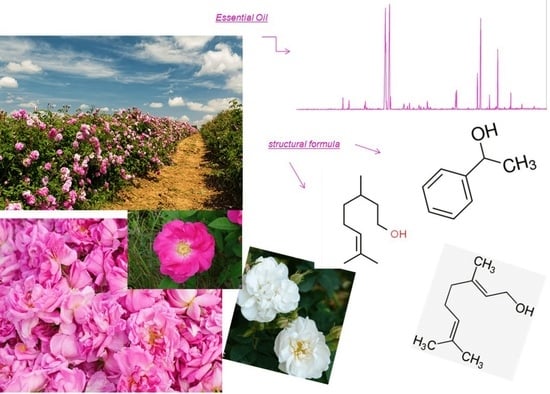

Comparative Study of the Yield and Chemical Profile of Rose Oils and Hydrosols Obtained by Industrial Plantations of Oil-Bearing Roses in Bulgaria

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials Collection and Identification

2.2. Distillation of Rose Oil and Hydrolats—Technological Conditions

2.3. Chromatographic Procedure

2.3.1. GC-FID/MS Analysis of Essential Oils

2.3.2. GC-FID/MS Analysis of Hydrosols

2.4. Chemicals and Solvents

2.5. Statistical Analysis

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Pal, P.K. Evaluation, genetic diversity, recent development of distillation method, challenges, and opportunities of Rosa damascena: A review. J. Essent. Oil Bear. Plants 2013, 16, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Rusanov, K.; Kovacheva, N.; Dobreva, A.; Atanassov, I. Rosa x damascena Mill. (Rose). In Medicinal, Aromatic and Stimulant Plants; Springer: Cham, Switzerland, 2020; pp. 467–500. [Google Scholar]

- Astadzhov, N. Studies on the Diversity of the Population of the Kazanlak Rose and Some Issues of Reproduction and Breeding to Improve Rose Production in Bulgaria. Ph.D. Thesis, Plovdiv, Bulgaria, 1988; p. 317. [Google Scholar]

- Naquvi, J.K.; Ansari, H.S.; Ali, M.; Najmi, A.K. Volatile oil composition of Rosa damascena Mill. (Rosaceae). Int. J. Pharmacogn Phytochem. 2014, 2, 177–181. [Google Scholar]

- Kovacheva, N.; Rusanov, K.; Atanassov, I. Industrial Cultivation of Oil-Bearing Rose and Rose Oil Production in Bulgaria During 21ST Century, Directions and Challenges. Biotechnol. Biotechnol. Equip. 2010, 24, 1793–1798. [Google Scholar] [CrossRef] [Green Version]

- Rusanov, R.; Kovacheva, N.; Rusanova, M.; Atanassov, I. Low variability of flower volatiles of Rosa damascena Mill. plants from rose plantations along the Rose Valley, Bulgaria. Ind. Crops Prod. 2012, 37, 6–10. [Google Scholar] [CrossRef]

- Kovatcheva, N.; Zheljazkov, V.; Astatkie, T. Productivity, oil content, composition, and bioactivity of oil-bearing rose accessions. HortScience 2011, 46, 710–714. [Google Scholar] [CrossRef] [Green Version]

- Dobreva, A.; Tintchev, F.; Heinz, V.; Schulz, H.; Toepfl, S. Effect of pulsed electric fields (PEF) on oil yield and quality during distillation of white oil-bearing rose (Rosa alba L.). J. Herbs Spices Med. Plants 2010, 15, 127–132. [Google Scholar]

- Kovacheva, N.; Rusanov, R. Introduced Species and Varieties of Oil-Bearing Roses in Kazanlak Field Conditions. Plant Sci. 2013, 50, 88–91. [Google Scholar]

- Kovatcheva, N.; Dobreva, A.; Petkov, M. Assessment of Essential Oils from Oil- Bearing roses. 20th International Scientific Conference—St. Zagora. Agric. Sci. J. Plant Stud. 2010, I, 187–192. [Google Scholar]

