2.1. Materials and Methods

The setup used in these experiments was designed in the first part of this research project [

2]. In this first study, numerical simulations were performed in order to design a setup optimizing mode excitation. It consisted of a 304 stainless steel flat plate, 1.6 mm thick, with five actuators attached to excite the natural frequencies of the structure. The plate was placed between two massive steel 44 w 50.8 mm (2″) thick blocks to create a Clamped-Clamped-Free-Free (CCFF) boundary conditions. The dimensions of the plate were 500 m (L) × 200 mm (W) (

Figure 1). Five Physik Instrumente (PI) P-876.A15 actuator patches were installed on the lower surface of the plate, at the centerline of the plate in the width direction. The patches, which are 61 mm in length by 35 mm wide with a total thickness of 0.8 mm, were positioned, as determined in the first phase of the project [

2], at both extremities of the plate, at its center and at 16 cm from each edge (

Figure 2).

A miniature single axis piezoelectric accelerometer was installed on one edge of the plate for acceleration measurements (

Figure 1). PCB Piezotronics model 352C22 was selected for the broad frequency range, dynamic range, small size and low weight. To drive and monitor the piezoelectric actuator system, an electrical system is required. This system uses an Agilient 33500B waveform generator to provide the electrical signal to the actuators. The driving signal for the actuators was amplified using an Amp-line AL-1000-HF-A amplifier with a range of 50 to 1000 V to generate the required vibration level. Since the operational voltage of the actuators is −250 to 1000 V, an Amp-line AL-100DC power source was used to offset the voltage to allow testing close to the limit of the actuators. By offsetting the voltage to values around 400 or 500 V, an alternative voltage of 1000 to 1250 Vpp could be applied without compromising the integrity of the actuators. The voltage applied to the actuators was measured with a Fluke 105B oscilloscope. To monitor and record the signal from the accelerometer a high sample rate National Instrument PCIe-6346 data acquisition card is used.

2.2. Results

Using frequency sweeps to achieve de-icing on a structure has been proven successful in a previous study [

4]. Ice cracking and delamination was only achieved in the past when sweeping through different frequency ranges, while all testing performed at fixed frequency were unsuccessful. The activation of the actuators with frequency sweeps during the de-icing tests performed during the previous studies were mostly based on trial and error. To better understand the phenomena occurring during frequency sweeps and the reasons for the successful de-icing, an investigation of the vibration response of the flat plate structure to frequency sweeps was performed experimentally. Frequency sweeps were performed at 200 Vpp with a single piezoelectric actuator. Those frequency sweeps were performed by linearly increasing in time the excitation frequency of the piezoelectric actuator during a single test to excite a frequency band. A voltage of 200 Vpp was selected to obtain significant mode deployment, based on results obtained in the first paper [

2], while observing a safe range from the actuator voltage limit to avoid damage. The sweep range was set from 100 Hz to 2500 Hz, which corresponds to the frequency range where de-icing occurred in a previous study [

4]. Five different sweep durations were selected, 1, 2, 3, 5 and 10 s, to measure the effect of the frequency sweep rate on the mode deployment.

Figure 3 shows the plate acceleration measured on the edge for frequency sweeps with actuators 4 and 5. Due to the position of the actuator 3, only odd resonant modes (with an odd number of anti-nodes) can be properly excited and for this reason it was not used for testing [

2].

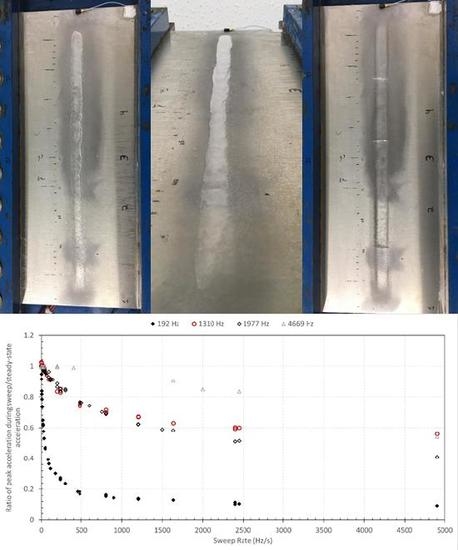

More testing was performed for individual resonant modes. For each of those modes, frequency sweeps were performed for different durations and different frequency ranges. The different frequency ranges were considered to determine if residual vibration of preceding modes during a frequency sweep can impact the acceleration amplitude and deployment obtained for a resonant mode. The resonant frequencies of 192 Hz, 1310 Hz, 1977 Hz and 4669 Hz were therefore selected due to the associated high relative acceleration peaks observed under frequency sweep excitation from 0 to 2500 Hz. The frequency sweeps were performed with piezoelectric actuator 5 and the amplitude of vibration for each sweep is presented in

Figure 4 as a function of the sweep rate. The amplitude of vibration obtained in steady-state mode is also shown for each mode.

2.3. Discussion

As is well known, the resonant modes activated by the actuators are easily distinguishable by the distinct peaks of the frequency response function. The two plots in

Figure 3 show that the resonant modes are not all activated by each actuator, and some modes have a better deployment (higher peak amplitudes) depending on the actuator activated, which was expected according to the conclusions obtained in the first phase of the project [

2].

