Simulation Study on Gas Holdup of Large and Small Bubbles in a High Pressure Gas–Liquid Bubble Column

Abstract

:1. Introduction

2. Experimental Setup

3. Mathematical Model

3.1. Two-Fluid Model

3.2. Interphase Force

3.2.1. Drag Force

3.2.2. Turbulent Dispersion Force

3.2.3. Horizontal Lift Force

3.2.4. Wall Lubrication Force

3.3. Bubble Breakup Model

3.4. Bubble Coalescence Model

4. Results and Discussion

4.1. Mesh Independence

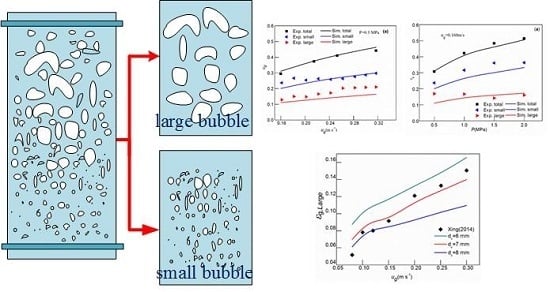

4.2. Determination of Critical Bubble Diameters

4.3. The Gas Holdup of Large Bubbles and Small Bubbles

4.3.1. Effect of the Superficial Gas Velocity on the Gas Holdup

4.3.2. Effect of the Different Pressure on the Gas Holdup

4.3.3. Effect of Surface Tension on the Gas Holdup of Large and Small Bubbles

4.3.4. Effect of the Viscosity on the Gas Holdup

5. Conclusions

- (1)

- Using 6, 7 and 8 mm as critical bubble diameters, the variation trend of the gas holdup of the large bubbles with the superficial gas velocity was obtained from the simulation results, and it was compared with the gas holdup of Xing [19] in the water–air system. It was finally determined the critical bubble diameter that divided the bubble into large and small bubbles was 7 mm.

- (2)

- Using the modified CFD-PBM coupling model, the effects of superficial gas velocity and operating pressure on the gas holdup of large bubbles and small bubbles were analyzed. It is found that as the superficial gas velocity increased, the gas holdup of large and small bubbles increased to varying degrees. On the other hand, with the increase of pressure, the influence of pressure on the gas holdup of large bubbles gradually weakened. In the high pressure, the gas holdup of the small bubble increased with the increase of the superficial gas velocity.

- (3)

- Compared with the results of the cold model experiment, it is found that the modified CFD-PBM coupling model could effectively estimate the influence of surface tension and viscosity on the gas holdup of large and small bubbles. That is, the gas holdup of the small bubbles gradually decreased as the surface tension and viscosity increased. The gas holdup of the large bubble gradually increased with the increase of the surface tension and viscosity.

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| εg | ——[--] | gas phase holdup |

| dc | ——[mm] | The critical bubble diameter, mm |

| ui | ——[m s−1] | velocity, m·s−1, i = 1: gas phase, i = 2: liquid phase |

| g | ——[m s−2] | gravitational acceleration, m s−2 |

| εL | ——[--] | liquid phase holdup |

| ρ | ——[kg m−3] | density, kg·m−3 |

| U | ——[m s−1] | velocity, m·s−1 |

| τ | ——[--] | effective pressure tensor |

| g | ——[m s2] | gravitational acceleration, m·s2 |

| ε | ——[m2 s−3] | turbulent dissipation rate, m2·s−3 |

| μt | ——[Pa s] | turbulent viscosity, Pa·s |

| K,kL | ——[m2 s−2] | turbulent kinetic energy, m2·s−2 |

| FD | ——[N m−3] | drag, N·m−3 |

| uG | ——[m s−1] | gas velocity, m·s−1 |

| uL | ——[m s−1] | liquid velocity, m·s−1 |

| CD | ——[--] | drag coefficient |

| CD,∞ | ——[--] | ideal state drag coefficient |

| Eo | ——[--] | parameter Eo |

| FL | ——[N] | transverse lift, N |

| CL | ——[--] | transverse lift coefficient |

| CTD | ——[--] | turbulent dispersion coefficient |

| FTD,L FTD,G | ——[N] | turbulent dispersion force, N |

| fTD,limiting | ——[--] | turbulent diffusion force model limiting function |

| FWL | ——[N] | wall lubrication force, N |

| CWL | ——[--] | wall lubrication coefficient |

| Eo | ——[--] | parameter Eo |

| dB | ——[m] | diameter of the bubble, m |

| Ωbr(V,V’) | ——[--] | bubble breakage rate |

| σ | ——[N s−1] | surface tension, N·s−1 |

| ζ | ——[--] | relative diameter of the bubble |

| ζmin | ——[--] | minimum relative diameter of the bubble |

| Ωag(ViVj) | ——[--] | bubble coalescence rate |

| ω(ViVj) | ——[m3 s−1] | collision frequency between bubbles of size di and dj, m3·s−1 |

