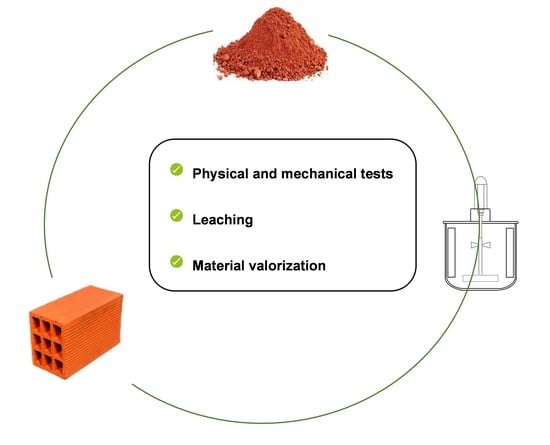

Valorization of Bayer Red Mud in a Circular Economy Process: Valuable Metals Recovery and Further Brick Manufacture

Abstract

:1. Introduction

2. Materials and Methods

2.1. Characterization of Red Mud and Clay

2.2. Red Mud Valorization by Leaching

2.3. Brick Manufacture

2.4. Heating Method for Firing Bricks

2.5. Testing Methods

2.5.1. Materials Characterization

2.5.2. Compressive Strength and Physical Tests

2.5.3. Environmental Assessment: Leaching Experiments

2.5.4. Radionuclide Activity

3. Results

3.1. Leaching Extraction

- Less than 10%: As, Ba, Ga, Mo, Mn, Pb, Se;

- 10–20%: Cr, Cu, Ni, Ti, and V;

- 20–50%: Sb and Zn;

- More than 50%: Ce, La, Sr, and Th.

3.2. Mathematical Leaching Models Description and Statistical Evaluation

3.3. Evaluation of the Solid Waste Remaining after Leaching

3.4. Physical Properties and Compressive Strength of Bricks

3.5. Environmental Properties

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- International Aluminium. Available online: https://international-aluminium.org/statistics/alumina-production/ (accessed on 28 August 2022).

- Liu, S.; Guan, X.; Zhang, S.; Dou, Z.; Feng, C.; Zhang, H.; Luo, S. Sintered Bayer red mud based ceramic bricks: Microstructure evolution and alkalis immobilization mechanism. Ceram. Int. 2017, 43, 13004–13008. [Google Scholar] [CrossRef]

- Aung, H.Y.; Boyarintsev, A.; Stepanov, S.; Shoustikov, A. Current key options for management of industrial alkaline waste of alumina production (red mud). In Proceedings of the Topical Problems of Green Architecture, Civil and Environmental Engineering (TPACEE-2021), Moscow, Russia, 28–30 April 2021; Volume 284, p. 01003. [Google Scholar] [CrossRef]

- Samal, S. Utilization of Red Mud as a Source for Metal Ions—A Review. Materials 2021, 14, 2211. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Jin, H.; Deng, Y.; Xiao, Y. Comprehensive utilization status of red mud in China: A critical review. J. Clean. Prod. 2021, 289, 125136. [Google Scholar] [CrossRef]

- Zhao, J.; Wang, Y.; Kang, J.; Ya, Q.; Khater, G.A.; Sheng, L.; Shi, Q.; Yue, Y. Effect of SnO2 on the structure and chemical durability of the glass prepared by red mud. J. Non. Cryst. Solids 2019, 209, 54–59. [Google Scholar] [CrossRef]

- Nie, Q.K.; Hu, W.; Huang, B.S.; Shu, X.; He, Q. Synergistic utilization of red mud for flue-gas desulfuration and fly-ash based geopolymer preparation. J. Hazard. Mater. 2019, 369, 503–511. [Google Scholar] [CrossRef]

- Mahinroosta, M.; Karimi, Z.; Allahverdi, A. Recycling of red mud for value-added applications: A comprehensive review. Encycl. Renew. Sustain. Mater. 2020, 2, 561–582. [Google Scholar] [CrossRef]

- Orescanin, V.; Nad, K.; Mikelic, L.; Mikulic, N.; Lulic, S. Utilization of Bauxite Slag for the Purification of Industrial Wastewaters. Process Saf. Environ. Prot. 2006, 84, 265–269. [Google Scholar] [CrossRef]

