CO2 Adsorption Performance on Surface-Functionalized Activated Carbon Impregnated with Pyrrolidinium-Based Ionic Liquid

Abstract

:1. Introduction

2. Materials and Methods

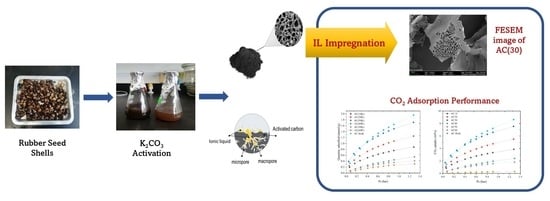

2.1. Synthesis of RSS Derived AC

2.2. Preparation of Functionalized AC

2.3. Characterization of Prepared Adsorbent

2.4. CO2 Adsorption Test

3. Results and Discussion

3.1. FESEM and EDX Mapping

3.2. TGA

3.3. FTIR Analysis

3.4. SAP Analysis

3.5. Raman Spectroscopy Analysis

3.6. CO2 Adsorption Study

3.7. Effect of IL Loading

3.8. Effect of Adsorption Temperature

3.9. Comparison with Previous Studies

4. Conclusions

- FTIR and BET analyses of fresh and functionalized AC confirm successful functionalization with the selected IL. BET analysis shows that both SBET and Vp are reduced with increasing IL concentration. The reduction of both surface properties is prominent at higher IL loading (40–60 wt%).

- The N2 adsorption isotherm analysis shows type I isotherms for fresh and functionalized AC and suggests the properties of a microporous material.

- Raman spectroscopy confirms that the structure of AC is unharmed by the incorporation of IL. The improved thermal stability of the functionalized adsorbents compared to the fresh AC is confirmed through TGA.

- The CO2 adsorption occurs by physisorption for fresh AC and is mainly affected by available surface area. The CO2 adsorption capacity of functionalized AC is affected by IL loading and adsorption temperature. The CO2 adsorption capacity initially increases with IL loading up to 30 wt.% and reduces afterward due to low surface area and resultant pore obstruction.

- The performance of functionalized AC is improved at higher adsorption temperature due to a better dispersion of IL.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| moles of helium dosed into the sample cell (mol) | |

| moles of adsorbate dosed into the sample cell (mol) | |

| moles of adsorbate remaining in the sample cell (mol) | |

| moles of adsorbate adsorbed by the sample (mol) | |

| pressure of the manifold before and after dosing (bar) | |

| pressure of sample cell before and after dosing Helium (bar) | |

| pressure of sample cell before and after dosing adsorbate (bar) | |

| pressure of sample cell for adsorption (bar) | |

| ambient temperature (298 K) | |

| temperature of the manifold before and after dosing (K) | |

| temperature of sample before and after dosing Helium (K) | |

| temperature of sample cell before and after dosing adsorbate (K) | |

| temerature of sample cell for adsorption (K) | |

| manifold temperature (K) | |

| gas compressibility of helium at and | |

| gas compressibility of helium at and | |

| gas compressibility at and respectively | |

| gas compressibility at and respectively | |

| gas compressibility at and respectively | |

| gas compressibility at and respectively | |

| gas compressibility at | |

| universal gas constant | |

| LP manifold volume | |

| free space volume at ambient temperature (cm3) | |

| manifold volume outside the temperature-controlled zone (cm3) | |

| free space volume at analysis temperature (cm3) | |

| lower stem volume (cm3) | |

| upper stem volume (3.5 cm3) |

References

- Sher, F.; Iqbal, S.Z.; Albazzaz, S.; Ali, U.; Mortari, D.A.; Rashid, T. Development of biomass derived highly porous fast adsorbents for post-combustion CO2 capture. Fuel 2020, 282, 118506. [Google Scholar] [CrossRef]

- Li, B.; Duan, Y.; Luebke, D.; Morreale, B. Advances in CO2 capture technology: A patent review. Appl. Energy 2013, 102, 1439–1447. [Google Scholar] [CrossRef]