| P(ViVj) | ——[--] | bubble coalescence efficiency |

| uij | ——[--] | characteristic velocity of bubble collision |

| Lower subscript | ||

| G | —— | gas phase |

| L | —— | liquid phase |

| i | —— | referring to the gas phase or the liquid phase |

| b | —— | bubble |

| i,j | —— | bubble section |

References

- Parisien, V.; Farrell, A.; Pjontek, D.; McKnight, C.; Wiens, J.; Macchi, A. Bubble swarm characteristics in a bubble column under high gas holdup conditions. Chem. Eng. Sci. 2017, 157, 88–98. [Google Scholar] [CrossRef]

- Hur, Y.; Yang, J.; Jung, H.; Lee, K. Continuous alcohol addition in vaporized form and its effect on bubble behavior in a bubble column. Chem. Eng. Res. Des. 2014, 92, 804–811. [Google Scholar] [CrossRef]

- Hlawitschka, M.; Kováts, P.; Zähringer, K.; Bart, H. Simulation and experimental validation of reactive bubble column reactors. Chem. Eng. Sci. 2016, 170, 306–319. [Google Scholar] [CrossRef]

- Sommerfeld, M.; Bröder, D. Analysis of Hydrodynamics and Microstructure in a Bubble Column by Planar Shadow Image Velocimetry. Ind. Eng. Chem. Res. 2009, 48, 330–340. [Google Scholar] [CrossRef]

- Saleh, S.; Mohammed, A.; Al-Jubory, F.; Barghi, S. CFD assesment of uniform bubbly flow in a bubble column. Petrol. Sci. Eng. 2018, 196, 96–107. [Google Scholar] [CrossRef]

- Sharaf, S.; Zednikova, M.; Ruzicka, M.; Azzopardi, M. Global and local hydrodynamics of bubble columns–Effect of gas distributor. Chem. Eng. J. 2016, 288, 489–504. [Google Scholar] [CrossRef]

- Sasaki, S.; Uchida, K.; Hayashi, K.; Tomiyama, A. Effects of column diameter and liquid height on gas holdup in air-water bubble columns. Exp. Therm. Fluid. Sci. 2017, 82, 359–366. [Google Scholar] [CrossRef]

- Mouza, A.; Dalakoglou, G.; Paras, S. Effect of liquid properties on the performance of bubble column reactors with fine pore spargers. Chem. Eng. Sci. 2005, 60, 1465–1475. [Google Scholar] [CrossRef]

- Jin, H.; Yang, S.; Zhang, T.; Tong, Z. Bubble behavior of a large-scale bubble column with elevated pressure. Chem. Eng. Technol. 2004, 27, 1007–1013. [Google Scholar] [CrossRef]

- Krishna, R.; Ellenberger, J. Gas holdup in bubble column reactors operating in the churn-turbulent flow regime. AIChE J. 1996, 42, 2627–2634. [Google Scholar] [CrossRef]

- Shetty, S.A.; Kantak, M.V.; Kelkar, B.G. Gas-phase backmixing in bubble-column reactors. AIChE J. 1992, 38, 1013–1026. [Google Scholar] [CrossRef]

- De Swart, J.W.A.; van Vliet, R.E.; Krishna, R. Size, structure and dynamics of large bubbles in a two-dimensional slurry bubble column. Chem. Eng. Sci. 1996, 51, 4619–4629. [Google Scholar] [CrossRef]

- Pourtousi, M.; Ganesan, P.; Sahu, J. Effect of bubble diameter size on prediction of flow pattern in Euler–Euler simulation of homogeneous bubble column regime. Measurement 2015, 76, 255–270. [Google Scholar] [CrossRef]

- Guan, X.; Yang, N. Bubble Properties Measurement in Bubble Columns: From Homogeneous to Heterogeneous Regime. Chem. Eng. Res. Des. 2017, 107, 103–122. [Google Scholar] [CrossRef]

