Recent Research of NiCo2O4/Carbon Composites for Supercapacitors

Abstract

:1. Introduction

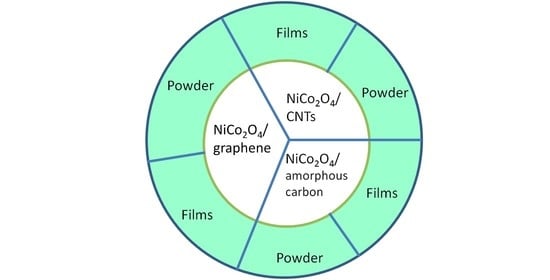

2. Composites of NiCo2O4 and Graphene

2.1. Powder Composites

2.2. Film Electrodes

3. Composites of NiCo2O4 and CNTs

3.1. Powder Composite Materials

3.2. Film Electrodes

4. Composites of NiCo2O4 and Amorphous Carbon

5. Summary and Prospects

Author Contributions

Funding

Conflicts of Interest

References

- Gonzalez, A.; Goikolea, E.; Barrena, J.A.; Mysyk, R. Review on supercapacitors: Technologies and materials. Renew. Sustain. Energy Rev. 2016, 58, 1189–1206. [Google Scholar]

- Wei, W.F.; Cui, X.W.; Chen, W.X.; Ivey, D.G. Manganese oxide-based materials as electrochemical supercapacitor electrodes. Chem. Soc. Rev. 2011, 40, 1697–1721. [Google Scholar]

- Zhai, Y.; Dou, Y.; Zhao, D.; Fulvio, P.F.; Mayes, R.T.; Dai, S. Carbon materials for chemical capacitive energy storage. Adv. Mater. 2011, 23, 4828–4850. [Google Scholar]

- Borenstein, A.; Hanna, O.; Attias, R.; Luski, S.; Brousse, T.; Aurbach, D. Carbon-based composite materials for supercapacitor electrodes: A review. J. Mater. Chem. A 2017, 5, 12653–12672. [Google Scholar]

- Yan, A.; Wang, W.; Chen, W.; Wang, X.; Liu, F.; Cheng, J. The synthesis of NiCo2O4-MnO2 core-shell nanowires by electrodeposition and its supercapacitive properties. Nanomaterials 2019, 9, 1398. [Google Scholar]

- Yan, A.; Wang, W.; Wang, B.; Wang, X.; Chen, J. Core-shell structured Co3O4@NiCo2O4 nanowires on nickel foam for supercapacitors. J. Electroanal. Chem. 2022, 907, 116061. [Google Scholar]

- Basirun, W.J.; Saeed, I.M.; Rahman, M.S.; Mazari, S.A. Nickel oxides/hydroxides-graphene as hybrid supercapattery nanocomposites for advanced charge storage materials—A review. Crit. Rev. Solid State 2021, 46, 553–586. [Google Scholar]

- Xu, J.; Yan, A.; Wang, X.; Wang, B.; Cheng, J. A review of cobalt monoxide and its composites for supercapacitors. Ceram. Int. 2021, 47, 22229–22239. [Google Scholar]

- Mahadik, S.M.; Chodankar, N.R.; Han, Y.K.; Dubal, D.P. Nickel cobaltite: A positive electrode material for hybrid supercapacitors. ChemSusChem 2021, 14, 5384–5398. [Google Scholar]

- Xu, J.; Li, M.; Sheng, W.; Wu, J.; Song, K.; Wang, X.; Cheng, J.P. One-step synthesis of ultra-small Fe2O3 nanoparticles on carbon nanotubes at a low temperature as a high-performance anode for supercapacitors. Ionics 2020, 26, 5211–5219. [Google Scholar]

- Wei, T.Y.; Chen, C.H.; Chien, H.C.; Lu, S.Y.; Hu, C.C. A cost-effective supercapacitor material of ultrahigh specific capacitances: Spinel nickel cobaltite aerogels from an epoxide-deriven sol-gel process. Adv. Mater. 2010, 22, 347. [Google Scholar]

- Li, Y.M.; Han, X.; Yi, T.F.; He, Y.B.; Li, X.F. Review and prospect of NiCo2O4-based composite materials for supercapacitor electrodes. J. Energy Chem. 2019, 31, 54–78. [Google Scholar]