- Leung, D.Y.C.; Caramanna, G.; Maroto-Valer, M.M. An overview of current status of carbon dioxide capture and storage technologies. Renew. Sustain. Energy Rev. 2014, 39, 426–443. [Google Scholar] [CrossRef] [Green Version]

- Fatima, S.S.; Borhan, A.; Ayoub, M.; Ghani, N.A. Development and progress of functionalzied silica-based adsorbents for CO2 capture. J. Mol. Liq. 2021, 338, 116913. [Google Scholar] [CrossRef]

- Borhan, A.; Hoong, P.K.; Taha, M.F. Biosorption of heavy metal ions, oil and grease from industrial waste water by banana peel. Appl. Mech. Mater. 2014, 625, 749–752. [Google Scholar] [CrossRef]

- Borhan, A.; Thangamuthu, S.; Taha, M.F.; Ramdan, A.N. Development of activated carbon derived from banana peel for CO2 removal. In Proceedings of the AIP Conference Proceedings 2015, Negeri Sembilan, Malaysia, 24−26 February 2015. [Google Scholar]

- Borhan, A.; Yusup, S.; Lim, J.W.; Show, P.L. Characterization and modelling studies of activated carbon produced from rubber-seed shell using KOH for CO2 adsorption. Processes 2019, 7, 855. [Google Scholar] [CrossRef] [Green Version]

- Quan, C.; Jia, X.; Gao, N. Nitrogen-doping activated biomass carbon from tea seed shell for CO2 capture and supercapacitor. Int. J. Energy Res. 2019, 44, 1218–1232. [Google Scholar] [CrossRef]

- Kumar, K.; Kumar, A. Enhanced CO2 adsorption and separation in ionic-liquid-impregnated mesoporous silica MCM-41: A molecular simulation study. J. Phys. Chem. C 2018, 122, 8216–8227. [Google Scholar] [CrossRef]

- Ao, W.; Fu, J.; Mao, X.; Kang, Q.; Ran, C.; Liu, Y.; Zhang, H.; Gao, Z.; Li, J.; Liu, G.; et al. Microwave assisted preparation of activated carbon from biomass: A review. Renew. Sustain. Energy Rev. 2018, 92, 958–979. [Google Scholar] [CrossRef]

- Hazzaa, R.; Hussein, M. Adsorption of cationic dye from aqueous solution onto activated carbon prepared from olive stones. Environ. Technol. Innov. 2015, 4, 36–51. [Google Scholar] [CrossRef]

- Yakout, S.M.; Sharaf El-Deen, G. Characterization of activated carbon prepared by phosphoric acid activation of olive stones. Arab. J. Chem. 2016, 9, 1155–1162. [Google Scholar] [CrossRef] [Green Version]

- Chen, J.; Yang, J.; Hu, G.; Hu, X.; Li, Z.; Shen, S.; Radosz, M.; Fan, M. Enhanced CO2 capture capacity of nitrogen-doped biomass-derived porous carbons. ACS Sustain. Chem. Eng. 2016, 4, 1439–1445. [Google Scholar] [CrossRef]

- Deng, S.; Hu, B.; Chen, T.; Wang, B.; Huang, J.; Wang, Y.; Yu, G. Activated carbons prepared from peanut shell and sunflower seed shell for high CO2 adsorption. Adsorption 2015, 21, 125–133. [Google Scholar] [CrossRef]

- Plaza, M.G.; Gonzalez, A.S.; Pevida, C.; Pis, J.J.; Rubiera, F. Volarisation of spent coffee grounds as CO2 adsorbents for postcombustion capture applications. Appl. Energy 2012, 99, 272–279. [Google Scholar] [CrossRef] [Green Version]

- Wei, H.; Deng, S.; Hu, B.; Chen, Z.; Wang, B.; Huang, J.; Yu, G. Granular bamboo-derived activated carbon for high CO2 adsorption: The dominant role of narrow micropores. ChemSusChem 2012, 5, 2354–2360. [Google Scholar] [CrossRef]

- Sha, Y.; Lou, J.; Bai, S.; Wu, D.; Liu, B.; Ling, Y. Facile preparation of nitrogen-doped porous carbon from waste tobacco by a simple pre-treatment process and their application in electrochemical capacitor and CO2 capture. Mater. Res. Bull. 2015, 64, 327–332. [Google Scholar] [CrossRef]

