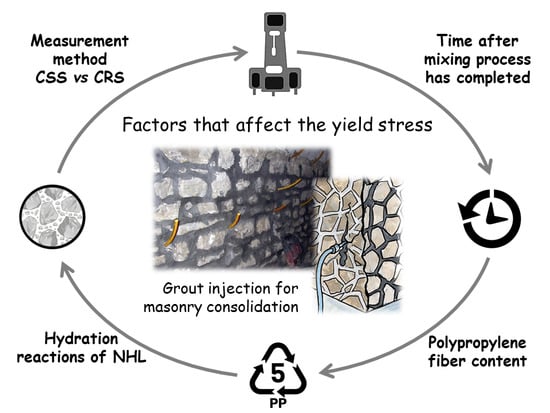

Effects of Polypropylene Fibers and Measurement Methods on the Yield Stress of Grouts for the Consolidation of Heritage Masonry Walls

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Mixture Proportions and Procedure

2.3. Experimental Procedures

3. Results and Discussion

3.1. Thixotropy and Yield Stress by CSR Method

3.2. Yield Stress by CSS Method

3.3. Comparison between Yield Stress, Critical Shear–Strain Rate and Time Period

4. Conclusions

- The static yield stress values were higher compared to the dynamic yield stress. Differences between both yield stresses were obtained in a range of 33% to 670%, depending on the content of PP fibers. This can be explained by the semi-disturbed state of the grout’s microstructure when the dynamic yield stress was determined, which was mainly due to the shear history dependence of the grout.

- The PP fibers influenced on the rheology of the NHL grouts by increasing their shear-thinning behavior. Moreover, both yield stress values increased with the presence of PP fibers. For example, for the reference grout (without fibers), the minimum and maximum values of the static yield stress varied from 0.05 to 15 Pa, while for the grout with 0.1% PP fibers, the values varied between 2 and 30 Pa. The amount of changes in the yield stress values was due to the structural build up and flocculation, which was a consequence of the mechanical interlocks between the NHL particles and fibers.

- The yield stress values depended on the measuring method. However, the yield values determined by CSS and CSR only showed moderate differences between them, which confirmed the efficiency of the Herschel–Bulkley model in determining the yield stress of NHL grouts whatever the measurement method used.

- The results and measurements performed showed that these methods enable us to evaluate the existence of a critical shear–strain rate range of 0.1 to 17.0 s−1 (depending on time period). Below this, there was a transition between dynamic and static yield stress.

- The dynamic yield stress should be used as design parameter at early stages of the grout injection process, whilst at a later stage, when the shear rate is slowing down, the static yield stress should be considered.

- Several equations that allow the estimation of the critical shear–strain rate as a function of time and yield stress have been proposed in order to promote better design of injection grouts.

- The critical shear–strain rate range increases over time. Therefore, to maximize the injectability of the grout, it is imperative to avoid stopping the grouting operation for periods longer than 20 min.

Author Contributions

Funding

Conflicts of Interest

References

- Kalagri, A.; Miltiadou-Fezans, A.; Vintzileou, E. Design and evaluation of hydraulic lime grouts for the strengthening of stone masonry historic structures. Mater. Struct. 2010, 43, 1135–1146. [Google Scholar] [CrossRef]

- Baltazar, L.G.; Henriques, F.M.A.; Cidade, M.T. Rheological characterization of injection grouts using rotational rheometry. In Advances in Rheology Research; Nova Science Publishers: New York, NY, USA, 2017; pp. 13–42. ISBN 978-1-53612-876-5. [Google Scholar]

- Baltazar, L.G.; Henriques, F.M.A.; Cidade, M.T. Rheology of natural hydraulic lime grouts for conservation of stone masonry—Influence of compositional and processing parameters. Fluids 2019, 4, 13. [Google Scholar] [CrossRef] [Green Version]

- Barnes, H.A.; Walters, K. The yield stress myth? Rheol. Acta 1985, 24, 323–326. [Google Scholar] [CrossRef]

- Hartnett, J.P.; Hu, R.Y.Z. Technical note: The yield stress—An engineering reality. J. Rheol. 1989, 33, 671. [Google Scholar] [CrossRef]

