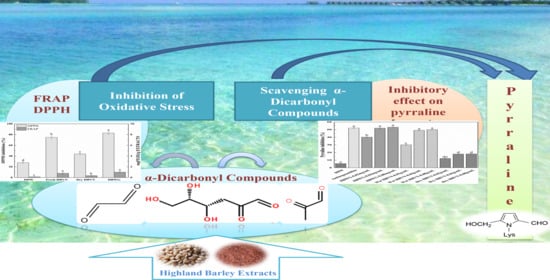

Highland Barley and Its By-Products Enriched with Phenolic Compounds for Inhibition of Pyrraline Formation by Scavenging α-Dicarbonyl Compounds

Abstract

:1. Introduction

2. Materials and Methods

2.1. Chemicals and Materials

2.2. Equipment

2.3. Purification of Pyrraline by Solid-Phase Extraction

2.4. Determination of Pyrraline by HPLC

2.5. Samples

2.6. Phenolic Profile Using UPLC–PAD–MS/MS Analysis

2.7. Determination of Phenolic Compound Scavenging by α-Dicarbonyl Compounds

2.8. Inhibition of Pyrraline Formation by Phenolic Compounds from HBWG and HBVN

2.9. Antioxidant Activities of HBWG and HBVN

2.10. Statistical Analysis

3. Results and Discussion

3.1. Optimization of Different Extraction Conditions of Phenolic Compounds from HBWG and HBVN

3.2. Antioxidant Activity of HBWG and HBVN Extracts

3.3. Inhibition of Pyrraline Formation by HBWG and HBVN Extracts in a Simulated Food System

3.4. Isolation and Identification of the Main Functional Compounds from HBWG and HBVN Extracts by 50% Acetone

3.5. Scavenging Experiment on α-Dicarbonyl Compounds by Phenolic Compounds from HBVN Extracts

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Maillard, L.C. Action des acids amines sur les sucres: Formation des melanoidines par voie methodique. Comptes R. Acad. Sci. 1912, 154, 66–68. [Google Scholar]

- Wu, C.H.; Huang, S.M.; Lin, J.A.; Yen, G.C. Inhibition of advanced glycation endproduct formation by foodstuffs. Food Funct. 2011, 2, 224–234. [Google Scholar] [CrossRef] [PubMed]

- Nooshkam, M.; Varidi, M.; Bashash, M. The Maillard reaction products as food-born antioxidant and antibrowning agents in model and real food systems. Food Chem. 2019, 275, 644–660. [Google Scholar] [CrossRef] [PubMed]

- Gupta, R.K.; Gupta, K.; Sharma, A.; Das, M.; Ansari, I.A.; Dwivedi, P.D. Maillard reaction in food allergy: Pros and cons. Crit. Rev. Food Sci. Nutr. 2018, 58, 208–226. [Google Scholar] [CrossRef]

- Yu, H.J.; Wang, J.H.; Tang, Z.; Li, X.; Yin, M.Q.; Zhang, F.; Shu, J.; Chen, W.T.; Yang, S.; Li, Z. Integrated glycomics strategy for the evaluation of glycosylation alterations in salivary proteins associated with type 2 diabetes mellitus. RSC Adv. 2020, 10, 39739–39752. [Google Scholar] [CrossRef]

- Delgado-Andrade, C.; Fogliano, V. Dietary advanced glycosylation end-products (dAGEs) and melanoidins formed through the Maillard reaction: Physiological consequences of their Intake. Annu. Rev. Food Sci. Technol. 2018, 9, 271–291. [Google Scholar] [CrossRef]

- Ping, S.N.; Liu, S.Y.; Zhou, Y.H.; Li, Z.Q.; Li, Y.H.; Liu, K.F.; Bardeesi, A.S.; Wang, L.I.; Chen, J.B.; Deng, L.; et al. Protein disulfide isomerase-mediated apoptosis and proliferation of vascular smooth muscle cells induced by mechanical stress and advanced glycosylation end products result in diabetic mouse vein graft atherosclerosis. Cell Death Dis. 2017, 8, e2818. [Google Scholar] [CrossRef] [Green Version]

- Khan, M.; Liu, H.L.; Wang, J.; Sun, B.G. Inhibitory effect of phenolic compounds and plant extracts on the formation of advance glycation end products: A comprehensive review. Food Res. Int. 2020, 130, 108933. [Google Scholar] [CrossRef]

