Development of Test Procedures Based on Chaotic Advection for Assessing Polymer Performance in High-Solids Tailings Applications

Abstract

:1. Introduction

2. Materials and Methods

2.1. Substrate and Polymer Preparation

2.2. Polymer-Initiated Thickening and Dewatering

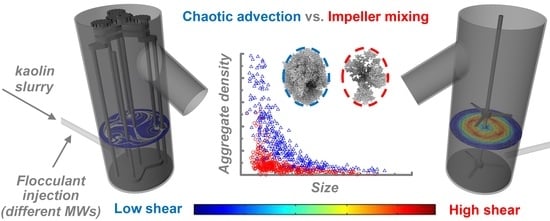

2.2.1. Initial Comparison of Chaotic vs. Impeller Mixing

2.2.2. Continuous Chaotic Mixing System with Tapered Shear

2.3. Aggregate Characterization

2.3.1. Focused Beam Reflectance Measurement

2.3.2. Floc Density Analysis

2.3.3. Particle Vision and Measurement

2.3.4. Rheological and Compressibility Characterization

3. Results and Discussion

3.1. The Impact of Applied Mixing

3.1.1. Chord Length Distributions and Dewatering Performance

3.1.2. Aggregate Free Settling Rates and Effective Densities

3.2. Tapered Shear and Chaotic Mixing

3.2.1. The Importance of Tapered Shear

3.2.2. The Impact of Polymer Molecular Weight

3.3. Relating Polymer Performance to Rheological Properties

4. Implications

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Davies, M.P.; Lupo, J.; Martin, T.; McRoberts, E.; Musse, M.; Ritchie, D. Dewatered tailings practice—Trends and observations. In Proceedings of the Fourteenth International Conference on Tailings and Mine Waste, Vail, Colorado, 17–20 October 2010; Taylor & Francis: London, UK; pp. 133–142. [Google Scholar]

- Fourie, A.B. Perceived and realised benefits of P&TT for surface deposition. In Proceedings of the 15th International Seminar on Paste and Thickened Tailings (Paste 2012), Sun City, South Africa, 16–19 April 2012; Jewell, R.J., Fourie, A.B., Paterson, A., Eds.; Australian Centre for Geomechanics: Nedlands, Australia; pp. 53–64. [Google Scholar]

- Williams, M.P.A.; Seddon, K.D.; Fitton, T.G. Surface disposal of paste and thickened tailings—A brief history and current confronting issues. In Proceedings of the 11th International Seminar on Paste and Thickened Tailings (Paste 2008), Kasane, Botswana, 5–9 May 2008; Fourie, A., Jewell, R., Slatter, P., Paterson, A., Eds.; Australian Centre for Geomechanics: Nedlands, Australia; pp. 143–164. [Google Scholar]

- Bedell, D.; Slottee, S.; Shoenbrunn, F.; Fawell, P. Chapter 7—Thickening. In Paste and Thickened Tailings—A Guide, 3rd ed.; Jewell, R.J., Fourie, A.B., Eds.; Australian Centre for Geomechanics: Nedlands, Australia, 2015; pp. 113–136. [Google Scholar]

- Cooling, D.J. Improving the sustainability of residue management practices—Alcoa World Alumina Australia. In Proceedings of the 10th International Seminar on Paste and Thickened Tailings (Paste 2007), Perth, Australia, 13–15 March 2007; Fourie, A., Jewell, R.J., Eds.; Australian Centre for Geomechanics: Nedlands, Australia; pp. 3–16. [Google Scholar]

- Hogg, R. Flocculation and dewatering. Int. J. Min. Process. 2000, 58, 223–236. [Google Scholar] [CrossRef]

- Kaminsky, H.A.W.; Etsell, T.H.; Ivey, D.G.; Omotoso, O. Distribution of clay minerals in the process streams produced by the extraction of bitumen from athabasca oil sands. Can. J. Chem. Eng. 2009, 87, 85–93. [Google Scholar] [CrossRef]

- McColl, P.; Scammell, S.; Philip, M.; Stephen, S. Treatment of Mineral Material, Especially Waste Mineral Slurries Transferring Material with Dispersed Particulate Solids as Fluid to Deposition Area by Combining with Material Aqueous Solution of Water-Soluble Polymer. Numerous Country Patents WO2004060819-A1 WOEP000042, 7 January 2004. [Google Scholar]

