The Influence of Dental Virtualization, Restoration Types, and Placement Angles on the Trueness and Contact Space in 3D-Printed Crowns: A Comprehensive Exploration

Abstract

:1. Introduction

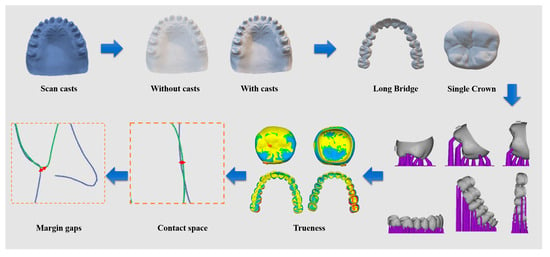

2. Materials and Methods

2.1. Preparation of Dental Casts

2.2. Dental Prosthesis Design and 3D Printing

2.3. Analysis of 3D Printing

2.4. Analysis of Trueness

2.5. Analysis of Contact, Margin, and Occlusion

2.6. Statistical Analysis

3. Results

3.1. Analysis of 3D Printing

3.2. Analysis of Trueness

3.3. Analysis of Contact, Margin, and Occlusion

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Leeson, D. The digital factory in both the modern dental lab and clinic. Dent. Mater. 2020, 36, 43–52. [Google Scholar] [CrossRef] [PubMed]

- Grachev, D.I.; Zolotnitsky, I.V.; Stepanov, D.Y.; Kozulin, A.A.; Mustafaev, M.S.; Deshev, A.V.; Arutyunov, D.S.; Tlupov, I.V.; Panin, S.V.; Arutyunov, S.D. Ranking Technologies of Additive Manufacturing of Removable Complete Dentures by the Results of Their Mechanical Testing. Dent. J. 2023, 11, 265. [Google Scholar] [CrossRef] [PubMed]

- Abad-Coronel, C.; Pazan, D.P.; Hidalgo, L.; Larriva Loyola, J. Comparative Analysis between 3D-Printed Models Designed with Generic and Dental-Specific Software. Dent. J. 2023, 11, 216. [Google Scholar] [CrossRef] [PubMed]

- Abad-Coronel, C.; Velez Chimbo, D.; Lupu, B.; Pacurucu, M.; Farez, M.V.; Fajardo, J.I. Comparative Analysis of the Structural Weights of Fixed Prostheses of Zirconium Dioxide, Metal Ceramic, PMMA and 3DPP Printing Resin-Mechanical Implications. Dent. J. 2023, 11, 249. [Google Scholar] [CrossRef] [PubMed]

- Han, Y.T.; Lin, W.C.; Fan, F.Y.; Chen, C.L.; Lin, C.C.; Cheng, H.C. Comparison of Dental Surface Image Registration and Fiducial Marker Registration: An In Vivo Accuracy Study of Static Computer-Assisted Implant Surgery. J. Clin. Med. 2021, 10, 4183. [Google Scholar] [CrossRef] [PubMed]

- Andersson, M.; Carlsson, L.; Persson, M.; Bergman, B. Accuracy of machine milling and spark erosion with a CAD/CAM system. J. Prosthet. Dent. 1996, 76, 187–193. [Google Scholar] [CrossRef] [PubMed]

- Baghani, M.T.; Shayegh, S.S.; Johnston, W.M.; Shidfar, S.; Hakimaneh, S.M.R. In vitro evaluation of the accuracy and precision of intraoral and extraoral complete-arch scans. J. Prosthet. Dent. 2021, 126, 665–670. [Google Scholar] [CrossRef]

- Fan, K.C.; Lin, Y.L.; Tsao, H.W.; Chen, H.; Lee, S.Y.; Cheng, Y.C.; Huang, H.P.; Lin, W.C. In Vivo Evaluation of the Effects of Sintering Temperature on the Optical Properties of Dental Glass-Ceramics. Nanomaterials 2022, 12, 2187. [Google Scholar] [CrossRef]

- Blatz, M.B.; Conejo, J. The Current State of Chairside Digital Dentistry and Materials. Dent. Clin. N. Am. 2019, 63, 175–197. [Google Scholar] [CrossRef]

- Sailer, I.; Benic, G.I.; Fehmer, V.; Hammerle, C.H.F.; Muhlemann, S. Randomized controlled within-subject evaluation of digital and conventional workflows for the fabrication of lithium disilicate single crowns. Part II: CAD-CAM versus conventional laboratory procedures. J. Prosthet. Dent. 2017, 118, 43–48. [Google Scholar] [CrossRef]

- Mahmood, D.J.H.; Braian, M.; Larsson, C.; Wennerberg, A. Production tolerance of conventional and digital workflow in the manufacturing of glass ceramic crowns. Dent. Mater. 2019, 35, 486–494. [Google Scholar] [CrossRef] [PubMed]

