Effect of the Testing Temperature on the Impact Property of a Multilayered Soft–Hard Copper–Brass Block

Abstract

:1. Introduction

2. Experimental

2.1. Materials and Preparation

2.2. Mechanical Tests

2.3. Microstructural Characterization

3. Results and Discussion

4. Conclusions

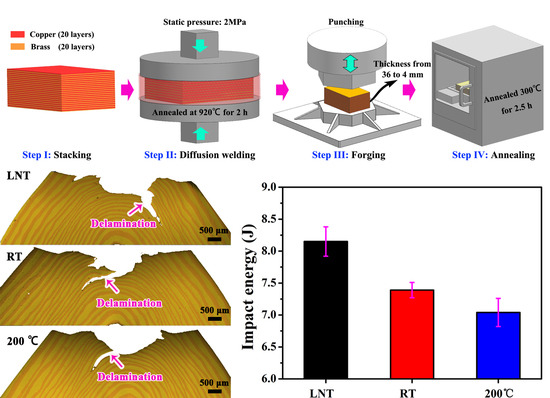

- The impact energies of the present multilayered soft–hard copper–brass blocks tested at LNT, RT, and 200 °C were 8.15 J, 7.39 J, and 7.04 J, respectively, which indicated that the impact energy was positively dependent on the testing temperature;

- The copper–brass layers that cracked under various testing temperatures show similar fracture morphologies. This can be ascribed to the fracturing of metals with a FCC crystal lattice usually being insensitive to the environmental temperature;

- The highest impact energy at LNT was attributed to the high density of tiny dimples caused by coordinated plastic deformation effects during the delamination of the soft–hard copper–brass interfaces. The high temperature of 200 °C can weaken the copper–brass interface, reduce the absorption of the deformation energy, and lead to decreased impact resistance.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liang, N.N.; Liu, J.Z.; Lin, S.C.; Wang, Y.; Wang, J.T.; Zhao, Y.H.; Zhu, Y.T. A multiscale architectured CuCrZr alloy with high strength, electrical conductivity and thermal stability. J. Alloys Comp. 2018, 735, 1389–1394. [Google Scholar] [CrossRef]

- Lu, X.K.; Zhao, Y.; Wang, G.; Zhu, X.B. Effects of structure characteristics and fluid on the effective thermal conductivity of sintered copper foam. Results Phys. 2020, 19, 103655. [Google Scholar] [CrossRef]

- Mao, Q.Z.; Zhang, Y.S.; Liu, J.Z.; Zhao, Y.H. Breaking material property trade-offs via macrodesign of microstructure. Nano Lett. 2021, 21, 3191–3197. [Google Scholar] [CrossRef] [PubMed]

- Mao, Q.Z.; Zhang, Y.S.; Guo, Y.Z.; Zhao, Y.H. Enhanced electrical conductivity and mechanical properties in thermally stable fine-grained copper wire. Commun. Mater. 2021, 2, 46. [Google Scholar] [CrossRef]

- Liang, N.N.; Zhao, Y.H.; Wang, J.T.; Zhu, Y.T. Effect of grain structure on Charpy impact behavior of copper. Sci. Rep. 2017, 7, 44738. [Google Scholar] [CrossRef]

- An, X.H.; Lin, Q.Y.; Wu, S.D.; Zhang, Z.F. Improved fatigue strengths of nanocrystalline Cu and Cu-Al Alloys. Mater. Res. Lett. 2015, 3, 135–141. [Google Scholar] [CrossRef]

- Shirdel, M.; Mirzadeh, H.; Parsa, M.H. Nano/ultrafine grained austenitic stainless steel through the formation and reversion of deformation-induced martensite: Mechanisms, microstructures, mechanical properties, and TRIP effect. Mater. Charact. 2015, 103, 150–161. [Google Scholar] [CrossRef]

- Straumal, B.B.; Pontikis, V.; Kilmametov, A.R.; Mazilkin, A.A.; Dobatkin, S.V.; Baretzky, B. Competition between precipitation and dissolution in Cu-Ag alloys under high pressure torsion. Acta Mater. 2017, 122, 60–71. [Google Scholar] [CrossRef]

- Tajally, M.; Huda, Z.; Masjuki, H.H. A comparative analysis of tensile and impact-toughness behavior of cold-worked and annealed 7075 aluminum alloy. Inter. J. Impact Eng. 2010, 37, 425–432. [Google Scholar] [CrossRef]

- Ma, X.L.; Huang, C.X.; Xu, W.Z.; Zhou, H.; Wu, X.L.; Zhu, Y.T. Strain hardening and ductility in a coarse-grain/nanostructure laminate material. Scr. Mater. 2015, 103, 57–60. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.F.; Yang, M.X.; Ma, X.L.; Wang, M.S.; Yin, K.; Huang, A.H.; Huang, C.X. Improved back stress and synergetic strain hardening in coarse-grain/nanostructure laminates. Mater. Sci. Eng. A 2018, 727, 113–118. [Google Scholar] [CrossRef]

- Ma, X.L.; Huang, C.X.; Moering, J.; Ruppert, M.; Hoppel, H.W.; Goken, M.; Narayan, J.; Zhu, Y.T. Mechanical properties of copper/bronze laminates: Role of interfaces. Acta Mater. 2016, 116, 43–52. [Google Scholar] [CrossRef]

- Huang, C.X.; Wang, Y.F.; Ma, X.L.; Yin, S.H.; Hoppel, W.; Goken, M.; Wu, X.L.; Gao, H.J.; Zhu, Y.T. Interface affected zone for optimal strength and ductility in heterogeneous laminate. Mater. Today 2018, 21, 713–719. [Google Scholar] [CrossRef]

