How to Identify Potentials and Barriers of Raw Materials Recovery from Tailings? Part I: A UNFC-Compliant Screening Approach for Site Selection

Abstract

:1. Introduction

- considerations necessary for the UNFC’s application to anthropogenic RMs

- argumentation for the consideration of tailings as anthropogenic RMs

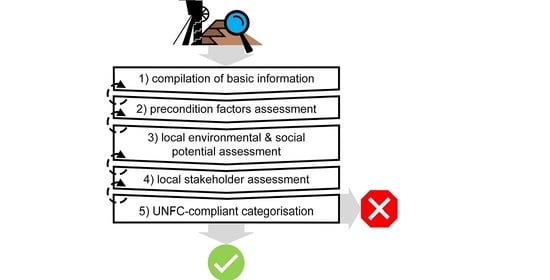

- development of a quick and efficient UNFC-compliant approach for a systematic TSF screening

- case study on the TSF Bollrich with recommendations for further assessment

- discussion of the limitations of the developed systematic approach due to data uncertainty

- discussion of the developed approach in the context of RMs classification

2. Considerations for Anthropogenic Raw Materials Assessment

2.1. Key Words and Definitions

2.2. Brief Introduction of the UNFC and Considerations for Its Application to Anthropogenic Raw Materials

- the E category ‘designates the degree of favourability of environmental-socio-economic conditions in establishing the viability of the project, including consideration of market prices and relevant legal, regulatory, social, environmental and contractual conditions’,

- the F category ‘designates the maturity of technology, studies and commitments necessary to implement the project. These projects range from early conceptual studies through to a fully developed project that is producing, and reflect standard value chain management principles’,

- and the G category ‘designates the degree of confidence in the estimate of the quantities of products from the project’.

- ESG issues must be addressed for the recycling of RMs,

- a broad spectrum of stakeholder perspectives must be included, and

- environmental and social impacts must be assessed and classified.

2.3. Justification for the Assessment of Tailings as Anthropogenic Raw Materials

3. Development of a UNFC-Compliant Approach for Systematic TSF Screening

3.1. Concept for a Systematic TSF Screening

3.2. Basic TSF Information for Project Definition

- content

- structure

- location

3.3. Precondition Factors Assessment to Identify Potential Project Drivers

3.4. Local Environmental and Social Potential Assessment to Identify Benefits and Risks

3.5. Local Stakeholder Assessment to Identify Potential Social Issues

3.6. UNFC-Compliant Categorisation and Final Decision

4. Case Study Results

4.1. Basic TSF Information

4.2. Precondition Factors Assessment

4.3. Local Environmental and Social Potential Assessment

4.4. Local Stakeholder Assessment

4.5. UNFC-Compliant Categorisation

4.6. Path Forward for the Case Study Bollrich

| Category & Factor | Data | Source & Data Quality |

|---|---|---|

| (1) content | ||

| (i) raw materials | sulphates: BaSO4; sulphides: Cu, Pb, Fe, Zn; others: Ag, Au, In | inferred from References [72,73] |

| (ii) resource criticality | BaSO4, & In are Critical Raw Materials in the EU; Cu, Pb, & Zn of very high economic importance in the EU | [59] |

| (iii) grade | - | - |

| (2) structure | ||

| (iv) history | start/end of operation in 1938/1988, froth flotation plant Bollrich closed in 1987, course of Gelmke was modified several times | [74] |

| (v) reasons for closure | closure of mine Rammelsberg in 1988 for economic reasons | [74] |

| (vi) design | valley impoundment, 1 small pond & 2 large ponds, 1 main dam & 2 intermediate dams, estimated dam height 35 m | observed on Google Earth [71], cf., Figure 3 |

| (xii) surface area | estimated 315,000 m2 | Ruler tool [74] |

| (xiii) volume | estimated 4.7 & 4 million m3 (including & excluding main dam, respectively) | Ruler tool [74], AutoCAD (Autodesk Inc.) |

| (iv) mass | estimated 9.4 & 8 million t (including & excluding main dam, respectively) | assumed tailings density 2 t/m2 [30] |

| (x) homogeneity | several changes of ore processing reported, heterogeneity of minerals inside TSF can be assumed | [74] |

| (xi) condition | partially dry but mostly covered with water, no observable signs of AMD, erosion or controlled reclamation | observed on Google Earth [71], cf. |

| (xii) current use | since 1988 neutralised mine waters from the closed mine Rammelsberg are discharged into the lower pond | observed on Google Earth [71,74] |

| (3) location | ||

| (xiii) position | Goslar district (51°54′8.97″ N, 10°27′47.31″ E, Lower Saxony, Germany), 270 m above mean sea level | observed on Google Earth [71] |

| (xiv) local geology | folded & faulted Palaeozoic rocks of the Harz Mountains are uplifted & thrust over younger Mesozoic rocks of the Harz foreland along the Northern Harz Boundary fault leading to steeply tilting & partly inverted Mesozoic strata, Mesozoic rocks are largely composed of Triassic to Cretaceous sedimentary rocks of varying composition (i.e., mostly impure limestones, clastic sandstones (greywackes) & shales), younger Quaternary sediments are rare & locally limited | [77] |

| (xv) topography | at the foot of Harz Mountain range, max. 1141 m altitude with deep valleys | [78] |

| (xvi) land use | in near vicinity: agricultural, forest, industrial & commercial, & recreation & residential areas | observed on Google Earth [71] |

| (xvii) climate | moderately warm, temperature −0.7 to 16.3 °C (average 7.9 °C), average rain precipitation 768 mm/a | [79] |

