Gravure Printing for PVDF Thin-Film Pyroelectric Device Manufacture

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

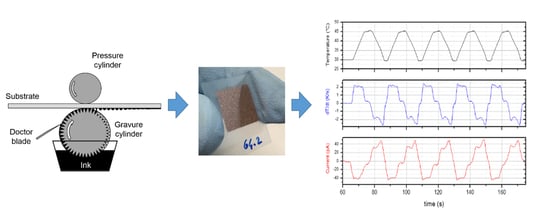

3.1. Overview on the Gravure Printable Pyroelectric Devices

3.2. PVDF Ink Formulation

3.3. Tuning of the Gravure Printing Process of the PVDF Film

3.4. Functional Characterization of the Printed Devices

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

References

- Karim, H.; Sarker, M.R.; Shahriar, S.; Shuvo, M.A.I.; Delfin, D.; Hodges, D.; Tseng, T.-L.; Roberson, D.; Love, N.; Lin, Y. Feasibility study of thermal energy harvesting using lead free pyroelectrics. Smart Mater. Struct. 2016, 25, 055022. [Google Scholar] [CrossRef]

- Wan, C.; Bowen, C.R. Multiscale-structuring of polyvinylidene fluoride for energy harvesting: The impact of molecular-, micro- and macro-structure. J. Mater. Chem. A 2017, 5, 3091–3128. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Z.; Hanrahan, B.; Shi, C.; Khaligh, A. Management and storage of energy converted via a pyroelectric heat engine. Appl. Energy 2018, 230, 1326–1331. [Google Scholar] [CrossRef]

- Thakur, P.; Kool, A.; Hoque, N.A.; Bagchi, B.; Khatun, F.; Biswas, P.; Brahma, D.; Roy, S.; Banerjee, S.; Das, S. Superior performances of in situ synthesized ZnO/PVDF thin film based self-poled piezoelectric nanogenerator and self-charged photo-power bank with high durability. Nano Energy 2018, 44, 456–467. [Google Scholar] [CrossRef]

- Hsiao, C.-C.; Siao, A.-S.; Tsai, Y.-J. A strategy for optimal energy conversion by pyroelectricity. Int. J. Green Energy 2018, 15, 780–788. [Google Scholar] [CrossRef]

- Khan, A.A.; Mahmud, A.; Ban, D. Evolution from single to hybrid nanogenerator: A contemporary review on multimode energy harvesting for self-powered electronics. IEEE Trans. Nanotechnol. 2019, 18, 21–36. [Google Scholar] [CrossRef]

- Bai, Y.; Jantunen, H.; Juuti, J. Energy harvesting research: The road from single source to multisource. Adv. Mater. 2018, 30, 1707271. [Google Scholar] [CrossRef] [Green Version]

- Costa, P.; Nunes-Pereira, J.; Pereira, N.; Castro, N.; Goncalves, S.; Lanceros-Mendez, S. Recent progress on piezoelectric, pyroelectric, and magnetoelectric polymer-based energy-harvesting devices. Energy Technol. 2019, 7, 1800852. [Google Scholar] [CrossRef]

- Ko, Y.J.; Yun, B.K.; Jung, J.H. A 0.7Pb(Mg1/3Nb2/3)O3-0.3PbTiO3-based pyroelectric generator and temperature sensor. J. Korean Phys. Soc. 2015, 66, 713–716. [Google Scholar] [CrossRef]

- Kim, J.; Lee, J.H.; Ryu, H.; Lee, J.-H.; Khan, U.; Kim, H.; Kwak, S.S.; Kim, S.-W. High-performance piezoelectric, pyroelectric, and, triboelectric nanogenerators based on P(VDF-TrFE) with controlled crystallinity and dipole alignment. Adv. Funct. Mater. 2017, 27, 1700702. [Google Scholar] [CrossRef]

- Zabek, D.; Seunarine, K.; Spacie, C.; Bowen, C. Graphene ink laminate structures on Poly(vinylidene difluoride) (PVDF) for pyroelectric thermal energy harvesting and waste heat recovery. ACS Appl. Mater. Interfaces 2017, 9, 9161–9167. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Beasley, A.E.; Bowen, C.R.; Zabek, D.A.; Clarke, C.T. Use it or lose it: The influence of second order effects of practical components on storing energy harvested by pyroelectric effects. Tm-Tech. Mess. 2018, 85, 533–540. [Google Scholar] [CrossRef]

