Improving the Leavening Effect of Ice like CO2 Gas Hydrates by Addition of Gelling Agents in Wheat Bread

Abstract

:1. Introduction

2. Results and Discussion

3. Conclusions

4. Materials and Methods

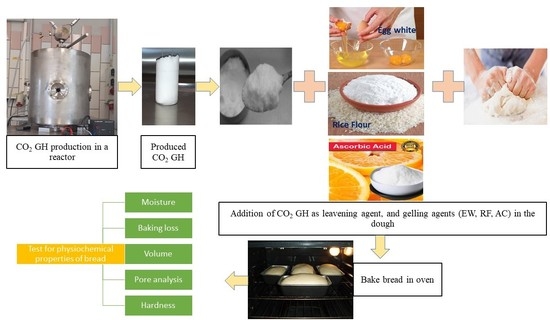

4.1. CO2 Gas Hydrates (GH) Production

4.2. Production of Wheat Bread with Gelling Agents

4.3. Analysis of GH Wheat Bread

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cai, Y.; Chen, Y.; Li, Q.; Li, L.; Huang, H.; Wang, S.; Wang, W. CO2 Hydrate Formation Promoted by a Natural Amino Acid l-Methionine for Possible Application to CO2 Capture and Storage. Energy Technol. 2017, 5, 1195–1199. [Google Scholar] [CrossRef]

- Srivastava, S.; Hitzmann, B.; Zettel, V. A future road map for carbon dioxide (CO2) gas hydrate as an emerging technology in food research. Food Bioprocess Technol. 2021, 14, 1758–1762. [Google Scholar] [CrossRef]

- Srivastava, S.; Kollemparembil, A.M.; Zettel, V.; Claßen, T.; Gatternig, B.; Delgado, A.; Hitzmann, B. Experimental investigation of CO2 uptake in CO2 hydrates formation with amino acids as kinetic promoters and its dissociation at high temperature. Sci. Rep. 2022, 12, 1–4. [Google Scholar] [CrossRef] [PubMed]

- Zhou, X.; Zang, X.; Long, Z.; Liang, D. Multiscale analysis of the hydrate based carbon capture from gas mixtures containing carbon dioxide. Sci. Rep. 2021, 11, 9197. [Google Scholar] [CrossRef]

- Struyf, N.; Van der Maelen, E.; Hemdane, S.; Verspreet, J.; Verstrepen, K.J.; Courtin, C.M. Bread dough and baker’s yeast: An uplifting synergy. Compr. Rev. Food Sci. Food Saf. 2017, 16, 850–867. [Google Scholar] [CrossRef] [Green Version]

- Goesaert, H.; Brijs, K.; Veraverbeke, W.S.; Courtin, C.M.; Gebruers, K.; Delcour, J.A. Wheat flour constituents: How they impact bread quality, and how to impact their functionality. Trends Food Sci. Technol. 2005, 16, 12–30. [Google Scholar] [CrossRef]

- Mancebo, C.M.; Martínez, M.M.; Merino, C.; de la Hera, E.; Gómez, M. Effect of oil and shortening in rice bread quality: Relationship between dough rheology and quality characteristics. J. Texture Stud. 2017, 48, 597–606. [Google Scholar] [CrossRef]

- Murat, K.M.; Gürbüz, K.H. Effect of partial baking, storage and rebaking process on the quality of white pan bread. Int. J. Food Sci. Technol. 2006, 41, 108–114. [Google Scholar] [CrossRef]

- Skendi, A.; Seni, I.; Varzakas, T.; Alexopoulos, A.; Papageorgiou, M. Preliminary Investigation into the Effect of Some Bakery Improvers in the Rheology of Bread Wheat Dough. Biol. Life Sci. Forum 2021, 6, 73. [Google Scholar]

- Liang, Z.; Gao, J.; Yu, P.; Yang, D. History, mechanism of action, and toxicity: A review of commonly used dough rheology improvers. Crit. Rev. Food Sci. Nutr. 2021, 17, 1–7. [Google Scholar] [CrossRef]

- Vargas, M.C.; Simsek, S. Clean Label in Bread. Foods 2021, 10, 2054. [Google Scholar] [CrossRef]

