The Economics of Fruit and Vegetable Production Irrigated with Reclaimed Water Incorporating the Hidden Costs of Life Cycle Environmental Impacts

Abstract

:1. Introduction

2. Materials and Methods

2.1. Assessment Framework

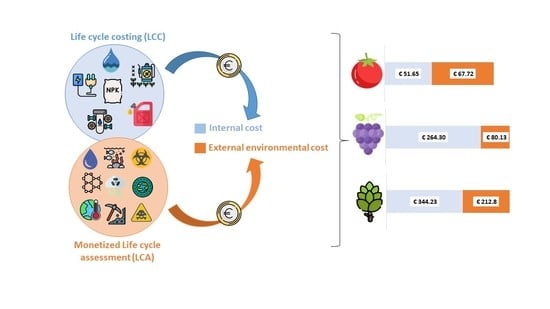

- (1)

- Make an inventory of relevant crop input-output data and convert it to actual environmental indicators through the LCA approach.

- (2)

- Apply economic weighting of LCA results and express results in economic terms as external environmental costs (EEC).

- (3)

- Calculate the internal cost (IC) through a simplified life cycle costing analysis.

- (4)

- Combine EEC with IC to produce a final synthetic economic–environmental indicator expressed in monetary terms, referred to as total cost.

2.1.1. Modeling External Environmental Cost Via LCA

2.1.2. Inventory Data

2.2. Cost Valuation

3. Results

3.1. What Is the Size of External Environmental Costs of Crops Irrigated with Reclaimed Water?

3.2. What Is the Total Cost of Crop Production with Reclaimed Water? The Role of Externalities

3.3. How Does the Performance of Crop Cultivation Irrigated with Reclaimed Water Compare to Irrigation with Groundwater?

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mancuso, G.; Lavrnić, S.; Toscano, A. Reclaimed water to face agricultural water scarcity in the mediterranean area: An overview using sustainable development goals preliminary data. In Wastewater treatment and Reuse—Present and Future Perspectives in Technological Developments and Management Issues; Elsevier: Amsterdam, The Netherlands, 2020; pp. 113–143. [Google Scholar] [CrossRef]

- Pistocchi, A.; Aloe, A.; Dorati, C.; Alcalde Sanz, L.; Bouraoui, F.; Gawlik, B.; Grizzetti, B.; Pastori, M.; Vigiak, O. The Potential of Water Reuse for Agricultural Irrigation in the EU a Hydro-Economic Analysis; Publications Office of the European Union: Luxembourg, 2018; ISBN 9789279772108. [Google Scholar]

- The European Parliament and the Council Regulation (EU) 2020/741, Minimum Requirements for Water Reuse; Office of the European Union: Luxembourg, 2020; Volume 177, pp. 32–55.

- Jaramillo, M.; Restrepo, I. Wastewater reuse in agriculture: A review about its limitations and benefits. Sustainability 2017, 9, 1734. [Google Scholar] [CrossRef] [Green Version]

- Arborea, S.; Giannoccaro, G.; de Gennaro, B.; Iacobellis, V.; Piccinni, A. Cost–benefit analysis of wastewater reuse in Puglia, southern Italy. Water 2017, 9, 175. [Google Scholar] [CrossRef] [Green Version]

- Azeb, L.; Hartani, T.; Aitmouheb, N.; Pradeleix, L.; Hajjaji, N.; Aribi, S. Life cycle assessment of cucumber irrigation: Unplanned water reuse versus groundwater resources in Tipaza (Algeria). J. Water Reuse Desalin. 2020, 10, 227–238. [Google Scholar] [CrossRef]

- Romeiko, X.X. A comparative life cycle assessment of crop systems irrigated with the groundwater and reclaimed water in northern China. Sustainability 2019, 11, 2743. [Google Scholar] [CrossRef] [Green Version]

- Arzate, S.; Pfister, S.; Oberschelp, C.; Sánchez-Pérez, J.A. Environmental impacts of an advanced oxidation process as tertiary treatment in a wastewater treatment plant. Sci. Total Environ. 2019, 694, 133572. [Google Scholar] [CrossRef]