- Heidari, A.; Younesi, H.; Rashidi, A.; Ghoreyshi, A.A. Evaluation of CO2 adsorption with eucalyptus wood based activated carbon modified by ammonia solution through heat treatment. Chem. Eng. J. 2014, 254, 503–513. [Google Scholar] [CrossRef]

- Department of Statistics Malaysia. Press Release Monthly rubber statistics Malaysia, January 2020. Available online: https://www.dosm.gov (accessed on 13 March 2020).

- Tran, H.N.; You, S.-J.; Chao, H.-P. Fast and efficient adsorption of methylene green 5 on activated carbon prepared from new chemical activation method. J. Environ. Manag. 2017, 188, 322–336. [Google Scholar] [CrossRef]

- Houshmand, A.; Wan Daud, W.M.A.; Shafeeyan, M.S. Exploring potential methods for anchoring amine groups on the surface of activated carbon for CO2 adsorption. Sep. Sci. Technol. 2011, 46, 1098–1112. [Google Scholar] [CrossRef]

- Plaza, M.G.; Pevida, C.; Arenillas, A.; Rubiera, F.; Pis, J.J. CO2 capture by adsorption with nitrogen enriched carbons. Fuel 2007, 86, 2204–2212. [Google Scholar] [CrossRef]

- Arenillas, A.; Smith, K.M.; Drage, T.C.; Snape, C.E. CO2 capture using some fly ash-derived carbon materials. Fuel 2005, 84, 2204–2210. [Google Scholar] [CrossRef]

- Maroto-Valer, M.M.; Lu, Z.; Zhang, Y.; Tang, Z. Sorbents for CO2 capture from high carbon fly ashes. Waste Manag. 2008, 28, 2320–2328. [Google Scholar] [CrossRef]

- Wei, J.; Shi, J.; Pan, H.; Zhao, W.; Ye, Q.; Shi, Y. Adsorption of carbon dioxide on organically functionalized SBA-16. Microporous Mesoporous Mater. 2008, 116, 394–399. [Google Scholar] [CrossRef]

- He, X.; Zhu, J.; Wang, H.; Zhou, M.; Zhang, S. Surface functionalization of activated carbon with phosphonium ionic liquid for CO2 adsorption. Coatings 2019, 9, 590. [Google Scholar] [CrossRef] [Green Version]

- Girish, C.R. Various impregnation methods used for the surface modification of the adsorbent: A review. Int. J. Eng. Technol. 2018, 7, 330–334. [Google Scholar] [CrossRef] [Green Version]

- Jain, S.; Bansiwal, A.; Biniwale, R.B.; Milmile, S.; Das, S.; Tiwari, S.; Antony, P.S. Enhancing adsorption of nitrate using metal impregnated alumina. J. Environ. Chem. Eng. 2015, 3, 232–2349. [Google Scholar] [CrossRef]

- Zhu, J.; He, B.; Huang, J.; Li, C.; Ren, T. Effect of immobilization methods and the pore structure on CO2 separation performance in silica-supported ionic liquids. Microporous Mesoporous Mater. 2018, 260, 190–200. [Google Scholar] [CrossRef]

- Sanz-Perez, E.S.; Arencibia, A.; Calleja, G.; Sanz, R. Tuning the textural properties of HMS mesoporous silica. Functionalization towards CO2 adsorption. Microporous Mesoporous Mater. 2018, 260, 235–244. [Google Scholar] [CrossRef]

- Houshmand, A.; Wan Daud, W.M.A.; Lee, M.-G.; Shafeeyan, M.S. Carbon dioxide capture with amine-grafted activated carbon. Water Air Soil Pollut. 2012, 223, 827–835. [Google Scholar] [CrossRef]

- Maroto-Valer, M.M.; Tang, Z.; Zhang, Y. CO2 capture by activated and impregnated anthracites. Fuel Process. Technol. 2005, 86, 1487–1502. [Google Scholar] [CrossRef]

