Impact of Copper Fungicide Use in Hop Production on the Total Metal Content and Stability of Wort and Dry-Hopped Beer

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Hop Treatments

2.3. Hop Boiling in Model Buffer

2.4. Dry Hopping in Model Buffer

2.5. Laboratory-Scale Wort Boiling

2.6. Pilot-Scale Dry Hopping

2.7. Metal Analysis by Inductively Coupled Plasma Mass Spectrometry (ICP-MS)

2.8. Measurement of Oxidative Stability of Hopped Beers by Electron Paramagnetic Resonance

2.9. Loss of 4-Mercapto-4-Methylpentan-2-One (4-MMP) During Accelerated Aging

2.10. Datasets and Statistical Analysis

3. Results

3.1. Metal Content of Hop Cones

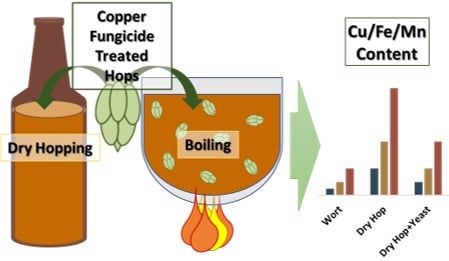

3.2. Effect of Copper-Treated Hops on Final Copper Content in Model Wort Buffer and Wort after Boiling

3.3. Copper Transfer from CBF-Treated Hops into Dry-Hopped Model and Pilot-Scale Beer

3.4. Impact of CBF Treatments on Oxidative Stability as Measured by EPR

3.5. Varietal Thiol Loss in Dry-Hopped Beers

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Vanderhaegen, B.; Neven, H.; Verachtert, H.; Derdelinckx, G. The chemistry of beer aging—A critical review. Food Chem. 2006, 95, 357–381. [Google Scholar] [CrossRef]

- Bamforth, C.W.; Lentini, A. The flavor instability of beer: A quality perspective. In Beer; Bamforth, C.W., Ed.; Academic Press: Cambridge, MA, USA, 2009; pp. 85–109. [Google Scholar]

- Bamforth, C.W.; Muller, R.E.; Walker, M.D. Oxygen and oxygen radicals in malting and brewing: A review. J. Am. Soc. Brew. Chem. 1993, 51, 79–88. [Google Scholar] [CrossRef]

- Kaneda, H.; Kano, Y.; Osawa, T.; Kawakishi, S.; Kamada, K. The role of free radicals in beer oxidation. J. Am. Soc. Brew. Chem. 1989, 47, 49–53. [Google Scholar] [CrossRef]

- Čejka, P.; Horák, T.; Dvořák, J.; Čulík, J.; Jurkova, M.; Kellner, V.; Hašková, D. Monitoring of the distribution of some heavy metals during brewing process. Ecol. Chem. Eng. S 2011, 18, 67–74. [Google Scholar]

- Ibanez, J.G.; Carreon-Alvarez, A.; Barcena-Soto, M.; Casillas, N. Metals in alcoholic beverages: A review of sources, effects, concentrations, removal, speciation, and analysis. J. Food Compos. Anal. 2008, 21, 672–683. [Google Scholar] [CrossRef]

- Passaghe, P.; Bertoli, S.; Tubaro, F.; Buiatti, S. Monitoring of some selected heavy metals throughout the brewing process of craft beers by inductively coupled plasma mass spectrometry. Eur. Food Res. Technol. 2015, 241, 199–215. [Google Scholar] [CrossRef]

- Wietstock, P.; Kunz, T.; Waterkamp, H.; Methner, F.-J. Uptake and release of Ca, Cu, Fe, Mg, and Zn during beer production. J. Am. Soc. Brew. Chem. 2015, 73, 179–184. [Google Scholar] [CrossRef]

- Bamforth, C.W.; Parsons, R. New procedures to improve the flavor stability of beer. J. Am. Soc. Brew. Chem. 1985, 43, 197–202. [Google Scholar] [CrossRef]

- Pohl, P. Metals in beer. In Beer in Health and Disease Prevention; Preedy, V.R., Ed.; Academic Press: Cambridge, MA, USA, 2009; pp. 349–358. [Google Scholar]

- Porter, J.R.; Bamforth, C.W. Manganese in brewing raw materials, disposition during the brewing process, and impact on the flavor instability of beer. J. Am. Soc. Brew. Chem. 2016, 74, 87–90. [Google Scholar] [CrossRef]