- Matthaiou, V.; Frontistis, Z.; Petala, A.; Solakidou, M.; Deligiannakis, Y.; Angelopoulos, G.N.; Mantzavinos, D. Utilization of raw red mud as a source of iron activating the persulfate oxidation of paraben. Process Saf. Environ. Prot. 2018, 119, 311–319. [Google Scholar] [CrossRef]

- Friday, O.; Yangxian Liu, O.; Adewuyi, Y.G. State-of-the-art review on capture of CO2 using adsorbents prepared from waste materials. Process Saf. Environ. Prot. 2020, 139, 1–25. [Google Scholar] [CrossRef]

- Li, G.; Liu, M.; Rao, M.; Jiang, T.; Zhuang, J.Q.; Zhang, Y.B. Stepwise extraction of valuable components from red mud based on reductive roasting with sodium salts. J. Hazard. Mater. 2014, 280, 774–780. [Google Scholar] [CrossRef]

- Qu, Y.; Li, H.; Tian, W.J.; Wang, X.Q.; Wang, X.M.; Jia, X.H.; Shi, B.; Song, G.D.; Tang, Y. Leaching of valuable metals form red mud via batch and continuous process by using fungi. Miner. Eng. 2015, 81, 1–4. [Google Scholar] [CrossRef]

- Arroyo, F.; Luna-Galiano, Y.; Leiva, C.; Vilches, L.F.; Fernández-Pereira, C. Environmental risks and mechanical evaluation of recycling red mud in bricks. Environ. Res. 2020, 186, 109537. [Google Scholar] [CrossRef] [PubMed]

- Communication from the Commission to the European Parlament, the Council, the European Economic and Social Committee and the Committee of the Regions. Critical Raw Materials Resilience: Charting a Path towards Greater Security and Sustainability; European Commision: Brussles, Belgium, 2020. [Google Scholar]

- Borra, C.R.; Pontikes, Y.; Binnemas, K.; Gerven, T.V. Leaching of rare earthes from bauxite residue (red mud). Min. Eng. 2015, 76, 20–27. [Google Scholar] [CrossRef] [Green Version]

- Pepper, R.A.; Couperthwaite, S.J.; Millar, G.J. Comprehensive examination of acid leaching behaviour of mineral phases from red mud: Recovery of Fe, Al, Ti, and Si. Min. Eng. 2016, 99, 8–18. [Google Scholar] [CrossRef] [Green Version]

- Cui, Y.; Chen, J.; Zhang, Y.; Peng, D.; Huang, T.; Sun, C. pH-dependant leaching characteristics of major and toxic elements from red mud. Int. J. Env. Res. Pub. Heal. 2019, 16, 2046. [Google Scholar] [CrossRef] [Green Version]

- Liu, Z.; Li, H. Metallurgical process for valuable elements recovery from red mud-a review. Hydrometallurgy 2015, 155, 29–43. [Google Scholar] [CrossRef]

- Leiva, C.; Rodriguez-Galán, M.; Arenas, C.; Alonso-Fariñas, B.; Peceño, B. A mechanical, leaching and radiological assessment of fired bricks with a high content of fly ash. Ceram. Int. 2018, 44, 13313–13319. [Google Scholar] [CrossRef]

- Leiva, C.; Arenas, C.; Alonso-Fariñas, B.; Rodriguez-Galán, M.; Baena, F. Characteristics of fired bricks with co-combustion fly ashes. J. Build. Eng. 2016, 5, 114–118. [Google Scholar] [CrossRef]

- EN 772-13; Methods for Masonry Units Part 13. Determination of Net and Gross Dry Density of Masonry Units (Except for Natural Stone). Asociacion Espanola de Normalizacion y Certificacion (AENOR): Madrid, Spain, 2013.

- EN 772-21; Methods for Masonry Units Part 21. Determination of Water Absorption of Clay and Calcium Silicate Masonry Units by Cold Water Absorption. Asociacion Espanola de Normalizacion y Certificacion (AENOR): Madrid, Spain, 2011.

- EN 772-1; Methods of Test for Masonry Units-Part 1: Determination of Compressive Strength. Asociacion Espanola de Normalizacion y Certificacion (AENOR): Madrid, Spain, 2016.

- EN 12457-4; Characterization of Waste: Leaching. Compliance Test for Leaching of Granular Waste Material and Sludges. Part 2. Asociacion Espanola de Normalizacion y Certificacion (AENOR): Madrid, Spain, 2002.