- Bezerra, D.P.; Oliveira, R.S.; Vieira, R.S.; Cavalcante, C.L., Jr. Adsorption of CO2 on nitrogen-enriched activated carbon and zeolite 13X. Adsorption 2011, 17, 235–246. [Google Scholar] [CrossRef]

- Aroua, M.K.; Wan Daud, W.M.A.; Yin, C.Y.; Adinata, D. Adsorption capacities of carbon dioxide, oxygen, nitrogen and methane on carbon molecular basket derived from polyethyleneimine impregnation on microporous palm shell activated carbon. Sep. Purif. Technol. 2008, 62, 609–613. [Google Scholar] [CrossRef]

- Zhang, C.; Song, W.; Sun, G.; Xie, L.; Wang, J.; Li, K.; Sun, C.; Liu, H.; Snape, C.E.; Drage, T. CO2 capture with activated carbon grafted by nitrogenous funtional groups. Energy Fuels 2013, 27, 4818–4823. [Google Scholar] [CrossRef]

- Grondein, A.; Bélanger, D. Chemical modification of carbon powders with aminophenyl and aryl-aliphatic amine groups by reduction of in situ generated diazonium cations: Applicability of the grafted powder towards CO2 capture. Fuel 2011, 90, 2684–2693. [Google Scholar] [CrossRef]

- McDonald, J.D.; Kracko, D.; Doyle-Eisele, M.; Garner, C.E.; Wegerski, C.; Senft, A.; Knipping, E.; Shaw, S.; Rohr, A. Carbon capture and sequestration: An exploratory inhalation toxicity assessment of amine-trapping solvents and their degradation products. Environ. Sci. Technol. 2014, 48, 10821–10828. [Google Scholar] [CrossRef]

- Ahmed, S.; Ramli, A.; Yusup, S. Development of polyethylenimine-functionalized mesoporous Si-MCM-41 for CO2 adsorption. Fuel Process. Technol. 2017, 167, 622–630. [Google Scholar] [CrossRef]

- Xu, X.; Song, C.; Andresen, J.M.; Miller, B.G.; Scaroni, A.W. Novel polyethylenimine-modified mesoporus molecular seive of MCM-41 type as high-capacity adsorbent for CO2 capture. Energy Fuels 2002, 16, 1463–1469. [Google Scholar] [CrossRef]

- Franchi, R.S.; Harlick, P.J.E.; Sayari, A. Applications of pore-expanded mesoporous silica. 2. Development of a high-capacity, water-tolerant adsorbent for CO2. Ind. Eng. Chem. Res. 2005, 44, 8007–8013. [Google Scholar] [CrossRef]

- Hasib-ur-Rahman, M.; Siaj, M.; Larachi, F. Ionic liquids for CO2 capture-Development and progress. Chem. Eng. Process. 2010, 49, 313–322. [Google Scholar] [CrossRef]

- Lemus, J.; Palomar, J.; Gilarraanz, M.A.; Rodriguez, J.J. Characterization of supported ionic liquid phase (SILP) materials prepared from different supports. Adsorption 2011, 17, 561–571. [Google Scholar] [CrossRef]

- Ban, Y.; Li, Z.; Li, P.D.Y.; Peng, Y.; Jin, H.; Wenmei, J.; Guo, A.; Wang, P.; Yang, P.D.Q.; Zhong, P.D.C.; et al. Confinement of ionic liquids in nanocages: Tailoring the molecular sieving properties of ZIF-8 for membrane based CO2 capture. Angew. Chem. 2015, 54, 15483–15487. [Google Scholar] [CrossRef] [PubMed]

- Yusuf, N.Y.; Masdar, M.S.; Isahak, W.N.R.W.; Nordin, D.; Husaini, T.; Majlan, E.H.; Rejab, S.A.M.; Chew, C.L. Ionic-liquid impregnated activated carbon for biohydrogen purification in an adsorption unit. In Proceedings of the IOP Conference Series: Materials Science and Engineering, 29th Symposium of Malaysian Chemical Engineers (SOMChE) 2016, Miri, Sarawak, Malaysia, 1–3 December 2016; IOP Publishing Ltd.: Bristol, UK, 2017. [Google Scholar]