| (xviii) settlements | nearest ~400 m E air-line distance downstream of main dam | observed on Google Earth [71], cf., Figure 3 |

| (xix) surface waters | 4 small rivers observed downstream of TSF within 1.5 km radius (Abzucht, Ammentalbach, Gelmke, Oker) | observed on Google Earth [71], cf., Figure 4 |

| (xx) site accessibility | dirt roads, federal highway B6 ~1.6 km N air-line distance from TSF, public railway ~500 m E air-line distance from TSF, disused railway tracks from processing plant Bollrich to public railway network (estimated abandonment in 1988) | observed on Google Earth [71,74] cf., Figure 3 |

| (xxi) infrastructure | disused processing plant Bollrich ~500 m W air-line distance from TSF, access to public electricity & water grid assumed | observed on Google Earth [71], cf., Figure 3 |

| Factor | Criterion | Indicator | Result | Source | Rating | UNFC Axis 1 |

|---|---|---|---|---|---|---|

| (1) TSF volume | TSF volume (V) high enough for a LOM 2 of ≥ 5 years | V ≥ 0.2 million m3 | 4 million m3 (excluding main dam) | estimated with Ruler tool in Google Earth [71] & AutoCAD (Autodesk Inc.) | ✓ | G |

| (2) infrastructure | buildings, transportation & utilities infrastructure present | observable | buildings, railway tracks, roads, highways, motorways & utilities infrastructure observable | assumption based on observation with Google Earth [71] | ✓ | F |

| (3) TSF condition | erosion of TSF and/or emissions (e.g., AMD 3) | not observable | no signs of erosion and/or emissions observable | observation with Google Earth [71] | ✓ | F |

| (4) resource criticality | number (n) of elements or minerals that are CRMs 4 in EU or that are of very high economic importance | n ≥ 1 | n = 4 (BaSO4, Cu, Pb & Zn expected to be present) | inferred from [73] | ✓ | E (econ.) |

| (5) climatic conditions | favourable climatic conditions with low probability of extreme climate or weather occurrences | moderate climate | moderately warm, average 7.9 °C, average rain precipitation 768 mm/a | [79] | ✓ | E (env.) |

| (6) human settlements | distance (d) to settlements | d ≤ 10 km | d ≈ 400 m E air-line | [71] | ✗ | E (soc.) |

| (7) investment conditions | good conditions as per Ease of Doing Business ranking | country rank ≤ 75 | rank 22 (Germany) | [60] | ✓ | E (leg.) |

| Domain 1 | Category | Criterion | Indicator | Result | Source | Rating |

|---|---|---|---|---|---|---|

| env. | waste | seismic hazard | peak ground acceleration > 3.2 m/s2 | 0.4 m/s2 | [80] | ✗ |

| water | aqueduct water risk | overall water risk > 3 (high) | 1–2 (low-medium) | [81] | ✗ | |

| nearby surface waters | downstream distance to TSF < 10 km | in near vicinity, cf., Figure 4 | [71] | ✓ | ||

| nearby water protection areas | downstream distance to TSF < 10 km | ~7.3 km N-E of the TSF near Vienenburg | [75] | ✓ | ||

| landscape | protected landscape areas | downstream distance to TSF < 10 km | nearest immediately at the foot of the dam, cf., Figure 4 | [75] | ✓ | |

| biodiversity | nature conservation areas | downstream distance to TSF < 10 km | ~3.5 km N-E of TSF, cf., Figure 4 | [75] | ✓ | |

| soc. | social vulnerability | proximity to human settlements | downstream distance to TSF < 10 km | nearest settlement Oker ~400 m E of main dam, potential flow path in direction of settlement, cf., Figure A1 | [71,82] | ✓ |

| Fragile States Index | country score ≥ 4 for social indicators | average score 2 (Germany) | [83] | ✗ | ||

| land use | human footprint | Human Footprint Index > 40% | 60–80% (area around the TSF) | [84] | ✓ |

| Stakeholder Category | Result | Source | Remark |

|---|---|---|---|

| nearby communities | (1) citizens of Goslar & its borough Oker | observation on Google Earth [71,76] | total population of ~50,000 inhabitants |

| TSF owner | (2) - | - | could not be clarified with internet search |

| local authorities | (3) Goslar administrative bodies | www.landkreis-goslar.de www.landkreis-goslar.de/eh- | Various departments, such as for Regional Economic Development or the Environment, the Circular Economy Department, are responsible for the disused landfill Paradiesgrund in near vicinity of the TSF |

| (4) State Office for Mining, Energy & Geology Office Clausthal-Zellerfeld | www.lbeg.niedersachsen.de | ~15 km S-W from TSF, included due to relevance for approval | |

| NGOs | (5) German Federation for the Environment & Nature Conservation in the western Harz region (BUND) | www.bund-westharz.de | ~600 members |

| (6) Nature & Biodiversity Conservation Union (NABU) | www.nabu-goslar.de | ~1000 members | |

| (7) Nature & Environmental Aid Goslar (NU) | www.nu-goslar.de | ~200 members | |

| other interested parties | (8) German Railway (DB) | observation on Google Earth [71] | connection to railway network would potentially have to be reactivated, a potential TSF failure might affect the railway |

| (9) farmers | observation on Google Earth [71] | proximity to farmlands around the TSF | |

| (10) foresters | observation on Google Earth [71] | proximity to forests around the TSF | |

| (11) Development Association World Cultural Heritage Ore Mine Rammelsberg Goslar/Harz | https://foerderverein-rammelsberg.de | the association is responsible for the preservation of the World Heritage | |

| (12) Oker-Chemie GmbH | observation on Google Earth [71] | a potential TSF failure might affect the industrial site | |