- Foglia, A.; Andreola, C.; Cipolletta, G.; Radini, S.; Akyol, Ç.; Eusebi, A.L.; Stanchev, P.; Katsou, E.; Fatone, F. Comparative life cycle environmental and economic assessment of anaerobic membrane bioreactor and disinfection for reclaimed water reuse in agricultural irrigation: A case study in Italy. J. Clean. Prod. 2021, 293, 126201. [Google Scholar] [CrossRef]

- Canaj, K.; Morrone, D.; Roma, R.; Boari, F.; Cantore, V.; Todorovic, M. Reclaimed water for vineyard irrigation in a mediterranean context: Life cycle environmental impacts, life cycle costs, and eco-efficiency. Water 2021, 13, 2242. [Google Scholar] [CrossRef]

- Hernández-Sancho, F.; Lamizana-Diallo, B.; Mateo-Sagasta, M.; Qadir, M. Economic Valuation of Wastewater: The Cost of Action and the Cost of No Action; United Nations Environment Programme (UNEP): Nairobi, Kenya, 2015; p. 72. ISBN 978-92-807-3474-4. [Google Scholar]

- De Bruyn, S.; Bijleveld, M.; de Graaff, L.; Schep, E.; Schroten, A.; Vergeer, R.; Ahdour, S. Environmental Prices Handbook EU28 Version-Methods and Numbers for Valuation of Environmental Impacts; CE Delft: Delft, The Netherlands, 2018; p. 177. [Google Scholar]

- de Groot Ruiz, A.; Fobelets, V.; Grosscurt, C.; Galgani, P.; Lord, R.; Hardwicke, R.; Tarin, M.; Gautham, P.; McNeil, D.; Aird, S. The External Costs of Banana Production: A Global Study; Fairtrade International: Bonn, Germany, 2017; p. 65. [Google Scholar]

- Pizzol, M.; Weidema, B.; Brandão, M.; Osset, P. Monetary valuation in life cycle assessment: A review. J. Clean. Prod. 2015, 86, 170–179. [Google Scholar] [CrossRef]

- Arendt, R.; Bachmann, T.M.; Motoshita, M.; Bach, V.; Finkbeiner, M. Comparison of different monetization methods in LCA: A review. Sustainability 2020, 12, 10493. [Google Scholar] [CrossRef]

- Canaj, K.; Mehmeti, A.; Morrone, D.; Toma, P.; Todorović, M. Life cycle-based evaluation of environmental impacts and external costs of treated wastewater reuse for irrigation: A case study in southern Italy. J. Clean. Prod. 2021, 293, 126142. [Google Scholar] [CrossRef]

- Morel, S.; Traverso, M.; Preiss, P. Discussion panel—assessment of externalities: Monetisation and social LCA. In Designing Sustainable Technologies, Products and Policies; Springer International Publishing: Cham, Switzerland, 2018; pp. 391–396. [Google Scholar] [CrossRef]

- Rajabi Hamedani, S.; Kuppens, T.; Malina, R.; Bocci, E.; Colantoni, A.; Villarini, M. Life cycle assessment and environmental valuation of biochar production: Two case studies in Belgium. Energies 2019, 12, 2166. [Google Scholar] [CrossRef] [Green Version]

- Olba-Zięty, E.; Stolarski, M.J.; Krzyżaniak, M.; Gołaszewski, J. Environmental external cost of poplar wood chips sustainable production. J. Clean. Prod. 2020, 252, 119854. [Google Scholar] [CrossRef]

- Huijbregts, M.A.J.; Steinmann, Z.J.N.; Elshout, P.M.F.; Stam, G.; Verones, F.; Vieira, M.; Zijp, M.; Hollander, A.; van Zelm, R. ReCiPe2016: A harmonised life cycle impact assessment method at midpoint and endpoint level. Int. J. Life Cycle Assess. 2017, 22, 138–147. [Google Scholar] [CrossRef]

- Al-Qahtani, A.; Parkinson, B.; Hellgardt, K.; Shah, N.; Guillen-Gosalbez, G. Uncovering the true cost of hydrogen production routes using life cycle monetisation. Appl. Energy 2021, 281, 115958. [Google Scholar] [CrossRef]

- Greenfeld, A.; Becker, N.; Bornman, J.F.; Spatari, S.; Angel, D.L. Monetizing environmental impact of integrated aquaponic farming compared to separate systems. Sci. Total Environ. 2021, 792, 148459. [Google Scholar] [CrossRef] [PubMed]

