A Dissipating Frames for Seismic Retrofitting and Building Energy-Efficiency

Abstract

:1. Introduction

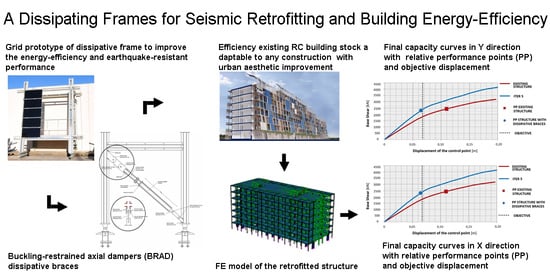

2. New Retrofitting Frame System

- -

- an inner metallic core, a part of which is designed to dissipate energy in the plastic field;

- -

- a steel tube that encloses it; and

- -

- a filling in cement mortar, whose purpose is to prevent the inner core becomes unstable.

- -

- the energy dissipation is located in a device that can be used as “fuse”, as it is easily replaceable, maintaining the main structure in the elastic field and therefore free from damage; and

- -

- the yield of BRAD devices does not affect the resistance to vertical loads of the structural system.

3. Energy and Seismic Retrofitting Building

3.1. Case-Study Description

3.2. Energy Refurbishment of Existing Building: Case-Study Analysis

- (I)

- external insulation (0.09 m of polystyrene),

- (II)

- external insulation and replacement of the obsolete gas boilers (η100% = 88.2%) with high-efficient gas boilers (η100% = 98%), and

- (III)

- external insulation, a geothermal heat pump and electrical boilers for hot water production.

3.3. Seismic Retrofitting System Design

4. Analysis Results

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| BRAD | Buckling-Restrained Axial Dampers |

| DB | Design Builder |

| FE | Finite Element |

| PRC | Popular Residential Construction |

| PP | Performance Point |

| PV | Photovoltaic |

| RC | Reinforced Concrete |

References

- European Standards (EN). Eurocode 2: Design of Concrete Structures EN1992-1-1. Available online: https://www.phd.eng.br/wp-content/uploads/2015/12/en.1992.1.1.2004.pdf (accessed on 30 June 2020).

- Directive 2010/31/EU of the European Parliament and of the Council of 19 May 2010 on the Energy Performance of Buildings. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32010L0031&from=en (accessed on 30 June 2020).

- Building Directive 2002/91/EC of the European Parliament and of the Council of 16 December 2002 on the Energy Performance of Buildings C. Available online: https://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=OJ:L:2003:001:0065:0071:EN:PDF (accessed on 30 June 2020).

- La Greca, P.; Margani, G. Seismic and Energy Renovation Measures for Sustainable Cities: A Critical Analysis of the Italian Scenario. Sustainability 2018, 10, 254. [Google Scholar] [CrossRef] [Green Version]

- Mangold, M.; Österbring, M.; Wallbaum, H.; Thuvander, L.; Femenias, P. Socio-economic impact of renovation and energy retrofitting of the Gothenburg building stock. Energy Build. 2016, 123, 41–49. [Google Scholar] [CrossRef] [Green Version]

- Italian Law n. 64/1974. Provvedimenti per le Costruzioni con Particolari Prescrizioni per le Zone Sismiche; Gazzetta Ufficiale della Repubblica Italiana: Rome, Italy, 1974. n. 76 del 2.2.1974. Available online: http://people.dicea.unifi.it/gianni.bartoli/normative/L_02.02.74_n.64.pdf (accessed on 30 June 2020). (In Italian).

- Italian Ministry of Public Works MIT: Ministry Decree D.M. 17th January 2018. Technical Regulations for Constructions Italian Lawor Aggiornamento Delle « Norme Tecniche per le Costruzioni ». Supplemento ordinario n. 8 alla Gazzetta Ufficiale della Repubblica Italiana n. 42 of 20-2-2018; Rome, Italy. Available online: https://www.gazzettaufficiale.it/eli/id/2018/2/20/18A00716/sg (accessed on 30 June 2020). (In Italian).

- Italian Ministry of Public Works: Circolare n.7 21st January 2019. Commentary on Technical Regulations for Constructionsor Istruzioni per L’applicazione Dell’«Aggiornamento Delle “Norme Tecniche per le Costruzioni» di cui al Decreto Ministeriale 17 Gennaio 2018”. Gazzetta Ufficiale n. 35 of 11-02-2019; Rome, Italy. Available online: https://www.gazzettaufficiale.it/eli/id/2019/02/11/19A00855/sg (accessed on 30 June 2020). (In Italian).

