3.1. Deposition and Characterisation of pH Sensing Films

One of the key steps in the fabrication of the pH sensors is the deposition of a sensitive film. Within this work, ruthenium oxide was employed as the active layer, given its ability to reversibly reduce the surface RuO

2 using H

+ groups according to the formula below [

27]:

This material shows a better stability compared to similar pH-sensing compounds such as IrO

2 [

16,

17,

18]. In this case, the RuO

2 sensing films were deposited by electrodeposition, using a copper substrate as the working electrode, a Ag/AgCl reference and a carbon-based counter. In this case, a voltage between 0 and 0.8 V was applied at a rate of 100 mV/s, and the resulting current was determined. Up to 10 cycles were applied, and the results using standardised laboratory equipment (AUTOLAB, Metrohm) and a low-cost potentiostat device reported here were compared.

After the fabrication of RuO

x films through electrodeposition directly onto the copper electrodes using laboratory-standard equipment and our low-cost microcontroller-based solution, the electrodes were characterised. Initially, the chemical composition was studied using FTIR, which could be used for the determination of chemical stretches on the nanoparticles. The presence of hydroxyl groups and Ru-O bonds on the RuO

x nanoparticles is crucial, since they are responsible for the H

+ sensitivity as previously shown [

27].

The FTIR revealed the presence of the Ru-OH stretches at 821 cm

−1 [

28] in both cases. In addition, the stretch corresponding to the peroxo groups was observed at 1014 cm

−1 [

29], along with the H

2O stretches at 1600 cm

−1 [

30] and the ones from hydroxyl groups at 3400 cm

−1 [

31]. These groups reflected the adsorption of water molecules onto the RuO

x nanoparticles, which is key for H

+ sensing. These stretches were present within the samples fabricated using both Autolab- and Arduino-based equipment, proving the suitability of the low-cost method for the fabrication of pH sensing films (

Figure 2a).

The morphology of the final sensing films was additionally evaluated by using SEM. Initially, pristine copper electrodes prior the deposition of films were studied. In this case, a homogeneous surface was obtained, with no presence of nanoparticles (

Figure 2b). After electrodeposition, a film of RuO

x nanoparticles was observed on the copper electrodes, with a size in the range of 200 nm, showing the deposition of the sensing material (

Figure 2c). Similar structures have been observed for the determination of pH changes in Lab-on-a-Chip devices [

18] and water quality monitoring [

13]. A similar morphology to the one obtained using the Autolab equipment was observed in the case of low-cost electrodeposition with the Arduino-based potentiostat, showing the presence of nanoparticle film onto the surface of the copper-based electrodes (

Figure 2d).

Our Arduino-based approach led to the successful deposition of sensing films onto the copper substrates with similar morphologies and grain sizes. These nanoparticles also showed a similar chemical composition as determined by FTIR. These films could also be used to determine the pH of solutions using a low-cost device as determined within the following sections.

3.2. Electrochemical Characterisation of Sensing Films

To test the initial sensitivity of the films after deposition using the lab-proof potentiostat, a two-electrode cell was prepared by coating a copper electrode using a silver ink. This silver ink was used as a Ag/AgCl electrode after oxidising it by using FeCl

3 for 1 min following previous work in the field [

32]. The full device was immersed in different pH buffers, and the voltage of the cells was recorded (

Figure 3c,d). In the case of the low-cost Arduino device calibration, an off-the-shelf device was employed for the voltage measurements.

When the sensing devices were characterised using laboratory equipment, a Nernst sensitivity of 53.7 mV/pH was achieved. This value demonstrated the suitability of our potentiostat in the fabrication of pH-sensitive electrodes, since it was similar to the Nernst sensitivity of 60 mV/pH sensitivity, which is the current standard for ion-selective electrodes. When the Arduino-based device was employed instead, a good linearity was observed within the measured pH range (R

2 = 0.987), similar to the results obtained by the laboratory equipment, with a sensitivity of 30.4 points/pH. This performance allowed an accurate determination of the pH of solutions within biological environments, since the chosen range comprises the pH values typically observed within tomato plant xylem saps [

12].