- Ravindran, S.K.T.; Huesgen, T.; Kroener, M.; Woias, P. A self-sustaining micro thermomechanic-pyroelectric generator. Appl. Phys. Lett. 2011, 99, 104102. [Google Scholar] [CrossRef]

- Hsiao, C.-C.; Huang, S.-W.; Chang, R.-C. Temperature field analysis for ZnO thin-film pyroelectric devices with partially covered electrode. Sens. Mater. 2012, 24, 421–441. [Google Scholar]

- Lingam, D.; Parikh, A.R.; Huang, J.; Jain, A.; Minary-Jolandan, M. Nano/microscale pyroelectric energy harvesting: Challenges and opportunities. Int. J. Smart Nano Mater. 2013, 4, 229–245. [Google Scholar] [CrossRef] [Green Version]

- Lee, S.; Singh, N.; Phelan, P.E.; Wu, C.-J. Harvesting CPU Waste Heat Through Pyroelectric Materials. In Proceedings of the ASME 2015 International Technical Conference and Exhibition on Packaging and Integration of Electronic and Photonic Microsystems, San Francisco, CA, USA, 6–9 July 2015; pp. 1–9. [Google Scholar]

- Zabek, D.; Morini, F. Solid state generators and energy harvesters for waste heat recovery and thermal energy harvesting. Therm. Sci. Eng. Prog. 2019, 9, 235–247. [Google Scholar] [CrossRef]

- Thakre, A.; Kumar, A.; Song, H.-C.; Jeong, D.-Y.; Ryu, J. Pyroelectric energy conversion and its applications-flexible energy harvesters and sensors. Sensors 2019, 19, 2170. [Google Scholar] [CrossRef] [Green Version]

- Bowen, C.R.; Taylor, J.; LeBoulbar, E.; Zabek, D.; Chauhan, A.; Vaish, R. Pyroelectric materials and devices for energy harvesting applications. Energy Environ. Sci. 2014, 7, 3836–3856. [Google Scholar] [CrossRef] [Green Version]

- Xie, M.; Zabek, D.; Bowen, C.; Abdelmageed, M.; Arafa, M. Wind-driven pyroelectric energy harvesting device. Smart Mater. Struct. 2016, 25, 125023. [Google Scholar] [CrossRef] [Green Version]

- Zhang, H.; Xie, Y.; Li, X.; Huang, Z.; Zhang, S.; Su, Y.; Wu, B.; He, L.; Yang, W.; Lin, Y. Flexible pyroelectric generators for scavenging ambient thermal energy and as self-powered thermosensors. Energy 2016, 101, 202–210. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, Y.; Yuan, F.; Ding, F.; Schmidt, O.G. A flexible PMN-PT ribbon-based piezoelectric-pyroelectric hybrid generator for human-activity energy harvesting and monitoring. Adv. Electron. Mater. 2017, 3, 1600540. [Google Scholar] [CrossRef] [Green Version]

- Pandya, S.; Velarde, G.; Zhang, L.; Wilbur, J.D.; Smith, A.; Hanrahan, B.; Dames, C.; Martin, L.W. New approach to waste-heat energy harvesting: Pyroelectric energy conversion. NPG Asia Mater. 2019, 11, 1–26. [Google Scholar] [CrossRef]

- Zabek, D.; Taylor, J.; Bowen, C.R. Performance of Thin Film Polyvinylidenefluoride (PVDF) for Pyroelectric Energy Harvesting. In Proceedings of the Joint IEEE International Symposium on the Applications of Ferroelectric, State College, PA, USA, 12–16 May 2014; pp. 1–4. [Google Scholar]

- Kishore, R.A.; Priya, S. A review on low-grade thermal energy harvesting: Materials, methods and devices. Materials 2018, 11, 1433. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zabek, D.; Taylor, J.; Le Boulbar, E.; Bowen, C.R. Micropatterning of flexible and free standing polyvinylidene difluoride (PVDF) films for enhanced pyroelectric energy transformation. Adv. Energy Mater. 2015, 5, 1401891. [Google Scholar] [CrossRef] [Green Version]