- Lafontaine, S.R.; Shellhammer, T.H. How hoppy beer production has redefined hop quality and a discussion of agricultural and processing strategies to promote it. MBAA TQ 2019, 56, 1–12. [Google Scholar]

- Han, R.; Li, H.; Li, Y.; Zhang, J.; Xiao, H.; Shi, J. Biosorption of copper and lead ions by waste beer yeast. J. Hazard. Mater. 2006, 137, 1569–1576. [Google Scholar] [CrossRef] [PubMed]

- Mochaba, F.; O’Connor-Cox, E.S.C.; Axcell, B.C. Effects of yeast quality on the accumulation and release of metals causing beer instability. J. Am. Soc. Brew. Chem. 1996, 54, 164–171. [Google Scholar] [CrossRef]

- Morimoto, M.; Kishimoto, T.; Kobayashi, M.; Yako, N.; Iida, A.; Wanikawa, A.; Kitagawa, Y. Effects of Bordeaux mixture (copper sulfate) treatment on blackcurrant/muscat-like odors in hops and beer. J. Am. Soc. Brew. Chem. 2010, 68, 30–33. [Google Scholar] [CrossRef]

- Montag, J.; Schreiber, L.; Schonherr, J. An In vitro study of the nature of protective activities of copper sulphate, copper hydroxide and copper oxide against conidia of Venturia inaequalis. J. Phytopathol. 2006, 154, 474–481. [Google Scholar] [CrossRef]

- Hollomon, D.W. Fungicide resistance: Facing the challenge. Plant Prot. Sci. 2015, 51, 170–176. [Google Scholar] [CrossRef]

- Kishimoto, T.; Kobayashi, M.; Yako, N.; Iida, A.; Wanikawa, A. Comparison of 4-mercapto-4-methylpentan-2-one contents in hop cultivars from different growing regions. J. Agric. Food Chem. 2008, 56, 1051–1057. [Google Scholar] [CrossRef]

- Vermeulen, C.; Gijs, L.; Collin, S. Sensorial contribution and formation pathways of thiols in foods: A review. Food Rev. Int. 2005, 21, 69–137. [Google Scholar] [CrossRef]

- Kreitman, G.Y.; Danilewicz, J.C.; Jeffery, D.W.; Elias, R.J. Reaction Mechanisms of Metals with Hydrogen Sulfide and Thiols in Model Wine. Part 1: Copper-Catalyzed Oxidation. J. Agric. Food Chem. 2016, 64, 4095–4104. [Google Scholar] [CrossRef]

- Andersen, M.L.; Skibsted, L.H. Electron Spin Resonance Spin Trapping Identification of Radicals Formed during Aerobic Forced Aging of Beer. J. Agric. Food. Chem. 1998, 46, 1272–1275. [Google Scholar] [CrossRef]

- Uchida, M.; Ono, M. Improvement for oxidative flavor stability of beer—Role of OH-radical in beer oxidation. J. Am. Soc. Brew. Chem. 1996, 54, 198–204. [Google Scholar] [CrossRef]

- Kirkpatrick, K.R.; Shellhammer, T.H. Evidence of dextrin hydrolyzing enzymes in Cascade hops (Humulus lupulus). J. Agric. Food Chem. 2018, 66, 9121–9126. [Google Scholar] [CrossRef] [PubMed]

- Huang, C.Y.L.; Schulte, E. Digestion of plant tissue for analysis by ICP emission spectroscopy. Commun. Soil Sci. Plant 1985, 16, 943–958. [Google Scholar] [CrossRef]

- Analysis, A.M.o. Measurement of Oxidative Resistance in Beer by Electron Paramagnetic Resonance. In Beer Method 46; American Society of Brewing Chemists: St. Paul, MN, USA, 2009. [Google Scholar]

- Capone, D.L.; Ristic, R.; Pardon, K.H.; Jeffery, D.W. Simple Quantitative Determination of Potent Thiols at Ultratrace Levels in Wine by Derivatization and High-Performance Liquid Chromatography–Tandem Mass Spectrometry (HPLC-MS/MS) Analysis. Anal. Chem. 2015, 87, 1226–1231. [Google Scholar] [CrossRef] [PubMed]