- Wang, C.G.; Zhou, E.; He, W.D.; Deng, X.L.; Huang, J.Z.; Ding, M.; Wei, X.Q.; Liu, X.J.; Xu, X.J. NiCo2O4-based supercapacitor nanomaterials. Nanomaterials 2017, 7, 41. [Google Scholar]

- Luo, Z.; Shu, D.; Yi, F.; Ling, J.; Wang, M.; Huang, C.; Gao, A. Urchin-like NiCo2O4 hollow microspheres with oxygen vacancies synthesized by self-template for supercapacitor. New J. Chem. 2021, 45, 22748–22757. [Google Scholar]

- Chen, X.; Song, L.; Zeng, M.; Tong, L.; Zhang, C.; Xie, K.; Wang, Y. Regulation of morphology and electronic configuration of NiCo2O4 by aluminum doping for high performance capacitors. J. Colloid Interface Sci. 2022, 610, 70–79. [Google Scholar]

- Eskandari, M.; Malekfara, R.; Buceta, D.; Taboada, P. NiCo2O4-based nanostructured composites for high-performance pseudocapacitor electrodes. Colloids Surf. A 2020, 584, 124039. [Google Scholar]

- Shewale, P.S.; Yun, K.S. NiCo2O4/RGO Hybrid Nanostructures on Surface-Modified Ni Core for Flexible Wire-Shaped Supercapacitor. Nanomaterials 2021, 11, 852. [Google Scholar]

- Wang, W.D.; Zhang, P.P.; Gao, S.Q.; Wang, B.Q.; Wang, X.C.; Li, M.; Liu, F.; Cheng, J.P. Core-shell nanowires of NiCo2O4@α-Co(OH)2 on Ni foam with enhanced performances for supercapacitors. J. Colloid Interface Sci. 2020, 579, 71–81. [Google Scholar]

- Wang, W.; Li, X.; Zhang, P.; Wang, B.; Gong, S.; Wang, X.; Liu, F.; Chen, J. Preparation of NiCo2O4@CoS heterojunction composite as electrodes for high-performance supercapacitors. J. Electroanal. Chem. 2021, 891, 115257. [Google Scholar]

- Guo, X.; Chen, C.; Zhang, Y.; Xu, Y.; Pang, H. The application of transition metal cobaltites in electrochemistry. Energy Storage Mater. 2019, 23, 439–465. [Google Scholar]

- Tomboc, G.M.; Gadisa, B.T.; Jun, M.; Chaudhari, N.K.; Kim, H.; Lee, K. Carbon Transition-metal Oxide Electrodes: Understanding the Role of Surface Engineering for High Energy Density Supercapacitors. Chem. Asian J. 2020, 15, 1628–1647. [Google Scholar]

- Cheng, J.P.; Wang, W.D.; Wang, X.C.; Liu, F. Recent research of core–shell structured composites with NiCo2O4 as scaffolds for electrochemical capacitors. Chem. Eng. J. 2020, 393, 124747. [Google Scholar]

- Zhao, W.; Li, M.; Qi, Y.; Tao, Y.; Shi, Z.; Liu, Y.; Chen, J. Ultrasound sonochemical synthesis of amorphous Sb2S3-graphene composites for sodium-ion batteries. J. Colloid Interface Sci. 2021, 586, 404–411. [Google Scholar]

- Wang, H.W.; Hu, Z.A.; Chang, Y.Q.; Chen, Y.L.; Wu, H.Y.; Zhang, Z.Y.; Yang, Y.Y. Design and synthesis of NiCo2O4–reduced graphene oxide composites for high performance supercapacitors. J. Mater. Chem. 2011, 21, 10504–10511. [Google Scholar]

- Salarizadeh, P.; Askari, M.B.; Seifi, M.; Rozati, S.M.; Eisazadeh, S.S. Pristine NiCo2O4 nanorods loaded rGO electrode as a remarkable electrode material for asymmetric supercapacitors. Mater. Sci. Semicond. Process. 2020, 114, 105078. [Google Scholar]

- Zhang, S.; Gao, H.; Zhou, J.; Jiang, F.; Zhang, Z. Hydrothermal synthesis of reduced graphene oxide-modified NiCo2O4 nanowire arrays with enhanced reactivity for supercapacitors. J. Alloys Compd. 2019, 792, 474–480. [Google Scholar]