- Bowen, C.R.; Xie, M.; Zhang, Y.; Topolov, V.Y.; Wan, C. Pyroelectric Energy Harvesting: Materials and Applications. In Ferroelectric Materials for Energy Applications; Huang, H., Scott, J.F., Eds.; Wiley-VCH Verlag GmbH &Co. KGaA: Weinheim, Germany, 2018; pp. 203–230. [Google Scholar]

- Sultana, A.; Alam, M.M.; Middya, T.R.; Mandal, D. A pyroelectric generator as a self-powered temperature sensor for sustainable thermal energy harvesting from waste heat and human body. Appl. Energy 2018, 221, 299–307. [Google Scholar] [CrossRef]

- He, H.; Lu, X.; Hanc, E.; Chen, C.; Zhang, H.; Lu, L. Advances in lead-free pyroelectric materials: A comprehensive review. J. Mater. Chem. C 2020, 8, 1494–1516. [Google Scholar] [CrossRef]

- Poprawski, W.; Gnutek, Z.; Radojewski, J.; Poprawski, R. Pyroelectric and dielectric energy conversion–a new view of the old problem. Appl. Therm. Eng. 2015, 90, 858–868. [Google Scholar] [CrossRef]

- Jankowski, N.R.; Smith, A.N.; Hanrahan, B.M. Thermal model of a thin film pulsed pyroelectric generator. In Proceedings of the ASME 2016 Heat Transfer Summer Conference, Washington, DC, USA, 10–14 July 2016. [Google Scholar]

- Yang, Y.; Guo, W.; Pradel, K.C.; Zhu, G.; Zhou, Y.; Zhang, Y.; Hu, Y.; Lin, L.; Wang, Z.L. Pyroelectric nanogenerator for harvesting thermoelectric energy. Nano Lett. 2012, 12, 2833–2838. [Google Scholar] [CrossRef]

- Dorey, R.A. Integrated Powder-Based Thick Films for Thermoelectric, Pyroelectric, and Piezoelectric Energy Harvesting Devices. IEEE Sens. J. 2014, 14, 2177–2184. [Google Scholar] [CrossRef] [Green Version]

- Ji, Y.; Wang, Y.; Yang, Y. Photovoltaic–Pyroelectric–Piezoelectric Coupled Effect Induced Electricity for Self-Powered Coupled Sensing. Adv. Electron. Mater. 2019, 5, 1900195. [Google Scholar] [CrossRef]

- Bevione, M.; Garofalo, E.; Cecchini, L.; Chiolerio, A. Liquid-state pyroelectric energy harvesting. MRS Energy Sustain. 2020, 7, 38. [Google Scholar] [CrossRef]

- Wu, W. Inorganic nanomaterials for printed electronics: A review. Nanoscale 2017, 9, 7342–7372. [Google Scholar] [CrossRef] [PubMed]

- Abbel, R.; Galagan, Y.; Groen, P. Roll-to-Roll Fabrication of Solution Processed Electronics. Adv. Eng. Mater. 2018, 20, 1701190–1701219. [Google Scholar] [CrossRef] [Green Version]

- Khan, S.; Lorenzelli, L.; Dahiya, R.S. Technologies for printing sensors and electronics over large flexible substrates: A review. IEEE Sens. J. 2014, 15, 3164–3185. [Google Scholar] [CrossRef]

- Arrabito, G.; Aleeva, Y.; Pezzilli, R.; Ferrara, V.; Medaglia, P.G.; Pignataro, B.; Prestopino, G. Printing ZnO Inks: From Principles to Devices. Crystals 2020, 10, 449. [Google Scholar] [CrossRef]

- Bodkhe, S.; Rajesh, P.S.M.; Gosselin, F.P.; Therriault, D. Simultaneous 3D printing and poling of PVDF and its nanocomposites. ACS Appl. Energy Mater. 2018, 1, 2474–2482. [Google Scholar] [CrossRef]

- Takamatsu, K.; Kobayashi, N.; Tsujimura, T.; Matsumoto, K.; Takada, K.; Ichimura, H. Ceramic Films of Pb4.95Ba0.05Ge3O11 by Printing Technique and Their Pyroelectric Characteristics. Jpn. J. Appl. Phys. 1985, 24, 175. [Google Scholar] [CrossRef] [Green Version]

- Futakuchi, T.; Tanino, K. Pyroelectric Properties of La-Modified PbTiO3 Thin Films Prepared by Screen Printing. Jpn. J. Appl. Phys. 1994, 33, 5294. [Google Scholar] [CrossRef]

