Instrumented Health Monitoring of an Earth Dam

Abstract

:1. Introduction

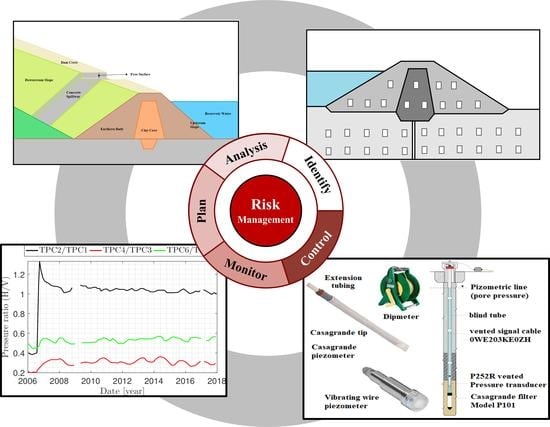

- Identify: Establish the risk components.

- Analysis: Evaluate the likelihood of each risk element, and the associated consequences.

- Plan: Determine the general strategies to minimize the risk likelihood.

- Monitor: Continuously measure and update all variables that may indicate risk.

- Control: Take various risk reduction actions.

2. Literature Review

3. Materials and Methods

3.1. Type of Instruments

- Mechanical instruments: The main system of these instruments measures the quantity of interest directly and converts the measurement into a target parameter [39]. Their installation is easy, and in the case of failure, they can be easily replaced. Moreover, they are relatively cheap, and can be easily manufactured in a large amount. However, their application is limited in some conditions, and they may fail to properly meet the required measurement accuracy.

- Electrical instruments: They initially developed to cover the shortcomings of the mechanical instruments. Their measurement factor is mainly vibrational. Electrical instruments measure the quantity indirectly, and their reading results should be converted to the parameters via some formulas [40].

- Stress measurements, e.g., Carlson soil stress meters and flat jacks.

- Pore pressure measurement, e.g., open standpipe piezometers and Casagrande piezometers.

- Flow measurement, e.g., weirs and impeller flow transducers.

- Temperature measurement, e.g., thermocouples and thermistors.

- Strong motion measurements.

3.2. Reading, Recording, and Processing the Data

4. Case Study Dam

4.1. Boostan Dam Characteristics

4.2. Instruments in Boostan Dam

- Piezometers: Variation of pore water pressure is very important parameter in dam health monitoring. An increase in pore water pressure decreases the (effective) shear stresses (and thus treats the dam stability). The pore pressure leakage during the dam construction are affected by the leakage force from the water flow into the dam. The required time for downstream soil satiation and creation of a stable leakage has a direct relation to the soil type and the water regime behind the dam. In the Boostan Dam, a homogeneous earth dam, the drainage blanket is very effective, and can make the current lines vertical. Moreover, the presence of the drainage blanket reduces the pore water pressure to a great extent.

- Casagrande Piezometer: This is an effective and economical tool to measure the water pressure. It involves a plastic porous pipe at the bottom of the bore and a PVC pipe to record the water level. When the probe is entered into the pipe, upon its contact with water level, a continuous vocal signal is produced. The upstream level of the piezometer pipes in elongation is determined through survey operations, based on which the level and water height (total head) calculations are performed. Total head (or piezometeric level) is a summation of the installed piezometer level, z, and , where U refers to pore pressure. Figure 4a shows a sample of installed Casagrande piezometer. Table 2 shows the instrument specifications and their locations corresponding to Figure 3.

- Vibrating Wire Piezometer: The vibrational piezometers are reliable and stable instruments to measure the pore water pressure. The output of the piezometer includes a signal that is independent from impedance and the contact resistance, and can transmit the signal to a long distance. The sensor includes a porous tip piece often made of ceramic materials and a diaphragm. This diaphragm at its bottom is attached to a prestressed piece. When the pore pressure changes, the diaphragm moves, and alters the tension in the attached warp. The frequency of the normal vibration wire is a function of the imposed stress. Sample of the installed wire piezometer is shown in Figure 4b. Table 3 shows the instrument specifications and their locations corresponding to Figure 3.

- Total Pressure Cell: The effective soil pressure as well as the water pressure can be measured by total pressure cells. The instrument includes a flat cell filled with oil. The pressure imposed on the cell is imposed on the oil and is transformed into some signals by a transducer. They are connected to a digital reading device via some cables. This device measures the pressure imposed on the cell, see Figure 4c. A total of six pressure cells have been installed in Boostan Dam. Table 4 shows the instrument specifications and their locations. the location of TPC-2 can be found in Figure 3 at the lower discharge place.