The low-cost approach described within the present work for the fabrication of the sensing films comprised a Wio Terminal device, which allowed the control of the components involved, and an interactive interface for the selection of the desired voltage range and speed by the user. This system could be complemented with multiple environmental sensors of interest such as the BME680 for temperature, humidity and gas measurements, and could additionally analyse the results in real-time. The whole circuit was enclosed within a plastic housing, and the three electrode cells were connected to the potentiostat (

Figure 3e,f). A schematical representation of the device circuit is shown in

Figure A1. In addition, the necessary codes have been made available on XOD.io, for object-oriented programming (

Figure A2).

Our results show that microcontroller-based potentiostats can be used for the deposition and pH sensing of RuOx nanoparticles, with similar sensitivities when compared to laboratory equipment. This microcontroller device greatly reduced the production and operation costs and enabled the portability of the developed devices, showing promise for their real implementation within real-world settings. The RuOx films showed a Nernst response when used in the presence of different pH buffers, and a good linearity was observed within the measured pH range (4–9). This level performance is advantageous for the development of implanted devices for plant monitoring. However, one of the limitations of the devices was the high noise rates that were seen, in the range of 0.16 mV/min, and 0.24 Point/min in the case of the Arduino-based devices. These noise rates could hinder applications in biologically relevant environments. As such, further modifications using cellulose-based coatings were tested to improve the performance of the sensors.

3.3. Deposition of Cellulose-Based Film on Sensing Device

The deposition using the Autolab equipment and microcontroller-based devices led to similar morphologies and sensing performances, showing promise for the incorporation of these low-cost methods in the fabrication of implantable devices. However, the noise rates of the films were high, which could lead to large uncertainties on the measured pH, especially given the logarithmic nature of this value [

33].

To improve the performance of the sensing films by reducing the electrochemical noise, a cellulose-based coating containing PDMS elastomer at a ratio of 60:40 was developed. This coating composition was selected following previous reported work that indicated an improvement in sensing stability of ion-selective electrodes using elastomer coatings [

34] and a potential decrease in biomolecule adsorption when PDMS is combined with ethyl cellulose [

25]. As such, it could be applied to improve the stability of the pH-sensing films, which could monitor biomarkers in biological solutions.

Thin films were deposited onto the RuO

x films using an aerosol-based method (

Figure 4a). The aerosol method developed in this work consisted of a piezoelectric atomizer, which could operate at a frequency of 110 kHz, and a low-cost air pump that could be connected to a microcontroller (

Figure 4a). The use of an air pump allowed the displacement of the generated aerosol from the precursor solution reservoir onto the electrodes, generating a uniform film with a roughness in the range of 3 nm. Initially, this deposition method was applied to copper wires to compare the performance with the drop casting method (

Figure 4b,c). A higher surface roughness was observed in the case of drop cast samples compared to the aerosol deposited films, evidencing a higher surface homogeneity of the case of aerosol deposited films. This improved homogeneity was key to produce sensing films with reproducible performances and reduce the adsorption of biomolecules. In addition, the thickness of the films fabricated by aerosol deposition could be controlled by changing the deposition time, which allowed a good control of the dimensions, with an estimated growth of 0.77 nm/s (

Figure 4d).

The presence of a cellulose-based coating could reduce the measured electrochemical noise, from 0.24 ± 0.02 Point/min, obtained in the case of uncoated electrodes, up to 0.19 ± 0.01 Point/min (

Figure 4e). In addition, the electrodes showed a similar sensitivity compared to the pristine RuO

x electrodes, with 35 point/pH, and a linear response within the same pH range as the uncoated electrodes (

Figure 4f).

