Effects of Diamond Nanoparticles Immobilisation on the Surface of Yeast Cells: A Phenomenological Study

Abstract

:1. Introduction

2. Materials and Methods

2.1. Nanoparticles and Their Functionalisation

2.2. Strains, Nutrient Medium and Culture Conditions

2.3. Preparation of Yeast Suspension and Immobilisation Procedure

2.4. Immobilisation Evaluation

2.5. Cell Viability Determination

2.6. Determinations of Lag Phase

2.7. Statistical Methods

3. Results and Discussion

3.1. ND Surface Characterisation and Charge Deposition

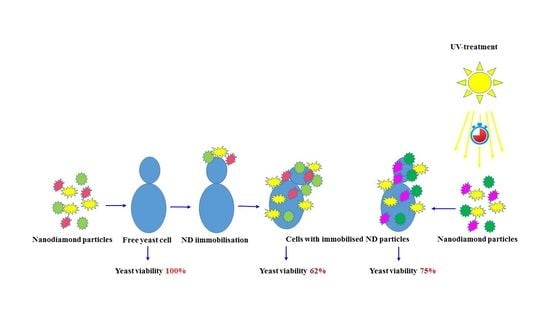

3.2. Viability of Yeast Cells with Immobilised Nanodiamond Particles

3.3. Growth of Yeast Cells with Immobilised Nanodiamond Particles

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kourkoutas, Y.; Bekatorou, A.; Banat, I.M.; Marchant, R.; Koutinas, A.A. Immobilization technologies and support materials suitable in alcohol beverages production: A review. Food Microbiol. 2004, 21, 377–397. [Google Scholar] [CrossRef]

- Peng, Q.; Liu, Y.; Zeng, G.; Xu, W.; Yang, C.; Zhang, J. Biosorption of copper (II) by immobilizing Saccharomyces cerevisiae on the surface of chitosan-coated magnetic nanoparticles from aqueous solution. J. Haz. Mat. 2010, 177, 676–682. [Google Scholar] [CrossRef]

- Rapoport, A.; Borovikova, D.; Kokina, A.; Patmalnieks, A.; Polyak, N.; Pavlovska, I.; Mezinskis, G.; Dekhtyar, Y. Immobilisation of yeast cells on the surface of hydroxyapatite ceramics. Proc. Biochem. 2011, 46, 665–670. [Google Scholar] [CrossRef]

- Borovikova, D.; Scherbaka, R.; Patmalnieks, A.; Rapoport, A. Effects of yeast immobilisation on bioethanol production. Biotechnol. Appl. Biochem. 2014, 61, 33–39. [Google Scholar] [CrossRef] [PubMed]

- Giese, E.C.; Silva, D.D.V.; Costa, A.F.M.; Almeida, S.G.C.; Dussán, K.J. Immobilized microbial nanoparticles for biosorption. Crit. Rev. Biotechnol. 2020, 40, 653–666. [Google Scholar] [CrossRef] [PubMed]

- Borovikova, D.; Rozenfelde, L.; Pavlovska, I.; Rapoport, A. Immobilisation increases yeast cells resistance to dehydration-rehydration treatment. J. Biotechnol. 2014, 184, 169–171. [Google Scholar] [CrossRef]

- Dotto, G.L.; Lima, E.C.; Pinto, L.A. Biosorption of food dyes onto Spirulina platensis nanoparticles: Equilibrium isotherm and thermodynamic analysis. Biores. Technol. 2012, 103, 123–130. [Google Scholar] [CrossRef]

- Azeez, R.A.; Al-Zuhairi, F.K.I. Biosorption of dye by immobilized yeast cells on the surface of magnetic nanoparticles. Alexandr. Engineer. J. 2022, 61, 5213–5222. [Google Scholar] [CrossRef]

- Li, X.; Ming, Q.Y.; Cai, R.; Yue, T.; Yuan, Y.; Gao, Z.; Wang, Z. Biosorption of Cd2+ and Pb2+ from apple juice by the magnetic nanoparticles functionalized lactic acid bacteria cells. Food Control. 2020, 109, 106916. [Google Scholar] [CrossRef]

- Khatoon, H.; Rai, J. Augmentation of atrazine biodegradation by two Bacilli immobilized on a-Fe2O3 magnetic nanoparticles. Sci. Rep. 2018, 8, 17831. [Google Scholar] [CrossRef] [Green Version]

- Taghizadeh, S.-M.; Ebrahiminezhad, A.; Ghoshoon, M.B.; Dehshahri, A.; Berenjian, A.; Ghasemi, Y. Magnetic immobilization of Pichia pastoris cells for the production of recombinant human serum albumin. Nanomaterials 2020, 10, 111. [Google Scholar] [CrossRef] [PubMed]