- Huysegoms, L.; Rousseau, S.; Cappuyns, V. Friends or foes? Monetized life cycle assessment and cost-benefit analysis of the site remediation of a former gas plant. Sci. Total Environ. 2018, 619, 258–271. [Google Scholar] [CrossRef] [PubMed]

- Theregowda, R.B.; Vidic, R.; Landis, A.E.; Dzombak, D.A.; Matthews, H.S. Integrating external costs with life cycle costs of emissions from tertiary treatment of municipal wastewater for reuse in cooling systems. J. Clean. Prod. 2016, 112, 4733–4740. [Google Scholar] [CrossRef] [Green Version]

- True Price. Available online: https://trueprice.org/true-price-resources (accessed on 28 August 2021).

- Hernández-Sancho, F.; Molinos-Senante, M.; Sala-Garrido, R. Economic valuation of environmental benefits from wastewater treatment processes: An empirical approach for Spain. Sci. Total Environ. 2010, 408, 953–957. [Google Scholar] [CrossRef]

- Molinos-Senante, M.; Hernández-Sancho, F.; Sala-Garrido, R. Cost–benefit analysis of water-reuse projects for environmental purposes: A case study for Spanish wastewater treatment plants. J. Environ. Manage. 2011, 92, 3091–3097. [Google Scholar] [CrossRef] [PubMed]

- Sieverding, H.; Kebreab, E.; Johnson, J.M.F.; Xu, H.; Wang, M.; Del Grosso, S.J.; Bruggeman, S.; Stewart, C.E.; Westhoff, S.; Ristau, J.; et al. A life cycle analysis (LCA) primer for the agricultural community. Agron. J. 2020, 112, 3788–3807. [Google Scholar] [CrossRef]

- Vergine, P.; Salerno, C.; Libutti, A.; Beneduce, L.; Gatta, G.; Berardi, G.; Pollice, A. Closing the water cycle in the agro-industrial sector by reusing treated wastewater for irrigation. J. Clean. Prod. 2017, 164, 587–596. [Google Scholar] [CrossRef]

- Disciglio, G.; Gatta, G.; Libutti, A.; Tarantino, A.; Frabboni, L.; Tarantino, E. Use of treated municipal wastewater on artichoke crop. Int. J. Agric. Biosyst. Eng. 2014, 8, 400–406. [Google Scholar] [CrossRef]

- Gatta, G.; Libutti, A.; Beneduce, L.; Gagliardi, A.; Disciglio, G.; Lonigro, A.; Tarantino, E. Reuse of treated municipal wastewater for globe artichoke irrigation: Assessment of effects on morpho-quantitative parameters and microbial safety of yield. Sci. Hortic. 2016, 213, 55–65. [Google Scholar] [CrossRef]

- Ecoinvent Database Version 3.1 Swiss Centre for Life Cycle Inventories, Switzerland. Available online: https://www.ecoinvent.org/database/ecoinvent-371/ecoinvent-371.html (accessed on 1 July 2021).

- Koeble, R. The Global Nitrous Oxide Calculator—GNOC—Online Tool Manual.; European Commission Joint Research Centre: Ispra, Italy, 2014; Volume 1.2.4, p. 40. [Google Scholar]

- Nemecek, T.; Kagi, T. Life cycle inventories of agricultural production systems. In Ecoinvent Report No. 15. Final Rep. Ecoinvent V2.0; Agroscope Reckenholz-Tanikon Research Station: Zürich, Switzerland, 2007; pp. 1–360. Available online: https://db.ecoinvent.org/reports/15_Agriculture.pdf (accessed on 15 June 2021).

- Ponsioen, T.; Nuhoff-isakhanyan, G.; Vellinga, T.; Baltussen, W.; Boone, K.; Woltjer, G. Monetisation of Sustainability Impacts of Food Production and Consumption; Wageningen Economic Research: Hague, The Netherlands, 2020. [Google Scholar] [CrossRef]

- Green Delta Open LCA Version 1.10. Green Delta GmbH: Berlin, Germany. Available online: https://www.openlca.org/download/ (accessed on 10 July 2021).