To allow a good control over the film dimensions and morphology, a heating element was incorporated within our low-cost deposition method. This heating element allowed us to obtain a homogeneous temperature for the evaporation of the carrying solvent. All film precursors had previously been dissolved in this carrying solvent, allowing the deposition of the films onto the copper conductive electrode. Deposition temperature is crucial during aerosol deposition, since it can greatly influence the roughness of the deposited films, thereby having an impact on the sensing performance [

25]. In this case, the temperature of the substrate was controlled using an analogue temperature sensor physically attached to the aluminium substrate where the sensing device was placed. The temperature readings from this sensor were used to regulate the substrate temperature via an Arduino microcontroller connected to a relay to power the heating element. By using this system, stable temperatures with a small deviation of ±1 °C could be obtained (

Figure 5a). To achieve a low roughness of the films, a moderate temperature of 40 °C was applied enabling the evaporation of ethyl cellulose. The final deposition method led to a low film roughness of approximately 3 nm.

Although the application of a relatively high temperature was crucial to achieve a high homogeneity and good thickness control, in some cases, it can also promote the degradation of the film components. As such, to study the stability of the film components after deposition, a pristine PDMS film and an ethyl cellulose film were deposited onto two different glass substrates each at a temperature of 40 °C. FTIR was then conducted on both films, and the presence of characteristic stretches from both components was analysed (

Figure 5b,c). In the case of PDMS, the stretches at 1260 cm

−1, 2960 cm

−1, 1076 cm

−1, and 796 cm

−1 were observed, as expected from the structure of PDMS [

23]. These peaks correspond to the CH

3 symmetric bending, C-H stretching, Si-O-Si bond, and CH

3 rocking, respectively. The presence of these peaks was indicative of a non-thermal degradation of PDMS during the deposition [

35]. After the study of PDMS, the stability of ethyl cellulose films deposited by aerosol was studied. Cellulose derivatives display multiple stabilities due to the presence of different functional groups over their surfaces. The observed FTIR spectrum in this case was consistent with the reported work, with stretches located at 1054 cm

−1, 1380 cm

−1, and 3499 cm

−1 consistent with the presence of C-O, CH

2 and -OH stretches, respectively [

36]. The obtained FTIR spectra from both components was indicative of no degradation of the protective film components upon deposition using the aerosol method here described. This stability was key for in vivo testing of the final devices and had an impact on the electrochemical performance of the sensors.

As previously observed, the incorporation of this protective film led to an increase in signal stability of the sensing films evidenced by the lower noise rates. To further demonstrate the increase in performance on sensing when using protective films, the electrochemical drift was assessed (

Figure 5d). This drift was measured by subjecting the pristine and coated electrodes to a solution with a pH of 8 and recording the changes in the measurements over 1 h. The results indicate a 7-fold decrease in drift, changing from 18.1 ± 3.1 to 2.5 ± 1.3 mV h

−1.

As observed, the modification of sensing devices using a cellulose-based coating led to an improvement in the stability of pH sensors. This stability was reflected in lower noise and drift rates, showing promise for the incorporation in biological tissues. A key aspect of the sensing performance is the selectivity of devices due to the high presence of electrolytes inside plant tissues. In the case of tomato plants, potassium could be considered one of the most important interferences, given its concentration of approximately 40 mM, as measured by Gallegos-Cedillo et al. [

12]. As such, the selectivity of the sensing devices was evaluated. In this case, the matched potential method was used, and selectivity coefficients of

and

were obtained for the pristine and cellulose-modified electrodes, respectively. These selectivity values were superior when compared to the coefficients obtained on similar metal oxide-based electrodes, such as iridium oxide thin films, which had values of approximately −2.24, as reported by Huang et al. [

37]. In addition, the similarities between selectivity coefficients in both cases indicate a non-interference of the protective coating with the sensing process carried out by the RuO

x nanoparticles.