- Ordoñez, D.; Foti, D.; Bozzo, L.M. Comparative Study of the Inelastic Structural Response of Base Isolated Buildings. Earthq. Eng. Struct. Dyn. 1998, 32, 151–164. [Google Scholar] [CrossRef]

- Foti, D.; Catalan Goni, A.; Vacca, S. On the dynamic response of rolling base isolation systems. Struct. Control Health Monit. 2013, 20, 639–648. [Google Scholar] [CrossRef]

- Menga, N.; Foti, D.; Carbone, G. Viscoelastic frictional properties of rubber-layer roller bearings (RLRB) seismic isolators. Meccanica 2017, 52, 2807–2817. [Google Scholar] [CrossRef]

- Shahabi, A.; Zamani Ahari, G.; Barghian, M. Base Isolation Systems–A State of the Art Review According to Their Mechanism. J. Rehabil. Civ. Eng. 2020, 8, 37–61. [Google Scholar] [CrossRef]

- Harvey, P.S., Jr.; Kelly, K.C. A review of rolling-type seismic isolation: Historical development and future directions. Eng. Struct. 2016, 125, 521–531. [Google Scholar] [CrossRef]

- Quaglini, V.; Gandelli, E.; Dubini, P. Experimental investigation of the re-centring capability of curved surface sliders. Struct. Control Health Monit. 2017, 24, e1870. [Google Scholar] [CrossRef]

- Sorace, S.; Terenzi, G. Seismic performance assessment and base isolated floor-protection of statues exhibited in museum halls. Bull. Earthq. Eng. 2015, 13, 1873–1892. [Google Scholar] [CrossRef]

- Foti, D.; Diaferio, M.; Nobile, R. Optimal Design of a New Seismic Passive Protection Device Made in Aluminium and Steel. Int. J. Struct. Eng. Mech. 2010, 35, 119–122. [Google Scholar] [CrossRef]

- Foti, D.; Diaferio, M.; Nobile, R. Dynamic Behavior of New Aluminum-Steel Energy Dissipating Devices. Struct. Cont. Health Monit. 2013, 20, 1106–1119. [Google Scholar] [CrossRef]

- Nuzzo, I.; Losanno, D.; Caterino, N.; Serino, G.; Rotondo, L.M.B. Experimental and analytical characterization of steel shear links for seismic energy dissipation. Eng. Struct. 2018, 172, 405–418. [Google Scholar] [CrossRef]

- Wang, C.L.; Liu, Y.; Zhou, L. Experimental and numerical studies on hysteretic behavior of all-steel bamboo-shaped energy dissipaters. Eng. Struct. 2018, 165, 38–49. [Google Scholar] [CrossRef]

- Ponzo, F.C.; Di Cesare, A.; Lamarucciola, N.; Nigro, D. Testing requirements of hysteretic energy dissipating devices according to italian seismic code. In Proceedings of the COMPDYN 2019, 7th ECCOMAS Thematic Conference on Computational Methods in Structural Dynamics and Earthquake, Crete, Greece, 24–26 June 2019. [Google Scholar]

- Palermo, M.; Silvestri, S.; Gasparini, G.; Trombetti, T. Crescent shaped braces for the seismic design of building structures. Mater. Struct. 2015, 48, 1485–1502. [Google Scholar] [CrossRef]

- López-Almansa, F.; Castro-Medin, J.C.; Oller, S. A numerical model of the structural behavior of buckling-restrained braces. Eng. Struct. 2012, 41, 108–117. [Google Scholar] [CrossRef] [Green Version]

- Qu, B.; Liu, X.; Hou, H.; Qiu, C.; Hu, D. Testing of buckling-restrained braces with replaceable steel angle fuses. J. Struct. Eng. 2018, 144, 04018001. [Google Scholar] [CrossRef] [Green Version]

- Lin, P.-C.; Tsai, K.-C.; Chang, C.-A.; Hsiao, Y.-Y.; Wu, A.-C. Seismic design and testing of buckling-restrained braces with a thin profile. Earthq. Eng. Struct. Dyn. 2016, 45, 339–358. [Google Scholar] [CrossRef]