- Balmford, A.; Amano, T.; Bartlett, H.; Chadwick, D.; Collins, A.; Edwards, D.; Field, R.; Garnsworthy, P.; Green, R.; Smith, P.; et al. The environmental costs and benefits of high-yield farming. Nat. Sustain. 2018, 1, 477–485. [Google Scholar] [CrossRef]

- Ntinas, G.K.; Neumair, M.; Tsadilas, C.D.; Meyer, J. Carbon footprint and cumulative energy demand of greenhouse and open-field tomato cultivation systems under southern and central European climatic conditions. J. Clean. Prod. 2017, 142, 3617–3626. [Google Scholar] [CrossRef]

- Roselli, L.; Casieri, A.; de Gennaro, B.C.; Sardaro, R.; Russo, G. Environmental and economic sustainability of table grape production in Italy. Sustainable 2020, 12, 3670. [Google Scholar] [CrossRef]

- Martin-Gorriz, B.; Soto-García, M.; Martínez-Alvarez, V. Energy and greenhouse-gas emissions in irrigated agriculture of SE (southeast) Spain. Effects of alternative water supply scenarios. Energy 2014, 77, 478–488. [Google Scholar] [CrossRef]

- Moretti, M.; Van Passel, S.; Camposeo, S.; Pedrero, F.; Dogot, T.; Lebailly, P.; Vivaldi, G.A. Modelling environmental impacts of treated municipal wastewater reuse for tree crops irrigation in the Mediterranean coastal region. Sci. Total Environ. 2019, 660, 1513–1521. [Google Scholar] [CrossRef]

- Arena, C.; Genco, M.; Mazzola, M.R. Environmental benefits and economical sustainability of urban wastewater reuse for irrigation—A cost-benefit analysis of an existing reuse project in Puglia, Italy. Water 2020, 12, 2926. [Google Scholar] [CrossRef]

| Parameter | Unit | Tomatoes | Table Grapes | Artichokes |

|---|---|---|---|---|

| Location | - | Trinitapoli | Acquaviva delle Fonti | Trinitapoli |

| Treatment system | m3/h | 12 | 280 | 300 |

| Type of system | - | Ultrafiltration + UV disinfection | Disk filtration + UV disinfection | Ultrafiltration + UV disinfection |

| Input | ||||

| Irrigation water | m3/ha | 5000 | 3160 | 3300 |

| Electricity | kWh/ha | 8400 | 2085.6 | 1760 |

| N-based fertilizers | kg/ha | 200 | 131.5 | 180 |

| P-based fertilizers | kg/ha | 250 | 70 | 70 |

| K-based fertilizers | kg/ha | 100 | 70 | 80 |

| Diesel fuel | kg/ha | 572 | 205 | 323 |

| Machine time | h/ha | 170 | 30 | 76 |

| Pesticide | kg/ha | - | 12.4 | 17 |

| Farm Output | ||||

| Crop Yield with reclaimed water | ton/ha | 80 | 21 | 8.5 |

| Ammonia | kg/ha | 24.28 | 15.96 | 21.85 |

| Dinitrogen monoxide | kg/ha | 4.16 | 2.74 | 3.75 |

| Nitrogen oxides | kg/ha | 0.66 | 0.43 | 0.59 |

| Nitrates | kg/ha | 263.75 | 173.41 | 237.37 |

| Ammonia | kg/ha | 0.01202 | 0.00431 | 0.00679 |

| Benzo(a)pyrene | kg/ha | 1.66 × 10−5 | 6.47 × 10−6 | 1.02 × 10−5 |

| Cadmium | kg/ha | 6.02 × 10−6 | 2.16 × 10−6 | 3.14 × 10−6 |

| Carbon dioxide, fossil | kg/ha | 1879.0 | 673.4 | 1061.1 |

| Carbon monoxide, fossil | kg/ha | 6.85 | 2.45 | 3.87 |

| Chromium | kg/ha | 3.01 × 10−5 | 1.08 × 10−5 | 1.7 × 10−5 |

| Copper | kg/ha | 0.00102 | 0.00037 | 0.00058 |

| Dinitrogen monoxide | kg/ha | 0.0721 | 0.0258 | 0.0407 |

| Tetrachlorodibenzo-p-dioxin | kg/ha | 3.64 × 10-11 | 1.29 × 10−11 | 2.03 × 10−11 |