- Aki, S.N.V.K.; Mellein, B.R.; Saurer, E.M.; Brennecke, J.F. High pressure phase behavior of carbon dioxide with imidazolium-based ionic liquids. J. Phys. Chem. B 2004, 108, 20355–20365. [Google Scholar] [CrossRef]

- Ramdin, M.; de Loos, T.W.; Vlugt, T.J.H. State-of-the-art of CO2 capture with ionic liquids. Ind. Eng. Chem. Res. 2012, 51, 8149–8177. [Google Scholar] [CrossRef]

- Blanchard, L.A.; Hancu, D.; Beckman, E.J.; Brennecke, J.F. Green processing using ionic liquids and CO2. Nature 1999, 399, 28–29. [Google Scholar] [CrossRef]

- Revelli, A.-L.; Mutelet, F.; Jaubert, J.N. High carbon dioxide solubilities in imidazolium-based ionic liquids and in poly(ethylene glycol) Dimethyl ether. J. Phys. Chem. B 2010, 114, 12908–12913. [Google Scholar] [CrossRef]

- Cadena, C.; Anthony, J.L.; Shah, J.K.; Morrow, T.I.; Brennecke, J.F.; Maginn, E.J. Why is CO2 so soluble in imidazolium-based ionic liquids? J. Am. Chem. Soc. 2004, 126, 5300–5308. [Google Scholar] [CrossRef]

- Jung, Y.-H.; Jung, J.-Y.; Jin, Y.-R.; Lee, B.-C.; Baek, I.-H.; Kim, S.-H. Solubility of carbon dioxide in imidazolium-based ionic liquids with a methanesulfonate anion. J. Chem. Eng. Data 2012, 57, 3321–3329. [Google Scholar] [CrossRef]

- Kumelan, J.; Tuma, D.; Kamps, A.P.-S.; Maurer, G. Solubility of the single gases carbon dioxide and hydrogen in the ionic liquid [bmpy][Tf2N]. J. Chem. Eng. Data 2010, 55, 165–172. [Google Scholar] [CrossRef]

- Zhang, Y.; Xing, W.; Liu, S.; Liu, Y.; Yang, M.; Zhao, J.; Song, Y. Pure methane, carbon dioxide, and nitrogen adsorption on anthracite from china over a wide range of pressures and temperatures: Experiments and modeling. RSC Adv. 2015, 5, 52612–52623. [Google Scholar] [CrossRef]

- Erto, A.; Silvestre-Albero, A.; Silvestre-Albero, J.; Rodriguez-Reinoso, F.; Balsamo, M.; Lancia, A.; Fabio, M. Carbon-supported ionic liquids as innovative adsorbents for CO2 separation from synthetic flue-gas. J. Colloid Interface Sci. 2015, 448, 41–50. [Google Scholar] [CrossRef]

- Singh, K.S.W.; Everett, D.H.; Haul, R.A.W.; Moscou, L.; Pierotti, R.A.; Rouquerol, J.; Siemeiniewska, T. Reporting physisorption data for gas/solid systems with special reference to the determination of surface area and porosity (recommendations 1984). Pure Appl. Chem. 1985, 57, 603–619. [Google Scholar] [CrossRef]

- Esteves, I.A.A.C.; Lopes, M.S.S.; Nunes, P.M.C.; Mota, J.P.B. Adsorption of natural gas and biogas components on activated carbon. Sep. Purif. Technol. 2008, 62, 281–296. [Google Scholar] [CrossRef]

- Ammendola, P.; Raganati, F.; Chirone, R. CO2 adsorption on a fine activated carbon in a sound assisted fluidized bed: Thermodynamics and kinetics. Chem. Eng. J. 2017, 322, 302–313. [Google Scholar] [CrossRef]

- Tamilarasan, P.; Ramaprabhu, S. Polyaniline-magnetite nanocapsules based nanocomposite for carbon dioxide adsorption. Int. J. Greenh. Gas Control. 2012, 10, 486–493. [Google Scholar] [CrossRef]

