Room Air-Conditioning Operating as a Filling Box

Abstract

:1. Introduction

2. Materials and Methods

2.1. Mathematical Description

2.1.1. General Description, Assumptions, and Approximations

- The densimetric Froude number, defined as . In general, high values of Froude number indicate that the flow is governed by inertial forces (jet-like behaviour), while low enough values indicate that buoyant forces dominate the flow (plume-like behaviour).

- The stratification parameter, defined as . This is directly related to the Brunt–Väisälä frequency , giving the frequency of oscillations of the trapped buoyant jet at the equilibrium level [46]. The parameter shows the stratification strength, where is the thermocline layer height. Stratification is strong if , moderate if and weak if [49].

- The characteristic length scale defined by [51]. It is herein used to normalise the geometric distances. The independent variables ψ, ξ and z are normalised to the dynamic distances , and . For either plane or round buoyant jets, experimental evidence has shown that a jet-like behaviour of flow occurs when , while a plume-like behaviour is obtained when .

- For the dependent variables of velocity, relative concentration and relative temperature, the scale is used, where stands for the corresponding value of variable at the exit.

2.1.2. Governing Equations of Flow and Temperature Field

2.1.3. Integration of PDE on the Buoyant Jet Cross-Section

2.1.4. Application to a Room Air-Conditioning

- Step 1. For a uniform room-air temperature of °C, the model runs for the above-prescribed exit and room conditions and predicts the trajectory of the buoyant jet. When the buoyant jet meets the room floor, is deflected and spreads horizontally sideways for 2 s up to fill a layer of height m. The layer temperature is , because the buoyant jet during its passage entrains warmer air from the room and mixes it with the produced cool air. Since , for the layer density is and, thus, this layer remains at the bottom as heavier than the above room air; note that the buoyant jet behaviour is plume-like near the bottom with insignificant momentum [9]. The room air stratification is now started with a Brunt–Väisälä frequency . At this step, the mean air temperature of the buoyant jet at the level of this layer is increased to due to entrainment. The total time needed from the air-conditioning start up to this point is considered as one cycle of operation.

- Step 2. The model runs from the beginning, but, as it approaches the bottom wall, it entrains and mixes air with temperature . Thus, its temperature and its density become and , correspondingly, while the buoyant jet temperature becomes . For the reasons described in Step 1, it pushes up the previous layer and takes its position, forming another stratified region with frequency . This is the second cycle of the procedure.

- Step 3. The procedure continues as described in Step 2 up to fill with layers the room space from the floor up to the exit level of the air-conditioning device. The total time needed for integrating the whole procedure is calculated as described in Step 1, accounting for all cycle steps. The air stratification reduces the buoyant jet momentum, and the flow is governed more and more by buoyant forces. This reason causes the buoyant jet to approach the bottom wall at the last step earlier than at the first step. However, no jet trapping happened during the runs for the inclination angles examined. It is observed that, at the last step, the room air temperature becomes uniform and equal to the exit temperature.

3. Results and Discussion

3.1. Buoyant Jet Characteric Variations

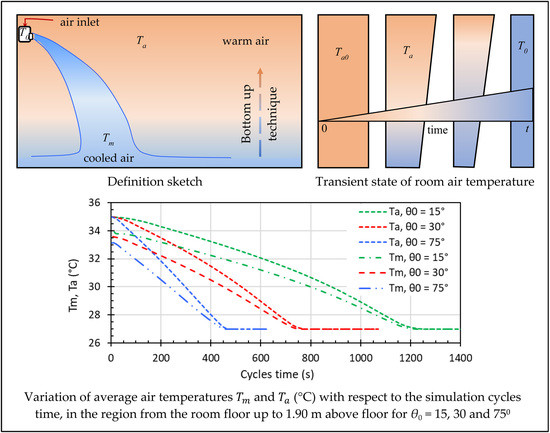

3.2. The Transient State of the Room Air Temperatures

3.3. Brunt–Väisälä Frequency Presentation

4. Conclusions

- As shown by the results and the associated discussion, the integral model EMA equipped with the conservation of tracer (relative concentration or relative temperature) and satisfactorily qualified was finally appropriate to perform the present study. The technique proposed to treat the transient phenomenon as a quasi-steady-state along with EMA and the novel bottom-up approach to produce layers by the buoyant jet formed by the cool air leaving the air-conditioning device proved successful.