- Gaillard, N.; Poncet, F. Treating Sludge from Mining or Mineral Industry before Spreading out into Soil, Comprises Contacting the Sludge with a Branched Flocculant such as a Water Soluble Organic Polymer Having a Specified Anionicity for a Specified Duration. Patent FR2937635-A1; US2010105976-A1; CA2682542-A1, 29 April 2010. [Google Scholar]

- Wells, P.S.; Revington, A.; Omotoso, O. Mature fine tailings drying—Technology update. In Proceedings of the 14th International Seminar on Paste and Thickened Tailings (Paste 2011), Perth, Australia, 5–7 April 2011; Jewell, R., Fourie, A., Eds.; Australian Centre for Geomechanics: Nedlands, Australia; pp. 155–166. [Google Scholar]

- Fawell, P. Solid-liquid separation of clay tailings. In Clays in the Minerals Processing Value Chain; Gräfe, M., Klauber, C., McFarlane, A.J., Robinson, D., Eds.; Cambridge University Press: Cambridge, UK, 2017; pp. 327–380. [Google Scholar]

- Botha, L.; Davey, S.; Nguyen, B.; Swarnakar, A.K.; Rivard, E.; Soares, J.B.P. Flocculation of oil sands tailings by hyperbranched functionalized polyethylenes (HBfPE). Min. Eng. 2017, 108, 71–82. [Google Scholar] [CrossRef]

- Vajihinejad, V.; Soares, J.B.P. Monitoring polymer flocculation in oil sands tailings: A population balance model approach. Chem. Eng. J. 2018, 346, 447–457. [Google Scholar] [CrossRef]

- Vedoy, D.R.L.; Soares, J.B.P. Water-soluble polymers for oil sands tailing treatment: A Review. Can. J. Chem. Eng. 2015, 93, 888–904. [Google Scholar] [CrossRef]

- Zhang, D.; Thundat, T.; Narain, R. Flocculation and dewatering of mature fine tailings using temperature-responsive cationic polymers. Langmuir 2017, 33, 5900–5909. [Google Scholar] [CrossRef] [PubMed]

- Lester, D.R.; Rudman, M.; Metcalfe, G. Low Reynolds number scalar transport enhancement in viscous and non-Newtonian fluids. Int. J. Heat Mass Transf. 2009, 52, 655–664. [Google Scholar] [CrossRef]

- Metcalfe, G.; Rudman, M. Fluid Mixer. International Patent WO 02/20144A1, 13 June 2002. [Google Scholar]

- Metcalfe, G.; Rudman, M.; Brydon, A.; Graham, L.J.W.; Hamilton, R. Composing chaos: An experimental and numerical study of an open duct mixing flow. Alche J. 2006, 52, 9–28. [Google Scholar] [CrossRef]

- Speetjens, M.; Metcalfe, G.; Rudman, M. Topological mixing study of non-Newtonian duct flows. Phys. Fluids 2006, 18, 103103. [Google Scholar] [CrossRef] [Green Version]

- Finn, M.D.; Thiffeault, J.L. Topological entropy of braids on the torus. Siam J. Appl. Dyn. Syst. 2007, 6, 79–98. [Google Scholar] [CrossRef] [Green Version]

- Finn, M.D.; Thiffeault, J.L. Topological optimization of rod-stirring devices. Siam Rev. 2011, 53, 723–743. [Google Scholar] [CrossRef] [Green Version]

- Bagusat, F.; Böhme, B.; Schiller, P.; Mögel, H.J. Shear induced periodic structure changes in concentrated alumina suspensions at constant shear rate monitored by FBRM. Rheol. Acta 2005, 44, 313–318. [Google Scholar] [CrossRef]

- Richmond, W.R.; Jones, R.L.; Fawell, P.D. The relationship between particle aggregation and rheology in mixed silica-titania suspensions. Chem. Eng. J. 1998, 71, 67–75. [Google Scholar] [CrossRef]

- Heath, A.R.; Fawell, P.D.; Bahri, P.A.; Swift, J.D. Estimating average particle size by focused beam reflectance measurement (FBRM). Part. Part. Syst. Char. 2002, 19, 84–95. [Google Scholar] [CrossRef]

- Senaputra, A.; Jones, F.; Fawell, P.D.; Smith, P.G. Focused beam reflectance measurement for monitoring the extent and efficiency of flocculation in mineral systems. Alche J. 2014, 60, 251–265. [Google Scholar] [CrossRef]

- The Next Generation FBRM® (Focused Beam Reflectance Measurement). Mettler-Toledo Autochem. Available online: https://www.mt.com (accessed on 23 June 2020).