- Symans, M.D.; Charney, F.A.; Whittaker, A.S.; Constantinou, M.C.; Kircher, C.A.; Johnson, M.W.; McNamara, R.J. Energy dissipation systems for seismic applications: Current practice and recent developments. J. Struct. Eng. 2008, 134, 3–21. [Google Scholar] [CrossRef] [Green Version]

- Kim, J.; Choi, H.; Min, K.-W. Performance-based design of added viscous dampers using capacity spectrum method. J. Earthq. Eng. 2003, 7, 1–24. [Google Scholar] [CrossRef]

- Hong-Nan, L.; Gang, L. Experimental study of structure with “dual function” metallic dampers. Eng. Struct. 2007, 29, 1917–1928. [Google Scholar]

- Tirca, D.; Foti, D.; Diaferio, M. Response of middle-rise steel frames with and without passive dampers to near-field ground motions. Eng. Struct. 2003, 25, 169–179. [Google Scholar] [CrossRef]

- Chung-Che, C.; Yu-Jen, L. Post-tensioned self-centering moment connections with beam bottom flange energy dissipators. J. Construct. Steel Res. 2009, 65, 1931–1941. [Google Scholar]

- Foti, D.; Bozzo, L.M.; Lopez-Almansa, F. Numerical Efficiency Assessment of Energy Dissipators for Seismic Protection of Buildings. Earthq. Eng. Struct. Dyn. 1998, 27, 543–556. [Google Scholar] [CrossRef]

- Altieri, D.; Tubaldi, E.; Pratelli, E.; Dall’Asta, A. Assessment of optimal design methods of viscous dampers. Procedia Eng. 2017, 199, 1152–1157. [Google Scholar] [CrossRef] [Green Version]

- Lavan, O.; Dargush, G.F. Multi-objectve evolutionary seismic design with passive energy dissipation systems. J. Earthq. Eng. 2009, 13, 758–790. [Google Scholar] [CrossRef]

- Roia, D.; Gara, F.; Balducci, A.; Dezi, L. Dynamic tests on an existing r.c. school building retrofitted with “dissipative towers”. In Proceedings of the 11th International Conference on Vibration Problems, Lisbon, Portugal, 9–12 September 2013; pp. 9–12. [Google Scholar]

- Feroldi, F.; Marini, A.; Badiani, B.; Plizzari, G.A.; Giuriani, E.; Riva, P.; Belleri, A. Energy efficiency upgrading, architectural restyling and structural retrofit of modern buildings by means of “engineered” double skin façade. In Proceedings of the 2nd International Conference on Structures & Architecture (ICSA2013), Guimarães, Portugal, 24–26 July 2013; pp. 1859–1866. [Google Scholar]

- Feroldi, F.; Marini, A.; Belleri, A.; Passoni, C.; Riva, P.; Preti, M.; Giuriani, E.; Plizzari, G. Miglioramento e adeguamento sismico di edifici contemporanei mediante approccio integrato energetico, architettonico e strutturale con soluzioni a doppio involucro a minimo impatto ambientale/Sustainable seismic retrofit of modern RC buildings through an integrated struc-tural, energetic and architectural approach adopting external engineered double skin façades. Progett. Sismica 2014, 5, 2. [Google Scholar]

- Di Sarno, L.; Manfredi, G. Seismic retrofitting of existing RC frames with buckling restrained braces. In Proceedings of the ATC and SEI Conference on Improving the Seismic Performance of Existing Buildings and Other Structures, San Francisco, CA, USA, 9–11 December 2009; pp. 741–752. [Google Scholar]

- Cancellara, D.; De Angelis, F. Steel braces in series with hysteretic dampers for reducing the seismic vulnerability of RC existing buildings: Assessment and retrofitting with a nonlinear model. Appl. Mech. Mater. 2012, 204–208, 2677–2689. [Google Scholar] [CrossRef]

- Cancellara, D.; De Cicco, S.; De Angelis, F. Assessment and vulnerability reduction of under-designed existing structures: Traditional vs. innovative strategy. Comput. Struct. 2019, 221, 44–64. [Google Scholar] [CrossRef]

- Di Turi, S.; Mastrorilli, A.; Ruggiero, F. Positive energy buildings in the regeneration of urban peripheries in the Mediterranean areas. In Proceedings of the 8th Mediterranean Congress of Heating, Ventilation and Air-Conditioning (CLIMAMED 15), Juan les Pins, France, 9–11 September 2015. [Google Scholar]