- Gajraj, V.; Kumar, A.; Ekta, D.; Kaushik, R.; Jose, D.A.; Ghosh, A.; Mariappan, C.R. Multifunctionality exploration of NiCo2O4–rGO nanocomposites: Photochemical water oxidation, methanol electro-oxidation and asymmetric supercapacitor applications. Dalton Trans. 2021, 50, 18001–18015. [Google Scholar]

- Sethi, M.; Shenoy, U.S.; Bhat, D.K. Porous graphene–NiCo2O4 nanorod hybrid composite as a high performance supercapacitor electrode material. New J. Chem. 2020, 44, 4033–4041. [Google Scholar]

- Wang, H.Z.; Dong, H.; Lu, J.; Sun, S.; Zhang, W.; Yao, S. Synthesis of NiCo2O4 Nanoneedles on rGO for Asymmetric Supercapacitors. J. Electron. Mater. 2021, 50, 4196–4206. [Google Scholar]

- Kavinkumar, T.; Naresh, N.; Mathew, G.; Neppolian, B. Urchin-like porous NiCo2O4 nanostructure: Morphology control using porous reduced graphene oxide nanosheets for high performance flexible transparent energy storage devices. J. Alloys Compd. 2021, 891, 162052. [Google Scholar]

- Hassanpoor, S.; Aghely, F. Sonochemical synthesis of NiCo2O4/NRGO nanocomposite as a cathodic material for the electrochemical capacitor application. J. Iran. Chem. Soc. 2021, 18, 993–1003. [Google Scholar]

- Jiu, H.F.; Jiang, L.Y.; Gao, Y.Y.; Zhang, Q.; Zhang, L.X. Synthesis of three-dimensional graphene aerogel-supported NiCo2O4 nanowires for supercapacitor application. Ionics 2019, 25, 4325–4331. [Google Scholar]

- Osaimany, P.; Samuel, A.S.; Johnboco, Y.; Kharwar, Y.P.; Chakravarthy, V. A study of synergistic effect on oxygen reduction activity and capacitive performance of NiCo2O4/rGO hybrid catalyst for rechargeable metal-air batteries and supercapacitor applications. Compos. Part B 2019, 176, 107327. [Google Scholar]

- Meng, F.; Zhao, L.; Zhang, Y.; Zhai, J.; Li, Y.; Zhang, W. Facile synthesis of NiCo2O4/rGO microspheres with high-performance for supercapacitor. Ceram. Int. 2019, 45, 23701–23706. [Google Scholar]

- Yuan, R.; Chen, W.; Zhang, J.; Zhang, L.; Ren, H.; Miao, T.; Wang, Z.; Zhan, K.; Zhu, M.; Zhao, B. Crumpled graphene microspheres anchored on NiCo2O4 nanoparticles as an advanced composite electrode for asymmetric supercapacitors with ultralong cycling life. Dalton Trans. 2022, 51, 4491–4501. [Google Scholar]

- Wei, Z.; Guo, J.; Qu, M.; Zhang, H. Honeycombed-like nanosheet array composite NiCo2O4/rGO for efficient methanol electrooxidation and supercapacitors. Electrochim. Acta 2020, 362, 137145. [Google Scholar]

- Xu, Z.; Yang, L.; Jin, Q.; Hu, Z. Improved capacitance of NiCo2O4/carbon composite resulted from carbon matrix with multilayered graphene. Electrochim. Acta 2019, 295, 376–383. [Google Scholar]

- Kim, J.; Park, S.J.; Kim, S. Preparation and Electrochemical Behaviors of Petal-like Nickel Cobaltite/Reduced Graphene Oxide Composites for Supercapacitor Electrodes. Appl. Chem. Eng. 2019, 30, 324–330. [Google Scholar]

- Chang, X.; Li, W.; Liu, Y.; He, M.; Zheng, X.; Lv, X.; Ren, Z. Synthesis and characterization of NiCo2O4 nanospheres/nitrogendoped graphene composites with enhanced electrochemical performance. J. Alloys Compd. 2019, 784, 293–300. [Google Scholar]