5. Results and Observations

5.1. Performance of the Casagrande Piezometers

5.2. Performance of the Vibration Wire Piezometers

5.3. Hysteresis Curve of the Foundation Piezometers

5.4. Excess Pore Pressure Ratio

- If : Dam conditions are safe and favorable

- If : There is a potential risk. The considered section should be continuously evaluated for updated results.

- If : Dam is in a critical condition. As the pore pressure is high, the water tends to exit the soil. This may eventually lead to dam failure.

- If (i.e., ): A hydraulic failure occurs in the dam.

5.5. Performance of the Total Pressure Cells

6. Summary

Author Contributions

Funding

Conflicts of Interest

References

- USACE. EM 1110-2-1908: Instrumentation of Embankment Dams and Levees; Technical Report; USACE: Washington, DC, USA, 1995. [Google Scholar]

- Ballard, R.F. The US Army Corps of engineers seismic strong-motion instrumentation program. In Strong Motion Instrumentation for Civil Engineering Structures; Springer: Berlin/Heidelberg, Germany, 2001; pp. 157–166. [Google Scholar]

- Taylor, P.W. Engineering and Design: Instrumentation for Safety Evaluations of Civil Works Projects; Technical Report; USACE: Washington, DC, USA, 1985. [Google Scholar]

- On Dams, U.S.S. Routine Instrumented and Visual Monitoring of Dams Based on Potential Failure Modes Analysis; Technical Report; U.S. Society on Dams: Denver, CO, USA, 2013. [Google Scholar]

- Dunnicliff, J. Geotechnical Instrumentation for Monitoring Field Performance; John Wiley & Sons: Hoboken, NJ, USA, 1993; pp. 97–108. [Google Scholar]

- Robertson, K. An Instrument to Monitor the Tilt of Large Structures; Technical Report; Army Engineer Topographic Labs: Fort Belvoir, VA, USA, 1983. [Google Scholar]

- US Department of the Interior, Bureau of Reclamation. Design Standards No. 13: Embankment Dams; Technical Report; US Department of the Interior, Bureau of Reclamation: Denver, CO, USA, 2014.

- Lindsey, J.; Edwards, D.; Keeter, A.; Payne, T.; Malloy, R. Instrumentation Automation for Concrete Structures; Report 1: Instrumentation Automation Techniques; Technical Report; Wyle Labs: Hampton, VA, USA, 1986. [Google Scholar]

- Currier, B.; Fenn, M.H. Repair, Evaluation, Maintenance, and Rehabilitation Research Program. Instrumentation Automation for Concrete Structures. Report. 3. Available Data Collection and Reduction Software; Technical Report; Wyle Labs: Hampton, VA, USA, 1987. [Google Scholar]

- O’Neil, E.F. IInstrumentation Automation for Concrete Structures. Report 4. Demonstration of Instrumentation Automation Techniques at Beaver Dam, Eureka Springs, Arkansas; Technical Report; Army Engineer Waterways Experiment Station Vicksburg Ms Structures Lab: Vicksburg, MS, USA, 1989. [Google Scholar]

- Bartholomew, C.L.; Murray, B.C. Embankment Dam Instrumentation Manual; US Department of the Interior, Bureau of Reclamation: Denver, CO, USA, 1987; pp. 71–83.

- ASCE Task Committee on Instrumentation and Monitoring Dam Performance. Guidelines for Instrumentation and Measurements for Monitoring Dam Performance; American Society of Civil Engineers: Reston, VA, USA, 2000. [Google Scholar]

- Li, X.; Li, Y.; Lu, X.; Wang, Y.; Zhang, H.; Zhang, P. An online anomaly recognition and early warning model for dam safety monitoring data. Struct. Health Monit. 2019, 1, 145–166. [Google Scholar] [CrossRef]

- Hariri-Ardebili, M.A. Risk, Reliability, Resilience (R3) and beyond in dam engineering: A state-of-the-art review. Int. J. Disaster Risk Reduct. 2018, 31, 806–831. [Google Scholar] [CrossRef]

- Ecorys, O. The Role of Market-Based Instruments in Achieving a Resource Efficient Economy. In Report for the European Commission, DG Environment; Ecorys, Cambridge Econometrics and COWI: Rotterdam, The Netherlands, 2011. [Google Scholar]

- Farias, M.M.d.; Cordão Neto, M.P. Advanced numerical simulation of collapsible earth dams. Can. Geotech. J. 2010, 47, 1351–1364. [Google Scholar] [CrossRef]

- Seyed-Kolbadi, S.; Sadoghi-Yazdi, J.; Hariri-Ardebili, M. An Improved Strength Reduction-Based Slope Stability Analysis. Geosciences 2019, 9, 55. [Google Scholar] [CrossRef] [Green Version]

