One-Step Fabrication of Paper-Based Inkjet-Printed Graphene for Breath Monitor Sensors

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Instruments

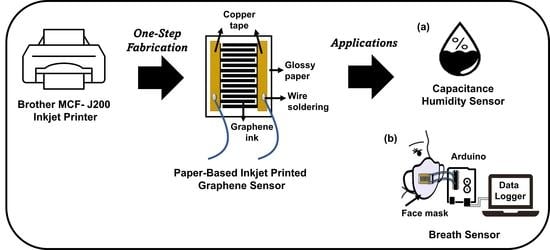

2.3. Fabrication of Paper-Based Inkjet-Printed Graphene Sensor

2.4. Relative Humidity Sensing Setup and Measurement

2.5. Monitoring for Breath Patterns

3. Results and Discussion

3.1. Characteristics of Paper-Based Inkjet-Printed Graphene Ink

3.2. Performance Measurement in Humidity Sensing

3.3. Breathe Patterns Monitoring

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Blouet, S.; Sutter, J.; Fresnel, E.; Kerfourn, A.; Cuvelier, A.; Patout, M. Prediction of Severe Acute Exacerbation Using Changes in Breathing Pattern of COPD Patients on Home Noninvasive Ventilation. Int. J. Chronic Obstr. Pulm. Dis. 2018, 13, 2577–2586. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Garde, A.; Sörnmo, L.; Jané, R.; Giraldo, B. Breathing Pattern Characterization in Chronic Heart Failure Patients Using the Respiratory Flow Signal. Ann. Biomed. Eng. 2010, 38, 3572–3580. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ryan, L.; Rahman, T.; Strang, A.; Heinle, R.; Shaffer, T.H. Diagnostic Differences in Respiratory Breathing Patterns and Work of Breathing Indices in Children with Duchenne Muscular Dystrophy. PLoS ONE 2020, 15, e0226980. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Fujiyah, E.F.; Purwanto, C.R.; Susanto, J.; Lutfiandini, C.T. Ineffective Breathing Pattern Nursing Care with Chronic Kidney Diseases Patient. J. Vocat. Nurs. 2022, 3, 80–85. [Google Scholar]

- AL-Khalidi, F.Q.; Saatchi, R.; Burke, D.; Elphick, H.; Tan, S. Respiration Rate Monitoring Methods: A Review. Pediatr. Pulmonol. 2011, 46, 523–529. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Contributors A. Respiratory Management of COVID-19. 2020. Available online: https://members.physio-pedia.com/learn/respiratory-management-of-people-with-covid-19/:Physiopedia (accessed on 3 August 2022).

- Massaroni, C.; Nicolò, A.; Lo Presti, D.; Sacchetti, M.; Silvestri, S.; Schena, E. Contact-Based Methods for Measuring Respiratory Rate. Sensors 2019, 19, 908. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Suresh Kumar, S.; Dashtipour, K.; Abbasi, Q.H.; Imran, M.A.; Ahmad, W. A Review on Wearable and Contactless Sensing for COVID-19 with Policy Challenges. Front. Commun. Netw. 2021, 2, 636293. [Google Scholar] [CrossRef]

- da Costa, T.D.; Vara, M.; Cristino, C.S.; Zanella, T.Z.; Neto, G.N.N.; Nohama, P. Breathing Monitoring and Pattern Recognition with Wearable Sensors. In Wearable Devices—The Big Wave of Innovation; Nasiri, N., Ed.; IntechOpen: London, UK, 2019. [Google Scholar] [CrossRef] [Green Version]

- Yao, Z.; Coatsworth, P.; Shi, X.; Zhi, J.; Hu, L.; Yan, R.; Gueder, F.; Yu, H.-D. Paper-Based Sensors for Diagnostics, Human Activity Monitoring, Food Safety and Environmental Detection. Sens. Diagn. 2022, 1, 312–342. [Google Scholar] [CrossRef]

- Xu, Y.; Fei, Q.; Page, M.; Zhao, G.; Ling, Y.; Stoll, S.B.; Yan, Z. Paper-Based Wearable Electronics. iScience 2021, 24, 102736. [Google Scholar] [CrossRef]