- Waziiroh, E.; Schoenlechner, R.; Jaeger, H.; Brusadelli, G.; Bender, D. Understanding gluten-free bread ingredients during ohmic heating: Function, effect and potential application for bread making. Eur. Food Res. Technol. 2022, 248, 1021–1034. [Google Scholar] [CrossRef]

- Weegels, P.L.; Groeneweg, F.; Esselink, E.; Smit, R.; Brown, R.; Ferdinando, D. Large and fast deformations crucial for the rheology of proofing dough. Cereal Chem. 2003, 80, 424–426. [Google Scholar] [CrossRef]

- Garzón, R.; Hernando, I.; Llorca, E.; Rosell, C.M. Understanding the effect of emulsifiers on bread aeration during bread making. J. Sci. Food Agric. 2018, 98, 5494–5502. [Google Scholar] [CrossRef] [Green Version]

- Mietton, L.; Samson, M.F.; Marlin, T.; Godet, T.; Nolleau, V.; Guezenec, S.; Segond, D.; Nidelet, T.; Desclaux, D.; Sicard, D. Impact of Leavening Agent and Wheat Variety on Bread Organoleptic and Nutritional Quality. Microorganisms 2022, 10, 1416. [Google Scholar] [CrossRef]

- Zhao, Q.; Ding, L.; Xia, M.; Huang, X.; Isobe, K.; Handa, A.; Cai, Z. Role of lysozyme on liquid egg white foaming properties: Interface behavior, physicochemical characteristics and protein structure. Food Hydrocoll. 2021, 120, 106876. [Google Scholar] [CrossRef]

- Tagliasco, M.; Tecuanhuey, M.; Reynard, R.; Zuliani, R.; Pellegrini, N.; Capuano, E. Monitoring the effect of cell wall integrity in modulating the starch digestibility of durum wheat during different steps of bread making. Food Chem. 2022, 396, 133678. [Google Scholar] [CrossRef]

- Lazaridou, A.; Duta, D.; Papageorgiou, M.; Belc, N.; Biliaderis, C.G. Effects of hydrocolloids on dough rheology and bread quality parameters in gluten-free formulations. J. Food Eng. 2007, 79, 1033–1047. [Google Scholar] [CrossRef]

- Masure, H.G.; Wouters, A.G.; Fierens, E.; Delcour, J.A. Electrical resistance oven baking as a tool to study crumb structure formation in gluten-free bread. Food Res. Int. 2019, 116, 925–931. [Google Scholar] [CrossRef]

- Wu, L.; Zhang, C.; Long, Y.; Chen, Q.; Zhang, W.; Liu, G. Food gelling agents: From functions to analytical methods. Crit. Rev. Food Sci. Nutr. 2022, 62, 8497–8517. [Google Scholar] [CrossRef]

- Srivastava, S.; Kollemparembil, A.M.; Zettel, V.; Claßen, T.; Mobarak, M.; Gatternig, B.; Delgado, A.; Jekle, M.; Hitzmann, B. An Innovative Approach in the Baking of Bread with CO2 Gas Hydrates as Leavening Agents. Foods 2022, 11, 3570. [Google Scholar] [CrossRef] [PubMed]

- Srivastava, S.; Kollemparembil, A.M.; Zettel, V.; Claßen, T.; Mobarak, M.; Gatternig, B.; Delgado, A.; Jekle, M.; Hitzmann, B. A comparative analysis of partial replacement of yeast with CO2 gas hydrates as leavening agents in baking of wheat bread. Processes 2023, 11, 653. [Google Scholar] [CrossRef]

- Purlis, E.; Salvadori, V.O. Modelling the browning of bread during baking. Food Res. Int. 2009, 42, 865–870. [Google Scholar] [CrossRef]

- Fleet, G.H. Yeasts in foods and beverages: Impact on product quality and safety. Curr. Opin. Biotechnol. 2007, 18, 170–175. [Google Scholar] [CrossRef] [PubMed]

- Ertop, M.H.; Tuğkan, Ş.İ. Optimization of the amount of chickpea sourdough and dry yeast in wheat bread formulation: Evaluation of physicochemical, sensory and antioxidant properties. Food Sci. Technol. Res. 2018, 24, 45–53. [Google Scholar] [CrossRef] [Green Version]