- It was certified by the model implementation that the most appropriate concentration to get reasonable results of the room air temperatures is based on the bulk dilution because it feeds the layers with the average air temperature of the near bottom cross-section of the buoyant jet.

- The simulation showed that a momentum-dominated buoyant jet within a uniform environment rather keeps this behaviour, while it gradually becomes buoyancy dominated within a stratified environment. Thus, although at the first cycle of simulation, when the room air is uniform, the buoyant jet has a nearly straight trajectory, at the last cycle of simulation, the trajectory bends over downward.

- The simulation time needed for stabilisation of the room temperature at 27 °C provided by the air-conditioning device is more than 28 min for 15° inclination angle of the jet exit; this result approximated closely the experimental time of 31 min.

- The cooling rates based on the average temperature of the buoyant jet cross-section, are 10 to 30% lower than the corresponding ones based on the room temperatures.

- The Brunt–Väisälä frequency occurring during the temperature transitions remains constant for the same inclination angle of the exit velocity. Its value is increased with increasing the inclination angle, ranging between 1.07 to 1.32 s−1.

- The model could be used for the evaluation of air-conditioning systems operating in closed rooms by recirculating the room air. Future studies could focus on simulating the heating of a room using air-conditioning systems or fan coils.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A. Qualification of the 2D Mode of EMA

References

- Baines, W.; Turner, J. Turbulent buoyant convection from a source in a confined region. J. Fluid Mech. 1969, 37, 51–80. [Google Scholar] [CrossRef]

- Turner, J.S. Buoyancy Effects in Fluids; Cambridge University Press: Cambridge, UK, 1973. [Google Scholar]

- Germeles, A. Forced plumes and mixing of liquids in tanks. J. Fluid Mech. 1975, 71, 601–623. [Google Scholar] [CrossRef]

- Worster, M.G.; Huppert, H.E. Time-dependent density profiles in a filling box. J. Fluid Mech. 1983, 132, 457–466. [Google Scholar] [CrossRef] [Green Version]

- Barnett, S.J. The Dynamics of Buoyant Releases in Confined Spaces. Ph.D. Thesis, University of Cambridge, Cambridge, UK, October 1991. [Google Scholar]

- Thomas, L.P.; Marino, B.M.; Tovar, R.; Castillo, J.A. Flow generated by a thermal plume in a cooled-ceiling system. Energy Build. 2011, 43, 2727–2736. [Google Scholar] [CrossRef]

- Cheng, Y.; Lin, Z. Experimental investigation into the interaction between the human body and room airflow and its effect on thermal comfort under stratum ventilation. Indoor Air 2016, 26, 274–285. [Google Scholar] [CrossRef]

- Yang, R.; Ng, C.S.; Chong, K.L.; Verzicco, R.; Lohse, D. Do increased flow rates in displacement ventilation always lead to better results? J. Fluid Mech. 2022, 932, A3. [Google Scholar] [CrossRef]

- Hunt, G.R.; Cooper, P.; Linden, P.F. Thermal stratification produced by jets and plumes in enclosed spaces. Build. Environ. 2001, 36, 871–882. [Google Scholar] [CrossRef]

- Kaye, N.B.; Hunt, G.R. Overturning in a filling box. J. Fluid Mech. 2007, 576, 297–323. [Google Scholar] [CrossRef]

- Kaye, N.B.; Hunt, G.R. Smoke filling time for a room due to a small fire: The effect of ceiling height to floor width aspect ratio. Fire Saf. J. 2007, 42, 329–339. [Google Scholar] [CrossRef]

- Van Sommeren, D.D.J.A.; Caulfield, C.P.; Woods, A.W. Turbulent buoyant convection from a maintained source of buoyancy in a narrow vertical tank. J. Fluid Mech. 2012, 701, 278–303. [Google Scholar] [CrossRef]

- Akhter, R.; Kaye, N.B. Experimental investigation of a line plume in a filling box. Environ. Fluid Mech. 2020, 20, 1579–1601. [Google Scholar] [CrossRef]

- Gladstone, C.; Woods, A.W. Detrainment from a turbulent plume produced by a vertical line source of buoyancy in a confined, ventilated space. J. Fluid Mech. 2014, 742, 35–49. [Google Scholar] [CrossRef]