- Reddy, S.; Bichler, J.; Wells-Knecht, K.J.; Thorpe, S.R.; Baynes, J.W. N-epsilon-(carboxymethyl)lysine is a dominant advanced glycation end product (AGE) antigen in tissue proteins. Biochemistry 1995, 34, 10872–10878. [Google Scholar] [CrossRef]

- Sell, D.R.; Monnier, V.M. Structure elucidation of a senescence cross-link from human extracellular matrix: Implication of pentoses in the aging process. J. Biol. Chem. 1990, 264, 21597–21602. [Google Scholar] [CrossRef]

- Nakamura, K.; Hasegawa, T.; Fukunaga, Y.; Ienaga, K. Crosslines A and B as candidates for the fluorophores in age- and diabetes-related cross-linked proteins, and their diacetates produced by Maillard reaction of α-N-acetyl-l-lysine with d-glucose. J. Chem. Soc. Chem. Commun. 1992, 14, 992–994. [Google Scholar] [CrossRef]

- Nakamura, K.; Nakazawa, Y.; Ienaga, K. Acid-stable fluorescent advanced glycation end products: Vesperlysines A, B, and C are formed as crosslinked products in the maillard reaction between lysine or proteins with glucose. Biochem. Biophys. Res. Commun. 1997, 30, 227–230. [Google Scholar] [CrossRef] [PubMed]

- Zhang, D.W.; Wang, Y.P.; Liu, H.L. Corn silk extract inhibit the formation of Nε-carboxymethyllysine by scavenging glyoxal/methyl glyoxal in a casein glucose-fatty acid model system. Food Chem. 2020, 309, 125708. [Google Scholar] [CrossRef]

- Portero-Otin, M.; Nagaraj, R.H.; Monnier, V.M. Chromatographic evidence for pyrraline formation during protein glycation in vitro and in vivo. Biochim. Biophys. Acta Protein Struct. Mol. Enzymol. 1995, 1247, 74–80. [Google Scholar] [CrossRef]

- Liu, H.L.; Mu, L.; Chen, X.M.; Wang, J.; Wang, S.; Sun, B.G. Core–shell metal–organic frameworks/molecularly imprinted nanoparticles as absorbents for the detection of pyrraline in milk and milk powder. J. Agric. Food Chem. 2017, 65, 986–992. [Google Scholar] [CrossRef]

- Liu, H.L.; Ni, T.H.; Mu, L.; Zhang, D.W.; Wang, J.; Wang, S.; Sun, B.G. Sensitive detection of pyrraline with a molecularly imprinted sensor based on metal-organic frameworks and quantum dots. Sens. Actuators B Chem. 2018, 256, 1038–1044. [Google Scholar] [CrossRef]

- Liu, H.L.; Chen, X.M.; Zhang, D.W.; Wang, J.; Sun, B.G. Effects of highland barley bran extract rich in phenolic acids on the formation of Nε-epsilon-carboxymethyllysine in a biscuit model. J. Agric. Food Chem. 2018, 66, 1916–1922. [Google Scholar] [CrossRef]

- Tieri, M.; Ghelfi, F.; Vitale, M.; Vetrani, C.; Marventano, S.; Lafranconi, A. Whole grain consumption and human health: An umbrella review of observational studies. Int. J. Food Sci. Nutr. 2020, 71, 668–677. [Google Scholar] [CrossRef]

- Ge, X.Z.; Jing, L.Z.; Zhao, K.; Su, C.Y.; Zhang, B.; Zhang, Q.; Han, L.H.; Yu, X.Z.; Li, W.H. The phenolic compounds profile, quantitative analysis and antioxidant activity of four naked barley grains with different color. Food Chem. 2021, 335, 127655. [Google Scholar] [CrossRef]

- Deng, N.; He, Z.Q.; Guo, R.X.; Zheng, B.S.; Li, T.; Liu, R.H. Highland barley whole grain (Hordeum vulgare L.) ameliorates hyperlipidemia by modulating cecal microbiota, miRNAs, and AMPK pathways in leptin receptor-deficient db/db mice. J. Agric. Food Chem. 2020, 68, 11735–11746. [Google Scholar] [CrossRef]

