flexible Micro-ZnO Composites" Biosensors 12, no. 4: 245. https://doi.org/10.3390/bios12040245

APA StyleZhang, X., Villafuerte, J., Consonni, V., Sarigiannidou, E., Capsal, J. -F., Bruhat, A., Grinberg, D., Petit, L., Cottinet, P. -J., & Le, M. -Q. (2022). Optimization Strategies Used for Boosting Piezoelectric Response of Biosensor Based on Flexible Micro-ZnO Composites. Biosensors, 12(4), 245. https://doi.org/10.3390/bios12040245