- Acimovic, M.; Teševic, V.; Smiljanic, K.; Cvetkovic, M.; Stankovic, J.; Kiprovski, B.; Sikora, V. Hydrolates: By-Products of Essential Oil Distillation: Chemical Composition, Biological Activity and Potential Uses. Adv. Technol. 2020, 9, 54–70. [Google Scholar] [CrossRef]

- ISO 9842:2003; Oil of Rose (Rosa x damascena Miller). International Organization for Standardization: Geneva, Switzerland, 2003. Available online: https://www.iso.org/standard/28611.html (accessed on 30 March 2023).

- Nazarenko, L.G. Raduga—New Sort Essential Oil Rose; Scientific Works of VNIEMK: Simpheropol, Ukraine, 1983; Volume 15, pp. 49–54. [Google Scholar]

- Staikov, V.; Balinova-Tsvetkova, A.; Decheva, R.; Kalaidjiev, I. Rose flower storage conditions and their influence on the quantity and quality of Rose Oil. Riv. Ital. 1975, 57, 176–180. [Google Scholar]

- NIST Chemistry WebBook. Available online: https://doi.org/10.18434/T4D303 (accessed on 10 January 2023).

- Baydar, H. Oil-bearing rose (Rosa damascena Mill.) cultivation and rose oil industry in Turkey. Eur. Cosmet. Mark. 2006, 14, 13–17. [Google Scholar]

- Kovacheva, N. Investigation on introduction species of oil—Bearing roses. In Proceedings of the International Science Conference, Stara Zagora, Bulgaria, 4–5 June 2008; pp. 1–6. [Google Scholar]

- Nedkov, N.; Kanev, K.; Kovacheva, N.; Stanev, S.; Djurmanski, A.; Seikova, K.; Lambev, H.; Dobreva, A. Handbook of major essential oil crops; Helicon: Kazanlak, Bulgaria, 2005. [Google Scholar]

- Baydar, H.; Baydar, G. The effects of harvest date, fermentation duration and Tween 20 treatment on essential oil content and composition of industrial oil rose (Rosa damascena Mill.). Ind. Crops Prod. 2005, 21, 251–255. [Google Scholar] [CrossRef]

- Erbas, S.; Baydar, H. Variation in scent compounds of oil-bearing Rose (Rose damascena Mill.) produced by Headspace Solid Phase Microextraction, hydrodistillation and solvent extraction, Academy of Chemistry of Globe publications. Rec. Nat. Prod. 2016, 10, 555–565. [Google Scholar]

- Karami, A.; Zandi, A.; Khosh-Khui, M.; Salehi, H.; Saharkhiz, J.M. Analysis of essential oil from nine distinct genotypes of Iranian Damask rose (Rosa damascena Mill). J. Med. Plants Res. 2012, 6, 5495–5498. [Google Scholar]

- Shamspur, T.; Mostafavi, A. Chemical Composition of the Volatile Oil of Rosa Kazanlik and Rosa gallica from Kerman Province in Iran. J. Essent. Oil-Bear. Plants 2010, 13, 78–84. [Google Scholar] [CrossRef]

- Khan, M.A.; Rehman, S.U. Extraction and analysis of essential oil of Rosa species. Int. J. Agric. Biol. 2005, 7, 973–974. [Google Scholar]

- Labadie, C.; Ginies, C.; Guinebretiere, M.H.; Renard, C.; Cerutti, C.; Carlin, F. Hydrosols of orange blossom (Citrus aurantium) and rose flower (Rosa damascena and Rosa centifolia) support the growth of a heterogeneous spoilage microbiota. Int. Food Res. J. 2015, 76, 576–586. [Google Scholar] [CrossRef] [Green Version]