- Guo, X.; Dias, D.; Pan, Q. Probabilistic stability analysis of an embankment dam considering soil spatial variability. Comput. Geotech. 2019, 113, 93–103. [Google Scholar] [CrossRef]

- Matsushima, K.; Mohri, Y.; Yamazaki, S.; Hori, T.; Ariyoshi, M.; Tatsuoka, F. Design of earth dams allowing temporary overtopping based on hydraulic failure experiments and flood analysis. In Geosynthetics in Civil and Environmental Engineering; Springer: Berlin/Heidelberg, Germany, 2008; Volume 1, pp. 757–762. [Google Scholar]

- Sui, W.; Zheng, G. An experimental investigation on slope stability under drawdown conditions using transparent soils. Bull. Eng. Geol. Environ. 2018, 77, 977–985. [Google Scholar] [CrossRef]

- Piqueras, J.M.; Pérez, E.S.; Menéndez-Pidal, I. Water seepage beneath dams on soluble evaporite deposits: A laboratory and field study (Caspe Dam, Spain). Bull. Eng. Geol. Environ. 2012, 71, 201–213. [Google Scholar] [CrossRef] [Green Version]

- Frémion, F.; Bordas, F.; Mourier, B.; Lenain, J.F.; Kestens, T.; Courtin-Nomade, A. Influence of dams on sediment continuity: A study case of a natural metallic contamination. Sci. Total. Environ. 2016, 547, 282–294. [Google Scholar] [CrossRef]

- Mizuno, M.; Hirose, T. Instrumentation and monitoring of dams and reservoirs. Water Storage Transp. Distrib. 2009, 1, 1–8. [Google Scholar]

- Charles, J.; Tedd, P.; Watts, K. The role of instrumentation and monitoring in safety procedures for embankment dams. Water Resour. Reserv. Eng. 1992, 1, 311–320. [Google Scholar]

- Majoros, M.; Sneed, H.M. The softest program test system. J. Syst. Softw. 1981, 2, 289–296. [Google Scholar] [CrossRef]

- Jansen, R.B. Advanced Dam Engineering for Design, Construction, and Rehabilitation; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Gikas, V.; Sakellariou, M. Settlement analysis of the Mornos earth dam (Greece): Evidence from numerical modeling and geodetic monitoring. Eng. Struct. 2008, 30, 3074–3081. [Google Scholar] [CrossRef]

- Zhu, P.; Leng, Y.; Zhou, Y.; Jiang, G. Safety inspection strategy for earth embankment dams using fully distributed sensing. Procedia Eng. 2011, 8, 520–526. [Google Scholar] [CrossRef] [Green Version]

- Masoumi, I.; Ahangari, K.; Noorzad, A. Integrated fuzzy decision approach for reliability improvement of dam instrumentation and monitoring. J. Struct. Integr. Maint. 2018, 3, 114–125. [Google Scholar] [CrossRef]

- Chugh, A.K. Stability assessment of a circular earth dam. Int. J. Numer. Anal. Methods Geomech. 2013, 37, 2833–2859. [Google Scholar] [CrossRef]

- ICOLD. Deterioration of Dams and Reservoirs; Laboratorio Nationai de Engenharia Civil, LNEC: Lisboa, Portugal, 1983; pp. 1–312. [Google Scholar]

- Shi, Z.M.; Wang, Y.Q.; Peng, M.; Chen, J.F.; Yuan, J. Characteristics of the landslide dams induced by the 2008 Wenchuan earthquake and dynamic behavior analysis using large-scale shaking table tests. Eng. Geol. 2015, 194, 25–37. [Google Scholar] [CrossRef]

- Rashidi, M.; Haeri, S.M. Evaluation of behaviors of earth and rockfill dams during construction and initial impounding using instrumentation data and numerical modeling. J. Rock Mech. Geotech. Eng. 2017, 9, 709–725. [Google Scholar] [CrossRef]

- Hui, S.; Charlebois, L.; Sun, C. Real-time monitoring for structural health, public safety, and risk management of mine tailings dams. Can. J. Earth Sci. 2018, 55, 221–229. [Google Scholar] [CrossRef] [Green Version]

- Masoumi, I.; Ahangari, K.; Noorzad, A. Optimal monitoring instruments selection using innovative decision support system framework. Smart Struct. Syst. 2018, 21, 123–137. [Google Scholar]

- Masoumi, I.; Naraghi, S.; Rashidi-nejad, F.; Masoumi, S. Application of fuzzy multi-attribute decision-making to select and to rank the post-mining land-use. Environ. Earth Sci. 2014, 72, 221–231. [Google Scholar] [CrossRef]