As demonstrated, the incorporation of this cellulose-based coating onto the electrode surface improved the noise rates of the sensors when compared to the pristine metal oxide-based device. This coating could also improve the long-term stability of the sensors which proved crucial when incorporated during in vivo studies, as shown in the next section. These improvements in the drift and noise rates were likely a consequence of the lowest adsorption of biomolecules, as described in previous reported work [

25]. The use of ruthenium oxide also led to a higher selectivity when compared to other metal oxide-based sensors, representing a promising approach for the development of low-cost devices for the in vivo monitoring of pH.

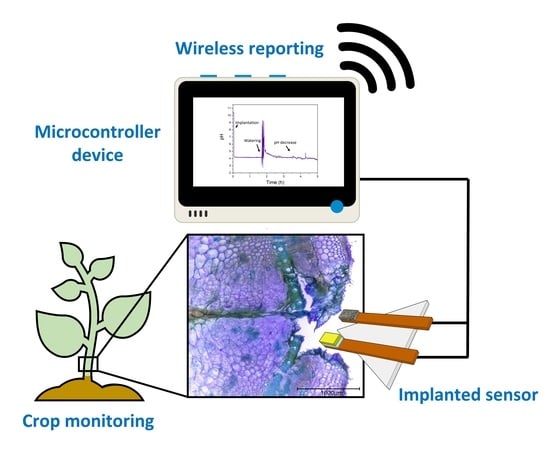

3.4. Testing of Final Device for In Vivo Plant pH Monitoring

After the fabrication and optimisation of the sensing devices through the incorporation of a cellulose-based coating, the electrodes were implanted inside tomato plants. The working and reference electrodes (1 mm wide) were glued onto a PP substrate to facilitate the implantation (

Figure 6a,b), and they were directly inserted onto the tomato stem (

Figure 6c). A Wio Terminal-based device was assembled, incorporating a low-cost voltage metre, and a BME680 sensor, able to measure environmental humidity, temperature, pressure and VOC concentrations. The device was also programmed to send data wirelessly to an online server for data analysis and could be directly powered using an inductive charger (

Figure 6d,e). All the necessary components for the environmental measurements were enclosed inside a portable box that enabled the easy handling of the devices. Finally, the results were downloaded from an online server, enabling the wireless reporting of results.

After the assembly of the low-cost system, the electrodes were implanted inside tomato plants. Initially, electrodes where no cellulose coating had been deposited were tested. The initial baseline was first recorded for 1 h, stabilizing at a pH of 2.42 ± 0.84. The plant was then watered using 20 mL DI water, increasing the pH to 3.44 ± 1.52 (

Figure 7a). However, given the increasing noise rates obtained in this case, an objective study of the plant response became difficult. Such high electrochemical noise was attributed to a protein adsorption and biofouling, which commonly takes place within implantable devices that incorporate similar materials such as iridium oxide [

38].

When the RuO

x sensing film was coated using a cellulose/elastomer film, the noise rates of the measured signal improved significantly compared with the pristine pH sensors. A pH baseline of 4.17 ± 0.03 was initially recorded when the devices were first implanted. This value was similar to previous measurements of xylem sap pH in tomatoes, which reported a slightly acidic value [

10]. Upon watering the plant, an initial increase in pH was observed, followed by a stabilisation of the value at 4.37 ± 0.07 (

Figure 7b). Changes in pH values have been observed in vascular plants due to an increase in transpiration [

10], change of season [

39], presence of light [

40] or fertilisation using nitrates [

41]. As such, the increase in pH was attributed to a higher water availability by the plant, demonstrating the potential application of the device for the continuous monitoring of pH in vivo. This low-cost system could also potentially be employed in smart agriculture, enabling the study of plant infections [

42] and wound response [

43], which could save costs and enhance productivity.