- Menil, F.; Debeda, H.; Lucat, C. Screen-printed thick-films: From materials to functional devices. J. Eur. Ceram. Soc. 2005, 25, 2105–2113. [Google Scholar] [CrossRef]

- Noh, H.-J.; Lee, S.-G.; Nam, S.-P. Dielectric and Pyroelectric Properties of Dy-doped BSCT Thick Films by Screen-printing Method. J. Electr. Eng. Technol. 2009, 4, 527–530. [Google Scholar] [CrossRef] [Green Version]

- Dorey, R. Microstructure–property relationships: How the microstructure of the film affects its properties. In Ceramic Thick Films for MEMS and Microdevices; Andrew, W., Ed.; Elsevier: Waltham, MA, USA, 2012; pp. 85–112. [Google Scholar]

- Wang, H.; Xu, Y.; Yu, X.; Xing, R.; Liu, J.; Han, Y. Structure and morphology control in thin films of conjugated polymers for an improved charge transport. Polymers 2013, 5, 1272–1324. [Google Scholar] [CrossRef] [Green Version]

- Diao, Y.; Shaw, L.; Bao, Z.; Mannsfeld, S.C.B. Morphology control strategies for solution-processed organic semiconductor thin films. Energy Environ. Sci. 2014, 7, 2145–2159. [Google Scholar] [CrossRef] [Green Version]

- Diao, Y.; Zhou, Y.; Kurosawa, T.; Shaw, L.; Wang, C.; Park, S.; Guo, Y.; Reinspach, J.A.; Gu, K.; Gu, X.; et al. Flow-enhanced solution printing of all-polymer solar cells. Nat. Commun. 2015, 6, 1–10. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Søndergaard, R.R.; Hösel, M.; Krebs, F.C. Roll-to-Roll fabrication of large area functional organic materials. J. Polym. Sci. Part. B Polym. Phys. 2013, 51, 16–34. [Google Scholar] [CrossRef]

- Krebs, F.C. Fabrication and processing of polymer solar cells: A review of printing and coating techniques. Sol. Energy Mater. Sol. Cells 2009, 93, 394–412. [Google Scholar] [CrossRef]

- Wu, C.-M.; Chou, M.-H.; Chala, T.F.; Shimamura, Y.; Murakami, R.-I. Infrared-driven poly(vinylidene difluoride)/tungsten oxide pyroelectric generator for non-contact energy harvesting. Compos. Sci. Technol. 2019, 178, 26–32. [Google Scholar] [CrossRef]

- Liang, J.; Jiang, C.; Wu, W. Printed flexible supercapacitor: Ink formulation, printable electrode materials and applications. Appl. Phys. Rev. 2021, 8, 021319. [Google Scholar] [CrossRef]

- Jiang, Y.; Ye, Y.; Yu, J.; Wu, Z.; Li, W.; Xu, J.; Xie, G. Study of thermally poled and corona charged poly(vinylidene fluoride) films. Polym. Eng. Sci. 2007, 47, 1344–1350. [Google Scholar] [CrossRef]

- Mahadeva, S.K.; Berring, J.; Walus, K.; Stoeber, B. Effect of poling time and grid voltage on phase transition and piezoelectricity of poly (vinylidene fluoride) thin films using corona poling. J. Phys. D Appl. Phys. 2013, 46, 285305. [Google Scholar] [CrossRef]

- Shaik, H.; Rachith, S.N.; Rudresh, K.J.; Sheik, A.S.; Raman, K.H.T.; Kondaiah, P.; Rao, G.M. Towards β-phase formation probability in spin coated PVDF thin films. J. Polym. Res. 2017, 24, 1–6. [Google Scholar] [CrossRef]

- Tan, K.S.; Gan, W.C.; Velayutham, T.S.; Abd Majid, W.H. Pyroelectricity enhancement of PVDF nanocomposites thin films doped with ZnO nanoparticles. Smart Mater. Struct. 2014, 23, 125006. [Google Scholar] [CrossRef]

- Martins, P.; Lopes, A.C.; Lanceros-Mendez, S. Electroactive phases of poly(vinylidene fluoride): Determination, processing and applications. Prog. Polym. Sci. 2014, 39, 683–706. [Google Scholar] [CrossRef]