- Arezoobakhsh, A.; Shayegh, S.S.; Jamali Ghomi, A.; Hakimaneh, S.M.R. Comparison of marginal and internal fit of 3-unit zirconia frameworks fabricated with CAD-CAM technology using direct and indirect digital scans. J. Prosthet. Dent. 2020, 123, 105–112. [Google Scholar] [CrossRef] [PubMed]

- Yu, B.Y.; Son, K.; Lee, K.B. Evaluation of intaglio surface trueness and margin quality of interim crowns in accordance with the build angle of stereolithography apparatus 3-dimensional printing. J. Prosthet. Dent. 2021, 126, 231–237. [Google Scholar] [CrossRef] [PubMed]

- Espinar, C.; Della Bona, A.; Tejada-Casado, M.; Pulgar, R.; Perez, M.M. Optical behavior of 3D-printed dental restorative resins: Influence of thickness and printing angle. Dent. Mater. 2023, 39, 894–902. [Google Scholar] [CrossRef] [PubMed]

- Yoo, S.Y.; Kim, S.K.; Heo, S.J.; Koak, J.Y.; Kim, J.G. Dimensional Accuracy of Dental Models for Three-Unit Prostheses Fabricated by Various 3D Printing Technologies. Materials 2021, 14, 1550. [Google Scholar] [CrossRef]

- Shin, S.H.; Kwon, J.S.; Shim, J.S.; Kim, J.E. Evaluating the Three-Dimensional Printing Accuracy of Partial-Arch Models According to Outer Wall Thickness: An In Vitro Study. Materials 2021, 14, 6734. [Google Scholar] [CrossRef] [PubMed]

- Rosenstiel, S.F.; Land, M.F.; Walter, R. Contemporary Fixed Prosthodontics-e-Book; Elsevier Health Sciences: Amsterdam, The Netherlands, 2022. [Google Scholar]

- Ellakany, P.; Al-Harbi, F.; El Tantawi, M.; Mohsen, C. Evaluation of the accuracy of digital and 3D-printed casts compared with conventional stone casts. J. Prosthet. Dent. 2022, 127, 438–444. [Google Scholar] [CrossRef]

- Sahrir, C.D.; Ruslin, M.; Lee, S.-Y.; Lin, W.-C. Effect of various post-curing light intensities, times, and energy levels on the color of 3D-printed resin crowns. J. Dent. Sci. 2023, in press. [CrossRef]

- Camargo, B.; Willems, E.; Jacobs, W.; Van Landuyt, K.; Peumans, M.; Zhang, F.; Vleugels, J.; Van Meerbeek, B. 3D printing and milling accuracy influence full-contour zirconia crown adaptation. Dent. Mater. 2022, 38, 1963–1976. [Google Scholar] [CrossRef]

- Tseng, C.-W.; Yong, C.-Y.; Fang, C.-Y.; Lee, S.-Y.; Wang, Y.-C.; Lin, W.-C. Comparative analysis of bonding strength between enamel and overlay of varying thicknesses following an aging test. J. Dent. Sci. 2023, 18, 1850–1858. [Google Scholar] [CrossRef]

- Ngatemi, P.T.; Kasihani, N.N. Independence of Brushing Teeth to Free-Plaque Score in Preschool Children: A Cross Sectional Study. Indian J. Forensic Med. Toxicol. 2021, 15, 3722–3727. [Google Scholar]

- Aspinall, S.R.; Parker, J.K.; Khutoryanskiy, V.V. Oral care product formulations, properties and challenges. Colloids Surf. B Biointerfaces 2021, 200, 111567. [Google Scholar] [CrossRef] [PubMed]

- Roberts, W.E.; Mangum, J.E.; Schneider, P.M. Pathophysiology of Demineralization, Part II: Enamel White Spots, Cavitated Caries, and Bone Infection. Curr. Osteoporos. Rep. 2022, 20, 106–119. [Google Scholar] [CrossRef] [PubMed]

- Suese, K. Progress in digital dentistry: The practical use of intraoral scanners. Dent. Mater. J. 2020, 39, 52–56. [Google Scholar] [CrossRef] [PubMed]

- Dawood, A.; Marti Marti, B.; Sauret-Jackson, V.; Darwood, A. 3D printing in dentistry. Br. Dent. J. 2015, 219, 521–529. [Google Scholar] [CrossRef] [PubMed]

- Carrillo-Perez, F.; Pecho, O.E.; Morales, J.C.; Paravina, R.D.; Della Bona, A.; Ghinea, R.; Pulgar, R.; Pérez, M.D.M.; Herrera, L.J. Applications of artificial intelligence in dentistry: A comprehensive review. J. Esthet. Restor. Dent. 2022, 34, 259–280. [Google Scholar] [CrossRef] [PubMed]