- Zhang, B. Numerical Simulation of Gas-Liquid Flow in a Pressurized Bubble Column Using the CFD-PBM Coupled Model. Master’s Thesis, Beijing Institute of Petrochemical Technology, Beijing, China, 2018. [Google Scholar]

- Besagni, G.; Inzoli, F. Bubble size distributions and shapes in annular gap bubble column. Exp. Therm. Fluid. Sci. 2016, 74, 27–48. [Google Scholar] [CrossRef] [Green Version]

- Gemello, L.; Plais, C.; Augier, F.; Cloupet, A.; Marchisio, D. Hydrodynamics and bubbe size in bubble columns: Effects of contaminants and spargers. Chem. Eng. Sci. 2018, 184, 93–102. [Google Scholar] [CrossRef]

- Zhang, T.; Jin, H.; He, G.; Yang, S.; Tong, Z. Application of Pressure Transducing Technology to Measurement of Hydrodynamics in Bubble Column. Chin. J. Chem. Eng. 2004, 55, 476–480. [Google Scholar] [CrossRef]

- Yang, S. The Hydrodynamic Characteristics of Slurry Bubble Column Reactors with Elevated Pressure. Master’s Thesis, Beijing University of Chemical Technology, Beijing, China, 2004. [Google Scholar]

- Xing, C. Experimental Study and Numerical Simulations of Bubble Column with a CFD-PBM Coupled Model. Ph.D. Thesis, Tsinghua University, Beijing, China, 2014. [Google Scholar]

- Shaikh, A.; Al-Dahhan, M. Scale-up of Bubble Column Reactors: A Review of Current State-of-the-Art. Ind. Eng. Chem. Res. 2013, 52, 8091–8108. [Google Scholar] [CrossRef]

- Sarhan, A.; Naser, J.; Brooks, G. CFD analysis of solid particles properties effect in three-phase flotation column. Sep. Purif. Technol. 2017, 185, 1–9. [Google Scholar] [CrossRef]

- Yang, G.; Guo, K.; Wang, T. Numerical simulation of the bubble column at elevated pressure with a CFD-PBM coupled model. Chem. Eng. Sci. 2017, 170, 251–262. [Google Scholar] [CrossRef]

- Roghair, I.; Van, S.; Kuipers, H. Drag force and clustering in bubble swarms. AIChE J. 2013, 59, 1791–1800. [Google Scholar] [CrossRef]

- Qin, Y. The Measurement of Hydrodynamic Parameters and CFD Simulation of Gas-Liquid Flow Behaviors in a Pressurized Bubble Column. Master’s Thesis, Beijing University of Chemical Technology, Beijing, China, 2012. [Google Scholar]

- Lopez, M. Turbulent Bubbly Two-Phase Flow in a Triangular Duct; Rensselaer Rolytechnic Institute: New York, NY, USA, 1992. [Google Scholar]

- Ueyama, K.; Miyauchi, T. Properties of recirculating turbulent two phase flow in gas bubble columns. AIChE J. 2010, 25, 258–266. [Google Scholar] [CrossRef]

- Drew, D. Mathematical modeling of two-phase flow. Annu. Rev. Fluid. Mech. 1983, 15, 261–291. [Google Scholar] [CrossRef]

- Zhang, Y. Hydrodynamics of Turbulent Bubble Column with and without Internals in Well-Developed Flow Region. Ph.D. Thesis, Zhejiang University, Hangzhou, China, 2011. [Google Scholar]

- Nguyen, V.; Song, C.; Bae, B.; Euh, D. The dependence of wall lubrication force on liquid velocity in turbulent bubbly two-phase flows. J. Nucl. Sci. Technol. 2013, 50, 781–798. [Google Scholar] [CrossRef] [Green Version]

- Tomiyama, A. Struggle with Computational Bubble Dynamics. Multiph. Sci. Technol. 1998, 10, 369–405. [Google Scholar] [CrossRef]

- Luo, H.; Svendsen, H.F. Theoretical Model for drop and bubble breakup in turbulent dispersions. AIChE J. 1996, 42, 1225–1233. [Google Scholar] [CrossRef]

- Lehr, F.; Millies, M.; Mewes, D. Bubble size distributions and flow fields in bubble column. AIChE J. 2002, 48, 2426–2443. [Google Scholar] [CrossRef]