| (13) Air Sports Community Goslar | www.segelfliegen-goslar.de | glider airfield in near vicinity of TSF | |

| (14) REWIMET e. V.—Recycling Cluster | www.rewimet.de | network of companies, scientific institutions & local authorities, promotes recycling from research up to the industrial scale | |

| (15) Clausthal University of Technology (TUC) | www.ifa.tu-clausthal.de | ~14 km S-W from TSF, included due to regional knowledge & research experience on mineral wastes of >25 years | |

| non-specifiable: | |||

| (16) responsible entity for mine water discharge into the TSF | observation on Google Earth [71] | could not be specified with internet search | |

| (17) owner of tennis courts downstream of the TSF | observation on Google Earth [71] | could not be specified with internet search | |

| (18) company downstream of the TSF | observation on Google Earth [71] | could not be specified with internet search |

5. Discussion

5.1. Limitations of the Developed Screening Approach

5.2. The Developed Screening Approach in a Global Raw Materials Classification Context

6. Conclusions and Recommendations

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Abbreviation/Unit | Description |

| Ag | lat. argentum (silver) |

| Au | lat. aurum (gold) |

| BaSO4 | barium sulphate (barite) |

| Cu | lat. cuprum (copper) |

| Fe | lat. ferrum (iron) |

| In | indium |

| Pb | lat. plumbum (lead) |

| Zn | zinc |

| AMD | acid mine drainage |

| CRIRSCO | Committee for Mineral Reserves International Reporting Standards |

| CRM | Critical Raw Material |

| E | East |

| E&S | environmental and social |

| EC | European Commission |

| EU | European Union |

| LOM | Life of Mine |

| N | North |

| N-E | Northeast |

| NGO | non-governmental organisation |

| REWIMET e. V. | Recycling Cluster Economically Strategic Metals |

| RM | raw material |

| S-W | Southwest |

| TSF | tailings storage facility |

| UNFC | United Nations Framework Classification for Resources |

| UNFC E category | represents environmental-socio-economic viability |

| UNFC F category | represents technical feasibility |

| UNFC G category | represents degree of confidence in the geological estimate |

| W | West |

| °C | degree Celsius (unit of temperature on the Celsius scale) |

| Gt/a | gigatons per year (unit of mass flow, equivalent to 1012 kg per year) |

| km | kilometre (unit of length, equivalent to 1,000 metres) |

| m | metre (SI unit of length) |

| m/s2 | metre per square second (unit of acceleration) |

| m3 | cubic metre (SI-derived unit of volume) |

| mm/a | millimetres per year (annual rain precipitation) |

| t | metric tonne (unit of weight, equivalent to 1,000 kg) |

Appendix A

References

- Singh, N.; Duan, H.; Yin, F.; Song, Q.; Li, J. Characterizing the Materials Composition and Recovery Potential from Waste Mobile Phones: A Comparative Evaluation of Cellular and Smart Phones. ACS Sustain. Chem. Eng. 2018, 6, 13016–13024. [Google Scholar] [CrossRef]

- Valero, A.; Valero, A.; Calvo, G.; Ortego, A.; Ascaso, S.; Palacios, J.-L. Global material requirements for the energy transition. An exergy flow analysis of decarbonisation pathways. Energy 2018, 159, 1175–1184. [Google Scholar] [CrossRef]

- Vidal, O.; Goffé, B.; Arndt, N. Metals for a low-carbon society. Nat. Geosci. 2013, 6, 894–896. [Google Scholar] [CrossRef]

- Watari, T.; McLellan, B.C.; Giurco, D.; Dominish, E.; Yamasue, E.; Nansai, K. Total material requirement for the global energy transition to 2050: A focus on transport and electricity. Resour. Conserv. Recycl. 2019, 148, 91–103. [Google Scholar] [CrossRef]

- Martins, F.F.; Castro, H. Raw material depletion and scenario assessment in European Union—A circular economy approach. Energy Rep. 2020, 6, 417–422. [Google Scholar] [CrossRef]

- Bastian, D.; Brandenburg, T.; Buchholz, P.; Huy, D.; Liedtke, M.; Schmidt, M.; Sievers, H. DERA List of Raw Materials; Deutsche Rohstoffagentur (DERA) in der Bundesanstalt für Geowissenschaften und Rohstoffe (BGR): Berlin, Germany, 2019; p. 116. ISBN 978-3-943566-61-1. Available online: https://www.deutsche-rohstoffagentur.de/DE/Gemeinsames/Produkte/Downloads/DERA_Rohstoffinformationen/rohstoffinformationen-40.pdf?__blob=publicationFile (accessed on 28 August 2020). (In German)

- Grilli, M.L.; Bellezze, T.; Gamsjäger, E.; Rinaldi, A.; Novak, P.; Balos, S.; Piticescu, R.R.; Ruello, M.L. Solutions for Critical Raw Materials under Extreme Conditions: A Review. Materials 2017, 10, 285. [Google Scholar] [CrossRef] [Green Version]

- Rabe, W.; Kostka, G.; Smith Stegen, K. China’s supply of critical raw materials: Risks for Europe’s solar and wind industries? Energy Policy 2017, 101, 692–699. [Google Scholar] [CrossRef]

- Sievers, H.; Tercero, L. European Dependence on and Concentration Tendencies of the Material Production. 2012. Available online: https://www.google.com/url?sa=t&rct=j&q=&esrc=s&source=web&cd=&ved=2ahUKEwjHtcbe453sAhWD3KQKHXxMAhIQFjAAegQIAxAC&url=https%3A%2F%2Fwww.isi.fraunhofer.de%2Fcontent%2Fdam%2Fisi%2Fdokumente%2Fccn%2Fpolinares%2FPolinares_WP_14_March_2012&usg=AOvVaw01huy0wOnuuqtkRHm0Q0K9 (accessed on 5 October 2020).