- Huang, C.X.; Ding, Y.H.; Hao, C.; Zhou, S.S.; Wang, X.H.; Gao, H.W.; Zhu, L.L.; Wu, J.B. PVP-assisted growth of Ni-Co oxide on N-doped reduced graphene oxide with enhanced pseudocapacitive behavior. Chem. Eng. J. 2019, 378, 122202. [Google Scholar]

- Paliwal, M.K.; Meher, S.K. “Wrapped” nitrogen-doped defective reduced graphene oxide(ND-rGO): A virtual electron bed for enhanced supercapacitive charge storage in stepped-surfaced-NiCo2O4/ND-rGO||Bi2O3 asymmetric device. Electrochim. Acta 2020, 338, 135819. [Google Scholar]

- Chao, Y.; Peng, W.; Wang, W.; Zhang, X.; Cao, Y. Facile synthesis of fluorinated graphene/NiCo2O4 nanorods composite with high supercapacitive performance. Appl. Nanosci. 2022, 12, 1–8. [Google Scholar] [CrossRef]

- Luo, J.; Wang, J.; Liu, S.; Wu, W.; Jia, T.; Yang, Z.; Mu, S.; Huang, Y. Graphene quantum dots encapsulated tremella-like NiCo2O4 for advanced asymmetric supercapacitors. Cabon 2019, 146, 1–8. [Google Scholar]

- Kharangarh, P.R.; Ravindra, N.M.; Rawal, R.A.; Singh, V. Gupta, Graphene quantum dots decorated on spinel nickel cobaltite nanocomposites for boosting supercapacitor electrode material performance. J. Alloys Compd. 2021, 876, 159990. [Google Scholar]

- Chen, X.; Xie, R.; Li, H.; Jaber, F.; Musharavati, F.; Zalnezhad, E.; Bae, S.; Hui, K.S.; Hui, K.N. Supercapacitor performance of porous nickel cobaltite nanosheets. Sci. Rep. 2020, 10, 18956. [Google Scholar]

- Feng, H.; Gao, S.; Shi, J.; Zhang, L.; Peng, Z.; Cao, S. Construction of 3D hierarchical porous NiCo2O4/graphene hydrogel/Ni foam electrode for high-performance supercapacitor. Electrochim. Acta 2019, 299, 116–124. [Google Scholar]

- Wei, G.; Deng, X.; Huang, H.; Zhou, Q.; Fan, Y.; Yan, L.; Liang, X.; Zhou, W.; Guo, J. Design and synthesis of NiCo2O4/NiCoO2/graphene hybrid nanoarrays with enhanced capacitive performance. Ceram. Int. 2020, 46, 20191–20200. [Google Scholar]

- Liu, T.; Zhou, S.; Yu, X.; Mao, C.; Wei, Y.; Yu, X.; Chen, L.; Zhao, X.; Tian, G.; Chen, L. Hexadecyl trimethyl ammonium bromide assisted growth of NiCo2O4@reduced graphene oxide/nickel foam nanoneedle arrays with enhanced performance for supercapacitor electrodes. RSC Adv. 2022, 12, 4029–4041. [Google Scholar]

- Lv, A.; Lu, S.; Xu, W.; Wang, Z.; Shen, Y.; Liu, G. One-pot synthesis of NiCo2O4/rGO/NF hybrid electrode materials realizing ultrahigh capacitance and rapid charge/discharge at large current density. Appl. Surf. Sci. 2020, 511, 145538. [Google Scholar]

- Shi, Z.T.; Sun, G.; Yuan, R.W.; Chen, W.X.; Wang, Z.; Zhang, L.; Zhan, K.; Zhu, M.; Yang, J.H.; Zhao, B. Scalable fabrication of NiCo2O4/reduced graphene oxide composites by ultrasonic spray as binder-free electrodes for supercapacitors with ultralong lifetime. J. Mater. Sci. Technol. 2022, 99, 260–269. [Google Scholar]

- Zhao, N.; Fan, H.; Zhang, M.; Ma, J.; Zhang, W.; Wang, C.; Li, H.; Jiang, X.; Cao, X. Investigating the large potential window of NiCo2O4 supercapacitors in neutral aqueous electrolyte. Electrochim. Acta 2019, 321, 134681. [Google Scholar]