- Zhang, W.; Gao, E.; Li, Y.; Bernards, M.T.; He, Y.; Shi, Y. CO2 capture with polyamine-based protic ionic liquid functionalized mesoporous silica. J. CO2 Util. 2019, 34, 606–615. [Google Scholar] [CrossRef]

- Boonpoke, A.; Chiarakorn, S.; Laosiripojana, N.; Towprayoon, S. Synthesis of activated carbon and MCM-41 from bagasse and rice husk and their carbon dioxide adsorption. J. Sustain. Energy Environ. 2011, 2, 77–81. [Google Scholar]

- Nasri, N.S.; Hamza, U.D.; Ismail, S.N.; Ahmed, M.M.; Mohsin, R. Assessment of porous carbons derived from sustainable palm solid waste for carbon dioxide capture. J. Clean. Prod. 2014, 71, 148–157. [Google Scholar] [CrossRef]

- Xu, Q.-Q.; Yin, J.-Z.; Zhou, X.-L.; Yin, G.-Z.; Liu, Y.-F.; Cai, P.; Wang, A.-Q. Impregnation of ionic liquids in mesoporous silica using supercritical carbon dioxide and co-solvent. RSC Adv. 2016, 6, 101079–101086. [Google Scholar] [CrossRef]

- Yin, J.-Z.; Zhen, M.-Y.; Cai, P.; Zhou, D.; Li, Z.-J.; Zhu, H.-Y.; Xu, Q.-Q. Supercritical CO2 preparation of SBA-15 supported ionic liquid and its adsorption for CO2. Mater. Res. Express 2018, 5, 065060. [Google Scholar] [CrossRef]

- Marliza, T.S.; Yarmo, M.A.; Hakim, A.; Abu Tahari, M.N.; Hisham, M.W.M.; Taufiq-Yap, Y.H. CO2 capture on NiO supported imidazolium-based ionic liquid. In Proceedings of the AIP Conference Proceedings, 2017, Selangor, Malaysia, 28–30 November 2016. [Google Scholar]

- Aquino, A.S.; Bernard, F.L.; Borges, J.V.; Mafra, L.; Vecchia, F.D.; Vieira, M.O.; Ligabue, R.; Seferin, M.; Chaban, V.V.; Cabrita, E.J.; et al. Rationalizing the role of the anion in CO2 capture and conversion using imidazolium based ionic liquid modified mesoporous silica. RSC Adv. 2015, 5, 64220–64227. [Google Scholar] [CrossRef]

| Elements | AC-Fresh | AC (10) | AC (20) | AC (30) | AC (40) | AC (50) | AC (60) | |

|---|---|---|---|---|---|---|---|---|

| Carbon | Weight (%) | 77.42 | 70.25 | 61.97 | 69.44 | 67.50 | 65.15 | 67.78 |

| Atomic (%) | 84.33 | 78.49 | 73.60 | 78.61 | 76.37 | 74.58 | 76.90 | |

| Oxygen | Weight (%) | 16.79 | 19.80 | 20.63 | 14.73 | 16.76 | 13.99 | 14.49 |

| Atomic (%) | 13.77 | 16.61 | 18.39 | 12.52 | 14.23 | 12.02 | 12.34 | |

| Potassium | Weight (%) | 5.79 | 4.91 | 11.58 | 4.37 | 3.33 | 2.58 | 2.91 |

| Atomic (%) | 1.94 | 1.68 | 4.22 | 1.52 | 1.16 | 0.91 | 1.02 | |

| Fluorine | Weight (%) | 3.84 | 3.89 | 8.51 | 10.20 | 12.97 | 11.82 | |

| Atomic (%) | 2.72 | 2.92 | 6.09 | 7.30 | 9.38 | 8.48 | ||

| Sulfur | Weight (%) | 1.20 | 1.93 | 2.74 | 2.22 | 3.72 | 3.00 | |

| Atomic (%) | 0.50 | 0.86 | 1.16 | 0.94 | 1.60 | 1.27 |

| Thermal Stability Regions | AC-fresh | AC (10) | AC (20) | AC (30) | AC (40) | AC (50) | AC (60) |