- Zhang, J.; Huang, L.; Lin, Y.; Chen, L.; Zeng, Z.; Shen, L.; Chen, Q.; Shi, W. Pencil-Trace on Printed Silver Interdigitated Electrodes for Paper-Based NO2 Gas Sensors. Appl. Phys. Lett. 2015, 106, 143101. [Google Scholar] [CrossRef]

- Tai, H.; Duan, Z.; Wang, Y.; Wang, S.; Jiang, Y. Paper-Based Sensors for Gas, Humidity, and Strain Detections: A Review. ACS Appl. Mater. Interfaces 2020, 12, 31037–31053. [Google Scholar] [CrossRef]

- Duan, Z.; Jiang, Y.; Yan, M.; Wang, S.; Yuan, Z.; Zhao, Q.; Sun, P.; Xie, G.; Du, X.; Tai, H. Facile, Flexible, Cost-Saving, and Environment-Friendly Paper-Based Humidity Sensor for Multifunctional Applications. ACS Appl. Mater. Interfaces 2019, 11, 21840–21849. [Google Scholar] [CrossRef]

- Guan, X.; Hou, Z.; Wu, K.; Zhao, H.; Liu, S.; Fei, T.; Zhang, T. Flexible Humidity Sensor Based on Modified Cellulose Paper. Sens. Actuators B Chem. 2021, 339, 129879. [Google Scholar] [CrossRef]

- Niarchos, G.; Dubourg, G.; Afroudakis, G.; Georgopoulos, M.; Tsouti, V.; Makarona, E.; Crnojevic-Bengin, V.; Tsamis, C. Humidity Sensing Properties of Paper Substrates and Their Passivation with ZnO Nanoparticles for Sensor Applications. Sensors 2017, 17, 516. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tao, L.-Q.; Zhang, K.-N.; Tian, H.; Liu, Y.; Wang, D.-Y.; Chen, Y.-Q.; Yang, Y.; Ren, T.-L. Graphene-Paper Pressure Sensor for Detecting Human Motions. ACS Nano 2017, 11, 8790–8795. [Google Scholar] [CrossRef] [PubMed]

- Liao, X.; Liao, Q.; Yan, X.; Liang, Q.; Si, H.; Li, M.; Wu, H.; Cao, S.; Zhang, Y. Flexible and Highly Sensitive Strain Sensors Fabricated by Pencil Drawn for Wearable Monitor. Adv. Funct. Mater. 2015, 25, 2395–2401. [Google Scholar] [CrossRef]

- Thiyagarajan, K.; Rajini, G.; Maji, D. Flexible, Highly Sensitive Paper-Based Screen Printed MWCNT/PDMS Composite Breath Sensor for Human Respiration Monitoring. IEEE Sens. J. 2020, 21, 13985–13995. [Google Scholar] [CrossRef]

- Lu, R.; Haider, M.R.; Gardner, S.; Alexander, J.I.D.; Massoud, Y. A Paper-Based Inkjet-Printed Graphene Sensor for Breathing-Flow Monitoring. IEEE Sens. Lett. 2018, 3, 1–4. [Google Scholar] [CrossRef]

- Kan, Y.; Meng, J.; Guo, Y.; Li, X.; Gao, D. Humidity Sensor Based on Cobalt Chloride/Cellulose Filter-Paper for Respiration Monitoring. J. Electroanal. Chem. 2021, 895, 115423. [Google Scholar] [CrossRef]

- Yoshida, A.; Wang, Y.-F.; Tachibana, S.; Hasegawa, A.; Sekine, T.; Takeda, Y.; Hong, J.; Kumaki, D.; Shiba, T.; Tokito, S. Printed, All-Carbon-Based Flexible Humidity Sensor Using a Cellulose Nanofiber/Graphene Nanoplatelet Composite. Carbon Trends 2022, 7, 100166. [Google Scholar] [CrossRef]