- Patil, A.; Kitiphatpiboon, N.; An, X.; Hao, X.; Li, S.; Hao, X.; Abudula, A.; Guan, G. Fabrication of a high-energy flexible all-solid-state supercapacitor using pseudocapacitive 2D-Ti3C2Tx-MXene and battery-type reduced graphene oxide/nickel-cobalt bimetal oxide electrode materials. ACS Appl. Mater. Interfaces 2020, 12, 52749–52762. [Google Scholar]

- Li, S.; Yang, K.; Ye, P.; Jiang, H.; Zhang, Z.; Huang, Q.; Wang, L. Hierarchical interpenetrating rHGO-decorated NiCo2O4 nanowires architectures for high-performance supercapacitors. Appl. Surf. Sci. 2019, 473, 326–333. [Google Scholar]

- Chen, Y.; Liu, T.; Zhang, L.; Yu, J. N-doped graphene framework supported nickel cobalt oxide as supercapacitor electrode with enhanced performance. Appl. Surf. Sci. 2019, 484, 135–143. [Google Scholar]

- Wang, H.Z.; Liu, J.; Zhang, W.G.; Sun, S.F.; Yao, S.W. Preparation of binder-free three-dimensional N-doped carbon framework/ nickel cobaltate composite for all-solid supercapacitor application. Appl. Surf. Sci. 2021, 561, 149893. [Google Scholar]

- Jiang, Y.; Li, X.; Liu, F.; Wang, B.; Zhou, W.; Dong, S.; Fan, X. In situ growth and anchoring NiCo2O4 nanowires on self-supported 3D holey graphene framework for supercapacitor. Appl. Surf. Sci. 2022, 576, 151801. [Google Scholar]

- Zhou, Y.; Huang, Z.; Liao, H.; Li, J.; Wang, H.; Wang, Y. 3D porous graphene/NiCo2O4 hybrid film as an advanced electrode for supercapacitors. Appl. Surf. Sci. 2020, 534, 147598. [Google Scholar]

- Eskandari, M.; García, C.A.; Buceta, D.; Malekfar, R.; Taboad, P. NiCo2O4/MWCNT/PANI coral-like nanostructured composite for electrochemical energy-storage applications. J. Electroanal. Chem. 2019, 851, 113481. [Google Scholar]

- Wang, X.; Han, X.; Lim, M.; Singh, N.; Gan, C.L.; Jan, M.; Lee, P.S. Nickel cobalt oxide-single wall carbon nanotube composite material for superior cycling stability and high-performance supercapacitor application. J. Phys. Chem. C 2012, 116, 12448–12454. [Google Scholar]

- Pathak, M.; Jose, J.R.; Chakrabortry, B.; Rout, C.S. High performance supercapacitor electrodes based on spinel NiCo2O4@MWCNT composite with insights from density functional theory simulations. J. Chem. Phys. 2020, 152, 064706. [Google Scholar]

- Zhang, J.; Fang, Z.; Li, T.; Rehman, S.; Luo, Q.; Chen, P.; Hu, L.; Zhang, F.; Wang, Q.; Bi, H. Highly Hydrophilic Carbon Dots’ Decoration on NiCo2O4 Nanowires for Greatly Increased Electric Conductivity, Supercapacitance, and Energy Density. Adv. Mater. Interfaces 2019, 6, 1900049. [Google Scholar]

- Li, Y.H.; Zheng, L.; Wang, W.Y.; Wen, Y.X. Controllable Synthesis of NiCo2O4/CNT Composites for Supercapacitor Electrode Materials. Int. J. Electrochem. Sci. 2020, 15, 11576–11583. [Google Scholar]

- Ko, T.H.; Radhakrishnan, S.; Choi, W.K.; Seo, M.K.; Kim, B.S. Core/shell-like NiCo2O4-decorated MWCNT hybrids prepared by a dry synthesis technique and its supercapacitor applications. Mater. Lett. 2016, 166, 105–109. [Google Scholar]

- Geng, L.; Xu, S.S.; Liu, J.C.; Guo, A.R.; Hou, F. Effects of CNT-film Pretreatment on the Characteristics of NiCo2O4/CNT Core-shell Hybrids as Electrode Material for Electrochemistry Capacitor. Electroanalysis 2017, 29, 778–786. [Google Scholar]

