Study on High-Speed Machining of 2219 Aluminum Utilizing Nanoparticle-Enhanced Minimum Quantity Lubrication (MQL) Technique

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials Used

2.2. Experimental Setup

2.3. MQL Dispersion Preparation

- Pure mineral oil;

- 0.2% Al2O3 nanoparticles;

- 0.5% Al2O3 nanoparticles;

- 1% Al2O3 nanoparticles; and

- 2% Al2O3 nanoparticles.

3. Results and Discussion

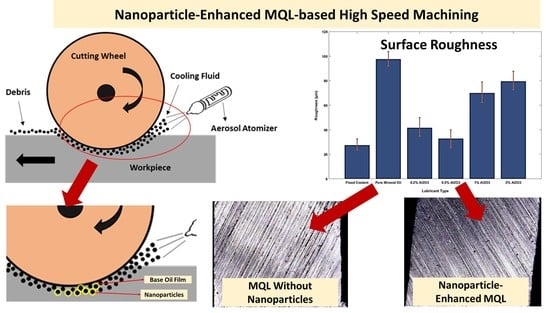

3.1. Surface Roughness and Surface Micromorphology

3.2. Temperature Generated during High-Speed Saw Cutting

4. Conclusions

- The addition of nanoparticles helped to improve the surface finish under MQL machining. However, the surface quality decreased beyond a threshold nanoparticle concentration (0.5% in this case);

- The surface roughness obtained using conventional flood coolant is comparable to that of MQL nanofluid with a concentration of 0.5%;

- Compared to pure MQL, a 0.5% concentration of MQL nanofluid resulted in a 63% improvement in surface finish;

- Temperature analysis of the cutting zone immediately after machining showed that a 0.5% nanoparticle concentration resulted in the lowest cutting temperature among the various MQL cutting conditions;

- Further investigations are needed to understand the impact of nanoparticle concentration on tool wear, tool life, and MQL-based machining economics;

- The results of this study could be instrumental in the development of environmental-friendly machining solutions for aluminum alloys at commercial scales.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mondol, S.; Kashyap, S.; Kumar, S.; Chattopadhyay, K. Improvement of high temperature strength of 2219 alloy by Sc and Zr addition through a novel three-stage heat treatment route. Mater. Sci. Eng. A 2018, 732, 157–166. [Google Scholar] [CrossRef]

- Sivaprasad, K.; Blessto, B.; Muthupandi, V.; Arumugam, M. Achieving Superior Strength and Ductility Combination through Cryorolling in 2219 Aluminum Alloy. J. Mater. Eng. Perform. 2020, 29, 6809–6817. [Google Scholar] [CrossRef]

- Gatto, A.; Bassoli, E.; Iuliano, L. Performance Optimization in Machining of Aluminium Alloys for Moulds Production: HSM and EDM. Alum. Alloy. Theory Appl. 2011, 355–376. [Google Scholar] [CrossRef] [Green Version]

- MuellerHummel, P. Process understanding of dry drilling CFRP/aluminium and AL/AL stacks in IT8 quality. SAE Int. J. Aerosp. 2016, 9, 217. [Google Scholar] [CrossRef]

- Jawahir, I.S.; Van Luttervelt, C.A. Recent developments in chip control research and applications. CIRP Ann. 1993, 42, 659–693. [Google Scholar] [CrossRef]

- Polvorosa, R.; Suárez, A.; de Lacalle, L.L.; Cerrillo, I.; Wretland, A.; Veiga, F. Tool wear on nickel alloys with different coolant pressures: Comparison of Alloy 718 and Waspaloy. J. Manuf. Process. 2017, 26, 44–56. [Google Scholar] [CrossRef]

- Park, K.-H.; Olortegui-Yume, J.; Yoon, M.-C.; Kwon, P. A study on droplets and their distribution for minimum quantity lubrication (MQL). Int. J. Mach. Tools Manuf. 2010, 50, 824–833. [Google Scholar] [CrossRef]

- James, S.; Nejadian, S.M. Experimental study on high-speed saw cutting of hybrid composite stacks using nanoparticle-enhanced minimum quantity lubrication. Int. J. Adv. Manuf. Technol. 2020, 110, 3077–3090. [Google Scholar] [CrossRef]

- Le Coz, G.; Dudzinski, D. Temperature variation in the workpiece and in the cutting tool when dry milling Inconel 718. Int. J. Adv. Manuf. Technol. 2014, 74, 1133–1139. [Google Scholar] [CrossRef]

- Meshreki, M.; Damir, A.; Sadek, A.; Attia, M.H. Investigation of drilling of CFRP-aluminum stacks under different cooling modes. In ASME International Mechanical Engineering Congress and Exposition; American Society of Mechanical Engineers: New York, NY, USA, 2016; p. V002T002A011. [Google Scholar]

- Sreejith, P.S. Machining of 6061 aluminium alloy with MQL, dry and flooded lubricant conditions. Mater. Lett. 2008, 62, 276–278. [Google Scholar] [CrossRef]

- De Lacalle, L.L.; Angulo, C.; Lamikiz, A.; Sanchez, J. Experimental and numerical investigation of the effect of spray cutting fluids in high speed milling. J. Mater. Process. Technol. 2006, 172, 11–15. [Google Scholar] [CrossRef]

- Goindi, G.S.; Sarkar, P. Dry machining: A step towards sustainable machining–Challenges and future directions. J. Clean. Prod. 2017, 165, 1557–1571. [Google Scholar] [CrossRef]

- Boubekri, N.; Shaikh, V.; Foster, P.R. A technology enabler for green machining: Minimum quantity lubrication (MQL). J. Manuf. Technol. Manag. 2010, 21, 556–566. [Google Scholar] [CrossRef]