- NEN 7375; Leaching Characteristics-Determination of the Leaching of Inorganic Components from Molded or Monolithic Materials with a Diffusion Test-Solid Earthy and Stony Materials. Asociacion Espanola de Normalizacion y Certificacion (AENOR): Madrid, Spain, 2005.

- ISO 11929-4:2022; Determination of the Characteristic Limits (Decision Threshold, Detection Limit and Limits of the Coverage Interval) for Measurements of Ionizing Radiation—Fundamentals and Application—Part 4: Guidelines to Applications. ISO: Geneva, Switzerland, 2022.

- Davris, P.; Balomenos, E.; Panias, D.; Paspliaris, I. Leaching of rare earths from bauxite residues using imidazolium based ionic liquids. In Proceedings of the 1st European Rare Earth Resources Conference (ERES 2014), Milos, Greece, 4–7 September 2014; pp. 241–252. [Google Scholar]

- Sayan, E.; Bayramoglu, M. Statistical modeling of sulfuric acid leaching of TiO2 from red mud. Hydrometallurgy 2004, 71, 397–401. [Google Scholar] [CrossRef]

- London Metal Exchange. Available online: www.lme.com (accessed on 1 August 2022).

- ISE. Available online: www.institut-seltene-erden.de (accessed on 1 August 2022).

- Borra, C.R.; Blanpain, Y.; Pontikes, K.; Binnemans, T.; Van Gerven, T. Recovery of rare earths and other valuable metals from bauxite residue (red mud): A review. J. Sustain. Metall. 2016, 2, 365–386. [Google Scholar] [CrossRef] [Green Version]

- Arroyo-Torralvo, F.; Fernández-Pereira, C. Recovery of Germanium from Solutions by Ion-Exchange Extraction of Its Catechol Complex. Ind. Eng. Chem. Res. 2010, 49, 4817–4823. [Google Scholar] [CrossRef]

- Frost, R.L.; Ruan, H.; Kloprogge, J.T.; Gates, W.P. Dehydration and dehydroxylation of nontronites and ferruginous smectite. Thermochim. Acta 2000, 346, 63–72. [Google Scholar] [CrossRef]

- Yao, G.; Zang, H.; Wang, J.; Wu, P.; Qiu, J.; Lyu, X. 2019. Effect of mechanical activation on the pozzolanic activity of muscovite. Clays Clay Miner. 2019, 67, 209–216. [Google Scholar] [CrossRef]

- Kim, Y.; Lee, Y.; Kim, M.; Park, H. Preparation of high porosity bricks by utilizing red mud and mine tailing. J. Clean. Prod. 2019, 207, 490–497. [Google Scholar] [CrossRef]

- Mandal, A.K.; Verma, H.R.; Sinha, O.P. Utilization of aluminum plant’s waste for production of insulation bricks. J. Clean. Prod. 2017, 162, 949–957. [Google Scholar] [CrossRef]

- Alonso-Santurde, R.; Coz, A.; Viguri, J.Z.; Andrés, A. Recycling of foundry by-products in the ceramic industry: Green and core sand in clay bricks. Constr. Build. Mater. 2012, 27, 97–106. [Google Scholar] [CrossRef]

- GB 5101; Fired Common Bricks; General Administration of Quality Supervision Inspection and Quarantine of China. China Standard Press: Beijing, China, 2003. Available online: http://www.samr.gov.cn/ (accessed on 1 August 2022).

- Deutou, J.N.G.; Van Essa, L.S.; Kaze, R.C.; Kamseu, E.; Sglavo, V.M. Thermal behaviour and phases evolution during the sintering of porous inorganic membranes. J. Eur. Ceram. Soc. 2020, 40, 2151–2162. [Google Scholar] [CrossRef]

- ASTM C62-13a; Standard Specification for Building Brick. Solid Masonry Units Made From Clay or Shale. ASTM International: West Conshohocken, PA, USA, 2013. [CrossRef]

- EN 771-1; Specification for Masonry Units-Part 1: Clay Masonry Units. Asociacion Espanola de Normalizacion y Certificacion (AENOR): Madrid, Spain, 2016.

