Addition of NaCl or Sucrose on the Protein Content, and Functional and Physicochemical Properties of Egg Whites Liquid under Heat Treatment

Abstract

:1. Introduction

2. Materials and Methods

2.1. Samples and Reagents

2.2. Total Soluble Protein Content

2.3. HPLC Analysis

2.4. Foam Stability and Foaming Capacity

2.5. Gel Properties

2.6. Sulfhydryl Group and Disulfide Bond Content

2.7. Particle Size and Distribution

2.8. Secondary Protein Structures

2.9. Transmission Electron Microscopy

2.10. Statistical Analysis

3. Results

3.1. Total Soluble Protein Content of Four Varieties of Ews under Heat Treatment

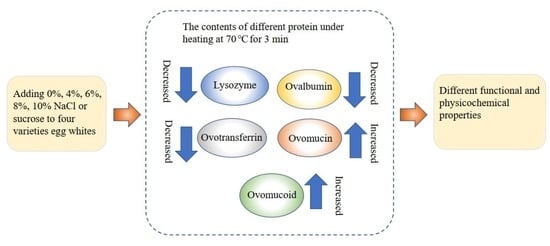

3.2. The Contents of Different Proteins in Four Varieties of EWs under Heat Treatment

3.3. Differences in the Foaming Properties of Four Varieties of EWs under Heat Treatment

3.4. Differences in the Gel Properties of the Four Varieties of EWs under Heat Treatment

3.5. Different Contents of Sulfhydryl Groups in Four Varieties of EWs under Heat Treatment

3.6. Different Contents of Secondary Structures in Four Varieties of EWs under Heat Treatment

3.7. Different Particle Sizes of Four Varieties of EWs under Heat Treatment

3.8. TEM Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ma, Z.; Chi, Y.; Zhang, H.; Chi, Y.; Ma, Y. Inhibiting effect of dry heat on the heat-induced aggregation of egg white protein. Food Chem. 2022, 387, 132850. [Google Scholar] [CrossRef] [PubMed]

- Ma, Y.; Shan, A.; Wang, R.; Zhao, Y.; Chi, Y. Characterization of egg white powder gel structure and its relationship with gel properties influenced by pretreatment with dry heat. Food Hydrocoll. 2021, 110, 106149. [Google Scholar] [CrossRef]

- Gezahegn, Y.A.; Tang, J.; Sablani, S.S.; Pedrow, P.D.; Hong, Y.-K.; Lin, H.; Tang, Z. Dielectric properties of water relevant to microwave assisted thermal pasteurization and sterilization of packaged foods. Innov. Food Sci. Emerg. Technol. 2021, 74, 102837. [Google Scholar] [CrossRef]

- Dabestani, M.; Yeganehzad, S. Effect of Persian gum and Xanthan gum on foaming properties and stability of pasteurized fresh egg white foam. Food Hydrocoll. 2019, 87, 550–560. [Google Scholar] [CrossRef]

- Chen, B.; Grandison, A.S.; Lewis, M.J. Effect of seasonal variation on some physical properties and heat stability of milk subjected to ultra-high temperature and in-container sterilisation. Food Chem. 2015, 181, 227–234. [Google Scholar] [CrossRef]

- Khemakhem, M.; Attia, H.; Ayadi, M.A. The effect of pH, sucrose, salt and hydrocolloid gums on the gelling properties and water holding capacity of egg white gel. Food Hydrocoll. 2019, 87, 11–19. [Google Scholar] [CrossRef]

- Batool, Z.; Hu, G.; Xinyue, H.; Wu, Y.; Fu, X.; Cai, Z.; Huang, X.; Ma, M. A comprehensive review on functional properties of preserved eggs as an excellent food ingredient with anti-inflammatory and anti-cancer aspects. Food Biosci. 2021, 44, 101347. [Google Scholar] [CrossRef]

- Yang, X.; Wang, Z.; Zhang, C.; Wang, L.; Pang, L.; Zhang, D.; Man, C.; Jiang, Y. Assessment of the production of Bacillus cereus protease and its effect on the quality of ultra-high temperature-sterilized whole milk. J. Dairy Sci. 2021, 104, 6577–6587. [Google Scholar] [CrossRef]