- Wang, F.; Zhao, X.; Li, J. PVDF energy-harvesting devices: Film preparation, electric poling, energy-harvesting efficiency. In Proceedings of the IEEE Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), Ann Arbor, MI, USA, 18–21 October 2015; pp. 80–83. [Google Scholar]

- Li, X.; Wang, Y.; He, T.; Hu, Q.; Yang, Y. Preparation of PVDF flexible piezoelectric film with high β-phase content by matching solvent dipole moment and crystallization temperature. J. Mater. Sci. Mater. Electron. 2019, 30, 20174–20180. [Google Scholar] [CrossRef]

- Tu, R.; Sprague, E.; Sodano, H.A. Precipitation-printed high-β phase Poly(vinylidene fluoride) for energy harvesting. ACS Appl. Mater. Interfaces 2020, 12, 58072–58081. [Google Scholar]

- Tansel, T. High beta-phase processing of polyvinylidenefluoride for pyroelectric applications. J. Polym. Res. 2020, 27, 95. [Google Scholar] [CrossRef]

- Ruan, L.; Yao, X.; Chang, Y.; Zhou, L.; Qin, G.; Zhang, X. Properties and applications of the β phase Poly(vinylidene fluoride). Polymers 2018, 10, 228. [Google Scholar] [CrossRef] [Green Version]

- Li, Y.; Ma, X.; Ding, Y.; Li, X.; Li, Z. Density Functional Theory Simulation of PVDF Transition in Electric Field Polarization. In Proceedings of the International Conference on Mathematics, Modeling and Simulation Technologies and Applications, Xiamen, China, 27–28 October 2019. [Google Scholar]

- Guo, X.; Wang, J.; Ding, J.; Jiang, Y. Study on preparation and polarization process of PVDF thin film. In Proceedings of the International Symposium on Advanced Optical Manufacturing and Testing Technologies, Harbin, China, 26–29 April 2014; p. 92841F-7. [Google Scholar]

- Satapathy, S.; Pawar, S.; Gupta, P.K.; Varma, K.B.R. Effect of annealing on phase transition in poly(vinylidene fluoride) films prepared using polar solvent. Bull. Mater. Sci. 2011, 34, 727–733. [Google Scholar] [CrossRef] [Green Version]

- Ma, J.; Zhang, Q.; Lin, K.; Zhou, L.; Ni, Z. Piezoelectric and optoelectronic properties of electrospinning hybrid PVDF and ZnO nanofibers. Mater. Res. Express 2018, 5, 035057. [Google Scholar] [CrossRef]

- Elashmawi, I.S.; Gaabour, L.H. Raman, morphology and electrical behavior of nanocomposites based on PEO/PVDF with multi-walled carbon nanotubes. Results Phys. 2015, 5, 105–110. [Google Scholar] [CrossRef] [Green Version]

- Barnakov, Y.A.; Paul, O.; Joaquim, A.; Falconer, A.; Mu, R.; Barnakov, V.Y.; Dikin, D.; Petranovskii, V.P.; Zavalin, A.; Ueda, A.; et al. Light intensity-induced phase transitions in Graphene oxide doped polyvinylidene fluoride. Opt. Mater. Express 2018, 8, 2579–2585. [Google Scholar] [CrossRef]

- Constantino, C.J.L.; Job, A.E.; Simoes, R.D.; Giacometti, J.A.; Zucolotto, V.; Oliveira, O.N.; Gozzi, G.; Chinaglia, D.L. Phase Transition in Poly(vinylidene fluoride) Investigated with Micro-Raman Spectroscopy. Appl. Spectrosc. 2005, 59, 275–279. [Google Scholar] [CrossRef] [PubMed]

- Ryu, H.; Kim, S.-W. Emerging pyroelectric nanogenerators to convert thermal energy into electrical energy. Small 2021, 17, 1903469. [Google Scholar] [CrossRef] [PubMed]

- Grau, G.; Cen, J.; Kang, H.; Kitsomboonloha, R.; Scheideler, W.J.; Subramanian, V. Gravure-printed electronics: Recent progress in tooling development, understanding of printing physics, and realization of printed devices. Flex. Print. Electron. 2016, 1, 1–23. [Google Scholar] [CrossRef]

- Lee, J.A.; Rothstein, J.P.; Pasquali, M. Computational study of viscoelastic effects on liquid transfer during gravure printing. J. Non-Newton. Fluid Mech. 2013, 199, 1–11. [Google Scholar] [CrossRef]