- Instituto Colombiano De Normas Técnicas Y Certificación (ICONTEC). Ingeniería Civil y Arquitectura. Unidades de Mampostería de Arcilla Cocida. Ladrillos y Bloques Cerámicos, Norma Técnica Colombiana. NTC 4205; Instituto Colombiano de Normas Técnicas y Certificación: Bogota, Colombia, 2000. [Google Scholar]

- SQD. Soil Quality Decree Dutch Ministry of Housing Spatial Planning and the Environment. Besluitbodemkwaliteit. Available online: rwsenvironment.eu/subjects/soil/legislation-and/soil-quality-decree/ (accessed on 1 August 2022).

- Taha, Y.; Benzaazoua, M.; Edahbi, M.; Mansori, M.; Hakkou, R. Leaching and geochemical behavior of fired bricks containing coal wastes. J. Environ. Manag. 2018, 209, 227–235. [Google Scholar] [CrossRef]

- European Commission. Council Directive 2013/59/EURATOM of 5 December 2013 laying Down Basic Safety Standards for Protection against the Dangers Arising from Exposure to Ionising Radiation; European Commission: Brussels, Belgium, 2013. [Google Scholar]

| Components | mg/kg | Components | mg/kg | Components | mg/kg |

|---|---|---|---|---|---|

| As | 63.9 | Mo | 12.3 | Ta | 7.0 |

| Ba | 193.7 | Nb | 161.2 | Th | 121.8 |

| Br | 4.0 | Nd | 84.1 | U | 13.0 |

| Ce | 259.0 | Ni | 17.3 | V | 1169 |

| Cr | 1818.0 | P | 1210 | W | 48.2 |

| Cu | 74.9 | Pb | 62.0 | Y | 115.8 |

| Ga | 73.4 | Sb | 5.6 | Zn | 46.0 |

| Hf | 20.2 | Sc | 57.9 | Zr | 2117 |

| In | 14.7 | Se | 2.0 | F | 2118 |

| La | 112.6 | Sn | 9.3 | S | 514 |

| Mn | 276.4 | Sr | 93.9 | ||

| Ag, Bi, Cd, Cl, Co, Cs, Ge, Hg, Rb, Sm, and Te | non-detected | ||||

| Screening Tests (Contact Time = 24 h and L/S = 10) | |

|---|---|

| Leaching agents | Concentration |

| Water | - |

| Sulfuric Acid | 0.5 M, 1 M, 2 M |

| Sodium hydroxide | 0.5 M, 1 M, 2 M |

| Optimization of leaching operating conditions (2 M H2SO4) | |

| L/S ratio | 2, 5, 10 L/kg |

| Contact time | 1, 2, 6, 24 h |

| CL | RM-T | Water/Solid Ratio | |

|---|---|---|---|

| CL-900 | 100 | 0 | 0.12 |

| RM-T-50-900 | 50 | 50 | 0.30 |

| RM-T-80-900 | 20 | 80 | 0.35 |

| CL-1100 | 100 | 0 | 0.12 |

| RM-T-50-1100 | 50 | 50 | 0.30 |

| RM-T-80-1100 | 20 | 80 | 0.35 |

| Water | Sulfuric Acid | Sodium Hydroxide | |||||

|---|---|---|---|---|---|---|---|

| 0.5 M | 1 M | 2 M | 0.5 M | 1 M | 2 M | ||

| pH | 5.4 | 0.8 | 0.4 | 0.3 | 13.1 | 13.2 | 13.3 |

| Component | Metal content (ppb) | ||||||

| As | <20 | 230 | 290 | 550 | 200 | 340 | 310 |

| Ba | 9 | 67 | 80 | 175 | <5 | <5 | 12 |

| Cr | 2575 | 5400 | 13,890 | 19,000 | 2324 | 2200 | 1980 |

| Cu | 14 | 850 | 960 | 1030 | <10 | <10 | <10 |

| Mn | <2 | 750 | 1347 | 1580 | <5 | <5 | <5 |

| Mo | 27 | <30 | 30 | 76 | <100 | <100 | <100 |

| Ni | <5 | 66 | 110 | 187 | <5 | <5 | <5 |