- Yazdanfar, N.; Mohamadi, S.; Zienali, T.; Sadighara, P. Quantification of Methanol, Ethanol, and Essential Oil Contents of Commonly Used Brands of Rosewater (Rosa damascena) in Iran. J. Nutr. Food Secur. 2022, 7, 374–378. [Google Scholar] [CrossRef]

- Ohloff, G.; Demole, E. Importance of the odoriferous principle of Bulgarian rose oil in flavor and fragrance chemistry. J. Chromatogr. A 1987, 406, 181–183. [Google Scholar] [CrossRef]

- Nicolov, N.; Tsoutsulova, A.; Nenov, N. Essence de Roses et aures huiles essentielles Bulgares. Riv. Ital. 1976, 58, 349–365. [Google Scholar]

- Baser, K.H. Turkish rose oil. Perfum. Flavor. 1992, 17, 45–52. [Google Scholar]

- Kovats, E. Composition of essential oils. 7. Bulgarian oil of rose (Rosa damascena Mill). J. Chromatogr. 1987, 406, 185–222. [Google Scholar]

- Omata, A.; Yomogida, K.; Nakamura, S.; Ota, T.; Toyoda, T.; Amano, A.; Mura, S. New sulphur components of roses oil. Flavour Fragr. J. 1991, 6, 149–152. [Google Scholar] [CrossRef]

- Tambe, E.; Gotmare, S. Study of Variation and Identification of Chemical Composition in Rosa Species Oil Collected from Different Countries. J. Appl. Chem. 2016, 9, 11–18. [Google Scholar]

- Toluei, Z.; Hosseini; Tafreshi, S.; Arefi; Torkabadi, M. Comparative Chemical Composition Analysis of Essential Oils in Different Populations of Damask Rose from Iran. J. Agric. Sci. Technol. 2019, 21, 423–437. [Google Scholar]

- Dobreva, A.; Velcheva, A.; Bardarov, V.; Bardarov, K. Chemical composition of different genotypes oil-bearing roses. Bulg. J. Agric. Sci. 2013, 19, 1213–1218. [Google Scholar]

- Neshev, G. Bulgarian Rose Oil—Pharmacological and Clinical Studies. Ph.D. Thesis, Medical Academy, Sofia, Bulgaria, 1990. [Google Scholar]

- Wittig, C.; Scheuer, C.; Parakenings, J.; Menger, M.D.; Laschke, M.W. Geraniol Suppresses Angiogenesis by Downregulating VEGF. PLoS ONE 2015, 10, e0131946. [Google Scholar] [CrossRef] [Green Version]

- Report of Carcinogens, 15th ed.; Methyleugenol. Available online: http://ntp.niehs.nih.gov/go/roc (accessed on 7 June 2023).

- Chipiga, A.; Volchenkov, V. On the intensification of the main technological processes of the essential oil-bearing raw material processing. In Proceedings of the 7th International Congress of Essential Oils, Kyoto, Japan, 7–11 October 1977; pp. 93–94. [Google Scholar]

- Ahsan, M.; Younis, A.; Nafees, M.; Tufail, A.; Shakeel, Q.; Raheel, M.; Nawaz, F.; Jaskani, M.; Amin, M.; Sajid, M.; et al. Marginal quality water arbitrated essential oil contents in metal hoarded flower petals of scented roses. Ecotoxicol. Environ. Saf. 2021, 226, 112853. [Google Scholar] [CrossRef]

- Younis, A.; Riaz, A.; Khan, M.A.; Khan, A. Effect of time of growing season and time of day for flower harvest on flower yield and essential oil quality and quantity of four rosa cultivars. Flori. Ornam. Biotech. 2009, 3, 98–103. [Google Scholar]

- Roques, D. My Favourite Rose. IFEAT World. 2018. Available online: www.ifeat.org (accessed on 1 July 2023).