- Xia, X.J.; Li, G.N.; Ding, Y.B.; Ren, T.Y.; Zheng, J.; Kan, J.Q. Effect of whole grain Qingke (Tibetan Hordeum vulgare L. Zangqing 320) on the serum lipid levels and intestinal microbiota of rats under high-fat diet. J. Agric. Food Chem. 2017, 65, 2686–2693. [Google Scholar] [CrossRef] [PubMed]

- Deng, N.; Zheng, B.S.; Li, T.; Liu, R.H. Assessment of the phenolic profiles, hypoglycemic activity, and molecular mechanism of different highland barley (Hordeum vulgare L.) varieties. Int. J. Mol. Sci. 2020, 21, 1175. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lee, S.M.; Zheng, L.W.; Jung, Y.; Hwang, G.S.; Kim, Y.S. Effects of hydroxycinnamic acids on the reduction of furan and α-dicarbonyl compounds. Food Chem. 2020, 312, 126085. [Google Scholar] [CrossRef]

- Aktağ, I.G.; Gökmen, V. Multiresponse kinetic modelling of α-dicarbonyl compounds formation in fruit juices during storage. Food Chem. 2020, 320, 126620. [Google Scholar] [CrossRef] [PubMed]

- Meneses, N.G.T.; Martins, S.; Teixeira, J.A.; Mussatto, S.I. Influence of extraction solvents on the recovery of antioxidant phenolic compounds from brewer’s spent grains. Sep. Purif. Technol. 2013, 108, 152–158. [Google Scholar] [CrossRef] [Green Version]

- Alves, G.H.; Ferreira, C.D.; Vivian, P.G.; Monks, J.L.F.; Elias, M.C.; Vanier, N.L.; de Oliveira, M. The revisited levels of free and bound phenolics in rice: Effects of the extraction procedure. Food Chem. 2016, 208, 116–123. [Google Scholar] [CrossRef]

- Zhang, Y.; Ni, T.H.; Zhang, D.W.; Liu, H.L.; Wang, J.; Sun, B.G. Consumption of avenanthramides extracted from oats reduces weight gain, oxidative stress, inflammation and regulates intestinal microflora in high fat diet-induced mice. J. Funct. Foods 2020, 65, 103774. [Google Scholar] [CrossRef]

- Nugroho, A.; Lim, S.C.; Byeon, J.S.; Choi, J.S.; Park, H.J. Simultaneous quantification and validation of caffeoylquinic acids and flavonoids in hemistepta lyrata and peroxynitrite-scavenging activity. J. Pharm. Biomed. Anal. 2013, 76, 139–144. [Google Scholar] [CrossRef]

- Matsuda, H.; Wang, T.; Managi, H.; Yoshikawa, M. Structural requirements of flavonoids for inhibition of protein glycation and radical scavenging activities. Bioorg. Med. Chem. 2003, 11, 5317–5323. [Google Scholar] [CrossRef]