| Pb | <5 | 98 | 800 | 560 | <25 | <25 | <25 |

| Se | 36 | 38 | <30 | <10 | 90 | 210 | 120 |

| Sn | <25 | <50 | <50 | <50 | <50 | <50 | <50 |

| Sr | 7 | 5945 | 5679 | 4710 | <5 | 15 | <5 |

| Ti | <5 | 63,000 | 452,000 | 612,000 | <25 | <25 | <25 |

| V | 133 | 8260 | 16,800 | 17,900 | 7800 | 8340 | 5470 |

| Zn | 111 | 560 | 580 | 1500 | 170 | 140 | 490 |

| Sb | 31.5 | <25 | 114 | 139 | <25 | <25 | <25 |

| Ga | 18.3 | 360 | 522 | 700 | 288 | 290 | 225 |

| Ce | <25 | 12,000 | 16,700 | 17,100 | <50 | <50 | <50 |

| La | <5 | 5690 | 7220 | 7437 | <5 | <5 | 237 |

| Th | <10 | 1860 | 5170 | 6270 | <25 | <25 | <25 |

| Contact Time | 1 h | 2 h | 6 h | 24 h | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| L/S ratio | 2 | 5 | 10 | 2 | 5 | 10 | 2 | 5 | 10 | 2 | 5 | 10 |

| As (ppb) | 700 | 680 | 500 | 756 | 570 | 500 | 785 | 507 | 500 | 1460 | 500 | 550 |

| B (ppb) | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 200 | 100 | 175 |

| Cr (ppb) | 12,400 | 9920 | 5490 | 14,050 | 10,950 | 6650 | 29,128 | 12,400 | 7930 | 36,560 | 20,200 | 19,000 |

| Cu (ppb) | 1910 | 1330 | 670 | 2100 | 1290 | 690 | 2940 | 1320 | 740 | 4300 | 1540 | 1030 |

| Mn (ppb) | 1386 | 1020 | 530 | 1660 | 1130 | 650 | 4070 | 1390 | 860 | 4010 | 2220 | 1580 |

| Mo (ppb) | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 76 |

| Pb (ppb) | 290 | 860 | 530 | 260 | 970 | 620 | 550 | 770 | 700 | 1700 | 1010 | 560 |

| Sr (ppb) | 9090 | 8410 | 5200 | 9790 | 7740 | 5340 | 12,109 | 7740 | 5350 | 18,530 | 8260 | 4710 |

| Ti (ppb) | 183 | 337 | 204 | 232 | 355 | 253 | 500 | 413 | 315 | 612 | 632 | 612 |

| V (ppb) | 32,160 | 27,570 | 14,860 | 32,710 | 24,920 | 15,330 | 39,100 | 25,010 | 16,160 | 60,800 | 27,110 | 17,900 |

| Zn (ppb) | 2840 | 810 | 1370 | 1780 | 710 | 410 | 2710 | 1470 | 985 | 3580 | 1750 | 1500 |

| Ce (ppb) | 19,150 | 17,470 | 10,330 | 20,520 | 16,890 | 11,100 | 30,800 | 17,290 | 11,570 | 46,090 | 20,420 | 17,100 |

| La (ppb) | 11,420 | 9340 | 5400 | 11,980 | 9090 | 5690 | 16,970 | 9180 | 5880 | 32,030 | 10,720 | 7437 |

| Th (ppb) | 6210 | 5580 | 3060 | 6620 | 5630 | 3430 | 11,290 | 5960 | 3760 | 15,370 | 7360 | 6270 |

| As | Ba | Cr | Cu | Mn | Mo | Pb | Ti | V | Zn | La | Ce | Th | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| L/S = 10 and 24 h of leaching time | |||||||||||||

| Experimental | 2.5 | 0.5 | 32.0 | 7.9 | 9.7 | 1.6 | 1.8 | 2.6 | 15.3 | 32.6 | 66.0 | 56.0 | 51.5 |

| Predicted | 2.5 | - | 30.4 | 9.3 | 9.5 | 1.8 | 2.5 | 2.2 | 14.6 | 27.8 | 61.2 | 57.6 | 51.0 |

| L/S = 5 and 2 h of leaching time | |||||||||||||

| Experimental | 3.9 | 0.3 | 55.6 | 10.2 | 14.1 | 4.1 | 8.1 | 8.3 | 11.5 | 19.0 | 47.6 | 39.4 | 30.2 |

| Predicted | 5.5 | - | 58.6 | 11.2 | 15.2 | 3.5 | 7.2 | 10.2 | 10.6 | 20.4 | 47.7 | 41.7 | 31.3 |