- Liu, H.; Zheng, H.; Xiang, H.; Wang, W.; Wu, H.; Li, Z.; Zhuang, J.; Zhou, H. Paper-Based Wearable Sensors for Humidity and VOC Detection. ACS Sustain. Chem. Eng. 2021, 9, 16937–16945. [Google Scholar] [CrossRef]

- Rahimi, R.; Ochoa, M.; Ziaie, B. A Comparison of Direct and Indirect Laser Ablation of Metallized Paper for Inexpensive Paper-Based Sensors. ACS Appl. Mater. Interfaces 2018, 10, 36332–36341. [Google Scholar] [CrossRef] [PubMed]

- Malik, S.; Ahmad, M.; Punjiya, M.; Sadeqi, A.; Baghini, M.S.; Sonkusale, S. Respiration Monitoring Using a Flexible Paper-Based Capacitive Sensor. In Proceedings of the 2018 IEEE Sensors, New Delhi, India, 28–31 October 2018; pp. 1–4. [Google Scholar] [CrossRef]

- Balakrishnan, V.; Dinh, T.; Foisal, A.R.M.; Nguyen, T.; Phan, H.-P.; Dao, D.V.; Nguyen, N.-T. Paper-Based Electronics Using Graphite and Silver Nanoparticles for Respiration Monitoring. IEEE Sens. J. 2019, 19, 11784–11790. [Google Scholar] [CrossRef]

- Wang, X.; Deng, Y.; Chen, X.; Jiang, P.; Cheung, Y.K.; Yu, H. An Ultrafast-Response and Flexible Humidity Sensor for Human Respiration Monitoring and Noncontact Safety Warning. Microsyst. Nanoeng. 2021, 7, 99. [Google Scholar] [CrossRef] [PubMed]

- Tsutsumi, H.; Tanabe, S.-i.; Harigaya, J.; Iguchi, Y.; Nakamura, G. Effect of Humidity on Human Comfort and Productivity After Step Changes from Warm and Humid Environment. Build. Environ. 2007, 42, 4034–4042. [Google Scholar] [CrossRef]

- Kano, S.; Jarulertwathana, N.; Mohd-Noor, S.; Hyun, J.K.; Asahara, R.; Mekaru, H. Respiratory Monitoring by Ultrafast Humidity Sensors with Nanomaterials: A Review. Sensors 2022, 22, 1251. [Google Scholar] [CrossRef]

- Lv, C.; Hu, C.; Luo, J.; Liu, S.; Qiao, Y.; Zhang, Z.; Song, J.; Shi, Y.; Cai, J.; Watanabe, A. Recent Advances in Graphene-Based Humidity Sensors. Nanomaterials 2019, 9, 422. [Google Scholar] [CrossRef] [Green Version]

- Yavari, F.; Koratkar, N. Graphene-Based Chemical Sensors. J. Phys. Chem. Lett. 2012, 3, 1746–1753. [Google Scholar] [CrossRef] [PubMed]

- Liang, R.; Luo, A.; Zhang, Z.; Li, Z.; Han, C.; Wu, W. Research Progress of Graphene-Based Flexible Humidity Sensor. Sensors 2020, 20, 5601. [Google Scholar] [CrossRef]

- Sett, A.; Biswas, K.; Majumder, S.; Datta, A.; Bhattacharyya, T.K. Graphene and Its Nanocomposites Based Humidity Sensors: Recent Trends and Challenges. In Humidity Sensors; Chani, M.T.S., Khan, S.B., Asiri, A.M., Eds.; IntechOpen: London, UK, 2021. [Google Scholar] [CrossRef]

- Farahani, H.; Wagiran, R.; Hamidon, M.N. Humidity Sensors Principle, Mechanism, and Fabrication Technologies: A Comprehensive Review. Sensors 2014, 14, 7881–7939. [Google Scholar] [CrossRef] [Green Version]

- Barmpakos, D.; Kaltsas, G. A Review on Humidity, Temperature and Strain Printed Sensors—Current Trends and Future Perspectives. Sensors 2021, 21, 739. [Google Scholar] [CrossRef] [PubMed]