- Schurz, J. The yield stress—An empirical reality. Rheol. Acta 1990, 29, 170–171. [Google Scholar] [CrossRef]

- Keentok, M. The measurement of the yield stress of liquids. Rheol. Acta 1982, 21, 325–332. [Google Scholar] [CrossRef]

- Dzuy, N.Q.; Boger, D.V. Yield stress measurement for concentrated suspensions. J. Rheol. 1983, 27, 321. [Google Scholar] [CrossRef]

- Coussot, P.; Nguyen, Q.D.; Huynh, H.T.; Bonn, D. Viscosity bifurcation in thixotropic, yielding fluids. J. Rheol. 2002, 573–589. [Google Scholar] [CrossRef] [Green Version]

- Barnes, H.A. The yield stress—A review or ‘παντα ρει’—Everything flows? J. Non Newton Fluid 1999, 81, 133–178. [Google Scholar] [CrossRef]

- Hakansson, U. Rheology of Fresh Cement-Based Grouts. Ph.D. Thesis, The Royal Institute of Technology, Stockholm, Sweden, 1993. [Google Scholar]

- Al-Martini, S.; Nehdi, M. Effect of chemical admixtures on rheology of cement pastes at high temperature. J. ASTM Int. 2007, 4, 1–17. [Google Scholar] [CrossRef]

- Vipulanandan, C.; Mohammed, A.S. Hyperbolic rheological model with shear stress limit for acrylamide polymer modified bentonite drilling muds. J. Petrol Sci. Eng. 2014, 122, 38–47. [Google Scholar] [CrossRef]

- Collepardi, M. Degradation and restoration of masonry walls of historical buildings. Mater. Struct. 1990, 23, 81–102. [Google Scholar] [CrossRef]

- Pozo-Antonio, J.S. Evolution of mechanical properties and drying shrinkage in lime-based and lime cement-based mortars with pure limestone aggregate. Constr. Build. Mater. 2015, 77, 472–478. [Google Scholar] [CrossRef]

- Puertas, F.; Amat, T.; Fernández-Jiménez, A.; Vázquez, T. Mechanical and durable behaviour of alkaline cement mortars reinforced with polypropylene fibres. Cem. Concr. Res. 2003, 33, 2031–2036. [Google Scholar] [CrossRef]

- Banthia, N.; Gupta, R. Influence of polypropylene fiber geometr on plastic shrinkage cracking in concrete. Cem. Concr. Res. 2006, 36, 1263–1267. [Google Scholar] [CrossRef]

- Noushini, A.; Samali, B.; Vessalas, K. Effect of polyvinyl alcohol (PVA) fibre on dynamic and material properties of fibre reinforced concrete. Constr. Build. Mater. 2013, 49, 374–383. [Google Scholar] [CrossRef]

- Liu, J.; Sun, W.; Miao, C.; Liu, J.; Li, C. Assessment of fiber distribution in steel fiber mortar using image analysis. J. Wuhan Univ. Technol. Mater. Sci. 2012, 27, 166–171. [Google Scholar] [CrossRef]

- Campello, E.; Pereira, M.V.; Darwish, F. The effect of short metallic and polymeric fiber on the fracture behavior of cement mortar. Procedia Mater. Sci. 2014, 3, 1914–1921. [Google Scholar] [CrossRef] [Green Version]

- Lucolano, F.; Liguori, B.; Colella, C. Fibre-reinforced lime-based mortars: A possible resource for ancient masonry restoration. Constr. Build. Mater. 2013, 38, 785–789. [Google Scholar] [CrossRef]

- Di Bella, G.; Fiore, V.; Galtieri, G.; Borsellino, C.; Valenza, A. Effect of natural fibers reinforcement in lime plasters (kenaf and sisal vs. polypropylene). Constr. Build. Mater. 2014, 58, 159–165. [Google Scholar] [CrossRef]

- Chan, R.; Bindiganavile, V. Toughness of fibre reinforced hydraulic lime mortar. Part 1: Quasi-static response. Mater. Struct. 2010, 43, 1435–1444. [Google Scholar] [CrossRef]