- Jo, Y.; Benoist, D.M.; Barbano, D.M.; Drake, M.A. Flavor and flavor chemistry differences among milks processed by high-temperature, short-time pasteurization or ultra-pasteurization. J. Dairy Sci. 2018, 101, 3812–3828. [Google Scholar] [CrossRef]

- Guo, S.; Lei, J.; Liu, L.; Qu, X.; Li, P.; Liu, X.; Guo, Y.; Gao, Q.; Lan, F.; Xiao, B.; et al. Effects of Macleaya cordata extract on laying performance, egg quality, and serum indices in Xuefeng black-bone chicken. Poult. Sci. 2021, 100, 101031. [Google Scholar] [CrossRef]

- Grintzalis, K.; Georgiou, C.D.; Schneider, Y.J. An accurate and sensitive Coomassie Brilliant Blue G-250-based assay for protein determination. Anal. Biochem. 2015, 480, 28–30. [Google Scholar] [CrossRef] [PubMed]

- Yu, R.; Chi, Y.; Ma, Y.; Chi, Y.; Wang, L. Differences in protein composition and functional properties of egg whites from four chicken varieties. Food Biosci. 2022, 46, 101614. [Google Scholar] [CrossRef]

- Guerin-Dubiard, C.; Pasco, M.; Hietanen, A.; Quiros del Bosque, A.; Nau, F.; Croguennec, T. Hen egg white fractionation by ion-exchange chromatography. J. Chromatogr. A 2005, 1090, 58–67. [Google Scholar] [CrossRef]

- Wang, X.; Gu, L.; Su, Y.; Li, J.; Yang, Y.; Chang, C. Microwave technology as a new strategy to induce structural transition and foaming properties improvement of egg white powder. Food Hydrocoll. 2020, 101, 105530. [Google Scholar] [CrossRef]

- Jin, H.; Chen, J.; Zhang, J.; Sheng, L. Impact of phosphates on heat-induced egg white gel properties: Texture, water state, micro-rheology and microstructure. Food Hydrocoll. 2021, 110, 106200. [Google Scholar] [CrossRef]

- Hasegawa, G.; Kikuchi, M.; Kobayashi, Y.; Saito, Y. Synthesis and characterization of a novel reagent containing dansyl group, which specifically alkylates sulfhydryl group: An example of application for protein chemistry. J. Biochem. Biophys. Methods 2005, 63, 33–42. [Google Scholar] [CrossRef]

- Sponton, O.E.; Perez, A.A.; Ramel, J.V.; Santiago, L.G. Protein nanovehicles produced from egg white. Part 1: Effect of pH and heat treatment time on particle size and binding capacity. Food Hydrocoll. 2017, 73, 67–73. [Google Scholar] [CrossRef]

- Fevzioglu, M.; Ozturk, O.K.; Hamaker, B.R.; Campanella, O.H. Quantitative approach to study secondary structure of proteins by FT-IR spectroscopy, using a model wheat gluten system. Int. J. Biol. Macromol. 2020, 164, 2753–2760. [Google Scholar] [CrossRef]

- Shu, J.J.; Yong, K.Y. Fourier-based classification of protein secondary structures. Biochem. Biophys. Res. Commun. 2017, 485, 731–735. [Google Scholar] [CrossRef] [Green Version]

- Pang, B.; Huang, L.; Teng, J.; Zhang, J.; Xia, N.; Wei, B. Effect of pile fermentation on the cells of Chinese Liupao tea: The first record of cell wall of Liupao tea on transmission electron microscope. Food Chem. 2021, 361, 130034. [Google Scholar] [CrossRef]

- Cenini, V.L.; Gallagher, L.; McKerr, G.; McCarthy, N.A.; McSweeney, D.J.; Auty, M.A.E.; O’Hagan, B.M.G. A novel approach for dynamic in-situ surface characterisation of milk protein concentrate hydration and reconstitution using an environmental scanning electron microscope. Food Hydrocoll. 2020, 108, 105881. [Google Scholar] [CrossRef]