Moreover, the two plots show that the vibration pattern is similar for all the different sweep durations when excited by the same actuator. The same modes are activated and their amplitude relative to the other modes is similar whether the frequency sweep is performed at a sweep rate of 2400 Hz/s (100 Hz to 2500 Hz in 1 s) or 240 Hz/s (100 Hz to 2500 Hz in 10 s). The acceleration amplitude for each resonant mode increases as frequency sweep rate decrease. For some modes, the amplitude is up to 1.8 times higher when the sweep rate is 240 Hz/s compared to 2400 Hz/s. These results indicate that when sweeping is performed at higher sweeping rates, complete mode deployment is not obtained and acceleration/displacement and stress generation is not optimal for de-icing operations. The vibration pattern being the same for all duration, there is no other transient effect distinguishable, like mode superposition or residual effect from previous activated modes, at those sweeping speed.

The results obtained for tests at individual resonant mode show that as the sweeping rate tends towards zero, acceleration tends toward the steady-state value, which means that there is no benefit in acceleration and displacement brought by transient effect during frequency sweeps from a de-icing perspective where maximum structural acceleration is targeted. This means that maximum mode deployment is obtained at a fixed frequency or when sweep rate tends towards zero.

The results also indicate that the frequency range of the sweep has no impact on the maximum acceleration and mode deployment during resonance. The curves for the vibration acceleration as a function of sweep rate for the different frequency range tested (

Figure 4) overlap each other and follow the same trends, which indicates that vibration of other modes deployed during the same frequency sweep does not influence mode deployment.

It is also possible to observe from

Figure 4a that at a lower frequency like 192 Hz, the maximum acceleration shows a very sharp increase at very low sweep rate while at a higher frequency like 4669 Hz (

Figure 4d), the maximum acceleration increases more steadily and reaches values close to the steady-state value at a much higher sweep rate.

Figure 5 presents the ratio of the maximum acceleration measured during sweep tests compared to the steady-state value in function of sweep rate. As expected, it can be observed that lower sweep rates are required to obtain significant mode deployment at low frequencies. With higher frequencies, faster sweep can be performed to obtain similar maximum acceleration ratio, which means that sweep rate during de-icing tests must take into account the frequency of the targeted modes to ensure sufficient mode deployment and strain generation. At a sweep rate of 4900 Hz/s, the ratio of acceleration compared to steady-state mode is below 0.56 for all the frequencies. At 200 Hz/s the ratio is 0.28 for 192 Hz, 0.84 for 1310 Hz, 0.88 for 1977 Hz and 0.99 for 4669 Hz, while at 20 Hz/s the ratio is above 0.98 for all frequencies except 192 Hz, where it is only 0.62.

Higher frequency equals a shorter time period for vibration cycle, which means that the same number of cycles for a mode occurs in less time than at lower frequency. The time and number of cycles before obtaining 95% of the steady-state acceleration is reached after voltage is applied is compared in

Table 1 for the four frequencies investigated. The number of cycles is in the same order of magnitude for all frequencies, ranging from 127 cycles to 297 cycles without a straight relationship to frequency value, while the time greatly diminishes as the frequency increases, from 0.660 s to 0.046 s.

The results of

Table 1 show that the transient effects occurring during frequency sweeps do not generate different deployments of the resonant modes and cannot provide increased acceleration values resulting in higher strain and stress generation on the plate. They also demonstrate that resonant modes require a minimum vibration cycle before they reach steady-state regime. During sweeping, if the sweep rate is too high, insufficient vibration cycles are generated, limiting the mode deployment and maximum acceleration amplitude obtained. As expected, as the sweep rate tends towards zero, the acceleration of a resonant mode during the sweep will tend towards its steady-state value. Since a minimum of vibration cycles is required for a complete mode deployment, this implies that at lower frequencies the time required to obtain full acceleration is higher. For this reason, lower sweep rates are required at lower frequencies. The frequency range of the sweep has no impact on the mode deployment and acceleration obtained for a resonant mode, meaning that no effect is transposed from mode to mode during the frequency sweeps performed. These conclusions indicate that frequency sweeps do not increase the amplitude of vibration during the de-icing process by generating higher acceleration or stress/strain on the plate and in an ice layer accumulated on the plate, and steady-state activation of a resonant mode is theoretically the ideal case. However, sweeping can help ensure that a resonant mode is excited by covering a defined frequency range. The exact frequency of a resonant mode will vary in function of the ice accumulation and other ambient condition effect impacting the mass and stiffness of the structure. By performing a frequency sweep, it is not required to target a very precise and specific frequency value that changes as the ice accumulates on the structure, which could be easier and more reliable for a de-icing system. The sweep rate of frequency sweeps, if used, must be studied appropriately to allow for a sufficient mode deployment and strain/stress optimal generation, while still permitting a rapid and efficient de-icing process. The conclusions obtained in this section do not explain the de-icing successes obtained with the frequency sweeps and unsuccessful results with steady-state frequencies in the previous phases of this project.