| No. | Compounds | Retention Time (min) | Content (%) |

|---|---|---|---|

| 1 | Galactonic acid | 1.35 | 46.50 a |

| 2 | Malic acid | 1.60 | 16.56 b |

| 3 | Citric acid | 1.97 | 6.99 c |

| 4 | Tiliroside | 4.69 | 5.31 c |

| 5 | Catechin | 6.98 | 0.82 e |

| 6 | Caffeic acid | 7.35 | 2.93 cd |

| 7 | Rutin | 8.89 | 0.51 e |

| 8 | Ferulic acid | 9.17 | 0.43 e |

| 9 | Azelaic acid | 9.74 | 0.59 e |

| 10 | Apigenin | 10.96 | 1.99 d |

| 11 | Octadecenoic acid | 11.86 | 5.44 c |

| 12 | Dodecanedioic acid | 12.39 | 1.90 d |

| 13 | Ibufenac | 13.66 | 6.45 c |

| 14 | Dihome | 14.08 | 3.58 cd |

| No. | Compounds | Retention Time (min) | Content (%) |

|---|---|---|---|

| 1 | DL-4-Hydroxyphenyllactic acid | 5.45 | 15.59 a |

| 2 | 2-Isopropylmalic acid | 6.51 | 8.12 b |

| 3 | Catechin | 7.15 | 1.97 c |

| 4 | Neochlorogenic acid | 7.62 | 0.08 d |

| 5 | Caffeic acid | 7.89 | 1.90 c |

| 6 | 2-Hydroxycaproic acid | 8.15 | 14.18 a |

| 7 | Astilibin | 8.42 | 0.14 d |

| 8 | Rutin | 8.90 | 0.11 d |

| 9 | 3-Phenyllactic acid | 9.06 | 2.71 c |

| 10 | Isoquercetin | 9.12 | 0.11 d |

| 11 | Cynaroside | 9.12 | 0.05 d |

| 12 | Ferulic acid | 9.25 | 0.21 d |

| 13 | Neodiosmin | 9.41 | 0.15 d |

| 14 | Formononetin | 9.36 | 0.06 d |

| 15 | Azelaic acid | 9.97 | 1.93 c |

| 16 | Glycitein | 10.00 | 2.21 c |

| 17 | Luteolin | 10.83 | 0.16 d |

| 18 | Quercetin | 10.88 | 9.93 b |

| 19 | Apigenin | 11.57 | 14.73 a |

| 20 | Naringenin | 11.65 | 0.08 d |

| 21 | Diosmetin | 11.65 | 2.88 c |

| Compounds | GO Scavenging | MGO Scavenging | 3-DG Scavenging | Inhibition of Pyrraline | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.1 mL | 0.2 mL | 0.5 mL | 0.1 mL | 0.2 mL | 0.5 mL | 0.1 mL | 0.2 mL | 0.5 mL | 0.1 mL | 0.2 mL | 0.5 mL | |

| Quercetin | 0.20 ± 0.03 b | 0.29 ± 0.02 b | 0.51 ± 0.04 a | 0.18 ± 0.02 c | 0.32 ± 0.01 b | 0.57 ± 0.07 a | 0.14 ± 0.01 b | 0.17 ± 0.03 b | 0.40 ± 0.05 a | 0.15 ± 0.02 b | 0.20 ± 0.02 b | 0.44 ± 0.05 a |

| Neochlorogenic acid | 0.17 ± 0.02 c | 0.23 ± 0.03 b | 0.47 ± 0.05 a | 0.14 ± 0.03 c | 0.29 ± 0.03 b | 0.50 ± 0.03 a | 0.13 ± 0.01 c | 0.25 ± 0.02 b | 0.41 ± 0.03 a | 0.11 ± 0.01 b | 0.19 ± 0.04 b | 0.41 ± 0.07 a |

| 2-Hydroxycaproic acid | 0.24 ± 0.01 c | 0.39 ± 0.02 b | 0.54 ± 0.01 a | 0.20 ± 0.03 c | 0.34 ± 0.02 b | 0.53 ± 0.02 a | 0.09 ± 0.00 b | 0.15 ± 0.01 b | 0.41 ± 0.03 a | 0.17 ± 0.01 c | 0.32 ± 0.06 b | 0.52 ± 0.03 a |

| Catechin | 0.22 ± 0.03 c | 0.35 ± 0.04 b | 0.51 ± 0.04 a | 0.19 ± 0.04 c | 0.33 ± 0.02 b | 0.55 ± 0.06 a | 0.11 ± 0.03 c | 0.23 ± 0.01 b | 0.47 ± 0.01 a | 0.19 ± 0.02 c | 0.27 ± 0.03 b | 0.55 ± 0.05 a |

| 4-Hydroxyphenyllactic acid | 0.21 ± 0.01 b | 0.30 ± 0.03 b | 0.50 ± 0.03 a | 0.15 ± 0.01 c | 0.32 ± 0.02 b | 0.51 ± 0.07 a | 0.18 ± 0.02 c | 0.27 ± 0.02 b | 0.44 ± 0.03 a | 0.16 ± 0.03 c | 0.24 ± 0.02 b | 0.43 ± 0.03 a |

| Ferulic acid | 0.22 ± 0.03 c | 0.33 ± 0.03 b | 0.53 ± 0.01 a | 0.19 ± 0.00 c | 0.37 ± 0.02 b | 0.52 ± 0.07 a | 0.09 ± 0.01 c | 0.18 ± 0.01 b | 0.37 ± 0.04 a | 0.15 ± 0.01 c | 0.26 ± 0.05 b | 0.51 ± 0.04 a |

| 2-Isopropylmalic acid | 0.21 ± 0.02 c | 0.31 ± 0.02 b | 0.47 ± 0.04 a | 0.19 ± 0.01 c | 0.27 ± 0.02 b | 0.42 ± 0.07 a | 0.14 ± 0.03 c | 0.27 ± 0.05 b | 0.51 ± 0.02 a | 0.13 ± 0.01 c | 0.20 ± 0.02 b | 0.46 ± 0.05 a |