- Yoo, K.-P.; Lim, L.-T.; Min, N.-K.; Lee, M.J.; Lee, C.J.; Park, C.-W. Novel Resistive-Type Humidity Sensor Based on Multiwall Carbon Nanotube/Polyimide Composite Films. Sens. Actuators B Chem. 2010, 145, 120–125. [Google Scholar] [CrossRef]

- Lee, C.-Y.; Lee, G.-B. Humidity Sensors: A Review. Sens. Lett. 2005, 3, 1–15. [Google Scholar] [CrossRef]

- Indrakumari, R.; Poongodi, T.; Suresh, P.; Balamurugan, B. The Growing Role of Internet of Things in Healthcare Wearables. In Emergence of Pharmaceutical Industry Growth with Industrial IoT Approach; Balas, V., Solanki, V., Kumar, R., Eds.; Elsevier Science LTD.: London, UK, 2020; pp. 163–194. [Google Scholar] [CrossRef]

- Romero, F.J.; Rivadeneyra, A.; Salinas-Castillo, A.; Ohata, A.; Morales, D.P.; Becherer, M.; Rodriguez, N. Design, Fabrication and Characterization of Capacitive Humidity Sensors Based on Emerging Flexible Technologies. Sens. Actuators B Chem. 2019, 287, 459–467. [Google Scholar] [CrossRef]

- Latthe, S.S.; Terashima, C.; Nakata, K.; Fujishima, A. Superhydrophobic Surfaces Developed by Mimicking Hierarchical Surface Morphology of Lotus Leaf. Molecules 2014, 19, 4256–4283. [Google Scholar] [CrossRef] [Green Version]

- Kovtun, A.; Jones, D.; Dell’Elce, S.; Treossi, E.; Liscio, A.; Palermo, V. Accurate Chemical Analysis of Oxygenated Graphene-Based Materials Using X-Ray Photoelectron Spectroscopy. Carbon 2019, 143, 268–275. [Google Scholar] [CrossRef] [Green Version]

- Yang, D.; Velamakanni, A.; Bozoklu, G.; Park, S.; Stoller, M.; Piner, R.D.; Stankovich, S.; Jung, I.; Field, D.A.; Ventrice, C.A., Jr. Chemical Analysis of Graphene Oxide Films After Heat and Chemical Rreatments by X-Ray Photoelectron and Micro-Raman Spectroscopy. Carbon 2009, 47, 145–152. [Google Scholar] [CrossRef]

- Hassan, S.; Yusof, M.; Embong, Z.; Ding, S.; Maksud, M. Surface Study ofGraphene Ink for Fine Solid Lines Printed on BOPP Substrate in Micro-Flexographic Printing Using XPS Analysis Technique. In Proceedings of the IOP Conference Series: Materials Science and Engineering, International Nuclear Science, Technology and Engineering Conference 2017, Kuala Lumpur, Malaysia, 25–27 September 2017; p. 012012. [Google Scholar]

- Banerjee, I.; Faris, T.; Stoeva, Z.; Harris, P.G.; Chen, J.; Sharma, A.K.; Ray, A.K. Graphene Films Printable on Flexible Substrates for Sensor Applications. 2D Mater. 2016, 4, 015036. [Google Scholar] [CrossRef]

- Wu, J.-B.; Lin, M.-L.; Cong, X.; Liu, H.-N.; Tan, P.-H. Raman Spectroscopy of Graphene-Based Materials and Its Applications in Related Devices. Chem. Soc. Rev. 2018, 47, 1822–1873. [Google Scholar] [CrossRef] [Green Version]

- Shen, J.; Li, T.; Long, Y.; Shi, M.; Li, N.; Ye, M. One-Step Solid State Preparation of Reduced Graphene Oxide. Carbon 2012, 50, 2134–2140. [Google Scholar] [CrossRef]

- Aliyev, E.; Filiz, V.; Khan, M.M.; Lee, Y.J.; Abetz, C.; Abetz, V. Structural Characterization of Graphene Oxide: Surface Functional Groups and Fractionated Oxidative Debris. Nanomaterials 2019, 9, 1180. [Google Scholar] [CrossRef] [Green Version]