- Burlakovs, J.; Kriipsalu, M.; Klavins, M.; Bhatnagar, A.; Vincevica-Gaile, Z.; Stenis, J.; Jani, Y.; Mykhaylenko, V.; Denafas, G.; Turkadze, T.; et al. Paradigms on landfill mining: From dump site scavenging to ecosystem services revitalization. Resour. Conserv. Recycl. 2017, 123, 73–84. [Google Scholar] [CrossRef] [Green Version]

- European Commission (EC). Towards a Circular Economy: A Zero Waste Programme for Europe. 2014. Available online: https://ec.europa.eu/environment/circular-economy/pdf/circular-economy-communication.pdf (accessed on 4 August 2019).

- Krook, J.; Baas, L. Getting serious about mining the technosphere: A review of recent landfill mining and urban mining research. J. Clean. Prod. 2013, 55, 1–9. [Google Scholar] [CrossRef]

- United Nations Environment Programme (UNEP). Critical Metals for Future Sustainable Technologies and their Recycling Potential: Sustainable Innovation and Technology Transfer Industrial Sector Studies; United Nations Environment Programme & United Nations University: Tokyo, Japan, 2009; Available online: https://www.oeko.de/oekodoc/1070/2009-129-en.pdf (accessed on 6 October 2020).

- Eurostat. Waste Statistics. 2020. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php/Waste_statistics (accessed on 25 October 2020).

- Lottermoser, B. Mine Wastes, 3rd ed.; Springer: Berlin/Heidelberg, Germany, 2010; p. 400. [Google Scholar] [CrossRef]

- Drif, B.; Taha, Y.; Hakkou, R.; Benzaazoua, M. Recovery of Residual Silver-Bearing Minerals from Low-Grade Tailings by Froth Flotation: The Case of Zgounder Mine, Morocco. Minerals 2018, 8, 273. [Google Scholar] [CrossRef] [Green Version]

- López, F.; García-Díaz, I.; Rodríguez Largo, O.; Polonio, F.; Llorens, T. Recovery and Purification of Tin from Tailings from the Penouta Sn–Ta–Nb Deposit. Minerals 2018, 8, 20. [Google Scholar] [CrossRef] [Green Version]

- Okereafor, U.; Makhatha, M.; Mekuto, L.; Mavumengwana, V. Gold Mine Tailings: A Potential Source of Silica Sand for Glass Making. Minerals 2020, 10, 448. [Google Scholar] [CrossRef]

- Su, Z.; Chen, Q.; Zhang, Q.; Zhang, D. Recycling Lead–Zinc Tailings for Cemented Paste Backfill and Stabilisation of Excessive Metal. Minerals 2019, 9, 710. [Google Scholar] [CrossRef] [Green Version]

- Tang, C.; Li, K.; Ni, W.; Fan, D. Recovering Iron from Iron Ore Tailings and Preparing Concrete Composite Admixtures. Minerals 2019, 9, 232. [Google Scholar] [CrossRef] [Green Version]

- Žibret, G.; Lemiere, B.; Mendez, A.-M.; Cormio, C.; Sinnett, D.; Cleall, P.; Szabó, K.; Carvalho, M.T. National Mineral Waste Databases as an Information Source for Assessing Material Recovery Potential from Mine Waste, Tailings and Metallurgical Waste. Minerals 2020, 10, 446. [Google Scholar] [CrossRef]

- Dong, L.; Deng, S.; Wang, F. Some developments and new insights for environmental sustainability and disaster control of tailings dam. J. Clean. Prod. 2020, 269, 122270. [Google Scholar] [CrossRef]

- Dong, L.; Tong, X.; Li, X.; Zhou, J.; Wang, S.; Liu, B. Some developments and new insights of environmental problems and deep mining strategy for cleaner production in mines. J. Clean. Prod. 2020, 210, 1562–1578. [Google Scholar] [CrossRef]

- Lee, E.-S.; Cho, S.-J.; Back, S.-K.; Seo, Y.-C.; Kim, S.-H.; Ko, J.-I. Effect of substitution reaction with tin chloride in thermal treatment of mercury contaminated tailings. Environ. Pollut. 2020, 264, 114761. [Google Scholar] [CrossRef]

- Lyu, Z.; Chai, J.; Xu, Z.; Qin, Y.; Cao, J. A Comprehensive Review on Reasons for Tailings Dam Failures Based on Case History. Adv. Civ. Eng. 2019, 2019, 4159306. [Google Scholar] [CrossRef]

- Wang, G.; Tian, S.; Hu, B.; Xu, Z.; Chen, J.; Kong, X. Evolution Pattern of Tailings Flow from Dam Failure and the Buffering Effect of Debris Blocking Dams. Water 2019, 11, 2388. [Google Scholar] [CrossRef] [Green Version]

- Blasenbauer, D.; Bogush, A.; Carvalho, T.; Cleall, P.; Cormio, C.; Guglietta, D.; Fellner, J.; Fernández-Alonso, M.; Heuss-Aßbichler, S.; Huber, F.; et al. Knowledge Base to Facilitate Anthropogenic Resource Assessment: Deliverable of COST Action Mining the European Anthroposphere. 2020. Available online: https://zenodo.org/record/3739164#.X6WHdFBo3b0 (accessed on 6 November 2020).