| 3-Phenyllactic acid | 0.18 ± 0.01 c | 0.29 ± 0.04 b | 0.49 ± 0.03 a | 0.14 ± 0.02 c | 0.25 ± 0.02 b | 0.47 ± 0.02 a | 0.15 ± 0.03 c | 0.29 ± 0.03 b | 0.40 ± 0.02 a | 0.11 ± 0.01 b | 0.17 ± 0.08 b | 0.40 ± 0.04 a |

| Rutin | 0.15 ± 0.01 c | 0.27 ± 0.03 b | 0.51 ± 0.03 a | 0.11 ± 0.01 c | 0.24 ± 0.01 b | 0.44 ± 0.05 a | 0.13 ± 0.02 c | 0.26 ± 0.04 b | 0.44 ± 0.01 a | 0.14 ± 0.02 c | 0.22 ± 0.06 b | 0.42 ± 0.02 a |

| Apigenin | 0.18 ± 0.02 c | 0.27 ± 0.02 b | 0.48 ± 0.05 a | 0.10 ± 0.02 c | 0.18 ± 0.00 b | 0.51 ± 0.04 a | 0.16 ± 0.02 c | 0.29 ± 0.03 b | 0.43 ± 0.04 a | 0.14 ± 0.01 c | 0.27 ± 0.03 b | 0.41 ± 0.05 a |

| Diosmetin | 0.13 ± 0.00 c | 0.25 ± 0.01 b | 0.47 ± 0.07 a | 0.12 ± 0.00 c | 0.23 ± 0.01 b | 0.48 ± 0.05 a | 0.15 ± 0.01 c | 0.29 ± 0.02 b | 0.50 ± 0.03 a | 0.11 ± 0.00 c | 0.22 ± 0.10 b | 0.43 ± 0.07 a |

| Azelaic acid | 0.17 ± 0.03 c | 0.28 ± 0.05 b | 0.43 ± 0.04 a | 0.10 ± 0.01 b | 0.12 ± 0.04 b | 0.47 ± 0.01 a | 0.14 ± 0.03 c | 0.27 ± 0.03 b | 0.45 ± 0.04 a | 0.10 ± 0.01 c | 0.20 ± 0.05 b | 0.44 ± 0.03 a |

| Caffeic acid | 0.19 ± 0.04 c | 0.29 ± 0.02 b | 0.46 ± 0.04 a | 0.11 ± 0.00 b | 0.17 ± 0.04 b | 0.50 ± 0.07 a | 0.14 ± 0.02 c | 0.21 ± 0.01 b | 0.41 ± 0.02 a | 0.13 ± 0.03 c | 0.21 ± 0.02 b | 0.45 ± 0.08 a |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, D.; Zhu, P.; Han, L.; Chen, X.; Liu, H.; Sun, B. Highland Barley and Its By-Products Enriched with Phenolic Compounds for Inhibition of Pyrraline Formation by Scavenging α-Dicarbonyl Compounds. Foods 2021, 10, 1109. https://doi.org/10.3390/foods10051109

Zhang D, Zhu P, Han L, Chen X, Liu H, Sun B. Highland Barley and Its By-Products Enriched with Phenolic Compounds for Inhibition of Pyrraline Formation by Scavenging α-Dicarbonyl Compounds. Foods. 2021; 10(5):1109. https://doi.org/10.3390/foods10051109

Chicago/Turabian StyleZhang, Dianwei, Pei Zhu, Luxuan Han, Xiaomo Chen, Huilin Liu, and Baoguo Sun. 2021. "Highland Barley and Its By-Products Enriched with Phenolic Compounds for Inhibition of Pyrraline Formation by Scavenging α-Dicarbonyl Compounds" Foods 10, no. 5: 1109. https://doi.org/10.3390/foods10051109

APA StyleZhang, D., Zhu, P., Han, L., Chen, X., Liu, H., & Sun, B. (2021). Highland Barley and Its By-Products Enriched with Phenolic Compounds for Inhibition of Pyrraline Formation by Scavenging α-Dicarbonyl Compounds. Foods, 10(5), 1109. https://doi.org/10.3390/foods10051109