- Meixner, O. Fuzzy AHP group decision analysis and its application for the evaluation of energy sources. In Proceedings of the 10th International Symposium on the Analytic Hierarchy/Network Process, Pittsburgh, PA, USA, 29 July–1 August 2009; Volume 29, pp. 2–16. [Google Scholar]

- Wieland, M.; Kirchen, G. Long-term dam safety monitoring of Punt dal Gall arch dam in Switzerland. Front. Struct. Civ. Eng. 2012, 6, 76–83. [Google Scholar] [CrossRef]

- Li, F.; Wang, Z.; Liu, G.; Fu, C.; Wang, J. Hydrostatic seasonal state model for monitoring data analysis of concrete dams. Struct. Infrastruct. Eng. 2015, 11, 1616–1631. [Google Scholar] [CrossRef]

- Machan, G.; Bennett, V.G. Use of inclinometers for geotechnical instrumentation on transportation projects: State of the practice. Transp. Res. Circ. 2008, 1, 1–92. [Google Scholar]

- Zhao, J.; Jin, J.; Zhu, J.; Xu, J.; Hang, Q.; Chen, Y.; Han, D. Water resources risk assessment model based on the subjective and objective combination weighting methods. Water Resour. Manag. 2016, 30, 3027–3042. [Google Scholar] [CrossRef]

| Body Specification | Reservoir Specification | Design Specification | |||

|---|---|---|---|---|---|

| Dam type | Homogeneous Earthen | Reservoir volume | 5 Mm | PGA | 0.15 g |

| Dam height | 35 m | Flood control volume | 18 Mm | Spillway capacity | 785 m/s |

| Dam length | 642 m | Normal level area | 4.1 km | Spillway type | Ogee |

| Foundation width | 265 m | Normal level high | 96 m | Spillway length | 40 m |

| Crest width | 10 m | Agriculture water volume | 28 Mm | Flood design | PMF |

| Name | Distance from Axis | Elevation | Location | Situation |

|---|---|---|---|---|

| SP-5 | 45.00 | 96.5 | Upstream | Foundation |

| SP-8 | 7.75 | 50.0 | Upstream | Foundation |

| Sp-10 | 33.00 | 61.0 | Downstream | Foundation |

| SP-12 | 113.25 | 68.0 | Downstream | Foundation |

| Name | Distance from Axis | Elevation | Location | Situation |

|---|---|---|---|---|

| EPF-1 | 65.00 | 60 | Upstream | Foundation |

| EPF-2 | 65.00 | 85 | Upstream | Dam Body |

| EPF-3 | 30.00 | 85 | Upstream | Dam Body |

| EPF-4 | 3.85 | 60 | Upstream | Foundation |

| EPF-5 | 3.85 | 60 | Downstream | Foundation |

| EPF-6 | 0.00 | 72 | Axis | Foundation |

| Name | Elevation | Direction | Location | Section |

|---|---|---|---|---|

| TPC-1 | 78.6 | Vertical | Lower Discharge | # 1 |

| TPC-2 | 77.6 | Horizontal | Lower Discharge | # 2 |

| TPC-3 | 77.1 | Vertical | Lower Discharge | # 3 |

| TPC-4 | 76.8 | Horizontal | Lower Discharge | # 4 |

| TPC-5 | 77.0 | Vertical | Lower Discharge | # 5 |

| TPC-6 | 75.9 | Horizontal | Lower Discharge | # 6 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Seyed-Kolbadi, S.M.; Hariri-Ardebili, M.A.; Mirtaheri, M.; Pourkamali-Anaraki, F. Instrumented Health Monitoring of an Earth Dam. Infrastructures 2020, 5, 26. https://doi.org/10.3390/infrastructures5030026

Seyed-Kolbadi SM, Hariri-Ardebili MA, Mirtaheri M, Pourkamali-Anaraki F. Instrumented Health Monitoring of an Earth Dam. Infrastructures. 2020; 5(3):26. https://doi.org/10.3390/infrastructures5030026

Chicago/Turabian StyleSeyed-Kolbadi, S.M., M.A. Hariri-Ardebili, M. Mirtaheri, and F. Pourkamali-Anaraki. 2020. "Instrumented Health Monitoring of an Earth Dam" Infrastructures 5, no. 3: 26. https://doi.org/10.3390/infrastructures5030026

APA StyleSeyed-Kolbadi, S. M., Hariri-Ardebili, M. A., Mirtaheri, M., & Pourkamali-Anaraki, F. (2020). Instrumented Health Monitoring of an Earth Dam. Infrastructures, 5(3), 26. https://doi.org/10.3390/infrastructures5030026