- Tanjga, B.B.; Lončar, B.; Aćimović, M.; Kiprovski, B.; Šovljanski, O.; Tomić, A.; Travičić, V.; Cvetković, M.; Raičević, V.; Zeremski, T. Volatile Profile of Garden Rose (Rosa hybrida) Hydrosol and Evaluation of Its Biological Activity In Vitro. Sci. Hortic. 2022, 8, 895. [Google Scholar] [CrossRef]

- Katekar, V.; Rao, A.; Sardeshpande, V. A cleaner and ecological rosewater production technology based on solar energy for rural livelihood. Clean. Circ. Bioeconomy 2022, 2, 100022. [Google Scholar] [CrossRef]

- Tomi, K.; Sakaguchi, E.; Ueda, S.; Matsumura, Y.; Hayashi, T. Physiological and Psychological Effects of Rose ‘Wishing’ Flowers and Their Hydrosols on the Human Autonomic Nervous System and Mood State. J. Hortic. 2017, 86, 105–112. [Google Scholar] [CrossRef] [Green Version]

| № | Compound | RI Calc. | RI Lit. | Main and Character Constituents, Rel.% | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| R. damascena | R. alba | R. gallica | R. centifolia | Rosa Raduga | R. damascena + Rosa Raduga | Rosa Krun | ||||

| 1 | Ethanol | 489 | 489 | tr | tr | tr | tr | tr | tr | tr |

| 2 | α-Pinene | 939 | 939 | tr | 0.01 ± 0.00 | tr | 0.21 ± 0.01 | tr | 0.01 ± 0.00 | tr |

| 3 | Limonene | 1031 | 1033 | tr | 4.81 ± 0.03 | 1.19 ± 0.01 | 0.78 ± 0.03 | 0.19 ± 0.03 | 0.10 ± 0.01 | tr |

| 4 | Linalool | 1097 | 1098 | 0.06 ± 0.01 | 1.34 ± 0.05 | 1.54 ± 0.01 | 1.26 ± 0.03 | 0.36 ± 0.05 | 0.15 ± 0.02 | 0.01 ± 0.00 |

| 5 | Phenylethanol | 1110 | 1110 | 65.52 ± 2.50 | 27.45 ± 0.92 | 42.47 ± 1.54 | 36.61 ± 0.92 | 69.88 ± 0.72 | 67.21 ± 1.12 | 29.54 ± 0.92 |

| 6 | Cis-rose oxide | 1106 | 1106 | 0.02 ± 0.00 | n.d. | n.d. | n.d. | 0.01 ± 0.00 | tr | n.d. |

| 7 | Trans-rose oxide | 1126 | 1126 | 0.01 ± 0.00 | n.d. | n.d. | n.d. | n.d. | n.d. | n.d. |

| 8 | Citronellol + Nerol | 1229 * | 1228 * | 8.94 ± 0.92 | 17.37 ± 0.78 | 8.80 ± 1.10 | 16.25 ± 0.92 | 4.56 ± 0.82 | 8.01 ± 0.12 | 6.11 ± 0.12 |

| 9 | Geraniol | 1248 | 1246 | 14.48 ± 1.12 | 28.67 ± 0.92 | 24.42 ± 1.10 | 17.55 ± 0.10 | 13.72 ± 1.12 | 13.96 ± 0.92 | 14.87 ± 0.52 |

| 10 | Eugenol | 1348 | 1351 | 1.58 ± 0.92 | 1.18 ± 0.03 | 0.67 ± 0.03 | 1.22 ± 0.05 | 0.13 ± 0.03 | 0.90 ± 0.05 | 0.78 ± 0.03 |

| 11 | Geranylacetate | 1352 | 1352 | 0.33 ± 0.03 | 0.39 ± 0.05 | 0.62 ± 0.001 | 0.38 ± 0.03 | 0.39 ± 0.01 | 0.39 ± 0.03 | 0.42 ± 0.03 |

| 12 | Methyl eugenol | 1405 | 1405 | 0.22 ± 0.03 | 0.08 ± 0.01 | 0.04 ± 0.00 | 0.03 ± 0.00 | 0.04 ± 0.00 | 0.18 ± 0.00 | 0.04 ± 0.00 |