- Zhu, L.P.; Wang, J.P.; Ding, X.M.; Bai, S.P.; Zeng, Q.F.; Su, Z.W.; Xuan, Y.; Applegate, T.J.; Zhang, K.Y. The effects of varieties and levels of rapeseed expeller cake on egg production performance, egg quality, nutrient digestibility, and duodenum morphology in laying hens. Poult. Sci. 2019, 98, 4942–4953. [Google Scholar] [CrossRef] [PubMed]

- Kuo, Y.M.; Shiue, Y.L.; Chen, C.F.; Tang, P.C.; Lee, Y.P. Proteomic analysis of hypothalamic proteins of high and low egg production strains of chickens. Theriogenology 2005, 64, 1490–1502. [Google Scholar] [CrossRef] [PubMed]

- Ali, M.S.; Waseem, M.; Subbarao, N.; Al-Lohedan, H.A. Dynamic interaction between lysozyme and ceftazidime: Experimental and molecular simulation approaches. J. Mol. Liq. 2021, 328, 115412. [Google Scholar] [CrossRef]

- Chaari, A.; Fahy, C.; Chevillot-Biraud, A.; Rholam, M. Investigating the effects of different natural molecules on the structure and oligomerization propensity of hen egg-white lysozyme. Int. J. Biol. Macromol. 2019, 134, 189–201. [Google Scholar] [CrossRef]

- Liu, X.; Yang, Q.; Yang, M.; Du, Z.; Wei, C.; Zhang, T.; Liu, B.; Liu, J. Ultrasound-assisted Maillard reaction of ovalbumin/xylose: The enhancement of functional properties and its mechanism. Ultrason. Sonochem. 2021, 73, 105477. [Google Scholar] [CrossRef]

- Wei, Z.; Huang, Q. Modification of ovotransferrin by Maillard reaction: Consequences for structure, fibrillation and emulsifying property of fibrils. Food Hydrocoll. 2019, 97, 105186. [Google Scholar] [CrossRef]

- Abeyrathne, E.D.; Lee, H.Y.; Ahn, D.U. Separation of ovotransferrin and ovomucoid from chicken egg white. Poult. Sci. 2014, 93, 1010–1017. [Google Scholar] [CrossRef]

- Jiang, Y.; Jia, J.; Xiong, D.; Xu, X.; Yang, Y.; Liu, X.; Duan, X. Effects of short-term fermentation with lactic acid bacteria on egg white: Characterization, rheological and foaming activities. Food Hydrocoll. 2020, 101, 105507. [Google Scholar] [CrossRef]

- Sheng, L.; Tang, G.; Wang, Q.; Zou, J.; Ma, M.; Huang, X. Molecular characteristics and foaming properties of ovalbumin-pullulan conjugates through the Maillard reaction. Food Hydrocoll. 2020, 100, 105384. [Google Scholar] [CrossRef]

- Duan, X.; Li, M.; Shao, J.; Chen, H.; Xu, X. Effect of oxidative modification on structural and foaming properties of egg white protein. Food Hydrocoll. 2018, 75, 223–228. [Google Scholar] [CrossRef]

- Shao, Y.; Zhao, Y.; Xu, M.; Chen, Z.; Wang, S.; Tu, Y. Effects of copper ions on the characteristics of egg white gel induced by strong alkali. Poult. Sci. 2017, 96, 4116–4123. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, F.; Wang, X. Changes of protein secondary structures of pollock surimi gels under high-temperature (100 °C and 120 °C) treatment. J. Food Eng. 2016, 171, 159–163. [Google Scholar] [CrossRef]

- Sinz, A.; Wang, K. Mapping spatial proximities of sulfhydryl groups in proteins using a fluorogenic cross-linker and mass spectrometry. Anal. Biochem. 2004, 331, 27–32. [Google Scholar] [CrossRef] [PubMed]