- Huang, M.; Xu, C.; Fan, G.H.; Maawad, E.; Gan, W.M.; Geng, L.; Lin, F.X.; Tang, G.Z.; Wu, H.; Du, Y.; et al. Role of layered structure in ductility improvement of layered Ti-Al metal composite. Acta Mater. 2018, 153, 235–249. [Google Scholar] [CrossRef]

- Qin, W.B.; Mao, Q.Z.; Kang, J.J.; Liu, Y.Y.; Shu, D.F.; She, D.S.; Liu, Y.F.; Li, J.S. Superior impact property and fracture mechanism of a multilayered copper/bronze laminate. Mater. Lett. 2019, 250, 60–63. [Google Scholar] [CrossRef]

- Li, J.S.; Wang, S.Z.; Mao, Q.Z.; Huang, Z.W.; Li, Y.S. Soft/hard copper/bronze laminates with superior mechanical properties. Mater. Sci. Eng. A 2019, 756, 213–218. [Google Scholar] [CrossRef]

- Liu, T.; Gu, C.Y.; Li, J.S.; Zhou, Z.C.; Lu, Y.; Gao, F.; Chen, M.; Mao, Q.Z.; Lu, X.K.; Li, Y.S. Effect of structural orientation on the impact properties of a soft/hard copper/brass laminate. Vacuum 2021, 191, 110388. [Google Scholar] [CrossRef]

- Zhu, Y.T.; Wu, X.L. Perspective on hetero-deformation induced (HDI) hardening and back stress. Mater. Res. Lett. 2019, 7, 393–398. [Google Scholar] [CrossRef]

- Osman, T.M.; Hassan, H.A.; Lewandowski, J.J. Interface effects on the quasi-static and impact toughness of discontinuously reinforced aluminum laminates. Metall. Mater. Trans. A 2008, 39A, 1993–2006. [Google Scholar] [CrossRef]

- Ibrahim, O.H.; Ibrahim, I.S.; Khalifa, T.A.F. Impact behavior of different stainless steel weldments at low temperatures. Eng. Fail. Anal. 2010, 17, 1069–1076. [Google Scholar] [CrossRef]

- Smirnov, I.; Konstantinov, A. Influence of ultrafine-grained structure produced by equal-channel angular pressing on the dynamic response of pure copper. Procedia Struct. Integrity 2018, 13, 1336–1341. [Google Scholar] [CrossRef]

- Cepeda-Jiménez, C.M.; García-Infanta, J.M.; Pozuelo, M.; Ruano, O.A.; Carreño, F. Impact toughness improvement of high-strength aluminum alloy by intrinsic and extrinsic fracture mechanisms via hot rolling bonding. Scr. Mater. 2009, 61, 407–410. [Google Scholar] [CrossRef]

- Gludovatz, B.; Hohenwarter, A.; Thurston, K.V.S.; Bei, H.; Wu, Z.; George, E.P.; Ritchie, R.O. Exceptional damage-tolerance of a medium-entropy alloy CrCoNi at cryogenic temperatures. Nat. Commun. 2015, 7, 10602. [Google Scholar] [CrossRef] [PubMed]

- Hasan, M.N.; Liu, Y.F.; An, X.H.; Gu, J.; Song, M.; Cao, Y.; Li, Y.S.; Zhu, Y.T.; Liao, X.Z. Simultaneously enhancing strength and ductility of a high-entropy alloy via gradient hierarchical microstructures. Inter. J. Plast. 2019, 123, 178–195. [Google Scholar] [CrossRef]

- Kulagin, R.; Beygelzimer, Y.; Ivanisenko, Y.; Mazilkin, A.; Straumal, B.; Hahn, H. Instabilities of interfaces between dissimilar metals induced by high pressure torsion. Mater. Lett. 2018, 222, 172–175. [Google Scholar] [CrossRef]

- Malik, A.; Chaudry, U.M.; Hamad, K.; Jun, T.S. Microstructure features and superplasticity of extruded, rolled and SPD-processed magnesium alloys: A short review. Metals 2021, 11, 1766. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, T.; Li, J.; Liu, K.; Wang, M.; Zhao, Y.; Zhou, Z.; Wei, Y.; Yang, Q.; Chen, M.; Mao, Q.; et al. Effect of the Testing Temperature on the Impact Property of a Multilayered Soft–Hard Copper–Brass Block. Coatings 2022, 12, 1236. https://doi.org/10.3390/coatings12091236

Liu T, Li J, Liu K, Wang M, Zhao Y, Zhou Z, Wei Y, Yang Q, Chen M, Mao Q, et al. Effect of the Testing Temperature on the Impact Property of a Multilayered Soft–Hard Copper–Brass Block. Coatings. 2022; 12(9):1236. https://doi.org/10.3390/coatings12091236

Chicago/Turabian StyleLiu, Tong, Jiansheng Li, Kezhang Liu, Mengmeng Wang, Yu Zhao, Zhongchen Zhou, Yong Wei, Qi Yang, Ming Chen, Qingzhong Mao, and et al. 2022. "Effect of the Testing Temperature on the Impact Property of a Multilayered Soft–Hard Copper–Brass Block" Coatings 12, no. 9: 1236. https://doi.org/10.3390/coatings12091236

APA StyleLiu, T., Li, J., Liu, K., Wang, M., Zhao, Y., Zhou, Z., Wei, Y., Yang, Q., Chen, M., Mao, Q., & Sun, Y. (2022). Effect of the Testing Temperature on the Impact Property of a Multilayered Soft–Hard Copper–Brass Block. Coatings, 12(9), 1236. https://doi.org/10.3390/coatings12091236