- Grau, G.; Kitsomboonloha, R.; Subramanian, V. Fabrication of a high-resolution roll for gravure printing of 2μm features. In Proceedings of the SPIE Organic Photonics + Electronics, San Diego, CA, USA, 9–13 August 2015. [Google Scholar]

- Grau, G.; Subramanian, V. Fully High-Speed Gravure Printed, Low-Variability, High-Performance Organic Polymer Transistors with Sub-5 V Operation. Adv. Electron. Mater. 2016, 2, 1500328. [Google Scholar] [CrossRef]

- Huang, Q.; Zhu, Y. Printing conductive nanomaterials for flexible and stretchable electronics: A review of materials, processes, and applications. Adv. Mater. Technol. 2019, 4, 1800546. [Google Scholar] [CrossRef]

- Bonnassieux, Y.; Brabec, C.J.; Cao, Y.; Breen Carmichael, T.; Chabinyc, M.L.; Cheng, K.-T.; Cho, G.; Chung, A.; Cobb, C.L.; Distler, A.; et al. The 2021 flexible and printed electronics roadmap. Flex. Print. Electron. 2021, 6, 023001. [Google Scholar] [CrossRef]

- Tiara, A.M.; Moon, H.; Cho, G.; Lee, J. Fully roll-to-roll gravure printed electronics: Challenges and the way to integrating logic gates. Jpn. J. Appl. Phys. 2022, 61, SE0802. [Google Scholar]

- Sico, G.; Montanino, M.; Prontera, C.T.; De Girolamo Del Mauro, A.; Minarini, C. Gravure printing for thin film ceramics manufacturing from nanoparticles. Ceram. Int. 2018, 44, 19526–19534. [Google Scholar] [CrossRef]

- Sico, G.; Montanino, M.; De Girolamo Del Mauro, A.; Imparato, A.; Nobile, G.; Minarini, C. Effects of the ink concentration on multi-layer gravure-printed PEDOT:PSS. Org. Electron. 2016, 28, 257–262. [Google Scholar] [CrossRef]

- Montanino, M.; Sico, G.; De Girolamo Del Mauro, A.; Asenbauer, J.; Binder, J.R.; Bresser, D.; Passerini, S. Gravure-Printed Conversion/Alloying Anodes for Lithium-Ion Batteries. Energy Technol. 2021, 9, 2100315. [Google Scholar] [CrossRef]

- Choi, Y.; Kim, G.H.; Jeong, W.H.; Kim, H.J.; Chin, B.D.; Yu, J.-W. Characteristics of gravure printed InGaZnO thin films as an active channel layer in thin film transistors. Thin Solid Film. 2010, 518, 6249–6252. [Google Scholar] [CrossRef]

- Khandavalli, S.; Rothstein, J.P. Ink transfer of non-Newtonian fluids from an idealized gravure cell: The effect of shear and extensional deformation. J. Non-Newton. Fluid Mech. 2017, 243, 16–26. [Google Scholar] [CrossRef]

- Pingulkar, H.; Peixinho, J.; Crumeyrolle, O. Liquid transfer for viscoelastic solutions. Langmuir 2021, 37, 10348–10353. [Google Scholar] [CrossRef] [PubMed]

- Sankaran, A.K.; Rothstein, J.P. Effect of viscoelasticity on liquid transfer during gravure printing. J. Non-Newton. Fluid Mech. 2012, 175, 64–75. [Google Scholar] [CrossRef]

- Jo, S.; Choo, S.; Kim, F.; Heo, S.H.; Son, J.S. Ink processing for thermoelectric materials and power-generating devices. Adv. Mater. 2018, 31, 1804930. [Google Scholar] [CrossRef] [PubMed]

- Schlisske, S.; Rosenauer, C.; Rödlmeier, T.; Giringer, K.; Michels, J.J.; Kremer, K.; Lemmer, U.; Morsbach, S.; Daoulas, K.C.; Hernandez-Sosa, G. Ink Formulation for Printed Organic Electronics: Investigating Effects of Aggregation on Structure and Rheology of Functional Inks Based on Conjugated Polymers in Mixed Solvents. Adv. Mater. Technol. 2020, 6, 2000335. [Google Scholar] [CrossRef]