- Dino, G.A.; Mehta, N.; Rossetti, P.; Ajmone-Marsan, F.; Luca, D.A.d. Sustainable approach towards extractive waste management: Two case studies from Italy: Two case studies from Italy. Resour. Policy 2018, 59, 33–43. [Google Scholar] [CrossRef]

- European Commission (EC). Assessment of Member States’ Performance Regarding the Implementation of the Extractive Waste Directive; Appraisal of Implementation Gaps and Their Root Causes; Identification of Proposals to Improve the Implementation of the Directive; European Commission: Brussels, Belgium, 2017; Available online: https://ec.europa.eu/environment/waste/studies/pdf/KH-01-17-904-EN-N.pdf (accessed on 6 November 2020).

- Kuhn, K.; Meima, J.A. Characterization and Economic Potential of Historic Tailings from Gravity Separation: Implications from a Mine Waste Dump (Pb-Ag) in the Harz Mountains Mining District, Germany. Minerals 2019, 9, 303. [Google Scholar] [CrossRef] [Green Version]

- Committee for Mineral Reserves International Reporting Standards (CRIRSCO). International Reporting Template for the Public Reporting of Exploration Targets, Exploration Results, Mineral Resources and Mineral Reserves. 2019. Available online: http://www.crirsco.com/templates/CRIRSCO_International_Reporting_Template_November_2019.pdf (accessed on 9 June 2020).

- Attila Resources. Attila to Acquire the Century Zinc Mine. 2017. Available online: https://www.newcenturyresources.com/wp-content/uploads/2018/01/170301-AYA-Acquisition-of-Century-ASX-Ann.pdf (accessed on 14 August 2019).

- Campbell, M.D.; Absolon, V.; King, J.; David, C.M. Precious Metal Resources of the Hellyer Mine Tailings. 2015. Available online: http://www.i2massociates.com/downloads/I2MHellyerTailingsResourcesMar9-2015Rev.pdf (accessed on 14 August 2019).

- Cronwright, M.; Gasela, I.; Derbyshire, J. Kamativi Lithium Tailings Project. 2018. Available online: http://sectornewswire.com/NI43-101TechnicalReport-Kamativi-Li-Nov-2018.pdf (accessed on 14 August 2019).

- Johansson, N.; Krook, J.; Eklund, M.; Berglund, B. An integrated review of concepts and initiatives for mining the technosphere: Towards a new taxonomy. J. Clean. Prod. 2013, 55, 35–44. [Google Scholar] [CrossRef] [Green Version]

- Hartman, H.L.; Mutmansky, J.M. Introductory Mining Engineering, 2nd ed.; Wiley: Hoboken, NJ, USA, 2002; p. 570. [Google Scholar]

- Laurence, D. Establishing a sustainable mining operation: An overview. J. Clean. Prod. 2011, 19, 278–284. [Google Scholar] [CrossRef]

- Owen, J.R.; Kemp, D.; Lèbre, É.; Svobodova, K.; Pérez Murillo, G. Catastrophic tailings dam failures and disaster risk disclosure. Int. J. Disaster Risk Reduct. 2020, 42, 101361. [Google Scholar] [CrossRef]

- Reid, C.; Bécaert, V.; Aubertin, M.; Rosenbaum, R.K.; Deschênes, L. Life cycle assessment of mine tailings management in Canada. J. Clean. Prod. 2009, 17, 471–479. [Google Scholar] [CrossRef]

- Roche, C.; Thygesen, K.; Baker, E.E. Mine Tailings Storage: Safety Is No Accident: A UNEP Rapid Response Assessment; United Nations Environment Programme and GRID-Arendal: Arendal, Norway, 2017; ISBN 978-827-701-170-7. Available online: https://www.grida.no/publications/383 (accessed on 10 January 2020).

- Worrall, R.; Neil, D.; Brereton, D.; Mulligan, D. Towards a sustainability criteria and indicators framework for legacy mine land. J. Clean. Prod. 2009, 17, 1426–1434. [Google Scholar] [CrossRef]

- United Nations Economic Commission for Europe (UNECE). United Nations Framework Classification for Resources—Update 2019; UNECE: Geneva, Switzerland, 2020; p. 20. Available online: https://www.unece.org/fileadmin/DAM/energy/se/pdfs/UNFC/publ/UNFC_ES61_Update_2019.pdf (accessed on 13 November 2020).

- United Nations Economic Commission for Europe (UNECE). Specifications for the Application of the United Nations Framework Classification for Resources to Anthropogenic Resources. 2018. Available online: https://www.unece.org/fileadmin/DAM/energy/se/pdfs/UNFC/Anthropogenic_Resources/UNFC_Antropogenic_Resource_Specifications.pdf (accessed on 4 October 2019).

- Heuss-Aßbichler, S.; Kral, U.; Løvik, A.; Mueller, S.; Simoni, M.; Stegemann, J.; Wäger, P.; Horváth, Z.; Winterstetter, A. Strategic Roadmap on Sustainable Management of Anthropogenic Resources. 2020. Available online: https://zenodo.org/record/3739269#.X6WBG1Bo3b1 (accessed on 6 November 2020).