- Ebrahiminezhad, A.; Varma, V.; Yang, S.; Berenjian, A. Magnetic immobilization of Bacillus subtilis natto cells for menaquinone-7 fermentation. Appl. Microbiol. Biotechnol. 2016, 100, 173–180. [Google Scholar] [CrossRef] [PubMed]

- Ebrahiminezhad, A.; Varma, V.; Yang, S.; Ghasemi, Y.; Berenjian, A. Synthesis and application of amine functionalized iron oxide nanoparticles on menaquinone-7 fermentation: A step towards process intensification. Nanomaterials 2015, 6, 1. [Google Scholar] [CrossRef]

- Raee, M.J.; Ebrahiminezhad, A.; Gholami, A.; Ghoshoon, M.B.; Ghasemi, Y. Magnetic immobilization of recombinant E. coli producing extracellular asparaginase: An effective way to intensify downstream process. Sep. Sci. Technol. 2018, 53, 1397–1404. [Google Scholar] [CrossRef]

- Taghizadeh, S.-M.; Jafari, S.; Ahmad-Kiadaliri, T.; Mobasher, M.A.; Lal, N.; Raee, M.J.; Berenjian, A.; Ghasemi, Y.; Ebrahiminezhad, A. Magnetic immobilisation as a promising approach against bacteriophage infection. Mater. Res. Express 2020, 6, 1250a8. [Google Scholar] [CrossRef]

- Gupta, C.; Prakash, D.; Gupta, S. Cancer treatment with nano-diamonds. Front. Biosci.-Schol. 2017, 9, 62–70. [Google Scholar] [CrossRef]

- Wang, M.; Thanou, M. Targeting nanoparticles to cancer. Pharmacol. Res. 2010, 62, 90–99. [Google Scholar] [CrossRef]

- Li, C. A targeted approach to cancer imaging and therapy. Nat. Mater. 2014, 13, 110–115. [Google Scholar] [CrossRef]

- Getts, D.R.; Terry, R.L.; Getts, M.T.; Deffrasnes, C.; Müller, M.; van Vreden, C.; Ashhurst, T.M.; Chami, B.; McCarthy, D.; Wu, H.; et al. Therapeutic inflammatory monocyte modulation using immune-modifying microparticles. Sci. Transl. Med. 2014, 6, 219ra7. [Google Scholar] [CrossRef]

- Gupta, A.S. Nanomedicine approaches in vascular disease: A review. Nanomed. Nanotechnol. Biol. Med. 2011, 7, 763–779. [Google Scholar] [CrossRef]

- Beranova, J.; Seydlova, G.; Kozak, H.; Benada, O.; Fiser, R.; Artemenko, A.; Konopasek, I.; Kromka, A. Sensitivity of bacteria to diamond nanoparticles of various size differs in gram-positive and gram-negative cells. FEMS Microbiol. Lett. 2014, 351, 179–186. [Google Scholar] [CrossRef] [PubMed]

- Hemelaar, S.R.; van der Laan, K.J.; Hinterding, S.R.; Koot, M.V.; Ellermann, E.; Perona-Martinez, F.P.; Roig, D.; Hommelet, S.; Novarina, D.; Takahashi, H.; et al. Generally applicable transformation protocols for fluorescent nanodiamond internalization into cells. Sci. Rep. 2017, 7, 5862. [Google Scholar] [CrossRef] [PubMed]

- Morita, A.; Hamoh, T.; Sigaeva, A.; Norouzi, N.; Nagl, M.A.; van der Laan, K.J.; Evans, E.P.P.; Schirhagl, R. Targeting nanodiamonds to the nucleus in yeast cells. Nanomaterials 2020, 10, 1962. [Google Scholar] [CrossRef]

- Baltacis, K.; Bystrov, V.; Bystrova, A.; Dekhtyar, Y.; Freivalds, T.; Raines, J.; Rozenberga, K.; Sorokins, H.; Zeidaks, M. Physical Fundamentals of Biomaterials Surface Electrical Functionalization. Materials 2020, 13, 4575. [Google Scholar] [CrossRef] [PubMed]

- Liang, X.; Jacobs, R.; Martens, W.; Hu, Y.; Adriaensens, P.; Quirynen, M.; Lambrichts, I. Macro- and micro-anatomical, histological and computed tomography scan characterization of the nasopalatine canal. J Clin. Periodontol. 2009, 36, 598–603. [Google Scholar] [CrossRef]

- Poonthiyil, V.; Lindhorst, T.K.; Golovko, V.B.; Fairbanks, A.J. Recent applications of click chemistry for the functionalization of gold nanoparticles and their conversion to glyco-gold nanoparticles. Beilstein. J. Org. Chem. 2018, 3, 11–24. [Google Scholar] [CrossRef] [PubMed]