- Marshall, J.E.; Zhenova, A.; Roberts, S.; Petchey, T.; Zhu, P.; Dancer, C.E.J.; McElroy, C.R.; Kendrick, E.; Goodship, V. On the solubility and stability of Polyvinylidene Fluoride. Polymers 2021, 13, 1354. [Google Scholar] [CrossRef]

- Glasser, A.; Cloutet, E.; Hadziioannou, G.; Kellay, H. Tuning the rheology of conductiong polymer inks for various deposition processes. Chem. Mater. 2019, 31, 6936–6944. [Google Scholar] [CrossRef]

- Chang, Q.; Cao, C.; Qiao, H.; Hu, Y.; Xiao, G.; Shi, W. Ink transfer for printed flexible microsupercapacitors. Carbon 2021, 178, 285–293. [Google Scholar] [CrossRef]

- Kamarudin, M.A.; Sahamir, S.R.; Datta, R.S.; Long, B.D.; Sabri, M.F.M.; Said, S.M. A review on fabrication of polymer-based thermoelectric materials and fabrication methods. Sci. World J. 2013, 2013, 1–17. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bottino, A.; Capannelli, G.; Munari, S.; Turturro, A. Solubility parameters of poly(vinylidene fluoride). J. Polym. Sci. Part B Polym. Phys. 1988, 26, 785–794. [Google Scholar] [CrossRef]

- Jee, T.; Lee, H.; Mika, B.; Liang, H. Effect of microstructures of PVDF on surface adhesive forces. Tribol. Lett. 2007, 26, 125–130. [Google Scholar] [CrossRef]

- Mai, M.; Fridkin, V.; Martin, B.; Leschhorn, A.; Kliem, H. The thickness dependence of the phase transition temperature in PVDF. Phys. B 2013, 421, 23–27. [Google Scholar] [CrossRef]

- Gregorio, R. Determination of the α, β, and γ crystalline phases of Poly(vinylidene fluoride) films prepared at different conditions. J. Appl. Polym. Sci. 2006, 100, 3272–3279. [Google Scholar] [CrossRef]

- Harstad, S.; D’Souza, N.; Soin, N.; El-Gendy, A.A.; Gupta, S.; Pecharsky, V.K.; Shah, T.; Siores, E.; Hadimani, R.L. Enhancement of β-phase in PVDF films embedded with ferromagnetic Gd5Si4 nanoparticles for piezoelectric energy harvesting. AIP Adv. 2017, 7, 056411. [Google Scholar] [CrossRef]

- Mahale, B.; Bodas, D.; Gangal, S.A. Study of β-phase development in spin-coated PVDF thick film. Bull. Mater. Sci. 2017, 40, 569–575. [Google Scholar] [CrossRef]

- Joshi, D.R.; Adhikari, N. An Overview on Common Organic Solvents and Their Toxicity. J. Pharm. Res. Int. 2019, 28, 1–18. [Google Scholar] [CrossRef]

- Cai, X.; Lei, T.; Sund, D.; Lind, L. A critical analysis of the α, β and γ phases in poly(vinylidene fluoride) using FTIR. RSC Adv. 2017, 7, 15382–15389. [Google Scholar] [CrossRef] [Green Version]

- Wu, L.; Jin, Z.; Liu, Y.; Ning, H.; Liu, X.; Alamusi; Hu, N. Recent advances in the preparation of PVDF-based piezoelectric materials. Nanotechnol. Rev. 2022, 11, 1386–1407. [Google Scholar] [CrossRef]

- Payne, A.P.; Clemens, B.M. Influence of roughness distributions and correlations on x-ray diffraction from superlattices. Phys. Rev. B 1993, 47, 2289. [Google Scholar] [CrossRef] [PubMed]

- Garcia, A.J.L.; Sico, G.; Montanino, M.; Defoor, V.; Pusty, M.; Mescot, X.; Loffredo, F.; Villani, F.; Nenna, G.; Ardila, G. Low-Temperature Growth of ZnO Nanowires from Gravure-Printed ZnO Nanoparticle Seed Layers for Flexible Piezoelectric Devices. Nanomaterials 2021, 11, 1430. [Google Scholar] [CrossRef] [PubMed]

- Tansel, T. Effect of electric field assisted crystallisation of PVDF-TrFE and their functional properties. Sens. Actuators A 2021, 332, 113059. [Google Scholar] [CrossRef]