- Jeong, J.H.; Oh, E.S. Characteristics of Fe2O3/exfoliated vapor-grown carbon fiber composite as anode material for lithium-ion batteries. J. Appl. Electrochem. 2015, 45, 983–990. [Google Scholar]

- Xue, Y.; Chen, T.; Song, S.H.; Kim, P.; Bae, J. DNA-directed fabrication of NiCo2O4 nanoparticles on carbon nanotubes as electrodes for high-performance battery-like electrochemical capacitive energy storage device. Nano Energy 2019, 56, 751–758. [Google Scholar]

- Hu, Y.; Wang, Q.; Chen, S.; Xu, Z.; Miao, M.; Zhang, D. Flexible Supercapacitors Fabricated by Growing Porous NiCo2O4 In Situ on a Carbon Nanotube Film Using a Hyperbranched Polymer Template. ACS Appl. Energy Mater. 2020, 3, 4043–4050. [Google Scholar]

- Ramesh, S.; Vikraman, D.; Karuppasamy, K.; Yadav, H.M.; Sivasamy, A.; Kim, H.S.; Kim, J.H.; Kim, H.S. Controlled synthesis of SnO2@NiCo2O4/nitrogen doped multiwalled carbon nanotube hybrids as an active electrode material for supercapacitors. J. Alloys Compd. 2019, 794, 186–194. [Google Scholar]

- Kathalingam, A.; Ramesh, S.; Sivasamy, A.; Kim, H.S.; Kim, H.S. Supercapacitor performance of MnO2/NiCo2O4@N-MWCNT hybrid nanocomposite electrodes. J. Sol-Gel Sci. Technol. 2019, 91, 154–164. [Google Scholar]

- Zhang, W.G.; Xu, J.L.; Wang, H.Z.; Yao, S.W. CNT anchored by NiCo2O4 nanoparticles with hybrid structure for ultrahigh-performance supercapacitor. J. Mater. Sci. Mater. Electron. 2020, 31, 5948–5957. [Google Scholar]

- Bhaskaran, S.; Singh, M.; Negi, C.M.S.; Gupt, S.K. Improved electrochemical performance of nickel cobaltite/multi-walled carbon nanotube composite as a hybrid electrode for supercapacitors. J. Phys. Chem. Solids 2021, 154, 110107. [Google Scholar]

- Cheng, J.P.; Wang, B.Q.; Gong, S.H.; Wang, X.C.; Sun, Q.S.; Liu, F. Conformal coatings of NiCo2O4 nanoparticles and nanosheets on carbon nanotubes for supercapacitor electrode. Ceram. Int. 2021, 47, 32727–32735. [Google Scholar]

- Wang, B.; Gong, S.; Sun, Q.; Liu, F.; Wang, X.; Cheng, J. Carbon nanotubes refined mesoporous NiCoO2 nanoparticles for high-performance supercapacitors. Electrochim. Acta 2022, 402, 139575. [Google Scholar]

- Shinde, S.K.; Karade, S.S.; Maile, N.C.; Yadav, H.M.; Ghodake, G.S.; Jagadale, A.D.; Jalak, M.B.; Lee, D.S.; Kim, D.Y. Synthesis of 3D nanoflower-like mesoporous NiCo2O4 N-doped CNTs nanocomposite for solid-state hybrid supercapacitor; efficient material for the positive electrode. Cearm. Int. 2021, 47, 31650–31665. [Google Scholar]

- Khan, A.S.; Pan, L.J.; Farid, A.; Javid, M.; Huang, H.; Zhao, Y.P. Carbon nanocoils decorated with a porous NiCo2O4 nanosheet array as a highly efficient electrode for supercapacitors. Nanoscale 2021, 13, 11943–11952. [Google Scholar]

- Gao, J.S.; Li, S.L.; Wang, H.H.; Zhou, Y.; Zhang, L.Y.; Liu, Z.M.; He, Y. Carbon nanotubes aerogels dispersed by thermal excitation on Ni Foam@NiCo2O4 nanoneedles with enhanced properties for supercapacitor. J. Alloys Compd. 2021, 861, 157963. [Google Scholar]

- Geuli, O.; Hao, Q.L.; Mandler, D. One-step fabrication of NiOx-decorated carbon nanotubes-NiCo2O4 as an advanced electroactive composite for supercapacitors. Electrochim. Acta 2019, 318, 51–60. [Google Scholar]

