This paper describes the results of the third part of a research project investigating the use of piezoelectric actuators in a low-energy de-icing system that could be implemented on small rotorcraft. With all the problematics that rotorcraft encounter during inflight icing events, like decrease in lift and increase in drag, torque, vibration and imbalance, the industry is in active research to find a low-energy solution. Different approaches using piezoelectric actuators have been explored in the past. First investigated by Ramanathan [

1] and later by Palacios [

2], resonating piezoelectric elements were used to generate ultrasonic surface waves to produce shear stress at the ice interface. Venna and al. [

3] used piezoelectric actuators located directly below the iced zones of a NACA 0012 leading edge to generate both local shear strains and normal impulse forces to de-ice—however with limited success. In the first part of this project, an experimental setup of a piezoelectric actuators based de-icing system integrated to a flat plate structure was designed. A numerical model of that setup was developed and validated experimentally. In the second part, the test setup was used to investigate transient vibration during frequency sweeps and determine optimal excitation for de-icing. It was also used to validate the results of transient vibration analysis with de-icing tests in cold room.

As part of third phase of this study, an ice layer was added to the flat plate structure and investigated numerically and experimentally. Stresses involved in different ice breaking scenarios were studied. The tensile and compressive strength of atmospheric ice are important parameters with regard to predicting and modeling de-icing phenomenon. Ambient environmental conditions during accretion and substrate structural parameters have a significant impact on the properties of atmospheric ice. As opposed to freezer ice formed by a water volume exposed to below freezing temperature, atmospheric ice is formed by small water droplets impinging on a structure under representative atmospheric icing conditions. Several parameters influence ice strength, such as accretion temperature, wind speed, liquid water content, median volumetric diameter, strain rate, porosity, etc. Petrovic [

4] published a review of the mechanical properties of ice and snow. In his review, Petrovic stated that tensile strength for atmospheric icing in the literature typically range from 0.70 to 3.10 MPa, with an average value of 1.43 MPa between −20 °C and −10 °C [

5]. For compressive strength, the values range from 5 to 25 MPa. The main variables that impact ice strength raised by the literature includes temperature, strain rate, tested volume and grain size. Studies indicate that both the tensile and compressive strength of ice increase with decreasing temperature. Compressive strength dependence to temperature is related to the ice dislocation and grain boundary sliding phenomena and varies by a factor of 4 from −40 °C to 0 °C. Tensile strength shows less dependence on temperature, with a factor of 1.3 over the temperature range as provided in literature [

5], which can be explained by the localization of stress-accommodating mechanisms at the tips of tensile flaws. The other important parameters for de-icing is the adhesion strength of the ice to the structure. Guérin [

6] has shown in his study of the adhesion of ice on different substrates that the main parameters influencing the properties of ice accretion are the material conduction and the surface roughness. Two types of rupture can be observed: cohesive, which happen in the ice itself, and adhesive, which happens at the ice/substrate interface. The literature review showed that tensile efforts tend to create cohesive break, leaving a small layer of ice on the substrate. Shearing, on the other hand, will generally lead to an adhesive break with a complete removal of ice from the surface. Jellinek [

7] reported two different experiments on adhesive strength: shear and tensile. For the shear experiments, the adhesive strength increased linearly and rapidly with decreased in temperature. Pure adhesive breaks were obtained down to −13 °C. Below this temperature, breaks suddenly changed to cohesive, which were almost temperature independent. In the tensile experiments, adhesive strength in tension was at minimum 15 times greater than the one under shear experiments. Jellinek explained this phenomenon by the presence of a liquid-like layer at the interface which hold the ice and substrate together by surface tension forces, adding to the overall adhesion strength [

7]. The adherence due to a pressure difference across a curved liquid-like layer-air interface does not have to be overcome in shearing. Hardesty presented the different values found in literature for adhesion strength on a steel plate in function of temperature [

8]. At −8 °C, which represents the temperature of the cold room in this study, adhesion varies from 0.20 to 0.90 MPa between studies, with the vast majority of the values between 0.30 and 0.60 MPa. This is a common variation between studies involving ice parameters that is mainly caused by different testing methods and substrate conditions. Very few researches have investigated numerically vibration based de-icing while including ice layers in the numerical model. Budinger [