- Zufall, C.; Tyrell, T. The influence of heavy metal ions on beer flavour stability. J. Inst. Brew. 2008, 114, 134–142. [Google Scholar] [CrossRef]

- Jenkins, D.; James, S.; Dehrmann, F.; Smart, K.; Cook, D. Impacts of copper, iron, and manganese metal ions on the EPR assessment of beer oxidative stability. J. Am. Soc. Brew. Chem. 2018, 76, 50–57. [Google Scholar] [CrossRef]

- Mochaba, F.; O’Connor-Cox, E.S.C.; Axcell, B.C. Metal Ion Concentration and Release by a Brewing Yeast: Characterization and Implications. J. Am. Soc. Brew. Chem. 1996, 54, 155–163. [Google Scholar] [CrossRef]

- Kishimoto, T.; Wanikawa, A.; Kono, K.; Shibata, K. Comparison of the odor-active compounds in unhopped beer and beers hopped with different hop varieties. J. Agric. Food Chem. 2006, 54, 8855–8861. [Google Scholar] [CrossRef]

- Lafontaine, S.; Varnum, S.; Roland, A.; Delpech, S.; Dagan, L.; Vollmer, D.; Kishimoto, T.; Shellhammer, T. Impact of harvest maturity on the aroma characteristics and chemistry of Cascade hops used for dry-hopping. Food Chem. 2019, 278, 228–239. [Google Scholar] [CrossRef]

- Gros, J.; Peeters, F.; Collin, S. Occurrence of odorant polyfunctional thiols in beers hopped with different cultivars. First evidence of an s-cysteine conjugate in hop (Humulus lupulus L.). J. Agric. Food Chem. 2012, 60, 7805–7816. [Google Scholar] [CrossRef]

- Gros, J.; Nizet, S.; Collin, S. Occurrence of odorant polyfunctional thiols in the super alpha Tomahawk hop cultivar. Comparison with the thiol-rich Nelson Sauvin bitter variety. J. Agric. Food Chem. 2011, 59, 8853–8865. [Google Scholar] [CrossRef]

- Kankolongo Cibaka, M.L.; Decourriere, L.; Lorenzo-Alonso, C.J.; Bodart, E.; Robiette, R.; Collin, S. 3-sulfanyl-4-methylpentan-1-ol in dry-hopped beers: First evidence of glutathione s-conjugates in hop (Humulus lupulus L.). J. Agric. Food Chem. 2016, 64, 8572–8582. [Google Scholar] [CrossRef] [PubMed]

- Takoi, K.; Degueil, M.; Shinkaruk, S.; Thibon, C.C.; Maeda, K.; Ito, K.; Bennetau, B.; Dubourdieu, D.; Tominaga, T. Identification and characteristics of new volatile thiols derived from the hop (Humulus luplus L.) cultivar Nelson Sauvin. J. Agric. Food Chem. 2009, 57, 2493–2502. [Google Scholar] [CrossRef] [PubMed]

- Lafontaine, S.R.; Shellhammer, T.H. Investigating the factors impacting aroma, flavor, and stability in dry-hopped beers. MBAA TQ 2019, 56, 13–23. [Google Scholar]

- Svendsen, R.; Lund, W. Speciation of Cu, Fe and Mn in beer using ion exchange separation and size-exclusion chromatography in combination with electrothermal atomic absorption spectrometry. Analyst 2000, 125, 1933–1937. [Google Scholar] [CrossRef]

- Blackwell, K.J.; Singleton, I.; Tobin, J.M. Metal cation uptake by yeast: A review. Appl. Microbiol. Biotechnol. 1995, 43, 579–584. [Google Scholar] [CrossRef]

- Wietstock, P.C.; Kunz, T.; Methner, F.J. Influence of hopping technology on oxidative stability and staling-related carbonyls in pale lager beer. Brew.Sci. 2016, 69, 73–84. [Google Scholar]

- Wietstock, P.C.; Kunz, T.; Perreira, F.; Methner, F.J. Metal chelation behavior of hop acids in buffered model systems. Brew.Sci. 2016, 69, 56. [Google Scholar]

- Mira, L.; Fernandez, M.T.; Santos, M.; Rocha, R.; Florêncio, M.H.; Jennings, K.R. Interactions of flavonoids with iron and copper ions: A mechanism for their antioxidant activity. Free Radic. Res. 2002, 36, 1199–1208. [Google Scholar] [CrossRef]