- Chaudhary, S.; Avinashi, S.K.; Rao, J.; Gautam, C. Recent Advances in Additive Manufacturing, Applications and Challenges for Dentistry: A Review. ACS Biomater. Sci. Eng. 2023, 9, 3987–4019. [Google Scholar] [CrossRef] [PubMed]

- Sulaiman, T.A. Materials in digital dentistry—A review. J. Esthet. Restor. Dent. 2020, 32, 171–181. [Google Scholar] [CrossRef]

- Rossini, G.; Parrini, S.; Castroflorio, T.; Deregibus, A.; Debernardi, C.L. Diagnostic accuracy and measurement sensitivity of digital models for orthodontic purposes: A systematic review. Am. J. Orthod. Dentofac. Orthop. 2016, 149, 161–170. [Google Scholar] [CrossRef]

- Lu, Y.; Wang, L.; Dal Piva, A.M.O.; Tribst, J.P.M.; Nedeljkovic, I.; Kleverlaan, C.J.; Feilzer, A.J. Influence of surface finishing and printing layer orientation on surface roughness and flexural strength of stereolithography-manufactured dental zirconia. J. Mech. Behav. Biomed. Mater. 2023, 143, 105944. [Google Scholar] [CrossRef]

- Ramalingam, S.; Sundar, C.; Jansen, J.A.; Alghamdi, H. Alveolar bone science: Structural characteristics and pathological changes. In Dental Implants and Bone Grafts; Elsevier: Amsterdam, The Netherlands, 2020; pp. 1–22. [Google Scholar]

- Bramantoro, T.; Irmalia, W.R.; Santoso, C.M.A.; Mohd Nor, N.A.; Utomo, H.; Ramadhani, A.; Kristanti, R.A.; Nugraha, A.P. The Effect of Caries on the Chewing Ability of Children: A Scoping Review. Eur. J. Dent 2022, in press. [Google Scholar] [CrossRef] [PubMed]

- Schwendicke, F.; Kern, M.; Blunck, U.; Dorfer, C.; Drenck, J.; Paris, S. Marginal integrity and secondary caries of selectively excavated teeth in vitro. J. Dent. 2014, 42, 1261–1268. [Google Scholar] [CrossRef] [PubMed]

- Maglad, A.; Wassell, R.; Barclay, S.; Walls, A. Risk management in clinical practice. Part 3. Crowns and bridges. Br. Dent. J. 2010, 209, 115–122. [Google Scholar] [CrossRef] [PubMed]

- McLean, J.W. The estimation of cement film thickness by an in vivo technique. Br. Dent. J. 1971, 131, 107–111. [Google Scholar] [CrossRef]

| Angle (Degree) | Single Crown | Long Bridge |

|---|---|---|

| 0 | 45 | 3 |

| 60 | 45 | 4 |

| 90 | 48 | 7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, T.-Y.; Lin, W.-C.; Yang, T.-H.; Sahrir, C.D.; Shen, Y.-K.; Feng, S.-W. The Influence of Dental Virtualization, Restoration Types, and Placement Angles on the Trueness and Contact Space in 3D-Printed Crowns: A Comprehensive Exploration. Dent. J. 2024, 12, 2. https://doi.org/10.3390/dj12010002

Lu T-Y, Lin W-C, Yang T-H, Sahrir CD, Shen Y-K, Feng S-W. The Influence of Dental Virtualization, Restoration Types, and Placement Angles on the Trueness and Contact Space in 3D-Printed Crowns: A Comprehensive Exploration. Dentistry Journal. 2024; 12(1):2. https://doi.org/10.3390/dj12010002

Chicago/Turabian StyleLu, Tsung-Yueh, Wei-Chun Lin, Tzu-Hsuan Yang, Citra Dewi Sahrir, Yung-Kang Shen, and Sheng-Wei Feng. 2024. "The Influence of Dental Virtualization, Restoration Types, and Placement Angles on the Trueness and Contact Space in 3D-Printed Crowns: A Comprehensive Exploration" Dentistry Journal 12, no. 1: 2. https://doi.org/10.3390/dj12010002

APA StyleLu, T. -Y., Lin, W. -C., Yang, T. -H., Sahrir, C. D., Shen, Y. -K., & Feng, S. -W. (2024). The Influence of Dental Virtualization, Restoration Types, and Placement Angles on the Trueness and Contact Space in 3D-Printed Crowns: A Comprehensive Exploration. Dentistry Journal, 12(1), 2. https://doi.org/10.3390/dj12010002