- Russo, M.A.; Santarelli, D.M.; O’Rourke, D. The Physiological Effects of Slow Breathing in the Healthy Human. Breathe 2017, 13, 298–309. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nazaroff, W.W. The Air Around Us. Indoor Air 2018, 28, 3–5. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dbouk, T.; Drikakis, D. On Coughing and Airborne Droplet Transmission to Humans. Phys. Fluids 2020, 32, 053310. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Li, Z.; Zhang, X.; Zhu, L.; Liu, Y.; Wang, S. The Motion of Respiratory Droplets Produced by Coughing. Phys. Fluids 2020, 32, 125102. [Google Scholar] [CrossRef] [PubMed]

- Luo, J.; Yao, Y.; Duan, X.; Liu, T. Force and Humidity Dual Sensors Fabricated by Laser Writing on Polyimide/Paper Bilayer Structure for Pulse and Respiration Monitoring. J. Mater. Chem. C 2018, 6, 4727–4736. [Google Scholar] [CrossRef]

| Type of Paper Substrate | Sensing Material | Fabrication Method | Output Signal | RH Range (%) | a Response/ b Recovery Time | Sensitivity | Reference |

|---|---|---|---|---|---|---|---|

| Filter paper (Whatman 4) | carbon black (CB) and reduced graphene oxide (rGO) | Coating and drying | Resistance | 33–95% | a 242 s/b 218 s |

| [14] |

| Printing paper | Polyimide | Laser writing | Resistance | 0–90% | - | - | [26] |

| Cellulose filter paper | cobalt chloride (CoCl2) | Soaking and drying | Voltage | 11–98% | a 143 s/b 45s | - | [15] |

| A4 printing paper | A4 printing paper | Facile pasting | Current | 7.2–91% | a 47 2s/b 19 s | - | [24] |

| A4 porous paper (metallic pearl) | graphite and silver nanoparticles | Screen printing and pencil drawing technique | Current | 70–95% | b 1.5–2.5 s (depend on electrode gap) | 0.0564% | [19] |

| Printing paper | glycidyl trimethyl ammonium chloride (EPTAC) | Screen printing | Impedance | 11–95% | a 25 s/b 188 s |

| [15] |

| Metalized paper (aluminum coated paper) | polymeric layer | Laser Ablation | Capacitance | 2–85% | a 266 s/b <10 s | 18.9 fF/%RH | [24] |

| Cellulose paper | Carbon nanotube and polydimethysiloxane composite | Screen printing | Capacitance | 30–95% |

|

| [19] |

| Glossy paper | Graphene printing ink | Inkjet printing | Capacitance | 40–70% |

| 0.03 pF/%RH | This work |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lim, W.Y.; Goh, C.-H.; Yap, K.Z.; Ramakrishnan, N. One-Step Fabrication of Paper-Based Inkjet-Printed Graphene for Breath Monitor Sensors. Biosensors 2023, 13, 209. https://doi.org/10.3390/bios13020209

Lim WY, Goh C-H, Yap KZ, Ramakrishnan N. One-Step Fabrication of Paper-Based Inkjet-Printed Graphene for Breath Monitor Sensors. Biosensors. 2023; 13(2):209. https://doi.org/10.3390/bios13020209

Chicago/Turabian StyleLim, Wei Yin, Choon-Hian Goh, Keenan Zhihong Yap, and Narayanan Ramakrishnan. 2023. "One-Step Fabrication of Paper-Based Inkjet-Printed Graphene for Breath Monitor Sensors" Biosensors 13, no. 2: 209. https://doi.org/10.3390/bios13020209

APA StyleLim, W. Y., Goh, C. -H., Yap, K. Z., & Ramakrishnan, N. (2023). One-Step Fabrication of Paper-Based Inkjet-Printed Graphene for Breath Monitor Sensors. Biosensors, 13(2), 209. https://doi.org/10.3390/bios13020209