9,

10] provided a computational method to estimate voltages and currents to generate first ice cracks or delamination in a piezoelectric de-icing system. The method was based on modal analysis and validated through experiments. They obtained cracking due to tensile stress within the ice, which lead to small delamination zones which followed cracking propagation. They only obtained delamination without cracking, due to shear stress, at high frequencies above around 40 kHz. Furthermore, they separated resonant modes into flexural and extensional modes, where extensional modes were found at higher frequencies. Only cracking of the ice layer was successful with flexural mode on a flat plate, without delaminating it from the plate. There is more power consumption at higher frequencies, making the need for investigating delamination at lower frequencies paramount for low power de-icing. Tian et al. [

11] developed a shear stress model with ANSYS to analyze the distribution of the shear stress at the ice/substrate interface. They showed from the shear stress distribution that the delamination starts from the edges of the ice layer. The model developed was a simplified 2D model and no direct experimental validation was done. They still validated the conclusions obtained for shear stress distribution by delaminating small zones of frozen purified water poured at positions of high shear stress on the plate in a freezer. They located those high shear stress zones by observing the resulting distribution of power sprinkled on the plate and not with measuring devices. A validation of the model without ice accumulation was done for the frequency values of the resonant modes, but not for the vibration amplitudes. While they obtained good accordance between the model and the experiments for most of the modes investigated, some discrepancies were found for some resonant modes which were explained by the 2D simplification as well as the inaccuracy of some model parameters. Harvey [

12], followed by Villeneuve et al. [

13], demonstrated a proof of concept for de-icing with piezoelectric actuator patches exciting structural resonant frequencies (modes of vibration). Total or partial de-icing was successfully achieved for a flat plate, a thinned Bell 206 main rotor blade and a Bell 206 tail rotor blade sections. Numerical simulations were used to predict the resonant frequencies and the mode shapes to optimally position and drive the actuators. However, the damping was not accounted for in these studies [

13], and only frequency analyses were used to determine the optimal position of the actuators. Moreover the ice was not modeled numerically and no stresses analysis was performed.

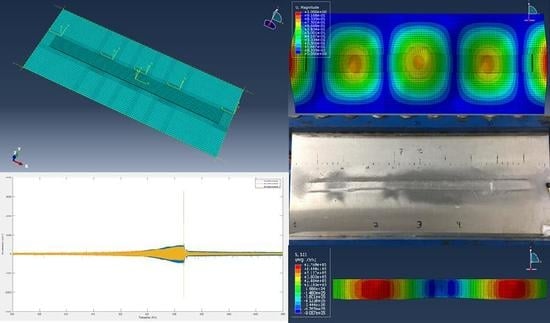

In this new study, an ice layer added on the surface of the structure was considered in the numerical model. Frequency analysis and direct steady-state dynamic analysis were performed with the numerical model and validated experimentally with the test setup. Numerical prediction of the stress calculated by the model were studied for the different ice breaking cases obtained experimentally and were used to predict ice breaking for different modes. The principal objective of this study was to characterize and validate an experimental set-up aiming at the de-icing of a structure using piezoelectric actuators to excite the natural modes of vibration of the structure. For completeness and to better highlight the objective and the outcome of this study it is important to reemphasize the preamble of the first article of the series of three describing the results and the methods used for this work [

14]: “Numerous challenges have been observed and addressed while implementing, numerically validating and characterizing this set-up. The numerical modal analysis implemented in this study faced some challenges related to the number and the dimensions of the required piezoelectric actuators. While it was evident that the success of the method was depending on the capability of the actuators to sustain and transfer the required power of excitation at a structural natural resonant frequency of interest, the dimensions of the actuator relative to the wavelength of vibration, their positioning and their number, as well as the phasing of excitation were expected to affect the integrity of some of the high frequency modes and consequently the ability to fully excite the targeted modes.” The numerical analysis served to validate the experimental observations and to define the parameters of the set-up to obtain the de-icing of a flat structure. The aim of this study was also to determine to what extent the large dimensions of the piezoelectric actuators would affect the integrity of the mode shapes, the efficiency of the set-up with regard to the numerically expected versus experimentally achieved amplitudes of deformation resulting in the required stresses generating the ice layer breaking. As was already stated in [

14], this comprehensive analysis comprises the evaluation of the numerical and experimental errors due to the sometime inefficient mode of excitation. This study allowed the full understanding of the expected performance of the set-up, shape of the modes of interest resulting in ice layer breaking and delamination as well as the optimal range of the amplitude voltage of excitation.