- Bonnebaigt, R.; Caulfield, C.P.; Linden, P.F. Detrainment of plumes from vertically distributed sources. Environ. Fluid Mech. 2016, 18, 3–25. [Google Scholar] [CrossRef] [Green Version]

- Kaye, N.B.; Cooper, P. Source and boundary condition effects on unconfined and confined vertically distributed turbulent plumes. J. Fluid Mech. 2018, 850, 1032–1065. [Google Scholar] [CrossRef]

- Cooper, P.; Hunt, G.R. The ventilated filling box containing a vertically distributed source of buoyancy. J. Fluid Mech. 2010, 646, 39–58. [Google Scholar] [CrossRef] [Green Version]

- Wong, A.B.D.; Griffiths, R.W. Stratification and convection produced by multiple turbulent plumes. Dyn. Atmos. Ocean. 1999, 30, 101–123. [Google Scholar] [CrossRef]

- Yin, S.; Li, Y.; Fan, Y.; Sandberg, M. Unsteady large-scale flow patterns and dynamic vortex movement in near-field triple buoyant plumes. Build Environ. 2018, 142, 288–300. [Google Scholar] [CrossRef]

- Yin, S.; Li, Y.; Fan, Y.; Sandberg, M. Experimental investigation of near-field stream-wise flow development and spatial structure in triple buoyant plumes. Build Environ. 2019, 149, 79–89. [Google Scholar] [CrossRef]

- Yin, S.; Fan, Y.; Sandberg, M.; Li, Y. PIV based POD analysis of coherent structures in flow patterns generated by triple interacting buoyant plumes. Build Environ. 2019, 158, 165–181. [Google Scholar] [CrossRef]

- Cariteau, B.; Brinster, J.; Tkatschenko, I. Experiments on the distribution of concentration due to buoyant gas low flow rate release in an enclosure. Int. J. Hydrog. Energy 2011, 36, 2505–2512. [Google Scholar] [CrossRef]

- Cariteau, B.; Tkatschenko, I. Experimental study of the effects of vent geometry on the dispersion of a buoyant gas in a small enclosure. Int. J. Hydrog. Energy 2013, 38, 8030–8038. [Google Scholar] [CrossRef]

- Gupta, S.; Brinster, J.; Studer, E.; Tkatschenko, I. Hydrogen related risks within a private garage concentration measurements in a realistic full scale experimental facility. Int. J. Hydrog. Energy 2009, 34, 5902–5911. [Google Scholar] [CrossRef]

- Cariteau, B.; Tkatschenko, I. Experimental study of the concentration build-up regimes in an enclosure without ventilation. Int. J. Hydrog. Energy 2012, 37, 17400–17408. [Google Scholar] [CrossRef]

- De Stefano, M.; Rocourt, X.; Sochet, I.; Daudey, N. Hydrogen dispersion in a closed environment. Int. J. Hydrog. Energy 2018, 44, 9031–90400. [Google Scholar] [CrossRef]

- Chen, M.; Zhao, M.; Huang, T.; Ji, S.; Chen, L.; Chang, H.; Li, X. Measurements of helium distributions in a scaled-down parking garage model for unintended releases from a fuel cell vehicle. Int. J. Hydrog. Energy 2020, 45, 22166–22175. [Google Scholar] [CrossRef]

- Cardoso, S.S.S.; Woods, A.W. Mixing by a plume in a confined stratified region. J. Fluid Mech. 1993, 250, 277–305. [Google Scholar] [CrossRef]

- Bloomfield, L.J.; Kerr, R.C. Turbulent fountains in a confined stratified environment. J. Fluid Mech. 1999, 389, 27–54. [Google Scholar] [CrossRef]

- Mott, R.W.; Woods, A.W. On the mixing of a confined stratified fluid by a turbulent buoyant plume. J. Fluid Mech. 2009, 623, 149–165. [Google Scholar] [CrossRef] [Green Version]

- Cleaver, R.P.; Marshal, M.R.; Linden, P.F. The build-up of concentration within a single enclosed volume following a release of natural gas. J. Hazard. Mater. 1994, 36, 209–226. [Google Scholar] [CrossRef]

- Kaye, N.B.; Ji, Y.; Cook, M.J. Numerical simulation of transient flow development in a naturally ventilated room. Build. Environ. 2009, 44, 889–897. [Google Scholar] [CrossRef]