- Thess, A.; Lee, R.; Nikolaev, P.; Dai, H.; Petit, P.; Robert, J.; Xu, C.; Lee, Y.H.; Kim, S.G.; Rinzler, A.G.; et al. Crystalline Ropes of Metallic Carbon Nanotubes. Science 1996, 26, 483–487. [Google Scholar] [CrossRef] [PubMed]

- Rapoport, A.I.; Meysel, M.N. Survival rates of yeast organisms after dehydration as determined by fluorescence microscopy. Microbiology 1985, 54, 53–55. [Google Scholar]

- Chemistry LibreTexts. Available online: https://chem.libretexts.org/Bookshelves/Physical_and_Theoretical_Chemistry_Textbook_Maps/Supplemental_Modules_(Physical_and_Theoretical_Chemistry)/Physical_Properties_of_Matter/Atomic_and_Molecular_Properties/Dipole_Moments (accessed on 5 December 2022).

- Lazzeretti, P.; Zanasi, R. On the CH bond dipole moment in alkanes. J. Chem. Phys. 1987, 87, 1681. [Google Scholar] [CrossRef]

- Hamill, P.G.; Stevenson, A.; McMullan, P.E.; Williams, J.P.; Lewis, A.D.R.; Sudharsan, S.; Stevenson, K.E.; Farnsworth, K.D.; Khroustalyova, G.; Takemoto, J.Y.; et al. Microbial lag phase can be indicative of, or independent from, cellular stress. Sci. Rep. 2020, 10, 5948. [Google Scholar] [CrossRef]

- Schrand, A.M.; Ciftan Hens, S.A.; Shenderova, O.A. Nanodiamond particles: Properties and perspectives for bioapplications. Crit. Rev. Solid State Mater. Sci. 2009, 34, 18–74. [Google Scholar] [CrossRef]

- Garifo, S.; Stanicki, D.; Ayata, G.; Muller, R.N.; Laurent, S. Nanodiamonds as nanomaterial for biomedical field. Front. Mater. Sci. 2021, 15, 334–351. [Google Scholar] [CrossRef]

- Lai, H.; Stenzel, M.H.; Xiao, P. Surface engineering and applications of nanodiamonds in cancer treatment and imaging. Int. Mater. Rev. 2020, 65, 189–225. [Google Scholar] [CrossRef]

- Yadav, A.K.; Shukla, R.; Flora, S.J.S. Nanodiamonds: A Versatile Drug-Delivery System in the Recent Therapeutics Scenario. Critic. Rev. Therap. Drug Carrier Syst. 2021, 38, 39–78. [Google Scholar] [CrossRef]

- Bilal, M.; Cheng, H.; Gonzalez-Gonzalez, R.B.; Parra-Saldıvar, R.; Iqbal, H.M.N. Bio-applications and biotechnological applications of nanodiamonds. J. Mater. Res. Technol. 2021, 15, 6175–6189. [Google Scholar] [CrossRef]

- Oberdörster, G.; Oberdörster, E.; Oberdörster, J. Nanotoxicology: An emerging discipline evolving from studies of ultrafine particles. Environ. Health Perspect. 2005, 113, 823–839. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dekhtyar, Y.; Abols, D.; Avotina, L.; Stoppel, A.; Balakin, S.; Khroustalyova, G.; Opitz, J.; Sorokins, H.; Beshchasna, N.; Tamane, P.; et al. Effects of Diamond Nanoparticles Immobilisation on the Surface of Yeast Cells: A Phenomenological Study. Fermentation 2023, 9, 162. https://doi.org/10.3390/fermentation9020162

Dekhtyar Y, Abols D, Avotina L, Stoppel A, Balakin S, Khroustalyova G, Opitz J, Sorokins H, Beshchasna N, Tamane P, et al. Effects of Diamond Nanoparticles Immobilisation on the Surface of Yeast Cells: A Phenomenological Study. Fermentation. 2023; 9(2):162. https://doi.org/10.3390/fermentation9020162

Chicago/Turabian StyleDekhtyar, Yuri, Dagnis Abols, Liga Avotina, Anita Stoppel, Sascha Balakin, Galina Khroustalyova, Joerg Opitz, Hermanis Sorokins, Natalia Beshchasna, Patricija Tamane, and et al. 2023. "Effects of Diamond Nanoparticles Immobilisation on the Surface of Yeast Cells: A Phenomenological Study" Fermentation 9, no. 2: 162. https://doi.org/10.3390/fermentation9020162

APA StyleDekhtyar, Y., Abols, D., Avotina, L., Stoppel, A., Balakin, S., Khroustalyova, G., Opitz, J., Sorokins, H., Beshchasna, N., Tamane, P., & Rapoport, A. (2023). Effects of Diamond Nanoparticles Immobilisation on the Surface of Yeast Cells: A Phenomenological Study. Fermentation, 9(2), 162. https://doi.org/10.3390/fermentation9020162