- Laakkonen, M.; Alopaeus, V.; Aittamaa, J. Validation of bubble breakage, coalescence and mass transfer models for gas–liquid dispersion in agitated vessel. Chem. Eng. Sci. 2006, 61, 218–228. [Google Scholar] [CrossRef]

- Zhang, B.; Kong, L.; Jin, H.; He, G.; Yang, S.; Guo, X. CFD simulation of gas–liquid flow in a high-pressure bubble column with a modified population balance model. Chin. J. Chem. Eng. 2018, 26, 125–133. [Google Scholar] [CrossRef]

- Jordan, U.; Schumpe, A. The gas gensity effect on mass transfer in bubble columns with organic liquids. Chem. Eng. Sci. 2001, 56, 6267–6272. [Google Scholar] [CrossRef]

- Khare, A.; Joshi, J. Effect of fine particles on gas hold-up in three-phase sparged reactors. Chem. Eng. J. 1990, 44, 11–25. [Google Scholar] [CrossRef]

| P(MPa) | ug | dB,exp | CD | Error | |||

|---|---|---|---|---|---|---|---|

| 0.1 | 1 | 0.088 | 9.64 | 0.17 | 0.70 | 0.18 | 0.17% |

| 0.132 | 9.91 | 0.22 | 0.40 | 0.21 | −1.94% | ||

| 0.154 | 10.05 | 0.23 | 0.28 | 0.22 | −2.08% | ||

| 0.199 | 10.32 | 0.25 | 0.21 | 0.25 | 0.51% | ||

| 0.5 | 5 | 0.199 | 9.67 | 0.35 | 0.51 | 0.36 | 0.42% |

| 0.233 | 9.84 | 0.39 | 0.46 | 0.39 | −0.83% | ||

| 0.275 | 10.08 | 0.42 | 0.41 | 0.42 | −0.81% | ||

| 0.317 | 10.30 | 0.45 | 0.36 | 0.44 | −0.97% | ||

| 1.0 | 10 | 0.199 | 9.39 | 0.35 | 0.51 | 0.36 | 0.42% |

| 0.233 | 9.83 | 0.49 | 0.68 | 0.49 | −0.93% | ||

| 0.275 | 10.13 | 0.51 | 0.55 | 0.50 | −1.09% | ||

| 0.317 | 10.22 | 0.52 | 0.46 | 0.53 | −0.78% | ||

| 1.5 | 15 | 0.199 | 9.15 | 0.50 | 0.88 | 0.51 | 0.50% |

| 0.233 | 9.69 | 0.53 | 0.75 | 0.53 | −0.96% | ||

| 0.275 | 9.93 | 0.55 | 0.63 | 0.55 | 0.11% | ||

| 0.317 | 10.06 | 0.56 | 0.49 | 0.56 | 0.82% | ||

| 2.0 | 20 | 0.199 | 8.98 | 0.54 | 0.97 | 0.54 | 0.37% |

| 0.233 | 9.14 | 0.56 | 0.78 | 0.56 | −0.27% | ||

| 0.275 | 9.36 | 0.57 | 0.63 | 0.57 | −0.64% | ||

| 0.317 | 9.50 | 0.58 | 0.52 | 0.58 | −0.41% |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tao, F.; Ning, S.; Zhang, B.; Jin, H.; He, G. Simulation Study on Gas Holdup of Large and Small Bubbles in a High Pressure Gas–Liquid Bubble Column. Processes 2019, 7, 594. https://doi.org/10.3390/pr7090594

Tao F, Ning S, Zhang B, Jin H, He G. Simulation Study on Gas Holdup of Large and Small Bubbles in a High Pressure Gas–Liquid Bubble Column. Processes. 2019; 7(9):594. https://doi.org/10.3390/pr7090594

Chicago/Turabian StyleTao, Fangfang, Shanglei Ning, Bo Zhang, Haibo Jin, and Guangxiang He. 2019. "Simulation Study on Gas Holdup of Large and Small Bubbles in a High Pressure Gas–Liquid Bubble Column" Processes 7, no. 9: 594. https://doi.org/10.3390/pr7090594

APA StyleTao, F., Ning, S., Zhang, B., Jin, H., & He, G. (2019). Simulation Study on Gas Holdup of Large and Small Bubbles in a High Pressure Gas–Liquid Bubble Column. Processes, 7(9), 594. https://doi.org/10.3390/pr7090594