- Soltanloo, M.; Kazazi, M.; Yeganeh, S.E.H.; Chermahini, M.D.; Mazinani, B. High-Performance Pseudocapacitive Electrode Based on Electrophoretically Deposited NiCo2O4/MWCNTs Nanocomposite on 316L Stainless Steel. JOM 2020, 72, 2235–2244. [Google Scholar]

- El-Shafei, M.H.; El-Deen, A.G.; El-Moneim, A.A.; Hessein, A. Controlled-synthesis of hierarchical NiCo2O4 anchored on carbon nanofibers mat for free-standing and highlyperformance supercapacitors. J. Mater. Sci. Mater. Electron. 2021, 32, 15882–15897. [Google Scholar]

- Jin, F.Q.; Tong, H.; Lu, L.; Meng, Q.; Yue, S.H.; Ding, B.; Zhang, X.G. Honeycombed NiCo2O4 nanosheets grown on the sponge of a carbon nanotube/graphene prepared by the flame burning method with an advanced performance as a supercapacitor. J. Alloys Compd. 2019, 787, 36–44. [Google Scholar]

- Yang, C.C.; Sun, W.C.; Kumar, A.; Pattanayak, B.; Tseng, T.Y. Templating synthesis of nickel cobaltite nanoflakes and their nanocomposites for making high-performance symmetric supercapacitors. Mater. Today Energy 2019, 14, 100356. [Google Scholar]

- Che, Q.; Zhang, F.; Zhang, X.G.; Lu, X.J.; Ding, B.; Zhu, J.J. Preparation of ordered mesoporous carbon/NiCo2O4 electrode and its electrochemical capacitive behavior. Acta Phys.-Chim. Sin. 2012, 28, 837–842. [Google Scholar]

- Huang, Y.; Wang, B.; Liu, F.; Liu, H.; Wang, S.; Li, Q.; Chen, J.; Zhang, L. Fabrication of Rambutan-like activated carbon sphere/carbon nanotubes and their application as supercapacitors. Energy Fuels 2021, 35, 8313–8320. [Google Scholar]

- Chen, G.H.; Yang, Y.; Dai, Y.; Wang, W. Preparation of High-capacity Carbon-coated Nickel Cobaltate Hollow Nanospheres Electrode for supercapacitors. Int. J. Electrochem. Sci. 2020, 15, 5342–5351. [Google Scholar]

- Dong, K.; Wang, Z.; Sun, M.; Wang, D.; Luo, S.; Liu, Y. Construction of NiCo2O4 nanorods into 3D porous ultrathin carbon networks for high-performance asymmetric supercapacitors. J. Alloys Compd. 2019, 783, 1–9. [Google Scholar]

- Zhao, T.; Liu, C.; Yi, F.; Deng, W.; Gao, A.; Shu, D.; Zheng, L. Hollow N-doped carbon@ O-vacancies NiCo2O4 nanocages with a built-in electric field as high-performance cathodes for hybrid supercapacitor. Electrochim. Acta 2020, 364, 137260. [Google Scholar]

- Nan, J.X.; Shi, Y.; Xiang, Z.Q.; Wang, S.; Yang, J.W.; Zhang, B. Ultrathin NiCo2O4 nanosheets assembled on biomass-derived carbon microsheets with polydopamine for high-performance hybrid supercapacitors. Electrochim. Acta 2019, 301, 107–116. [Google Scholar]

- Nguyen, N.V.; Tran, T.V.; Luong, S.T.; Pham, T.M.; Nguyen, K.V.; Vu, T.D.; Nguyen, H.S.; To, N.V. Facile Synthesis of a NiCo2O4 Nanoparticles Mesoporous Carbon Composite as Electrode Materials for Supercapacitor. ChemistrySelect 2020, 5, 7060–7068. [Google Scholar]

- Zeng, M.J.; Li, X.F.; Hao, S.M.; Qu, J.; Li, W.; Wu, J.; Zhao, T.; Yu, Z.Z. Hierarchically porous graphene/wood-derived carbon activated using ZnCl2 and decorated with in situ grown NiCo2O4 for high-performance asymmetric supercapacitors. New J. Chem. 2022, 46, 533–541. [Google Scholar]