- Xue, H.; Tu, Y.; Xu, M.; Liao, M.; Luo, W.; Guo, W.; Zhang, G.; Zhao, Y. Changes in physicochemical properties, gel structure and in vitro digestion of marinated egg white gel during braising. Food Chem. 2020, 330, 127321. [Google Scholar] [CrossRef]

- Babaei, J.; Khodaiyan, F.; Mohammadian, M. Effects of enriching with gellan gum on the structural, functional, and degradation properties of egg white heat-induced hydrogels. Int. J. Biol. Macromol. 2019, 128, 94–100. [Google Scholar] [CrossRef]

- Bozkurt, M.; Kocer, B.; Ege, G.; Tuzun, A.E.; Biyik, H.H.; Poyrazoglu, E. Influence of the particle size and form of feed on growth performance, digestive tract traits and nutrient digestibility of white egg-laying pullets from 1 to 112 D of age. Poult. Sci. 2019, 98, 4016–4029. [Google Scholar] [CrossRef]

- Xiong, L.; Zhang, B.; Niu, M.; Zhao, S. Protein polymerization and water mobility in whole-wheat dough influenced by bran particle size distribution. Food Sci. Technol. 2017, 82, 396–403. [Google Scholar] [CrossRef]

- Liu, J.; Zhu, K.; Ye, T.; Wan, S.; Wang, Y.; Wang, D.; Li, B.; Wang, C. Influence of konjac glucomannan on gelling properties and water state in egg white protein gel. Food Res. Int. 2013, 51, 437–443. [Google Scholar] [CrossRef]

- Yao, K.; Guo, W.; Yao, Y.; Wu, N.; Xu, M.; Zhao, Y.; Tu, Y. Properties, digestion and peptide release of heat-induced duck egg white. LWT 2022, 154, 112788. [Google Scholar] [CrossRef]

| Sulfhydryl Content (mmol/g) | Surface Sulfhydryl | Total Sulfhydryl | Disulfide Bonds |