| 13 | Heptadecane (C17) | 1700 | 1700 | 0.01 ± 0.00 | 0.06 ± 0.01 | 0.09 ± 0.01 | 0.14 ± 0.03 | 0.02 ± 0.00 | 0.01 ± 0.00 | 0.02 ± 0.00 |

| 14 | Farnesol | 1712 | 1713 | 0.15 ± 0.01 | 0.85 ± 0.03 | 0.13 ± 0.03 | 0.52 ± 0.05 | 0.12 ± 0.01 | 0.15 ± 0.03 | 0.12 ± 0.01 |

| 15 | Nonadecene | 1880 | 1880 | 0.02 ± 0.00 | 0.33 ± 0.03 | 0.13 ± 0.03 | 0.12 ± 0.01 | tr | 0.01 ± 0.00 | 0.02 ± 0.00 |

| 16 | Nonadecane (C19) | 1901 | 1901 | 0.10 ± 0.00 | 0.53 ± 0.01 | 0.66 ± 0.05 | 0.29 ± 0.03 | 0.17 ± 0.03 | 0.21 ± 0.01 | 0.57 ± 0.03 |

| 17 | Eicosane | 2000 | 2000 | 0.01 ± 0.00 | 0.05 ± 0.01 | 0.06 ± 0.01 | 0.03 ± 0.00 | 0.03 ± 0.00 | 0.01 ± 0.00 | 0.02 ± 0.00 |

| 18 | Heneicosane (C21) | 2100 | 2100 | 0.04 ± 0.00 | 0.25 ± 0.03 | 0.17 ± 0.03 | 0.14 ± 0.01 | 0.06 ± 0.01 | 0.06 ± 0.01 | 0.14 ± 0.00 |

| 19 | Tricosane (C23) | 2300 | 2300 | 0.01 ± 0.00 | 0.05 ± 0.00 | 0.07 ± 0.01 | 0.07 ± 0.01 | 0.12 ± 0.03 | 0.01 ± 0.00 | 0.05 ± 0.00 |

| 20 | Pentacosane | 2500 | 2500 | 0.09 ± 0.01 | 0.37 ± 0.03 | 0.30 ± 0.03 | 0.26 ± 0.07 | 0.20 ± 0.03 | 0.24 ± 0.01 | 0.31 ± 0.03 |

| 21 | Heptacosane | 2700 | 2700 | 0.02 ± 0.00 | 0.05 ± 0.00 | 0.05 ± 0.01 | 0.03 ± 0.00 | 0.07 ± 0.01 | 0.02 ± 0.00 | 0.04 ± 0.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dobreva, A.; Nedeva, D.; Mileva, M. Comparative Study of the Yield and Chemical Profile of Rose Oils and Hydrosols Obtained by Industrial Plantations of Oil-Bearing Roses in Bulgaria. Resources 2023, 12, 83. https://doi.org/10.3390/resources12070083

Dobreva A, Nedeva D, Mileva M. Comparative Study of the Yield and Chemical Profile of Rose Oils and Hydrosols Obtained by Industrial Plantations of Oil-Bearing Roses in Bulgaria. Resources. 2023; 12(7):83. https://doi.org/10.3390/resources12070083

Chicago/Turabian StyleDobreva, Ana, Deyana Nedeva, and Milka Mileva. 2023. "Comparative Study of the Yield and Chemical Profile of Rose Oils and Hydrosols Obtained by Industrial Plantations of Oil-Bearing Roses in Bulgaria" Resources 12, no. 7: 83. https://doi.org/10.3390/resources12070083

APA StyleDobreva, A., Nedeva, D., & Mileva, M. (2023). Comparative Study of the Yield and Chemical Profile of Rose Oils and Hydrosols Obtained by Industrial Plantations of Oil-Bearing Roses in Bulgaria. Resources, 12(7), 83. https://doi.org/10.3390/resources12070083