- Chan, R.; Bindiganavile, V. Toughness of fibre reinforced hydraulic lime mortar. Part 2: Dynamic response. Mater. Struct. 2010, 43, 1445–1455. [Google Scholar] [CrossRef]

- Barbero-Barrera, M.M.; Medin, N.F. The effect of polypropylene fibers on graphite-natural hydraulic lime pastes. Constr. Build. Mater. 2018, 184, 591–601. [Google Scholar] [CrossRef]

- CEN. Building Lime-Part 1: Definitions, Specifications and Conformity Criteria; EN 459-1; CEN, European Committee for Standardization: Brussels, Belgium, 2010. [Google Scholar]

- Binda, L.; Saisi, A.; Tedeschi, C. Compatibility of materials used for repair of masonry buildings: Research and applications. Fracture Failure Nat. Build. Stone 2006, 167–182. [Google Scholar] [CrossRef]

- Jorne, F.; Henriques, F.M.A.; Baltazar, L.G. Influence of superplasticizer, temperature, resting time and injection pressure on hydraulic lime grout injectability. Correlation analysis between fresh grout parameters and grout injectability. J. Build. Eng. 2015, 4, 140–151. [Google Scholar] [CrossRef]

- Baltazar, L.G.; Henriques, F.M.A.; Cidade, M.T. Experimental study and modeling of rheological and mechanical properties of NHL grouts. J. Mater. Civil Eng. 2015, 27. [Google Scholar] [CrossRef]

- ASTM. Standard Specification for Chemical Admixtures for Concrete; ASTM C494; ASTM International: West Conshohocken, PA, USA, 2005. [Google Scholar]

- Baltazar, L.G.; Henriques, F.M.A.; Cidade, M.T. Combined effect of silica fume and nanosilica on the performance of injection grouts for consolidation of heritage buildings. In Advances in Rheology Research; Nova Science Publishers: New York, NY, USA, 2019; Volume 32, pp. 197–238. ISBN 978-1-53616-684-2. [Google Scholar]

- Yoshimura, A.S. A comparison of techniques for measuring yield stresses. J. Rheol. 1987, 31, 699. [Google Scholar] [CrossRef]

- Sugiura, J.; Samuel, R.; Oppelt, J.; Ostermeyer, G.P.; Hedengren, J.; Pastusek, P. Drilling modeling and simulation: Current state and future goals. J. Pet. Technol. 2015, 67, 140–142. [Google Scholar] [CrossRef]

- Mohammed, A.; Mahmood, W.; Ghafor, K. TGA, rheological properties with maximum shear stress and compressive strength of cement-based grout modified with polycarboxylate polymers. Constr. Build. Mater. 2020, 235, 117534. [Google Scholar] [CrossRef]

- Bala, M.; Zentar, R.; Boustingorry, P. Comparative study of the yield stress determination of cement pastes by different methods. Mater Struct. 2019, 52, 102. [Google Scholar] [CrossRef]

- Vance, K.; Sant, G.; Neithalath, N. The rheology of cementitious suspensions: A closer look at experimental parameters and property determination using common rheological models. Cem. Concr. Compo. 2015, 59, 38–48. [Google Scholar] [CrossRef]

- Jiao, D.; Shi, C.; Yuan, Q.; Zhu, D.; De Schutter, G. Effects of rotational shearing on rheological behavior of fresh mortar with short glass fiber. Constr. Build. Mater. 2019, 203, 314–321. [Google Scholar] [CrossRef]

- Jiao, D.; Shi, C.; Yuan, Q. Time-dependent rheological behavior of cementitious paste under continuous shear mixing. Constr. Build. Mater. 2019, 226, 591–600. [Google Scholar] [CrossRef]

- Mostafa, A.M. Physical and Chemical Kinetics of Structural Build-Up of Cement Suspensions. Ph.D. Thesis, Université de Sherbrooke, Sherbrooke, QC, Canada, 2016. [Google Scholar]

- Zhang, K.; Pan, L.; Li, J.; Lin, C.; Cao, Y.; Xu, N.; Pang, S. How does adsorption behavior of polycarboxylate superplasticizer effect rheology and flowability of cement paste with polypropylene fiber? Cem. Concr. Compos. 2019, 95, 228–236. [Google Scholar] [CrossRef]