|---|---|---|---|

| HY-LINE 0% NaCl | 1.32 ± 0.08 a | 2.32 ± 0.09 a | 0.50 ± 0.03 a |

| HY-LINE 4% NaCl | 1.42 ± 0.11 b | 2.49 ± 0.11 b | 0.54 ± 0.04 ab |

| HY-LINE 6% NaCl | 1.47 ± 0.09 b | 2.64 ± 0.14 c | 0.59 ± 0.03 bc |

| HY-LINE 8% NaCl | 1.54 ± 0.06 c | 2.76 ± 0.13 d | 0.61 ± 0.05 cd |

| HY-LINE 10% NaCl | 1.61 ± 0.09 d | 2.88 ± 0.11 e | 0.64 ± 0.02 d |

| HW 0% NaCl | 1.29 ± 0.09 a | 2.27 ± 0.12 a | 0.49 ± 0.05 a |

| HW 4% NaCl | 1.41 ± 0.11 b | 2.47 ± 0.09 b | 0.53 ± 0.03 ab |

| HW 6% NaCl | 1.44 ± 0.10 b | 2.59 ± 0.14 c | 0.57 ± 0.04 bc |

| HW 8% NaCl | 1.53 ± 0.08 c | 2.72 ± 0.10 d | 0.60 ± 0.03 cd |

| HW 10% NaCl | 1.60 ± 0.09 d | 2.85 ± 0.11 e | 0.63 ± 0.05 d |

| GS 0% NaCl | 1.61 ± 0.08 a | 2.92 ± 0.09 a | 0.66 ± 0.05 a |

| GS 4% NaCl | 1.65 ± 0.06 a | 3.04 ± 0.10 b | 0.70 ± 0.07 ab |

| GS 6% NaCl | 1.75 ± 0.09 b | 3.19 ± 0.07 c | 0.73 ± 0.06 bc |

| GS 8% NaCl | 1.80 ± 0.07 bc | 3.30 ± 0.12 d | 0.75 ± 0.05 cd |

| GS 10% NaCl | 1.84 ± 0.08 c | 3.40 ± 0.13 e | 0.78 ± 0.06 d |

| BB 0% NaCl | 1.66 ± 0.07 a | 3.12 ± 0.10 a | 0.73 ± 0.04 a |

| BB 4% NaCl | 1.75 ± 0.06 b | 3.29 ± 0.12 b | 0.77 ± 0.04 ab |

| BB 6% NaCl | 1.80 ± 0.09 b | 3.38 ± 0.11 c | 0.79 ± 0.03 bc |

| BB 8% NaCl | 1.93 ± 0.06 c | 3.55 ± 0.10 d | 0.81 ± 0.05 cd |

| BB 10% NaCl | 1.98 ± 0.08 c | 3.66 ± 0.12 e | 0.84 ± 0.06 d |

| Sulfhydryl Content (mmol/g) | Surface Sulfhydryl | Total Sulfhydryl | Disulfide Bonds |

|---|---|---|---|

| HY-LINE 0% sucrose | 1.32 ± 0.08 a | 2.32 ± 0.09 a | 0.50 ± 0.03 a |

| HY-LINE 4% sucrose | 1.38 ± 0.05 b | 2.41 ± 0.11 b | 0.52 ± 0.02 ab |

| HY-LINE 6% sucrose | 1.41 ± 0.07 b | 2.53 ± 0.13 c | 0.56 ± 0.04 bc |

| HY-LINE 8% sucrose | 1.49 ± 0.11 c | 2.67 ± 0.10 d | 0.59 ± 0.04 cd |

| HY-LINE 10% sucrose | 1.57 ± 0.12 d | 2.80 ± 0.12 e | 0.62 ± 0.03 d |

| HW 0% sucrose | 1.29 ± 0.09 a | 2.27 ± 0.10 a | 0.49 ± 0.05 a |

| HW 4% sucrose | 1.36 ± 0.08 b | 2.38 ± 0.13 b | 0.51 ± 0.02 ab |

| HW 6% sucrose | 1.42 ± 0.11 c | 2.54 ± 0.09 c | 0.56 ± 0.06 bc |

| HW 8% sucrose | 1.49 ± 0.10 d | 2.67 ± 0.08 d | 0.59 ± 0.04 cd |

| HW 10% sucrose | 1.56 ± 0.07 e | 2.79 ± 0.11 e | 0.62 ± 0.03 d |

| GS 0% sucrose | 1.61 ± 0.08 a | 2.92 ± 0.09 a | 0.66 ± 0.05 a |

| GS 4% sucrose | 1.63 ± 0.09 a | 3.01 ± 0.13 b | 0.69 ± 0.06 ab |

| GS 6% sucrose | 1.73 ± 0.06 b | 3.17 ± 0.13 c | 0.72 ± 0.05 bc |

| GS 8% sucrose | 1.77 ± 0.04 c | 3.25 ± 0.11 d | 0.74 ± 0.04 cd |

| GS 10% sucrose | 1.82 ± 0.03 d | 3.33 ± 0.08 e | 0.76 ± 0.07 d |

| BB 0% sucrose | 1.66 ± 0.10 a | 3.12 ± 0.10 a | 0.73 ± 0.03 a |

| BB 4% sucrose | 1.73 ± 0.12 b | 3.25 ± 0.11 b | 0.76 ± 0.04 ab |

| BB 6% sucrose | 1.78 ± 0.08 c | 3.34 ± 0.13 c | 0.78 ± 0.06 bc |

| BB 8% sucrose | 1.88 ± 0.09 d | 3.48 ± 0.12 d | 0.80 ± 0.03 cd |

| BB 10% sucrose | 1.96 ± 0.07 e | 3.62 ± 0.09 e | 0.83 ± 0.05 d |

| Secondary Structure Content (%) | α-Helixes | β-Sheets | β-Turns | Random Coils |

|---|---|---|---|---|

| HY-LINE 0%NaCl | 27.96 ± 0.32 a | 18.21 ± 0.21 a | 32.43 ± 0.43 a | 21.40 ± 0.26 a |

| HY-LINE 4% NaCl | 29.43 ± 0.33 b | 20.27 ± 0.19 b | 30.53 ± 0.36 b | 19.77 ± 0.32 b |

