Influence of Parasitic Effects in Negative Differential Resistance Characteristics of Resonant Tunneling

Abstract

:1. Introduction

2. Research Theory and Method

3. Results and Discussion

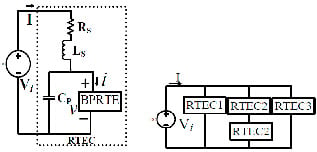

3.1. Design of RTEC Unit

3.2. Simulation of Single PVCDR Value Using RTEC Unit without Cp, RS, and LS

3.3. Simulation of Single PVCDR Value Using RTEC Unit with Cp, RS, and LS

3.4. Simulation of Multiple PVCDR Values Using Two RTEC Units with Cp, RS, and LS

3.5. Simulation of Triple PVCDR Values Using RTEC Units with Cp, RS, and LS

3.6. Experiment of Single PVCDR Value in RTEC Unit

3.7. Practical Double PVCDR RTEC Unit

4. Conclusions

Funding

Conflicts of Interest

References

- Yang, C.C. Influence of parasitic effects in negative differential resistance characteristics of resonant. In Proceedings of the IEEE International Symposium on Computer, Consumer and Control, Taichung, Taiwan, 6–8 December 2018. [Google Scholar]

- Ji, Y.C.; Chang, S.; Wang, H.; Huang, Q.; He, J.; Yi, F. Multi-valued logic design methodology with double negative differential resistance transistors. IET Micro Nano Lett. 2017, 12, 738–743. [Google Scholar] [CrossRef]

- Yang, C.C. High performance multiple stepped quantum well resonant microwave devices. Electron. Lett. 2006, 42, 1485–1487. [Google Scholar] [CrossRef]

- Yang, C.C.; Su, Y.K. Well-defined electrical properties high-strain resonant interband tunneling structure. Microelectron. J. 2008, 39, 67–69. [Google Scholar] [CrossRef]

- Yang, C.C.; Su, Y.K. High performance aluminum arsenic intraband resonant microwave devices. Microelectron. J. 2008, 39, 90–93. [Google Scholar] [CrossRef]

- Tsu, R.; Esaki, L. Tunneling in a finite superlattice. Appl. Phys. Lett. 1973, 22, 562–564. [Google Scholar] [CrossRef]

- Mokhov, A.; Burns, F.P.; Murphy, J.P.; Koelmans, A.; Yakovlev, A. Mixed radixreed-muller expansions. IEEE Comput. 2012, 61, 1189–1202. [Google Scholar]

- Khan, M.E.; Lee, J.H.; Byeon, S.J.; Kim, Y.H. Semimetallicity and negative differential resistance from hybrid halideperovskite nanowires. Adv. Funct. Mater. 2019, 29, 1807620. [Google Scholar] [CrossRef]

- Felix, A.B.; Pacheco, M.; Orellana, P.; Latgé, A. Negative differential resistance in hybrid carbon-based structures. Phys. Rev. 2019, B99, 195442. [Google Scholar] [CrossRef]

- Seabaugh, A.C.; Kao, Y.C.; Yuan, H.T. Nine-state resonant tunneling diode memory. IEEE Electron. Device Lett. 1992, 13, 479–481. [Google Scholar] [CrossRef]

- Zhou, J.R.; Han, G.Q.; Li, J.; Liu, Y.; Peng, Y.; Zhang, J.C.; Sun, Q.Q.; Zhang, D.W.; Hao, Y. Negative differential resistance in negative capacitance EFTs. IEEE Electron. Device Lett. 2018, 39, 622–625. [Google Scholar] [CrossRef]

- Atmaca, Ö.; Narin, P.; Kutlu, E.; Malin, T.V.; Mansurov, V.G.; Zhuravlev, K.S.; Lişesivdin, S.B.; Özbay, E. Negative differential resistance observation and a new fitting model for electron drift velocity in GaN-based heterostructures. IEEE Trans. Electron. Devices 2018, 65, 950–956. [Google Scholar] [CrossRef]

- Ulansky, V.; Raza, A.; Oun, H. Electronic circuit with controllable negative differential resistance and its applications. Electronics 2019, 8, 409. [Google Scholar] [CrossRef]

- Shin, J.M.; Ko, E.N.; Shin, C.H. Analysis on the operation of negative differential resistance Fin FET with Pb (Zr0.52Ti0.48)O3 threshold selector. IEEE Trans. Electron. Devices 2018, 65, 19–22. [Google Scholar] [CrossRef]

- Hwang, W.S.; Tahy, K.; Myers-Ward, R.L.; Campbell, P.M.; Eddy, C.R., Jr.; Gaskill, D.K.; Xing, H.; Seabaugh, A.C.; Jena, D. Fabrication of top-gated epitaxial grapheme nano-ribbon FETs using hydrogen silsesquioxane (HSQ). J. Vac. Sci. Technol. B 2012, 30, 104–108. [Google Scholar] [CrossRef]