- Banfill, P.F.G.; Starrs, G.; Derruau, G.; McCarter, W.J.; Chrisp, T.M. Rheology of low carbon fibre contente reinforced cement mortar. Cem. Concr. Compos. 2006, 28, 773–780. [Google Scholar] [CrossRef]

- Tabatabaeian, M.; Khaloo, A.; Joshaghani, A.; Hajibandeh, E. Experimental investigation on effects of hybrid fibers on rheological, mechanical, and durability properties of high-strength SCC. Constr. Build. Mater. 2017, 147, 497–509. [Google Scholar] [CrossRef]

- Beigi, M.H.; Berenjian, J.; Omran, O.L.; Nik, A.S.; Nikbin, I.M. An experimental survey on combined effects of fibers and nanosilica on the mechanical, rheological, and durability properties of self-compacting concrete. Mater. Des. 2013, 50, 1019–1029. [Google Scholar] [CrossRef]

- Mezger, T.G. The Rheology Handbook: For Users of Rotational and Oscillatory Rheometers; Vincentz Network: Hannover, Germany, 2006; ISBN 978-3-87870-174-3. [Google Scholar]

- De Larrard, F.; Ferraris, C.; Sedran, T. Fresh concrete: A Herschel-Bulkley material. Mater. Struct. 1998, 31, 494–498. [Google Scholar] [CrossRef]

- Benyounes, K. Rheological behavior of cement-based grout with Algerian bentonite. SN App. Sci. 2019, 1, 1037. [Google Scholar] [CrossRef] [Green Version]

| Parameter | Value |

|---|---|

| Compression resistance at 28 days | 5.5 MPa |

| Setting time | Start: 2 h |

| end: 6 h | |

| Density | 2.73 g/cm3 |

| Specific surface area B.e.T. | 480 m2/kg |

| Al2O3 | 2.00% |

| CaO | 85.00% |

| Fe2O3 | 2.00% |

| MgO | 1.00% |

| MnO | 0.03% |

| SiO2 | 8.00% |

| SiC | 0.01% |

| SO3 | 1.00% |

| SrO | 0.05% |

| K2O | 0.70% |

| Notation | Water/Binder (-) | Superplasticizer (wt%) | PP Fiber (vol%) |

|---|---|---|---|

| Ref | 0.4 | 0.2 | 0 |

| 0.03% PP | 0.4 | 0.2 | 0.03 |

| 0.1% PP | 0.4 | 0.2 | 0.1 |

| Measurement Instant | Shear–Strain Rate Range of Transition Zone 1 |

|---|---|

| 10 min | 0.1–1.0 s−1 |

| 20 min | 1.0–3.0 s−1 |

| 30 min | 5.0–9.0 s−1 |

| 40 min | 8.0–12.0 s−1 |

| 50 min | 11.0–17.0 s−1 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Baltazar, L.G.; Henriques, F.M.A.; Cidade, M.T. Effects of Polypropylene Fibers and Measurement Methods on the Yield Stress of Grouts for the Consolidation of Heritage Masonry Walls. Fluids 2020, 5, 53. https://doi.org/10.3390/fluids5020053

Baltazar LG, Henriques FMA, Cidade MT. Effects of Polypropylene Fibers and Measurement Methods on the Yield Stress of Grouts for the Consolidation of Heritage Masonry Walls. Fluids. 2020; 5(2):53. https://doi.org/10.3390/fluids5020053

Chicago/Turabian StyleBaltazar, Luis G., Fernando M. A. Henriques, and Maria Teresa Cidade. 2020. "Effects of Polypropylene Fibers and Measurement Methods on the Yield Stress of Grouts for the Consolidation of Heritage Masonry Walls" Fluids 5, no. 2: 53. https://doi.org/10.3390/fluids5020053

APA StyleBaltazar, L. G., Henriques, F. M. A., & Cidade, M. T. (2020). Effects of Polypropylene Fibers and Measurement Methods on the Yield Stress of Grouts for the Consolidation of Heritage Masonry Walls. Fluids, 5(2), 53. https://doi.org/10.3390/fluids5020053