- Yang, X.; Zhong, K.; Kang, Y.; Tao, T. Numerical investigation on the airflow characteristics & thermal comfort in buoyancy-driven natural ventilation rooms. Energy Build. 2015, 109, 255–266. [Google Scholar] [CrossRef]

- El-Amin, M.F.; Sun, S.; Heidemann, W.; Müller-Steinhagen, H. Analysis of a turbulent buoyant confined jet modeled using realizable k–ɛ model. Heat Mass Transf. 2010, 46, 943–960. [Google Scholar] [CrossRef]

- George, A.M.; Kay, A. Numerical simulations of a line plume impinging on a ceiling in cold fresh water. Int. J. Heat Mass Transf. 2017, 108, 1364–1373. [Google Scholar] [CrossRef] [Green Version]

- Hattori, T.; Armfield, S.W.; Kirkpatrick, M.P. Transitional ventilated filling box flow with a line heat source. Int. J. Heat Mass Transf. 2012, 55, 3650–3665. [Google Scholar] [CrossRef]

- Gao, X.; Li, A.; Yang, C. Study on thermal stratification of an enclosure containing two interacting turbulent buoyant plumes of equal strength. Build Environ. 2018, 141, 236–246. [Google Scholar] [CrossRef]

- Cao, G.; Kurnitski, J.; Ruponen, M.; Seppänen, O. Experimental investigation and modelling of a buoyant attached plane jet in a room. Appl. Therm. Eng. 2009, 29, 2790–2798. [Google Scholar] [CrossRef] [Green Version]

- Cao, G.; Sivukari, M.; Kurnitski, J.; Ruponen, M. PIV measurement of the attached plane jet velocity field at a high turbulence intensity level in a room. Int. J. Heat Fluid Flow. 2010, 31, 897–908. [Google Scholar] [CrossRef]

- Ji, K.; Cai, W.; Zhang, X.; Wu, B.; Ou, X. Modeling and validation of an active chilled beam terminal unit. J. Build. Eng. 2019, 22, 161–170. [Google Scholar] [CrossRef]

- Filipsson, P.; Trüschel, A.; Gräslund, J.; Dalenbäck, J.-O. Modelling of rooms with active chilled beams. J. Build. Perform. Simul. 2020, 13, 409–418. [Google Scholar] [CrossRef]

- Wu, B.; Cai, W.; Chen, H.; Ji, K. Experimental investigation on airflow pattern for active chilled beam system. Energy Build. 2018, 166, 438–449. [Google Scholar] [CrossRef]

- Cao, G.; Kurnitski, J.; Mustakallio, P.; Seppänen, O. Active Chilled Beam Wall Jet Prediction by the Free Convection Model. Int. J. Vent. 2008, 7, 169–178. [Google Scholar] [CrossRef]

- Nielsen, P.V.; Restivo, A.; Whitelaw, J.H. The Velocity Characteristics of Ventilated Rooms. J. Fluids Eng. 1978, 100, 291–298. [Google Scholar] [CrossRef]

- Yannopoulos, P.C.; Bloutsos, A.A. Escaping mass approach for inclined plane and round buoyant jets. J. Fluid Mech. 2012, 695, 81–111. [Google Scholar] [CrossRef]

- Lee, J.H.W.; Chu, V.H. Turbulent Jets and Plumes—A Lagrangian Approach; Kluwer Academic Publishers: Boston, MA, USA, 2003; ISBN 1-4020-7520-0. [Google Scholar]

- Bloutsos, A.A.; Yannopoulos, P.C. Curvilinear coordinate system for mathematical analysis of inclined buoyant jets using the integral method. Math. Probl. Eng. 2018, 2018, 3058425. [Google Scholar] [CrossRef]

- Bloutsos, A.A.; Yannopoulos, P.C. Revisiting Mean Flow and Mixing Properties of Negatively Round Buoyant Jets Using the Escaping Mass Approach (EMA). Fluids 2020, 5, 131. [Google Scholar] [CrossRef]

- Wallace, R.B.; Sheff, B.B. Two-dimensional buoyant jets in two-layer ambient fluid. J. Hydraul. Eng. 1987, 113, 992–1005. [Google Scholar] [CrossRef]

- Batchelor, G. An Introduction to Fluid Dynamics; Cambridge University Press: Cambridge, UK, 2000; ISBN 9780511800955. [Google Scholar]