- Zhang, T.; Guérin, D.; Alibart, F.; Vuillaume, D.; Lmimouni, K.; Lenfant, S.; Yassin, A.; Oçafrain, M.; Blanchard, P.; Roncali, J. Functions based on monolayer devices derived from gold nanoparticles functionalized with electropolymerizable TEDOT units. J. Phys. Chem. C 2017, 121, 10131–10139. [Google Scholar] [CrossRef]

- Breuil, L.; Haspeslagh, L.; Blomme, P.; Wellekens, D.; DeVos, J.; Lorenzini, M.; Van Houdt, J. A new scalable self-aligned dual-bit split-gate charge-trapping memory device. IEEE Trans. Electron. Devices 2005, 52, 2250–2257. [Google Scholar] [CrossRef]

| Characteristics of Single PVCDR RETC | |||||

| PCD (A) | VCD (A) | PV (V) | VV (V) | PVCDR | |

| nth NDR peak | 1st | 1st | 1st | 1st | 1st |

| Simulation without Cp, RS, LS [1] | 1.32 | 0.10 | 0.25 | 0.44 | 13.2 |

| Simulation with Cp, RS, LS [1] | 1.35 | 0.20 | 0.28 | 0.46 | 6.75 |

| Experiment without Cp, RS, LS [1] | 32μ | 1.4μ | 1.1 | 1.2 | 23 |

| Paralleled structure of units | 2.6 | 0.5 | 0.44 | 0.52 | 5.2 |

| Ref [13] | 15m | 6m | 1.75 | 7.0 | 2.5 |

| Characteristics of Double PVCDR RTEC | |||||

| PCD (A) | VCD (A) | PV (V) | VV (V) | PVCDR | |

| nth NDR peak | 1st | 1st | 1st | 1st | 1st |

| Simulation with Cp, RS, LS | 1.80 | 0.95 | 0.29 | 0.36 | 1.89 |

| Experiment without Cp, RS, LS | 44μ | 2 μ | 1.60 | 1.80 | 22 |

| Characteristics of Double PVCDR RTEC | |||||

| PCD (A) | VCD (A) | PV (V) | VV (V) | PVCDR | |

| nth NDR peak | 2nd | 2nd | 2nd | 2nd | 2nd |

| Simulation with Cp, RS, LS | 1.85 | 1.10 | 0.66 | 0.72 | 1.68 |

| Experiment without Cp, RS, LS | 42μ | 2μ | 2.20 | 2.80 | 21 |

| Characteristics of Triple PVCDR RETC | |||||

| PCD (A) | VCD (A) | PV (V) | VV (V) | PVCDR | |

| nth NDR peak | 1st | 1st | 1st | 1st | 1st |

| Simulation with Cp, RS, LS | 2.6 | 1.7 | 0.32 | 0.36 | 1.5 |

| Experiment without Cp, RS, LS | 36μ | 24μ | 1.2 | 1.3 | 1.5 |

| Characteristics of Triple PVCDR RETC | |||||

| PCD (A) | VCD (A) | PV (V) | VV (V) | PVCDR | |

| nth NDR peak | 2nd | 2nd | 2nd | 2nd | 2nd |

| Simulation with Cp, RS, LS | 2.7 | 2.1 | 0.53 | 0.53 | 1.3 |

| Experiment without Cp, RS, LS | 44μ | 8μ | 1.6 | 1.8 | 5.5 |

| Characteristics of Triple PVCDR RETC | |||||

| PCD (A) | VCD (A) | PV (V) | VV (V) | PVCDR | |

| nth NDR peak | 3rd | 3rd | 3rd | 3rd | 3rd |

| Simulation with Cp, RS, LS | 2.9 | 2.0 | 0.74 | 0.77 | 1.5 |

| Experiment without Cp, RS, LS | 46μ | 10μ | 2.2 | 2.8 | 4.6 |

© 2019 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, C.C. Influence of Parasitic Effects in Negative Differential Resistance Characteristics of Resonant Tunneling. Electronics 2019, 8, 673. https://doi.org/10.3390/electronics8060673

Yang CC. Influence of Parasitic Effects in Negative Differential Resistance Characteristics of Resonant Tunneling. Electronics. 2019; 8(6):673. https://doi.org/10.3390/electronics8060673

Chicago/Turabian StyleYang, Chih Chin. 2019. "Influence of Parasitic Effects in Negative Differential Resistance Characteristics of Resonant Tunneling" Electronics 8, no. 6: 673. https://doi.org/10.3390/electronics8060673

APA StyleYang, C. C. (2019). Influence of Parasitic Effects in Negative Differential Resistance Characteristics of Resonant Tunneling. Electronics, 8(6), 673. https://doi.org/10.3390/electronics8060673