- Farrow, J.B.; Warren, L.J. Measurement of the Size of Aggregates in Suspension; Coagulation and Flocculation—Theory and Application; Dobias, B., Ed.; Marcel Dekker: New York, NY, USA, 1993; pp. 391–426. [Google Scholar]

- Happel, J.; Brenner, H. Low Reynolds Number Hydrodynamics; Noordhoff International Publishing: Leyden, The Netherlands, 1973. [Google Scholar]

- Usher, S.P.; De Kretser, R.G.; Scales, P.J. Validation of a new filtration technique for dewaterability characterization. Alche J. 2001, 47, 1561–1570. [Google Scholar] [CrossRef]

- Benn, F.A.; Fawell, P.D.; Halewood, J.; Austin, P.J.; Costine, A.D.; Jones, W.G.; Francis, N.S.; Druett, D.C.; Lester, D. Sedimentation and consolidation of different density aggregates formed by polymer-bridging flocculation. Chem. Eng. Sci. 2018, 184, 111–125. [Google Scholar] [CrossRef]

- Costine, A.D.; Vajihinejad, V.; Botha, L.; Fawell, P.D.; Soares, J.B.P. Aggregate structures formed by hyperbranched functionalized polyethylene (HBfPE) treatment of oil sands tailings. Can. J. Chem. Eng. 2019, 97, 99–102. [Google Scholar] [CrossRef] [Green Version]

- Farrow, J.B.; Johnston, R.R.M.; Simic, K.; Swift, J.D. Consolidation and aggregate densification during gravity thickening. Chem. Eng. J. 2000, 80, 141–148. [Google Scholar] [CrossRef]

- Kyoda, Y.; Costine, A.D.; Fawell, P.D.; Bellwood, J.; Das, G.K. Using focused beam reflectance measurement (FBRM) to monitor aggregate structures formed in flocculated clay suspensions. Min. Eng. 2019, 138, 148–160. [Google Scholar] [CrossRef]

- Owen, A.T.; Fawell, P.D.; Swift, J.D.; Labbett, D.M.; Benn, F.A.; Farrow, J.B. Using turbulent pipe flow to study the factors affecting polymer-bridging flocculation of mineral systems. Int. J. Min. Process. 2008, 87, 90–99. [Google Scholar] [CrossRef]

- Nan, J.; He, W. Characteristic analysis on morphological evolution of suspended particles in water during dynamic flocculation process. Desalin. Water Treat. 2012, 41, 35–44. [Google Scholar] [CrossRef]

- Yukselen, M.A.; O’Halloran, K.R.; Gregory, J. Effect of tapering on the break-up and reformation of flocs formed using hydrolyzing coagulants. Water Sci. Technol. Water Supply 2006, 6, 139–145. [Google Scholar] [CrossRef]

- Grabsch, A.F.; Fawell, P.D.; Adkins, S.J.; Beveridge, A. The impact of achieving a higher aggregate density on polymer-bridging flocculation. Int. J. Min. Process. 2013, 124, 83–94. [Google Scholar] [CrossRef]

- Li, H.; Long, J.; Xu, Z.; Masliyah, J.H. Effect of molecular weight and charge density on the performance of polyacrylamide in low-grade oil sand ore processing. Can. J. Chem. Eng. 2008, 86, 177–185. [Google Scholar] [CrossRef]

- Proskurina, V.E.; Myagchenkov, V.A. Flocculation activity of anionic copolymers of acrylamide with respect to titanium dioxide suspension as influenced by their molecular properties. Russ. J. Appl. Chem. 2006, 79, 301–305. [Google Scholar] [CrossRef]