|---|---|---|---|---|---|---|---|

| Moisture Evaporation Region (Below 200 °C) | 9.08 | 9.69 | 8.46 | 6.06 | 1.88 | 4.94 | 1.78 |

| Rapid Weight Loss Region (200–600 °C) | 52.00 | 25.54 | 32.81 | 32.30 | 38.37 | 48.17 | 51.64 |

| Decomposition Region (Above 700 °C) | 36.31 | 6.76 | 11.62 | 9.36 | 14 | 14.76 | 28.87 |

| Sample | Specific Surface Area (SBET) | T-Plot Micropore Area (Smicro) | External Surface Area (Sext) | Total Pore Volume (Vp) | Average Pore Diameter (D) | Percent Micropores |

|---|---|---|---|---|---|---|

| (m2/g) | (m2/g) | (m2/g) | (cm3/g) | nm | (%) | |

| AC-fresh | 683 | 579 | 104 | 0.37 | 2.16 | 79.6 |

| AC (10) | 599 | 496 | 103 | 0.33 | 2.18 | 77.2 |

| AC (20) | 559 | 478 | 81 | 0.31 | 2.18 | 79.7 |

| AC (30) | 404 | 319 | 86 | 0.23 | 2.31 | 69.5 |

| AC (40) | 140 | 116 | 23 | 0.08 | 2.27 | 74.7 |

| AC (50) | 126 | 103 | 23 | 0.07 | 2.31 | 72.2 |

| AC (60) | 14 | 7 | 7 | 0.01 | 2.73 | 37.6 |

| Adsorbent | Functionalization Method | Chemicals | CO2 Adsorption Capacity at 25 °C (mmol/g) | Ref. |

|---|---|---|---|---|

| RSS AC | wet impregnation | K2CO3 | 2.160 | This study |

| RSS AC | wet impregnation | KOH | 1.231 | [7] |

| Rice husk | wet impregnation | ZnCl2 | 1.330 | [15] |

| Bagasse pith | wet impregnation | ZnCl2 | 1.747 | [59] |

| Palm kernel shell | physical activation | CO2 | 1.660 | [60] |

| RSS AC | wet impregnation | [bmpy][Tf2N] | 1.124 | This study |

| Palm shell AC | wet impregnation | PEI | 0.759 | [34] |

| SBA-15 | wet impregnation | [bmim][BF4] | 0.816 | [61] |

| AC Norit CGP Super | wet impregnation | DETA | 1.760 | [22] |

| SBA-15 | wet impregnation | [bmim][Ac] | 0.926 | [62] |

| SiO2 | wet impregnation | [Emim][HSO4] | 1.095 | [63] |

| SiO2 | grafting | [P8883][TFSI] | 0.99 | [29] |

| MCM-41 | water-aided grafting | [(MeO)3Sipmim][Cl] | 1.48 | [64] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fatima, S.S.; Borhan, A.; Ayoub, M.; Ghani, N.A. CO2 Adsorption Performance on Surface-Functionalized Activated Carbon Impregnated with Pyrrolidinium-Based Ionic Liquid. Processes 2022, 10, 2372. https://doi.org/10.3390/pr10112372

Fatima SS, Borhan A, Ayoub M, Ghani NA. CO2 Adsorption Performance on Surface-Functionalized Activated Carbon Impregnated with Pyrrolidinium-Based Ionic Liquid. Processes. 2022; 10(11):2372. https://doi.org/10.3390/pr10112372

Chicago/Turabian StyleFatima, Syeda Saba, Azry Borhan, Muhammad Ayoub, and Noraini Abd Ghani. 2022. "CO2 Adsorption Performance on Surface-Functionalized Activated Carbon Impregnated with Pyrrolidinium-Based Ionic Liquid" Processes 10, no. 11: 2372. https://doi.org/10.3390/pr10112372

APA StyleFatima, S. S., Borhan, A., Ayoub, M., & Ghani, N. A. (2022). CO2 Adsorption Performance on Surface-Functionalized Activated Carbon Impregnated with Pyrrolidinium-Based Ionic Liquid. Processes, 10(11), 2372. https://doi.org/10.3390/pr10112372