- Suppes, R.; Heuss-Aßbichler, S. Resource potential of mine wastes: A conventional and sustainable perspective on a case study tailings mining project. J. Clean. Prod. 2021. [Google Scholar] [CrossRef]

- Ilich, M. On the use of geological exploration data in mineral projects. J. Environ. Geol. 2018, 2, 61–63. [Google Scholar]

- Revuelta, M.B. Mineral Resources; Springer International Publishing: Cham, Switzerland, 2018; p. 653. [Google Scholar] [CrossRef]

- Winterstetter, A.; Laner, D.; Rechberger, H.; Fellner, J. Evaluation and classification of different types of anthropogenic resources: The cases of old landfills, obsolete computers and in-use wind turbines. J. Clean. Prod. 2016, 133, 599–615. [Google Scholar] [CrossRef]

- Huber, F.; Fellner, J. Integration of life cycle assessment with monetary valuation for resource classification: The case of municipal solid waste incineration fly ash. Resour. Conserv. Recycl. 2018, 139, 17–26. [Google Scholar] [CrossRef]

- Mueller, S.R.; Kral, U.; Wäger, P.A. Developing material recovery projects: Lessons learned from processing municipal solid waste incineration residues. J. Clean. Prod. 2020, 259, 120490. [Google Scholar] [CrossRef]

- Mueller, S.R.; Wäger, P.A.; Widmer, R.; Williams, I.D. A geological reconnaissance of electrical and electronic waste as a source for rare earth metals. Waste Manag. 2015, 45, 226–234. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dino, G.A.; Rossetti, P.; Perotti, L.; Alberto, W.; Sarkka, H.; Coulon, F.; Wagland, S.; Griffiths, Z.; Rodeghiero, F. Landfill mining from extractive waste facilities: The importance of a correct site characterisation and evaluation of the potentialities. A case study from Italy. Resour. Policy 2018, 59, 50–61. [Google Scholar] [CrossRef] [Green Version]

- Wates, J.; Goetz, A. Practical Considerations in the Hydro Re-Mining of Gold Tailings. In Gold Ore Processing; Adams, M.D., Ed.; Elsevier Science: San Diego, CA, USA, 2016; pp. 729–738. [Google Scholar]

- Sözen, S.; Orhon, D.; Dinçer, H.; Ateşok, G.; Baştürkçü, H.; Yalçın, T.; Öznesil, H.; Karaca, C.; Allı, B.; Dulkadiroğlu, H.; et al. Resource recovery as a sustainable perspective for the remediation of mining wastes: Rehabilitation of the CMC mining waste site in Northern Cyprus. Bull. Eng. Geol. Environ. 2017, 76, 1535–1547. [Google Scholar] [CrossRef]

- Candeias, C.; Melo, R.; Ávila, P.F.; da Silva, E.F.; Salgueiro, A.R.; Teixeira, J.P. Heavy metal pollution in mine–soil–plant system in S. Francisco de Assis—Panasqueira mine (Portugal). Appl. Geochem. 2014, 44, 12–26. [Google Scholar] [CrossRef] [Green Version]

- Bleicher, A.; David, M.; Rutjes, H. When environmental legacy becomes a resource: On the making of secondary resources. Geoforum 2019, 101, 18–27. [Google Scholar] [CrossRef]

- Poggendorf, C.; Rüpke, A.; Gock, E.; Saheli, H.; Kuhn, K.; Martin, T. Nutzung des Rohstoffpotentials von Bergbau- und Hüttenhalden am Beispiel des Westharzes. 2015, p. 22. Available online: https://www.researchgate.net/profile/Tina_Martin5/publication/303941732_Nutzung_des_Rohstoffpotentials_von_Bergbau-_und_Huttenhalden_am_Beispiel_des_Westharzes/links/575fbf8d08aed884621bbfa3/Nutzung-des-Rohstoffpotentials-von-Bergbau-und-Huettenhalden-am-Beispiel-des-Westharzes.pdf (accessed on 13 November 2020).

- Statista. Duration of the Extraction Period of a Mine by Selected Commodities. 2013. Available online: https://www.statista.com/statistics/255479/mine-life-per-commodity/ (accessed on 12 September 2020).

- European Commission (EC). Critical Raw Materials Resilience: Charting a Path towards Greater Security and Sustainability. 2020. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:52020DC0474&from=EN (accessed on 21 December 2020).

- World Bank. Doing Business 2020: Comparing Business Regulation in 190 Economies; World Bank: Washington, DC, USA, 2020; p. 135. Available online: http://documents1.worldbank.org/curated/en/688761571934946384/pdf/Doing-Business-2020-Comparing-Business-Regulation-in-190-Economies.pdf (accessed on 13 November 2020).

- Roemer, F.; Binder, A.; Goldmann, D. Basic Considerations for the Reprocessing of Sulfidic Tailings Using the Example of the Bollrich Tailing Ponds. World Metall. 2018, 71, 1–9. [Google Scholar]

- Federal Agency for Nature Conservation (BfN). Landscape Protection Areas. 2019. Available online: https://www.bfn.de/en/activities/protected-areas/landscape-protection-areas.html (accessed on 11 November 2020).

- Azapagic, A. Developing a framework for sustainable development indicators for the mining and minerals industry. J. Clean. Prod. 2004, 12, 639–662. [Google Scholar] [CrossRef]

- European Commission. Establishment of Guidelines for the Inspection of Mining Waste Facilities, Inventory and Rehabilitation of Abandoned Facilities and Review of the BREF Document: Annex 3—Supporting Document on Closure Methodologies for Closed and Abandoned Mining Waste Facilities. 2012. Available online: https://ec.europa.eu/environment/waste/mining/pdf/Annex3_closure_rehabilitation%20.pdf (accessed on 23 September 2020).

- Valenta, R.K.; Kemp, D.; Owen, J.R.; Corder, G.D.; Lèbre, É. Re-thinking complex orebodies: Consequences for the future world supply of copper. J. Clean. Prod. 2019, 220, 816–826. [Google Scholar] [CrossRef]

- Environmental Law Alliance Worldwide. Guidebook for Evaluating Mining Project EIAs. 2010. Available online: https://www.elaw.org/files/mining-eia-guidebook/Full-Guidebook.pdf (accessed on 16 August 2020).