- Watson, P.; Farinato, R.; Fenderson, T.; Hurd, M.; Macy, P.; Mahmoudkhani, A. Novel polymeric additives to improve oil sands tailings consolidation. In Proceedings of the SPE International Symposium on Oilfield Chemistry, The Woodlands, TX, USA, 11–13 April 2011; pp. 703–709. [Google Scholar]

- Costine, A.; Cox, J.; Travaglini, S.; Lubansky, A.; Fawell, P.; Misslitz, H. Variations in the molecular weight response of anionic polyacrylamides under different flocculation conditions. Chem. Eng. Sci. 2018, 176, 127–138. [Google Scholar] [CrossRef]

- Witham, M.I.; Grabsch, A.F.; Owen, A.T.; Fawell, P.D. The effect of cations on the activity of anionic polyacrylamide flocculant solutions. Int. J. Min. Process. 2012, 114–117, 51–62. [Google Scholar] [CrossRef]

- Owen, A.T.; Nguyen, T.V.; Fawell, P.D. The effect of flocculant solution transport and addition conditions on feedwell performance in gravity thickeners. Int. J. Min. Process. 2009, 93, 115–127. [Google Scholar] [CrossRef]

- Jeldres, R.I.; Fawell, P.D.; Florio, B.J. Population balance modelling to describe the particle aggregation process: A review. Powder Technol. 2018, 326, 190–207. [Google Scholar] [CrossRef]

- Clark, A.Q.; Herrington, T.M.; Petzold, J.C. The flocculation of kaolin suspensions with anionic polyacrylamides of varying molar mass and anionic character. Colloids Surf. 1990, 44, 247–261. [Google Scholar] [CrossRef]

- Gill, R.I.S.; Herrington, T.M. The flocculation of kaolin suspensions with cationic polyacrylamides of varying molar mass but the same cationic character. Colloids Surf. 1987, 22, 51–76. [Google Scholar] [CrossRef]

- Strandman, S.; Vachon, R.; Dini, M.; Giasson, S.; Zhu, X.X. Polyacrylamides revisited: Flocculation of kaolin suspensions and mature fine tailings. Can. J. Chem. Eng. 2018, 96, 20–26. [Google Scholar] [CrossRef] [Green Version]

- Wang, H.; Chao, L.; Wei, X.; Qi, X.; Li, J.; Jiang, L.; Li, W.; Jia, P. Design and preparation of flocculant with self-degrading characteristics for dewatering of oil sand tailings. J. Disper. Sci. Technol. 2019. [Google Scholar] [CrossRef]

- Lester, D.R.; Chryss, A. Topological mixing of yield stress materials. Phys. Rev. Fluids 2019, 4, 064502. [Google Scholar] [CrossRef]

- Carrière, P. On a three-dimensional implementation of the baker’s transformation. Phys. Fluids 2007, 19, 118110. [Google Scholar] [CrossRef] [Green Version]

| SiO2 | Al2O3 | Fe2O3 | CaO | TiO2 | MgO | K2O | Na2O |

|---|---|---|---|---|---|---|---|

| 46.1 | 36.5 | 0.9 | 0.9 | 0.8 | 0.5 | 0.2 | 0.1 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Costine, A.; Fawell, P.; Chryss, A.; Dahl, S.; Bellwood, J. Development of Test Procedures Based on Chaotic Advection for Assessing Polymer Performance in High-Solids Tailings Applications. Processes 2020, 8, 731. https://doi.org/10.3390/pr8060731

Costine A, Fawell P, Chryss A, Dahl S, Bellwood J. Development of Test Procedures Based on Chaotic Advection for Assessing Polymer Performance in High-Solids Tailings Applications. Processes. 2020; 8(6):731. https://doi.org/10.3390/pr8060731

Chicago/Turabian StyleCostine, Allan, Phillip Fawell, Andrew Chryss, Stuart Dahl, and John Bellwood. 2020. "Development of Test Procedures Based on Chaotic Advection for Assessing Polymer Performance in High-Solids Tailings Applications" Processes 8, no. 6: 731. https://doi.org/10.3390/pr8060731

APA StyleCostine, A., Fawell, P., Chryss, A., Dahl, S., & Bellwood, J. (2020). Development of Test Procedures Based on Chaotic Advection for Assessing Polymer Performance in High-Solids Tailings Applications. Processes, 8(6), 731. https://doi.org/10.3390/pr8060731