| Methane, fossil | kg/ha | 0.097 | 0.035 | 0.055 |

| Nickel | kg/ha | 4.22 × 10−5 | 1.51 × 10−5 | 2.38 × 10−5 |

| Nitrogen oxides | kg/ha | 265.1 | 95.0 | 149.7 |

| NMVOC | kg/ha | 3.11 | 1.11 | 1.76 |

| PAH, polycyclic aromatic hydrocarbons | kg/ha | 0.0020 | 0.0007 | 0.0011 |

| Particulates, <2.5 um | kg/ha | 2.43 | 0.87 | 1.37 |

| Particulates, >10 um | kg/ha | 0.162 | 0.058 | 0.091 |

| Particulates, >2.5 um, and <10 um | kg/ha | 0.108 | 0.039 | 0.061 |

| Selenium | kg/ha | 6.02 × 10−6 | 2.16 × 10−6 | 3.4 × 10−6 |

| Sulfur dioxide | kg/ha | 0.61 | 0.22 | 0.34 |

| Zinc | kg/ha | 6.02 × 10−4 | 2.16 × 10−4 | 3.4 × 10−4 |

| Impact Categories | Unit | Monetization Factors |

|---|---|---|

| Fine particulate matter formation | kg PM2.5-eq | 14.00 |

| Fossil resource scarcity | kg oil eq | 0.39 |

| Freshwater ecotoxicity | kg 1,4-DCB eq | 0.008 |

| Freshwater eutrophication | kg P eq. | 2.00 |

| Global warming | kg CO2-eq | 0.15 |

| Human carcinogenic toxicity | kg 1,4-DCB eq | 0.24 |

| Human non—carcinogenic toxicity | kg 1,4-DCB eq | 0.016 |

| Ionizing radiation | kBq Co-60-eq | 0.00061 |

| Land use | m2a crop eq | 0.10 |

| Marine ecotoxicity | kg 1,4-DCB eq | 0.0012 |

| Marine eutrophication | kg N eq. | 3.10 |

| Mineral resource scarcity | kg Cu eq | 0.20 |

| Ozone formation, Human health | kg NOx-eq | 0.066 |

| Ozone formation, Terrestrial ecosystems | kg NOx-eq | 0.0093 |

| Stratospheric ozone depletion | kg CFC11-eq | 38.00 |

| Terrestrial acidification | kg SO2-eq. | 2.73 |

| Terrestrial ecotoxicity | kg 1,4-DCB eq | 0.00013 |

| Water consumption | m3 | 0.045 |

| Parameter | Unit | Tomatoes | Table Grapes | Artichokes |

|---|---|---|---|---|

| Reclaimed water | €/m3 | 0.24 | 0.53 | 0.42 |

| Groundwater | €/m3 | 0.1 | 0.62 | 0.37 |

| Electricity | €/kWh | 0.12 | 0.12 | 0.12 |

| Nitrogen fertilizers | €/kg | 1.60 | 0.33 | 0.33 |

| P-based fertilizers | €/kg | 0.96 | 0.25 | 0.25 |

| K-based fertilizers | €/kg | 2.40 | 0.55 | 0.55 |

| Diesel fuel | €/kg | 1 | 1 | 1 |

| Machine | €/h | 25 | 25 | 25 |

| Pesticide | €/kg | - | 12.40 | 17.00 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Canaj, K.; Mehmeti, A.; Berbel, J. The Economics of Fruit and Vegetable Production Irrigated with Reclaimed Water Incorporating the Hidden Costs of Life Cycle Environmental Impacts. Resources 2021, 10, 90. https://doi.org/10.3390/resources10090090

Canaj K, Mehmeti A, Berbel J. The Economics of Fruit and Vegetable Production Irrigated with Reclaimed Water Incorporating the Hidden Costs of Life Cycle Environmental Impacts. Resources. 2021; 10(9):90. https://doi.org/10.3390/resources10090090

Chicago/Turabian StyleCanaj, Kledja, Andi Mehmeti, and Julio Berbel. 2021. "The Economics of Fruit and Vegetable Production Irrigated with Reclaimed Water Incorporating the Hidden Costs of Life Cycle Environmental Impacts" Resources 10, no. 9: 90. https://doi.org/10.3390/resources10090090

APA StyleCanaj, K., Mehmeti, A., & Berbel, J. (2021). The Economics of Fruit and Vegetable Production Irrigated with Reclaimed Water Incorporating the Hidden Costs of Life Cycle Environmental Impacts. Resources, 10(9), 90. https://doi.org/10.3390/resources10090090