- Heitmann, M.; Zannini, E.; Arendt, E. Impact of Saccharomyces cerevisiae metabolites produced during fermentation on bread quality parameters: A review. Crit. Rev. Food Sci. Nutr. 2018, 58, 1152–1164. [Google Scholar] [CrossRef]

- Gallagher, E.; Kunkel, A.; Gormley, T.R.; Arendt, E.K. The effect of dairy and rice powder addition on loaf and crumb characteristics, and on shelf life (intermediate and long-term) of gluten-free breads stored in a modified atmosphere. Eur. Food Res. Technol. 2003, 218, 44–48. [Google Scholar] [CrossRef]

- Matos, M.E.; Rosell, C.M. Understanding gluten-free dough for reaching breads with physical quality and nutritional balance. J. Sci. Food Agric. 2015, 95, 653–661. [Google Scholar] [CrossRef]

- Verheyen, C.; Jekle, M.; Becker, T. Effects of Saccharomyces cerevisiae on the structural kinetics of wheat dough during fermentation. LWT Food Sci. Technol. 2014, 58, 194–202. [Google Scholar] [CrossRef]

- Kotoki, D.; Deka, S.C. Baking loss of bread with special emphasis on increasing water holding capacity. J. Food Sci. Technol. 2010, 47, 128–131. [Google Scholar] [CrossRef] [Green Version]

- Ziobro, R.; Juszczak, L.; Witczak, M.; Korus, J. Non-gluten proteins as structure forming agents in gluten free bread. J. Food Sci. Technol. 2016, 53, 571–580. [Google Scholar] [CrossRef] [Green Version]

- Elgeti, D.; Peng, L.; Jekle, M.; Becker, T. Foam stabilization during processing of starch-based dough systems. Innov. Food Sci. Emerg. Technol. 2017, 39, 267–274. [Google Scholar] [CrossRef]

- Zhang, L.; Lucas, T.; Doursat, C.; Flick, D.; Wagner, M. Effects of crust constraints on bread expansion and CO2 release. J. Food Eng. 2007, 80, 1302–1311. [Google Scholar] [CrossRef]

| Standard | % of the GH | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Std. Yeast + EW+ RF | Std. EW + RF | Std. AC + EW + RF | 40 + AC | 40 + RF + EW | 40 + AC + RF + EW | 60 + AC | 60 + RF + EW | 60 + AC + RF + EW | 70 + AC | 70 + RF + EW | 70 + AC + RF + EW | |

| MC (%) | 43.3 a± 2.0 | 38.7 a ± 2.0 | 40.9 a ± 2.1 | 38.7 a ± 2.1 | 39.7 a ± 2.4 | 41.4 a ± 1.1 | 43.1 a ± 1.0 | 42.1 a ± 2.0 | 43.2 a ± 2.1 | 42.7 a ± 1.3 | 43.0 a ± 2.2 | 44.3 a ± 1.0 |

| BL (%) | 8.0 b ± 2.1 | 9.2 b ± 1.1 | 7.0 b ± 1.2 | 6.3 b ± 3.0 | 7.2 b ± 2.0 | 7.5 b ± 3.2 | 9.3 b ± 3.7 | 8.7 b ± 2.4 | 7.4 b ± 2.0 | 6.3 b ± 1.3 | 17.7 b ± 2.0 | 16.6 b ± 2.4 |

| Vol. (mL) | 1090.1 c± 25.2 | 631.4 c ± 25.3 | 802.1 c ± 36.6 | 517.6 c ± 15.7 | 823.1 c ± 38.1 | 835.2 c ± 10.2 | 845.1 c ± 12.2 | 859.1 c ± 10.2 | 862.3 c ± 23.5 | 884.2 c ± 17.8 | 941.7 c ± 26.8 | 989.8 c ± 10.8 |

| Spe. Vol. (mL/g) | 2.1 d ± 1.0 | 1.0 d ± 0.5 | 1.1 d ± 0.0 | 1.0 d ± 0.1 | 1.3 d ± 0.2 | 1.4 d ± 0.1 | 1.4 d ± 0.0 | 1.5 d ± 0.3 | 1.6 d ± 0.4 | 1.8 d ± 0.2 | 1.9 d ± 0.1 | 2.0 d ± 0.2 |