To complement the information obtained by the in vivo devices, we incorporated a BME680 environmental sensor, which recorded information about the temperature, humidity and VOCs concentrations (

Figure 7c–e). The built-in light sensor from the Wio Terminal Device was additionally used to study the day-night cycles of plants (

Figure 7f). As expected, the magnitude of environmental humidity increased upon watering the tomato plant. As such, this sensor, combined with the pH information from the implantable device, could offer information about the water or nutritional needs of the plant. The resistance measured by the VOC sensor also increased. However, in this case, given the nature of the resistor-based VOC sensor, this increase in resistance can be translated into a lower concentration of VOCs. The information recorded form other physical sensors such as light and temperature was correlated, with lower temperatures recorded at night-time. These sensors could be exploited in the future for adjusting the growing conditions of plants when they are kept under controlled environments.

As expected, the decrease in daylight was linked to a decrease in environmental temperature and an increase in humidity. In addition, the pH inside the stem increased after the stabilization due to watering increased, with a value of 4.37 ± 0.07 compared to the original baseline. This slight increase in the pH values of tomatoes during night-time has been previously described in tomato plants. This increase has been shown to be a consequence of differences in transpiration between day and night rather than changes in electrolyte concentrations in xylem [

25].

3.5. Materials Biocompatibility for Long-Term Applications

One of the major challenges in the field of implanted biosensors is tissue compatibility with the host organism. Due to the healing process taking place at the interface between tissue cells and sensors, the accuracy of measured pH is decreased over time. In the case of implanted devices in humans, the foreign body response has been widely documented, involving the inflammation of surrounding tissue [

44] and the formation of a fibrotic tissue that isolates the sensor surface [

45]. However, this process is not well-understood in plants, limiting the development of sensing approaches in the field. As such, we conducted a study to determine the impact of the pH sensors developed in this work on the tissue morphology and healing process, as well as the changes due to the modification of devices using ethyl cellulose.

Both pristine sensing devices, containing the RuO

x films alone, and the modified sensors containing ethyl cellulose were initially implanted onto the tomato plants. A cross-section of the stem where the sensors had been implanted was imaged by optical microscopy in the same day that the sensors had been implanted (

Figure 8a,b). In this case, a Toluidine Blue O-based stain was used. This cationic dye binds to cell wall components such as lignin or pectins [

26], allowing a visualization and identification of the cells contained in the pith and xylem due to the differences in composition. Plant xylem is a vascular tissue responsible for the transport of water and electrolytes, including electrolytes such as potassium ions and nitrate [

25]. As such, we targeted xylem for the study of pH variations in plants. This tissue was located within 600 µm from the tomato plant stem epidermis and showed a thickness of 500 µm, as measured from optical micrographs.

Within the first hour after the insertion of the electrodes inside the plant xylem, no significant wound response could be observed from the plant. As determined in the previous section, in both cases, the electrodes were put into contact with the sap and could determine the concentration of xylem sap pH for at least 1 h. Due to the continuous contact with the xylem sap solution, the magnitude of the electrical impedance was low in pristine and cellulose-modified electrodes, showing an average value of approximately 3 kΩ in both cases (

Figure 8c). The impedance recorded within the lowest frequency range, being indicative of the electrical resistance of the films, was 22.01 and 22.99 kOhm for the uncoated and EC/PDMS protected RuO

x films, respectively. These results indicate a relatively low electrical resistance of the nanoparticulate coatings and a low resistance of the thin EC/PDMS films. As such, the incorporation of the protective coating film showed a low electrical interference in the electrical properties of the electrodes. In the case of the high frequency range of the impedance plots, resistance values of 76.97 and 61.31 Ohms were measured, indicating a low ionic resistance, which is crucial for the sensing of H

+ ions. The values of real and imaginary impedance recorded at different frequencies could additionally be used to estimate the changes in tissue resistance by fitting the results into an equivalent circuit (

Figure A3). In this case, a resistor and capacitor in parallel were used for the modelling, as reported previously [

46]. This modelling could be used to measure both the intracellular and extracellular resistance as well as the cell capacitance, which is indicative of the movement of ions within the cells. In this case, the extracellular and intracellular resistance were similar, at approximately 8 kOhm and 80 Ohms, respectively. In addition, the capacitance was approximately 10 µF.