- Johansson, K.S. Surface Modification of Plastics. In Applied Plastics Engineering Handbook, 2nd ed.; Kutz, M., Ed.; William Andrew: Oxford, UK, 2017; pp. 443–487. [Google Scholar]

- Fabbri, P.; Messori, M. Surface Modification of Polymers: Chemical, Physical, and Biological Routes. In Modification of Polymer Properties; Jasso-Gastinel, C.F., Kenny, J.M., Eds.; William Andrew: Oxford, UK, 2017; pp. 109–130. [Google Scholar]

- McKeen, L.W. Powder Coating and Films. In Fluorinated Coatings and Finishes Handbook; William Andrew: Norwich, NY, USA, 2006; pp. 185–209. [Google Scholar]

- Jung, M.-H.; Choi, H.-S. Surface treatment and characterization of ITO thin films using atmospheric pressure plasma for organic light emitting diodes. J. Colloid Interface Sci. 2007, 310, 550–558. [Google Scholar] [CrossRef]

- Homola, T.; Matousek, J.; Medvecka, V.; Zahoranova, A.; Kormunda, M.; Kovacik, D.; Cernak, M. Atmospheric pressure diffuse plasma in ambient air for ITO surface cleaning. Appl. Surf. Sci. 2012, 258, 7135–7139. [Google Scholar] [CrossRef]

- Son, I.; Yoo, J.Y.; Kim, J.H.; Lee, B.; Kim, C.; Lee, J.H. Vertical alignment of liquid crystal using an in situ self-assembled molecular layer on hydrophilic ITO electrodes. Ferroelectrics 2016, 495, 174–180. [Google Scholar] [CrossRef]

- Wu, Y.; Du, X.; Gao, R.; Li, J.; Li, W.; Yu, H.; Jiang, Z.; Wang, Z.; Tai, H. Self-polarization of PVDF film triggered by hydrophilic treatment for pyroelectric sensor with ultra-low piezoelectric noise. Nanoscale Res. Lett. 2019, 14, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Grau, G.; Subramanian, V. Dimensional scaling of high-speed printed organic transistors enabling high-frequency operation. Flexible Printed Electron. 2020, 5, 014013. [Google Scholar] [CrossRef]

| Corona Pre-Treatment Time(s) | Nominal Rate dT/dt (K/s) | ip (pA) | p (nC·m−2·K−1) |

|---|---|---|---|

| 4 | 0.8 | −9.1 ± 1.1 | −96 ± 9 |

| 1.7 | −16.1 ± 0.1 | ||

| 2.1 | −18.9 ± 0.3 | ||

| 2.5 | −22.0 ± 0.1 | ||

| 16 | 0.8 | −20.1 ± 0.1 | −242 ± 7 |

| 1.7 | −40.7 ± 0.7 | ||

| 2.1 | −52.0 ± 0.4 | ||

| 2.5 | −58.1 ± 7.5 | ||

| 64 | 0.8 | −34.7 ± 11.2 | −427 ± 9 |

| 1.7 | −73.1 ± 0.7 | ||

| 2.1 | −89.2 ± 0.1 | ||

| 2.5 | −105. 8 ± 1.3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sico, G.; Montanino, M.; Loffredo, F.; Borriello, C.; Miscioscia, R. Gravure Printing for PVDF Thin-Film Pyroelectric Device Manufacture. Coatings 2022, 12, 1020. https://doi.org/10.3390/coatings12071020

Sico G, Montanino M, Loffredo F, Borriello C, Miscioscia R. Gravure Printing for PVDF Thin-Film Pyroelectric Device Manufacture. Coatings. 2022; 12(7):1020. https://doi.org/10.3390/coatings12071020

Chicago/Turabian StyleSico, Giuliano, Maria Montanino, Fausta Loffredo, Carmela Borriello, and Riccardo Miscioscia. 2022. "Gravure Printing for PVDF Thin-Film Pyroelectric Device Manufacture" Coatings 12, no. 7: 1020. https://doi.org/10.3390/coatings12071020

APA StyleSico, G., Montanino, M., Loffredo, F., Borriello, C., & Miscioscia, R. (2022). Gravure Printing for PVDF Thin-Film Pyroelectric Device Manufacture. Coatings, 12(7), 1020. https://doi.org/10.3390/coatings12071020