| Bread Type | Pore Class (mm2) | ||||

|---|---|---|---|---|---|

| Small (0.10–2.00) | Somewhat Medium (2.01–3.00) | Medium (3.01–6.00) | A Little Bigger (6.00–10.00) | Large (10.00–11.00) | |

| Std. Yeast + EW+ RF | 82.8 a ± 1.0 | 6.6 b ± 1.0 | 8.7 c ± 1.0 | 1.1 d ± 0.0 | 0.5 d ± 0.0 |

| Std. EW + RF | 93.7 a ± 1.0 | 3.1 b ± 1.0 | 1.5 c ± 1.2 | 3.9 d ± 0.7 | 0.0 d ± 0.0 |

| Std. AC + EW + RF | 92.4 a ± 2.1 | 4.1 b ± 1.4 | 5.1 c ± 1.9 | 1.0 d ± 0.2 | 0.5 d ± 0.0 |

| 40 + AC | 85.2 a ± 2.4 | 4.3 b ± 1.1 | 8.3 c ± 1.1 | 2.2 d ± 0.2 | 0.3 d ± 0.0 |

| 40 + RF + EW | 85.7 a ± 2.9 | 4.4 b ± 2.7 | 9.3 c ± 1.4 | 2.4 d ± 1.1 | 1.2 d ± 0.0 |

| 40 + AC + RF + EW | 88.0 a ± 2.2 | 7.7 b ± 1.1 | 10.7 c ± 1.2 | 3.1 d ± 1.0 | 1.3 d ± 0.0 |

| 60 + AC | 89.4 a ± 2.0 | 4.5 b ± 1.2 | 8.8 c ± 1.7 | 2.7 d ± 1.0 | 1.4 d ± 0.0 |

| 60 + RF + EW | 89.9 a ± 2.8 | 5.5 b ± 1.8 | 8.9 c ± 1.3 | 2.8 d ± 1.2 | 1.4 d ± 0.0 |

| 60 + AC + RF + EW | 90.5 a ± 2.1 | 6.6 b ± 1.9 | 8.9 c ± 2.4 | 3.1 d ± 1.3 | 1.5 d ± 0.0 |

| 70 + AC | 89.8 a ± 2.9 | 5.7 b ± 2.3 | 8.9 c ± 1.7 | 2.9 d ± 1.0 | 1.5 d ± 0.0 |

| 70 + RF + EW | 90.4 a ± 2.1 | 6.0 b ± 1.7 | 8.8 c ± 2.4 | 3.2 d ± 1.0 | 1.7 d ± 0.0 |

| 70 + AC + RF + EW | 91.9 a ± 2.9 | 6.8 b ± 2.8 | 9.6 c ± 2.3 | 4.2 d ± 2.2 | 1.9 d ± 0.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Srivastava, S.; Kollemparembil, A.M.; Zettel, V.; Delgado, A.; Jekle, M.; Hitzmann, B. Improving the Leavening Effect of Ice like CO2 Gas Hydrates by Addition of Gelling Agents in Wheat Bread. Gels 2023, 9, 223. https://doi.org/10.3390/gels9030223

Srivastava S, Kollemparembil AM, Zettel V, Delgado A, Jekle M, Hitzmann B. Improving the Leavening Effect of Ice like CO2 Gas Hydrates by Addition of Gelling Agents in Wheat Bread. Gels. 2023; 9(3):223. https://doi.org/10.3390/gels9030223

Chicago/Turabian StyleSrivastava, Shubhangi, Ann Mary Kollemparembil, Viktoria Zettel, Antonio Delgado, Mario Jekle, and Bernd Hitzmann. 2023. "Improving the Leavening Effect of Ice like CO2 Gas Hydrates by Addition of Gelling Agents in Wheat Bread" Gels 9, no. 3: 223. https://doi.org/10.3390/gels9030223

APA StyleSrivastava, S., Kollemparembil, A. M., Zettel, V., Delgado, A., Jekle, M., & Hitzmann, B. (2023). Improving the Leavening Effect of Ice like CO2 Gas Hydrates by Addition of Gelling Agents in Wheat Bread. Gels, 9(3), 223. https://doi.org/10.3390/gels9030223