- Kocherginsky, N.M.; Kostetski, Y.Y.; Smirnov, A.I. Antioxidant Pool in Beer and Kinetics of EPR Spin-Trapping. J. Agric. Food Chem. 2005, 53, 6870–6876. [Google Scholar] [CrossRef]

- Saison, D.; De Schutter, D.P.; Vanbeneden, N.; Daenen, L.; Delvaux, F.; Delvaux, F.R. Decrease of aged beer aroma by the reducing activity of brewing yeast. J. Agric. Food Chem. 2010, 58, 3107–3115. [Google Scholar] [CrossRef]

- Saison, D.; De Schutter, D.P.; Delvaux, F.; Delvaux, F.R. Improved flavor stability by aging beer in the presence of yeast. J. Am. Soc. Brew. Chem. 2011, 69, 50–56. [Google Scholar] [CrossRef]

- Wilson, D.F.; Chance, B. Azide inhibition of mitochondrial electron transport. I. The aerobic steady state of succinate oxidation. Biochim. Biophys. Acta 1967, 131, 421–430. [Google Scholar] [CrossRef]

- Liu, Y.; Gu, X.-h.; Tang, J.; Liu, K. Antioxidant activities of hops (Humulus lupulus) and their products. J. Am. Soc. Brew. Chem. 2007, 65, 116–121. [Google Scholar] [CrossRef]

- Pohl, P. Determination and fractionation of metals in beer: A review. Food Addit. Contam. Part A Chem. Anal. Control. Expo. Risk Assess. 2008, 25, 693–703. [Google Scholar] [CrossRef] [PubMed]

- Sakellari, A.; Karavoltsos, S.; Plavšić, M.; Bempi, E.; Papantonopoulou, G.; Dassenakis, M.; Kalogeropoulos, N. Copper complexing properties, trace metal content and organic matter physico-chemical characterization of Greek beers. Microchem. J. 2017, 135, 66–73. [Google Scholar] [CrossRef]

- Bokare, A.D.; Choi, W. Review of iron-free Fenton-like systems for activating H2O2 in advanced oxidation processes. J. Hazard. Mater. 2014, 275, 121–135. [Google Scholar] [CrossRef] [PubMed]

- Kreitman, G.Y. Reaction Mechanisms of Transition Metals with Hydrogen Sulfide and Thiols in Wine. Ph.D. Thesis, The Pennsylvania State University, State College, PA, USA, May 2016. [Google Scholar]

| Harvest Year | ||||||

|---|---|---|---|---|---|---|

| 2018 | 2019 | |||||

| Cu | Fe | Mn | Cu | Fe | Mn | |

| Control | 7.22 (1.51) | 50.99 (4.68) | 59.10 (7.96) | 8.39 (0.93) | 76.48 (22.11) | 65.37 (13.46) |

| Low Copper | - | - | - | 18.04 (4.40) | 60.83 (17.52) | 61.32 (13.19) |

| High Copper | 18.71 (5.37) | 53.72 (5.66) | 58.83 (7.08) | 19.67 (2.66) | 49.08 (12.21) | 57.03 (15.63) |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chrisfield, B.J.; Hopfer, H.; Elias, R.J. Impact of Copper Fungicide Use in Hop Production on the Total Metal Content and Stability of Wort and Dry-Hopped Beer. Beverages 2020, 6, 48. https://doi.org/10.3390/beverages6030048

Chrisfield BJ, Hopfer H, Elias RJ. Impact of Copper Fungicide Use in Hop Production on the Total Metal Content and Stability of Wort and Dry-Hopped Beer. Beverages. 2020; 6(3):48. https://doi.org/10.3390/beverages6030048

Chicago/Turabian StyleChrisfield, Benjamin J., Helene Hopfer, and Ryan J. Elias. 2020. "Impact of Copper Fungicide Use in Hop Production on the Total Metal Content and Stability of Wort and Dry-Hopped Beer" Beverages 6, no. 3: 48. https://doi.org/10.3390/beverages6030048

APA StyleChrisfield, B. J., Hopfer, H., & Elias, R. J. (2020). Impact of Copper Fungicide Use in Hop Production on the Total Metal Content and Stability of Wort and Dry-Hopped Beer. Beverages, 6(3), 48. https://doi.org/10.3390/beverages6030048