| CL-900 | CL-1100 | RM-T-50-900 | RM-T-50-1100 | RM-T-80-900 | RM-T-80-1100 | Limits | |

|---|---|---|---|---|---|---|---|

| As | 0.73 | 2.83 | 1.56 | 2.41 | 1.09 | 1.43 | 260 |

| Ba | 0.49 | 0.43 | ≤0.4 | ≤0.4 | ≤0.4 | ≤0.4 | 1500 |

| Cd | ≤0.4 | ≤0.4 | ≤0.4 | ≤0.4 | ≤0.4 | ≤0.4 | 3.8 |

| Co | ≤0.4 | ≤0.4 | ≤0.4 | ≤0.4 | ≤0.4 | ≤0.4 | 60 |

| Cr | ≤0.4 | ≤0.4 | ≤0.4 | ≤0.4 | 0.42 | ≤0.4 | 120 |

| Cu | 0.55 | ≤0.4 | ≤0.4 | ≤0.4 | ≤0.4 | ≤0.4 | 98 |

| Hg | ≤1.26 | ≤1.26 | ≤1.26 | ≤1.26 | ≤1.26 | ≤1.26 | 1.4 |

| Mo | ≤0.4 | ≤0.4 | 1.01 | ≤0.4 | 2.42 | 0.60 | 144 |

| Ni | ≤0.4 | ≤0.4 | ≤0.4 | ≤0.4 | ≤0.4 | ≤0.4 | 81 |

| Pb | ≤0.4 | ≤0.4 | ≤0.4 | ≤0.4 | ≤0.4 | ≤0.4 | 400 |

| Se | ≤0.4 | ≤0.4 | ≤0.4 | ≤0.4 | ≤0.4 | ≤0.4 | 4.8 |

| Sn | ≤0.4 | ≤0.4 | ≤0.4 | ≤0.4 | ≤0.4 | ≤0.4 | 50 |

| V | 5.29 | 0.76 | 119.46 | 6.71 | 235.48 | 36.59 | 320 |

| Zn | 1.68 | 0.48 | ≤0.4 | ≤0.4 | ≤0.4 | ≤0.4 | 800 |

| Sb | ≤0.4 | ≤0.4 | ≤0.4 | ≤0.4 | ≤0.4 | ≤0.4 | 8.7 |

| Th | ≤0.4 | ≤0.4 | ≤0.4 | ≤0.4 | ≤0.4 | ≤0.4 | - |

| Materials | ||||

|---|---|---|---|---|

| Radionuclides | RM | CL | CL-1100 | RM-T-80-1100 |

| K-40 | 98 | 650 | 618 | 203 |

| Ra-226 | 235 | 35 | 11 | 4 |

| Th-232 | 249 | 37 | 33 | 104 |

| ACI | 2.06 | 0.52 | 0.41 | 0.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Leiva, C.; Arroyo-Torralvo, F.; Luna-Galiano, Y.; Villegas, R.; Vilches, L.F.; Fernández Pereira, C. Valorization of Bayer Red Mud in a Circular Economy Process: Valuable Metals Recovery and Further Brick Manufacture. Processes 2022, 10, 2367. https://doi.org/10.3390/pr10112367

Leiva C, Arroyo-Torralvo F, Luna-Galiano Y, Villegas R, Vilches LF, Fernández Pereira C. Valorization of Bayer Red Mud in a Circular Economy Process: Valuable Metals Recovery and Further Brick Manufacture. Processes. 2022; 10(11):2367. https://doi.org/10.3390/pr10112367

Chicago/Turabian StyleLeiva, Carlos, Fátima Arroyo-Torralvo, Yolanda Luna-Galiano, Rosario Villegas, Luis Francisco Vilches, and Constantino Fernández Pereira. 2022. "Valorization of Bayer Red Mud in a Circular Economy Process: Valuable Metals Recovery and Further Brick Manufacture" Processes 10, no. 11: 2367. https://doi.org/10.3390/pr10112367

APA StyleLeiva, C., Arroyo-Torralvo, F., Luna-Galiano, Y., Villegas, R., Vilches, L. F., & Fernández Pereira, C. (2022). Valorization of Bayer Red Mud in a Circular Economy Process: Valuable Metals Recovery and Further Brick Manufacture. Processes, 10(11), 2367. https://doi.org/10.3390/pr10112367