- Franks, D.M.; Davis, R.; Bebbington, A.J.; Ali, S.H.; Kemp, D.; Scurrah, M. Conflict translates environmental and social risk into business costs. Proc. Natl. Acad. Sci. USA 2014, 111, 7576–7581. [Google Scholar] [CrossRef] [Green Version]

- Goldmann, D.; Zeller, T.; Niewisch, T.; Klesse, L.; Kammer, U.; Poggendorf, C.; Stöbich, J. Recycling of Mine Processing Wastes for the Extraction of Economically Strategic Metals Using the Example of Tailings at the Bollrich in Goslar (REWITA): Final Report; TU Clausthal: Clausthal-Zellerfeld, Germany, 2019; Available online: https://www.tib.eu/de/suchen/id/TIBKAT:1688127496/ (accessed on 22 July 2020). (In German)

- Roemer, F. Investigations on the Processing of Deposited Flotation Residues at the Tailings Pond Bollrich with Special Consideration of the Extraction of Economically Strategic Raw Materials. Ph.D. Thesis, Clausthal University of Technology, Clausthal, Germany, 28 November 2019. (In German). [Google Scholar]

- Woltemate, I. Assessment of the Geochemical and Sediment Petrographic Significance of Drilling Samples from Flotation Tailings in Two Tailing Ponds of the Rammelsberg Ore Mine (German). Ph.D. Thesis, University of Hanover, Hanover, Germany, 5 November 1987. (In German). [Google Scholar]

- Google Earth Pro 7. Available online: https://www.google.com/earth/ (accessed on 20 December 2020).

- Bertrand, G.; Cassard, D.; Arvanitidis, N.; Stanley, G. Map of Critical Raw Material Deposits in Europe. Energy Procedia 2016, 97, 44–50. [Google Scholar] [CrossRef] [Green Version]

- Large, D.; Walcher, E. The Rammelsberg massive sulphide Cu-Zn-Pb-Ba-Deposit, Germany: An example of sediment-hosted, massive sulphide mineralisation. Miner. Depos. 1999, 34, 522–538. [Google Scholar] [CrossRef]

- Eichhorn, P. Ore Processing Rammelsberg—Origin, Operation, Comparison; Förderverein Weltkulturerbe Rammelsberg Goslar/Harz e.V.: Goslar, Germany, 2012; Available online: https://docplayer.org/16359673-Erzaufbereitung-rammelsberg.html (accessed on 30 August 2020). (In German)

- District of Goslar, Environmental Service. Map of Nature Conservation Areas. 2020. Available online: https://webgis.landkreis-goslar.de/MapSolution/apps/map/client/Umweltinformation?view=[Umweltinformation][true][3] (accessed on 15 August 2020). (In German).

- Ackers, W.; Pechmann, S. Integriertes Stadtentwicklungskonzept Goslar 2025; GOSLAR Marketing Gmbh: Goslar, Germany, 2011; Available online: https://www.goslar.de/stadt-buerger/stadtentwicklung/isek-2025 (accessed on 28 July 2020). (In German)

- Mohr, K. Geology and Mineral Deposits of the Harz Mountains: With 37 Tables in Text and on 5 Folded Inserts and 2 Overview Tables on the Inside Pages of the Cover, 2nd ed.; Schweizerbart: Stuttgart, Germany, 1993; p. 496. (In German) [Google Scholar]

- Liessmann, W. Historical Mining in the Harz Mountains, 3rd ed.; Springer: Berlin/Heidelberg, Germany, 2010; p. 470, (In German). [Google Scholar] [CrossRef]

- Climate-Data.org. Climate Goslar (Germany). Available online: https://de.climate-data.org/europa/deutschland/niedersachsen/goslar-22981/ (accessed on 23 August 2020).

- Giardini, D.; Grünthal, G.; Shedlock, K.M.; Zhang, P. The GSHAP Global Seismic Hazard Map. In International Handbook of Earthquake & Engineering Seismology; Lee, W., Kanamori, H., Jennings, P., Kisslinger, C., Eds.; Academic Press: Amsterdam, The Netherlands, 2003; pp. 1233–1239. [Google Scholar]

- Hofste, R.W.; Kuzma, S.; Walker, S.; Sutanudajaja, E.H.; Bierkens, M.F.P.; Kuijper, M.J.M.; Sanchez, M.F.; van Beek, R.; Wada, Y.; Rodriguez, S.G.; et al. Aqueduct 3.0: Updated Decision-Relevant Global Water Risk Indicators; World Resources Institute: Washington, DC, USA, 2019; Available online: https://www.wri.org/publication/aqueduct-30 (accessed on 11 June 2020).

- Topographic-map.com. Topography of Germany. Available online: https://en-gb.topographic-map.com/maps/d93/Germany/ (accessed on 23 August 2020).

- The Fund for Peace. Frage States Index. 2020. Available online: https://fragilestatesindex.org/ (accessed on 16 August 2020).