However, after 7 days of continuous contact with the xylem tissue, this impedance increased to 90.4 kΩ for the pristine electrodes and 72.5 kΩ in the case of the cellulose-coated sensors. This increase in the electrical impedance of the sensors over time was attributed to the formation of necrotic tissues surrounding the electrodes, with a high content of lignin. Similar responses from plants have been observed during the grafting process, whereby a defence response is triggered to seal the tissues from the plants [

47]. In this case, the obtained resistance within low-frequency ranges was approximately 947 and 811 kOhm in the case of pristine and EC/PDMS-coated sensors, respectively. The lower resistance obtained in the case of the EC/PDMS was indicative of a lower lignification of tissues around the sensor area, suggesting a better biocompatibility of the coating. On the contrary, the resistance obtained within the high-frequency range was similar to the one obtained in the previous case on day 1, being 58.51 and 64.20 Ohms. When the impedance plots were simulated using the same equivalent circuit, the intracellular electrical resistance was similar to the one obtained in the previous case, being approximately 60 Ohms. On the contrary, the extracellular resistance greatly increased, reaching 1.84 MOhm in the case of uncoated sensors and 1.16 MOhms when EC/PDMS-coated devices were employed. This increase in extracellular resistance was consistent with the formation of the necrotic tissue area around the sensing electrodes. The calculated capacitance also decreased, from 10 µF measured on day 1 to 1 µF after a week of continuous exposure to the plant tissue. As a consequence of this wound-healing process, the contact of sap solution with the sensor surface is restricted, reducing the accuracy of the sensing devices. Due to this healing process, the drift of the sensors also increased (

Figure 8d).

These results suggested the formation of a necrotic tissue film surrounding the pH sensing electrodes, leading to an increase in impedance and electrical drift. This drift increased by over 10-fold after 7 days, changing from 6.8 mV h−1 to 71.5 mV h−1. These measurements were taken after re-equilibrating the pH sensors for 7 days. In this case, the devices were kept implanted inside the tomato plants, but no electrochemical measurements were taken between day 1 and day 7. As such, this high value in drift was influenced by the initial drift from initializing the OCP sensing device, and the wound healing mechanism of the plant, which restricts the sap flow onto the sensing area. In addition, it is expected that the wound healing mechanism in the plant involves the production of metabolites and the release of electrolytes which might compromise the composition of the sensing films within the sensing area. These phenomena explain the relatively similar pH recorded in both day 1 and day 7 despite the high drift of the devices.

As mentioned, the healing process leads to a decrease in sensing accuracy, reflected in a high electrochemical drift. The lignification of the tissues around the sensing electrodes could be observed after 7 days of continuous contact of the electrodes with the films. The formation of necrotic tissue was visible even without the staining using Toluidine Blue (

Figure 9a,b). Upon examination with the microscope, a dark tissue around the edges of the wound, not observed in day 1 microscopy pictures, was present. Non-disorganized cells of variable sizes were present around this dark tissue layer, being indicative of the regenerative process of the tissues (

Figure 9c,d).

When cellulose-coated sensors were implanted in the tomato plant, a similar response was observed. However, the thickness of the necrotic tissue surrounding the sensor was significantly lower than the one in the case of pristine electrodes. In addition, the cells surrounding this lignified tissue did not share the disorganized morphology obtained with pristine electrodes, indicating a better integration of the sensors with the plant. The lower thickness of the lignified tissue around the electrodes was also consistent with the lower impedance magnitude measured.

The study of biological responses from plant tissues towards the electrodes and cellulose-coated electrodes showed a limitation of the incorporation of implanted sensors in long-term applications. Although this process could not be prevented by the incorporation of the protective film, the plants showed a lower degree of tissue damage, and the obtained drift was significantly lower than that of the pristine RuOx films. Thus, this work demonstrates the need for the development of materials that can minimize the tissue responses and enable a true monitoring of biomarkers in plants.