| HY-LINE 6% NaCl | 30.60 ± 0.43 c | 21.31 ± 0.22 c | 29.00 ± 0.41 c | 19.09 ± 0.35 c |

| HY-LINE 8% NaCl | 31.94 ± 0.49 d | 22.72 ± 0.25 d | 26.66 ± 0.26 d | 18.68 ± 0.37 d |

| HY-LINE 10% NaCl | 33.08 ± 0.36 e | 23.76 ± 0.43 e | 25.10 ± 0.58 e | 18.06 ± 0.46 e |

| HW 0%NaCl | 27.27 ± 0.31 a | 18.02 ± 0.49 a | 32.77 ± 0.44 a | 21.94 ± 0.32 a |

| HW 4% NaCl | 29.14 ± 0.47 b | 20.82 ± 0.42 b | 29.66 ± 0.22 b | 20.38 ± 0.34 b |

| HW 6% NaCl | 30.31 ± 0.44 c | 21.73 ± 0.42 c | 28.12 ± 0.33 c | 19.84 ± 0.36 c |

| HW 8% NaCl | 31.21 ± 0.39 d | 22.64 ± 0.45 d | 26.97 ± 0.32 d | 19.18 ± 0.25 d |

| HW 10% NaCl | 32.39 ± 0.48 e | 23.66 ± 0.52 e | 25.22 ± 0.27 e | 18.73 ± 0.46 e |

| GS 0%NaCl | 30.95 ± 0.30 a | 22.10 ± 0.45 a | 27.50 ± 0.23 a | 19.45 ± 0.39 a |

| GS 4% NaCl | 32.93 ± 0.46 b | 23.38 ± 0.49 b | 24.84 ± 0.37 b | 18.85 ± 0.20 b |

| GS 6% NaCl | 33.84 ± 0.33 c | 24.62 ± 0.33 c | 25.61 ± 0.34 c | 17.93 ± 0.22 c |

| GS 8% NaCl | 34.18 ± 0.42 d | 25.73 ± 0.43 d | 22.78 ± 0.29 d | 17.31 ± 0.37 d |

| GS 10% NaCl | 35.14 ± 0.37 e | 26.27 ± 0.45 e | 22.30 ± 0.38 e | 16.29 ± 0.46 e |

| BB 0%NaCl | 31.56 ± 0.39 a | 23.06 ± 0.45 a | 26.56 ± 0.46 a | 18.82 ± 0.47 a |

| BB 4% NaCl | 33.53 ± 0.21 b | 24.78 ± 0.47 b | 24.04 ± 0.43 b | 17.65 ± 0.30 b |

| BB 6% NaCl | 34.57 ± 0.37 c | 25.72 ± 0.31 c | 22.90 ± 0.38 c | 16.81 ± 0.33 c |

| BB 8% NaCl | 35.56 ± 0.23 d | 26.86 ± 0.41 d | 21.37 ± 0.34 d | 16.21 ± 0.23 d |

| BB 10% NaCl | 36.25 ± 0.37 e | 27.72 ± 0.46 e | 20.83 ± 0.24 e | 15.20 ± 0.13 e |

| Secondary Structure Content (%) | α-Helixes | β-Sheets | β-Turns | Random Coils |

|---|---|---|---|---|

| HY-LINE 0% sucrose | 27.96 ± 0.32 a | 18.21 ± 0.21 a | 32.43 ± 0.43 a | 21.40 ± 0.26 a |

| HY-LINE 4% sucrose | 29.04 ± 0.37 b | 19.82 ± 0.43 b | 30.18 ± 0.27 b | 20.96 ± 0.37 b |

| HY-LINE 6% sucrose | 29.59 ± 0.36 c | 20.96 ± 0.25 c | 29.40 ± 0.21 c | 20.05 ± 0.41 c |

| HY-LINE 8% sucrose | 31.31 ± 0.43 d | 21.27 ± 0.28 d | 28.03 ± 0.32 d | 19.39 ± 0.33 d |

| HY-LINE 10% sucrose | 32.89 ± 0.33 e | 22.03 ± 0.34 e | 26.20 ± 0.43 e | 18.88 ± 0.39 e |