- Yannopoulos, P.C. An improved integral model for plane and round turbulent buoyant jets. J. Fluid Mech. 2006, 547, 267–296. [Google Scholar] [CrossRef]

- Yannopoulos, P.C.; Noutsopoulos, G.C. Interaction of vertical round turbulent buoyant jets—Part I: Entrainment restriction approach. J. Hydraul. Res. 2006, 44, 218–232. [Google Scholar] [CrossRef]

- Yannopoulos, P.C.; Noutsopoulos, G.C. Interaction of vertical round turbulent buoyant jets—Part II: Superposition method. J. Hydraul. Res. 2006, 44, 233–248. [Google Scholar] [CrossRef]

- Bloutsos, A.A.; Yannopoulos, P.C. Round turbulent buoyant jets discharged vertically upwards forming a regular polygon. J. Hydraul. Res. 2009, 47, 263–274. [Google Scholar] [CrossRef]

- Yannopoulos, P.C. Advanced integral model for groups of interacting round turbulent buoyant jets. Env. Fluid Mech 2010, 10, 415–450. [Google Scholar] [CrossRef]

- He, L.; Zhao, S.; Xu, G.; Wu, X.; Xie, J.; Cai, S. Prediction and evaluation of dynamic variations of the thermal environment in an air-conditioned room using collaborative simulation method. Energies 2021, 14, 5378. [Google Scholar] [CrossRef]

- Pasquill, F.; Smith, F.B. Atmospheric Diffusion, 3rd ed.; Ellis Horwood: Cambridge, UK, 1983. [Google Scholar]

- Wallace, R.B.; Wright, S.J. Spreading layer of two-dimensional buoyant jet. J. Hydraul. Eng. 1984, 110, 813–828. [Google Scholar] [CrossRef]

- Lee, J.H.W.; Cheung, V.W.L. Inclined plane buoyant jet in stratified fluid. J. Hydraul. Eng. 1986, 112, 580–589. [Google Scholar] [CrossRef]

| 15 | 5.286 1 | 4.339 | 14.16 | 8.40 | 1687.41 |

| 30 | 3.829 | 3.228 | 7.07 | 5.32 | 1070.04 |

| 45 | 2.919 | 2.692 | 4.70 | 4.07 | 812.15 |

| 60 | 2.482 | 2.401 | 3.66 | 3.39 | 683.08 |

| 75 | 2.275 | 2.254 | 3.21 | 3.10 | 621.93 |

| 15 | −0.134 | −0.884 |

| 30 | −0.244 | −0.771 |

| 45 | −0.293 | −0.719 |

| 60 | −0.319 | −0.687 |

| 75 | −0.326 | −0.678 |

| Interval (s) | Interval (s) | Interval (s) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| 15 | 45–450 | −0.266 | −0.293 | 450–850 | −0.352 | −0.402 | 850–1200 | −0.451 | −0.533 |

| 30 | 45–450 | −0.508 | −0.587 | 450–750 | −0.605 | −0.754 | ≥750 | 0 | 0 |

| 45 | 45–550 | −0.704 | −0.871 | ≥550 | 0 | 0 | |||

| 60 | 45–500 | −0.787 | −992 | ≥500 | 0 | 0 | |||

| 75 | 45–450 | −0.839 | −1.087 | ≥550 | 0 | 0 |

| 15 | 30 | 45 | 60 | 75 | |

|---|---|---|---|---|---|

| f (s−1) | 1.07 | 1.17 | 1.25 | 1.30 | 1.32 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bloutsos, A.A.; Yannopoulos, P.C. Room Air-Conditioning Operating as a Filling Box. Processes 2022, 10, 213. https://doi.org/10.3390/pr10020213

Bloutsos AA, Yannopoulos PC. Room Air-Conditioning Operating as a Filling Box. Processes. 2022; 10(2):213. https://doi.org/10.3390/pr10020213

Chicago/Turabian StyleBloutsos, Aristeidis A., and Panayotis C. Yannopoulos. 2022. "Room Air-Conditioning Operating as a Filling Box" Processes 10, no. 2: 213. https://doi.org/10.3390/pr10020213

APA StyleBloutsos, A. A., & Yannopoulos, P. C. (2022). Room Air-Conditioning Operating as a Filling Box. Processes, 10(2), 213. https://doi.org/10.3390/pr10020213