- Takeuchi, T. Buckling-Restrained Brace: History, Design and Applications. Key Eng. Mater. 2018, 763, 50–60. [Google Scholar] [CrossRef]

- Sadeghi, S.; Rofooei, F.R. Improving the seismic performance of diagrid structures using buckling restrained braces. J. Constr. Steel Res. 2020, 166, 105905. [Google Scholar] [CrossRef]

- Parisi, N.; Ruggiero, F.; Bernasconi, C.; Lerario, G.V.; Maranci, A.; Moramarco, C.; Rotolo, N.; Treglia, P. Renew Urban. Edifici ad energia positiva nella rigenerazione delle periferie urbane; Arti Grafiche Favia s.r.l.: Bari, Italy, 2015; ISBN 978-88-6922-037-1. (In Italian) [Google Scholar]

- Ruggiero, F.; Di Turi, S.; Mastrorilli, A. Study of an Integrated Retrofit System for Energy Positive Buildings in Urban Areas. Adv. Model. Anal. A 2018, 55, 136–143. [Google Scholar] [CrossRef]

- Legge Numero 1086 del 5 Novembre 1971 “Norme per la Disciplina delle Opere di Conglomerato Cementizio Armato, Normale e Precompresso ed a Struttura Metallica”. Available online: https://www.stradeanas.it/sites/default/files/pdf/3.5.2/02%20-%20Legge%205%20novembre%201971%20n.%201086.pdf (accessed on 30 June 2020). (In Italian).

- Software Design Builder, v4.2.0.054.

- Meteotest. Meteonorm Version 7.1. Available online: www.meteonorm.com (accessed on 30 June 2018).

- International Organization for Standardization. Energy Performance of Buildings—Indicators for Partial EPB Requirements Related to Thermal Energy Balance and Fabric Features; ISO 52018:2017; ISO: Geneva, Switzerland, 2017. [Google Scholar]

- STRAUSS 7, v 2.3.3, Strand 7 Pty Ltd (AUS), Sydney, Australia.

| Config. | EH | GH | GDHW | ||

|---|---|---|---|---|---|

| Current | 61,839 kWh (58.89 kWh m−2 year−1) | 70,727 kWh (67.36 kWh m−2 year−1) | 107,371 kWh (102.26 kWh m−2 year−1) | ||

| Hyp. I | 46,517 kWh (44.30 kWh m−2 year−1) | 52,860 kWh (50.34 kWh m−2 year−1) | 107,371 kWh (102.26 kWh m−2 year−1) | ||

| Hyp. II | 46,491 kWh (44.28 kWh m−2 year−1) | 47,440 kWh (45.18 kWh m−2 year−1) | 96,415 kWh (91.82 kWh m−2 year−1) | ||

| Hyp. III | EH | EC | ElH | ElC | ElDHW |

| 44,244 kWh (42.14 kWh m−2 year−1) | 27,556 kWh (26.24 kWh m−2 year−1) | 11,432 kWh (10.89 kWh m−2 year−1) | 9906 kWh (9.43 kWh m−2 year−1) | 86,483 kWh (82.36 kWh m−2 year−1) | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Foti, D.; Ruggiero, F.; Sabbà, M.F.; Lerna, M. A Dissipating Frames for Seismic Retrofitting and Building Energy-Efficiency. Infrastructures 2020, 5, 74. https://doi.org/10.3390/infrastructures5090074

Foti D, Ruggiero F, Sabbà MF, Lerna M. A Dissipating Frames for Seismic Retrofitting and Building Energy-Efficiency. Infrastructures. 2020; 5(9):74. https://doi.org/10.3390/infrastructures5090074

Chicago/Turabian StyleFoti, Dora, Francesco Ruggiero, Maria Francesca Sabbà, and Michela Lerna. 2020. "A Dissipating Frames for Seismic Retrofitting and Building Energy-Efficiency" Infrastructures 5, no. 9: 74. https://doi.org/10.3390/infrastructures5090074

APA StyleFoti, D., Ruggiero, F., Sabbà, M. F., & Lerna, M. (2020). A Dissipating Frames for Seismic Retrofitting and Building Energy-Efficiency. Infrastructures, 5(9), 74. https://doi.org/10.3390/infrastructures5090074