| HW 0% sucrose | 27.27 ± 0.21 a | 18.02 ± 0.49 a | 32.77 ± 0.34 a | 21.94 ± 0.22 a |

| HW 4% sucrose | 28.84 ± 0.32 b | 20.04 ± 0.45 b | 29.75 ± 0.32 b | 21.37 ± 0.26 b |

| HW 6% sucrose | 29.57 ± 0.35 c | 21.18 ± 0.38 c | 28.38 ± 0.42 c | 20.87 ± 0.27 c |

| HW 8% sucrose | 30.85 ± 0.33 d | 22.08 ± 0.29 d | 27.34 ± 0.35 d | 19.73 ± 0.29 d |

| HW 10% sucrose | 31.92 ± 0.31 e | 23.09 ± 0.33 e | 25.87 ± 0.29 e | 19.12 ± 0.34 e |

| GS 0% sucrose | 30.95 ± 0.20 a | 22.10 ± 0.40 a | 27.50 ± 0.26 a | 19.45 ± 0.29 a |

| GS 4% sucrose | 31.18 ± 0.35 b | 23.03 ± 0.33 b | 26.76 ± 0.25 b | 19.03 ± 0.32 a |

| GS 6% sucrose | 32.07 ± 0.22 c | 24.13 ± 0.20 c | 25.46 ± 0.33 c | 18.34 ± 0.38 b |

| GS 8% sucrose | 33.86 ± 0.38 d | 25.22 ± 0.31 d | 23.18 ± 0.24 d | 17.74 ± 0.29 c |

| GS 10% sucrose | 34.77 ± 0.41 e | 25.84 ± 0.29 e | 22.73 ± 0.27 d | 16.66 ± 0.31 d |

| BB 0% sucrose | 31.56 ± 0.29 a | 23.06 ± 0.35 a | 26.56 ± 0.26 a | 18.82 ± 0.24 a |

| BB 4% sucrose | 32.83 ± 0.37 b | 24.19 ± 0.29 b | 25.03 ± 0.35 b | 17.95 ± 0.27 b |

| BB 6% sucrose | 33.54 ± 0.42 c | 25.28 ± 0.33 c | 23.61 ± 0.32 c | 17.57 ± 0.30 c |

| BB 8% sucrose | 34.79 ± 0.46 d | 26.47 ± 0.44 d | 21.85 ± 0.29 d | 16.89 ± 0.21 d |

| BB 10% sucrose | 35.96 ± 0.32 e | 27.05 ± 0.42 e | 21.38 ± 0.27 e | 15.61 ± 0.17 e |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, R.; Wang, L.; Ma, Y.; Zang, J.; Qing, M.; Chi, Y.; Chi, Y. Addition of NaCl or Sucrose on the Protein Content, and Functional and Physicochemical Properties of Egg Whites Liquid under Heat Treatment. Foods 2023, 12, 881. https://doi.org/10.3390/foods12040881

Yu R, Wang L, Ma Y, Zang J, Qing M, Chi Y, Chi Y. Addition of NaCl or Sucrose on the Protein Content, and Functional and Physicochemical Properties of Egg Whites Liquid under Heat Treatment. Foods. 2023; 12(4):881. https://doi.org/10.3390/foods12040881

Chicago/Turabian StyleYu, Ruihan, Lifeng Wang, Yanqiu Ma, Jingnan Zang, Mingmin Qing, Yujie Chi, and Yuan Chi. 2023. "Addition of NaCl or Sucrose on the Protein Content, and Functional and Physicochemical Properties of Egg Whites Liquid under Heat Treatment" Foods 12, no. 4: 881. https://doi.org/10.3390/foods12040881

APA StyleYu, R., Wang, L., Ma, Y., Zang, J., Qing, M., Chi, Y., & Chi, Y. (2023). Addition of NaCl or Sucrose on the Protein Content, and Functional and Physicochemical Properties of Egg Whites Liquid under Heat Treatment. Foods, 12(4), 881. https://doi.org/10.3390/foods12040881