- Cheng, C.; Li, X.; Liu, K.; Zou, F.; Tung, W.; Huang, Y.; Xia, X.; Wang, C.; Vogt, B.D.; Zhu, Y. A high-performance lithium-ion capacitor with carbonized NiCo2O4 anode and vertically-aligned carbon nanoflakes cathode. Energy Storage Mater. 2019, 22, 265–274. [Google Scholar]

- Wang, Z.; Hao, Y.; Qiang, H.; Xu, C.; Chen, C. Facile synthesis of nitrogen-doped mesoporous hollow carbon nanospheres@NiCo2O4 for high-performance supercapacitors. Ionics 2021, 27, 315–323. [Google Scholar]

- Zhou, Y.; Li, C.; Li, X.; Huo, P.; Wang, H. Construction of high-performance electrode materials of NiCo2O4 nanoparticles encapsulated in ultrathin N-doped carbon nanosheets for supercapacitors. Dalton Trans. 2021, 50, 1097–1105. [Google Scholar]

- Lohani, P.C.; Tiwari, A.P.; Chhetri, K.; Muthurasu, A.; Fahal, B.; Chae, S.H.; Ko, T.H.; Lee, J.Y.; Chuang, Y.S.; Kim, H.Y. Polypyrrole nanotunnels with luminal and abluminal layered double hydroxide nanosheets grown on a carbon cloth for energy storage applications. ACS Appl. Mater. Interfaces 2022, 14, 23285–23296. [Google Scholar]

- Tiwari, A.P.; Mukhiya, T.; Muthurasu, A.; Chhetri, K.; Lee, M.J.; Dahal, B.; Lohani, P.C.; Kim, H.Y. A review of electrospun carbon nanofiber-based negative electrode materials for supercapacitor. Electrochem 2021, 2, 236–250. [Google Scholar]

- Xu, L.; Zhang, L.Y.; Cheng, B.; Yu, J.G. Rationally designed hierarchical NiCo2O4-C@Ni(OH)2 core-shell nanofibers for high performance supercapacitors. Carbon 2019, 152, 652–660. [Google Scholar]

- Li, J.; Liu, Y.; Zhan, D.; Zou, Y.; Xu, F.; Sun, L.; Xiang, C.; Zhang, J. Electrospinning synthesis of NiCo2O4 embedded N-doped carbon for high-performance supercapacitors. J. Energy Storage 2021, 39, 102665. [Google Scholar]

- Luo, W.J.; Xue, H. The synthesis and electrochemical performance of NiCo2O4 embedded carbon nanofibers for highperformance supercapacitors. Fuller. Nanotub. Carbon Nanostruct. 2019, 27, 189–197. [Google Scholar]

- Sun, J.; Wang, W.; Yu, D. NiCo2O4 nanosheet-decorated carbon nanofiber electrodes with high electrochemical performance for flexible supercapacitors. J. Electron. Mater. 2019, 48, 3833–3843. [Google Scholar]

- El-Deen, A.G.; El-Shafei, M.H.; Hessein, A.; Hassanin, A.H.; Shaalan, N.M.; El-Moneim, A.A. High-performance asymmetric supercapacitor based hierarchical NiCo2O4@carbon nanofibers//Activated multichannel carbon nanofibers. Nanotechnology 2020, 31, 365404. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, J.; Shi, Y.; Cheng, J.; Wang, X. Recent Research of NiCo2O4/Carbon Composites for Supercapacitors. Surfaces 2022, 5, 334-349. https://doi.org/10.3390/surfaces5030025

Xu J, Shi Y, Cheng J, Wang X. Recent Research of NiCo2O4/Carbon Composites for Supercapacitors. Surfaces. 2022; 5(3):334-349. https://doi.org/10.3390/surfaces5030025

Chicago/Turabian StyleXu, Junming, Yang Shi, Jipeng Cheng, and Xinchang Wang. 2022. "Recent Research of NiCo2O4/Carbon Composites for Supercapacitors" Surfaces 5, no. 3: 334-349. https://doi.org/10.3390/surfaces5030025

APA StyleXu, J., Shi, Y., Cheng, J., & Wang, X. (2022). Recent Research of NiCo2O4/Carbon Composites for Supercapacitors. Surfaces, 5(3), 334-349. https://doi.org/10.3390/surfaces5030025