- Wildlife Conservation Society (WCS) and Center for International Earth Science Information Network (CIESIN). Last of the Wild Project, (LWP-2): Global Human Footprint Dataset (Geographic); NASA Socioeconomic Data and Applications Center (SEDAC): Palisades, NY, USA, 2005. [CrossRef]

- Lèbre, É.; Corder, G. Integrating Industrial Ecology Thinking into the Management of Mining Waste. Resources 2015, 4, 765–786. [Google Scholar] [CrossRef]

- European Union. Raw Materials Scoreboard 2018: European Innovation Partnership on Raw Materials; Publications Office of the European Union: Luxembourg, 2018. [Google Scholar] [CrossRef]

| Group & Factor | Feature | Considerations for Tailings Assessment | UNFC Axis 1 |

|---|---|---|---|

| similarities with the assessment of natural mineral raw materials | |||

| mine planning | |||

| mining methods | same as for ores | existing portfolio of proven methods to resort to | F |

| valorisation | same as for ores | existing portfolio of proven methods to resort to | F |

| deposit modelling | same as for ores | existing portfolio of proven methods to resort to | F |

| economic evaluation | same as for ores | existing portfolio of proven methods to resort to | E (econ.) |

| differences from the assessment of natural mineral raw materials | |||

| project identification | |||

| location | remnants of mining operations | mapped (non-)active mine sites can be investigated to locate TSFs | G |

| composition | similar to ore composition | first indication of tailings composition derivable from ore composition | G |

| TSF content | |||

| characterisation | with historical & newly generated data | brownfield exploration: remote localisation & assessment of TSFs possible | G |

| target minerals | formerly & newly relevant raw materials | re-assessment of project viability might be necessary for inventoried TSFs | G |

| state of target minerals | can alter with time | geological re-assessment might be necessary for inventoried TSFs | G |

| project boundaries | |||

| socio-environmental impact | inherent footprint of TSFs | not only geological data but also status quo impacts must be considered | E (env., soc.) |

| involved actors | broader scope of actors involved | broad stakeholder assessment necessary from screening phase on | E (soc.) |

| legislation | legal situation less clear | individual assessment necessary to clarify which laws are applicable | E (leg.) |

| Screening Step | Generated Knowledge | General Positive Rating Criteria |

|---|---|---|

| (1) basic TSF information compilation | overview is obtained, base for project definition created | all readily available basic information captured for later evaluation |

| (2) precondition factors assessment | potential project drivers identified, favourable technological & legal conditions identified | criteria of the G & F categories fulfilled, minimum one criterion of the E subcategories met |

| (3) local E&S potential assessment | possible environmental and social risks identified, potentials to reduce environmental risks and/or to create social benefits identified | minimum one conceivable positive environmental and/or social impact identified |

| (4) local stakeholder assessment | potentially affected stakeholders by TSF failure or raw materials recovery identified, potential social issues identified | all potentially affected stakeholder captured |

| (5) UNFC-compliant categorisation | generally favourable project conditions warrant on-site exploration | economic, environmental and/or social potentials/barriers identified |

| Precondition Factor | Assessed Aspect | UNFC Axis 1 |

|---|---|---|

| (1) TSF volume | justification for mid- to long-term investment | G |

| (2) local infrastructure | cost savings due to accessible infrastructure or incurred costs due to necessary disposal of existing infrastructure | F |

| (3) TSF condition | necessity of special safety measures during mining or extensive environmental rehabilitation due to contamination | F |

| (4) resource criticality | economic importance of targeted minerals | E (econ.) |

| (5) climatic conditions | enhanced environmental risks due to TSF’s location | E (env.) |

| (6) proximity to human settlements | necessity of special protective measures during mining | E (soc.) |

| (7) investment conditions | general regulatory conditions in a country | E (leg.) |

| Category | Derived Benefits from TSF Removal | UNFC Axis 1 |

|---|---|---|

| (1) waste | reduced exposure to potential tailings flood by TSF collapse | E (env.) |

| (2) water | reduced risks to scarce water, aquatic ecosystems & drinking water | E (env.) |

| (3) landscape | reduced risk to ecosystems, aesthetically valuable lands & recreational lands | E (env.) |

| (4) biodiversity | reduced risk to nearby ecosystems | E (env.) |

| (5) land use | reduced social tensions due to land use conflicts | E (soc.) |

| (6) social vulnerability | reduced risk of harm to human health & social unrest | E (soc.) |

| Category | Selection Criterion | UNFC Axis 1 |

|---|---|---|

| (1) nearby communities | potentially economically or physically affected by TSF failure or mining | E (soc.) |

| (2) TSF owner | approval required | E (soc.) |

| (3) local authorities | approval required, representing certain political interests which are relevant for tailings valorisation | E (soc.) |

| (4) NGOs 2 | representing environmental and/or social interest associated with TSF failure or tailings mining | E (soc.) |

| (5) other interested parties | any of the above | E (soc.) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Suppes, R.; Heuss-Aßbichler, S. How to Identify Potentials and Barriers of Raw Materials Recovery from Tailings? Part I: A UNFC-Compliant Screening Approach for Site Selection. Resources 2021, 10, 26. https://doi.org/10.3390/resources10030026

Suppes R, Heuss-Aßbichler S. How to Identify Potentials and Barriers of Raw Materials Recovery from Tailings? Part I: A UNFC-Compliant Screening Approach for Site Selection. Resources. 2021; 10(3):26. https://doi.org/10.3390/resources10030026

Chicago/Turabian StyleSuppes, Rudolf, and Soraya Heuss-Aßbichler. 2021. "How to Identify Potentials and Barriers of Raw Materials Recovery from Tailings? Part I: A UNFC-Compliant Screening Approach for Site Selection" Resources 10, no. 3: 26. https://doi.org/10.3390/resources10030026

APA StyleSuppes, R., & Heuss-Aßbichler, S. (2021). How to Identify Potentials and Barriers of Raw Materials Recovery from Tailings? Part I: A UNFC-Compliant Screening Approach for Site Selection. Resources, 10(3), 26. https://doi.org/10.3390/resources10030026