- Brinksmeier, E.; Janssen, R. Drilling of multi-layer composite materials consisting of carbon fiber reinforced plastics (CFRP), titanium and aluminum alloys. CIRP Ann. 2002, 51, 87–90. [Google Scholar] [CrossRef]

- Khan, I.; Saeed, K.; Khan, I. Nanoparticles: Properties, applications and toxicities. Arab. J. Chem. 2019, 12, 908–931. [Google Scholar] [CrossRef]

- Gharaibeh, N. Vegetable and mineral used oils as cutting fluids: Effect on surface roughness of aluminum alloy. J. Surf. Eng. Mater. Adv. Technol. 2016, 6, 176–182. [Google Scholar] [CrossRef] [Green Version]

- Singh, G.; Singh, S.; Singh, M.; Kumar, A. Experimental investigations of vegetable & mineral oil performance during machining of EN-31 steel with minimum quantity lubrication. Int. J. Res. Eng. Technol. 2013, 2, 1030–1037. [Google Scholar]

- Salur, E.; Kuntoğlu, M.; Aslan, A.; Pimenov, D.Y. The Effects of MQL and Dry Environments on Tool Wear, Cutting Temperature, and Power Consumption during End Milling of AISI 1040 Steel. Metals 2021, 11, 1674. [Google Scholar] [CrossRef]

- Zhang, D.; Li, C.; Jia, D.; Zhang, Y.; Zhang, X. Specific grinding energy and surface roughness of nanoparticle jet minimum quantity lubrication in grinding. Chin. J. Aeronaut. 2015, 28, 570–581. [Google Scholar] [CrossRef] [Green Version]

- Pereira, O.; Martín-Alfonso, J.; Rodríguez, A.; Calleja, A.; Fernández-Valdivielso, A.; De Lacalle, L.L. Sustainability analysis of lubricant oils for minimum quantity lubrication based on their tribo-rheological performance. J. Clean. Prod. 2017, 164, 1419–1429. [Google Scholar] [CrossRef]

- Molaie, M.M.; Zahedi, A.; Akbari, J. Effect of water-based nanolubricants in ultrasonic vibration assisted grinding. J. Manuf. Mater. Process. 2018, 2, 80. [Google Scholar] [CrossRef] [Green Version]

- Duc, T.M.; Chien, T.Q. Performance evaluation of MQL parameters using Al2O3 and MoS2 nanofluids in hard turning 90CrSi steel. Lubricants 2019, 7, 40. [Google Scholar] [CrossRef] [Green Version]

- Jain, A.; Bajpai, V. Introduction to high-speed machining (HSM). In High Speed Machining; Elsevier: Amsterdam, The Netherlands, 2020; pp. 1–25. [Google Scholar]

- Nouzil, I.; Eltaggaz, A.; Pervaiz, S.; Deiab, I. Toxicity Analysis of Nano-Minimum Quantity Lubrication Machining—A Review. Lubricants 2022, 10, 176. [Google Scholar] [CrossRef]

- Sengul, A.B.; Asmatulu, E. Toxicity of metal and metal oxide nanoparticles: A review. Environ. Chem. Lett. 2020, 18, 1659–1683. [Google Scholar] [CrossRef]

- Girigoswami, K. Toxicity of Metal Oxide Nanoparticles, in Cellular and Molecular Toxicology of Nanoparticles; Springer: Berlin/Heidelberg, Germany, 2018; pp. 99–122. [Google Scholar]

- Virdi, R.L.; Chatha, S.S.; Singh, H. Performance evaluation of nanofluid-based minimum quantity lubrication grinding of Ni-Cr alloy under the influence of CuO nanoparticles. Adv. Manuf. 2021, 9, 580–591. [Google Scholar] [CrossRef]

- James, S.; Nejadian, S. Preliminary Study on High-Speed Machining of Hybrid Composite Stacks Using Nanoparticle Enhanced MQL. In Proceedings of the International Manufacturing Science and Engineering Conference, Online, 3 September 2020; p. V002T006A034. [Google Scholar]

| Al | Mn | Mg | V | Si | Cr | Ni | Ti | Cu | Zr | Fe | Zn |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 92.3 | 0.31 | 0.01 | 0.088 | 0.06 | 0.003 | 0.00 | 0.062 | 6.35 | 0.12 | 0.12 | 0.02 |

| Yield Str. (Ksi) * | Ultimate. Str. (Ksi) | % Elongation | Hardness (HRBW) | % Conductivity (IACS) ** |

|---|---|---|---|---|

| 53.8 | 68.0 | 9.5 | 74–76 | 35.5–36.0 |

| Tool Name | Manufacturer | Model | Major Specifications |

|---|---|---|---|

| Circular High-Speed Saw | PORTER-CABLE | PCE700 | Speed: 3800 RPM Power: 1.8 KW Size: 14-Inch |

| Saw Wheel/Blade | PORTER-CABLE | A24-R | Size: 14″ × 3/32″ × 1″ Max RPM: 4300 Permashield coating |

| * Laser Thermometer | Extech | 42510A | Temperature Range: −58 to 1200 °F Resolution: 0.1 °F degree |

| * Profilometer/Surface Roughness Tester | Mitutoyo | SJ-310 | Resolution: 0.002 µm (0.078 µin) |

| Automatic Electric Mist Spray | Reditbone | E-01 | Bottle size: 350 mL Flow Rate Range: 4200–460 mL/h |

| Electric Lab Centrifuge | DOC.ROYAL | GH-44 | Speed: 0–4000 RPM Timer Range: 0–60 min or always on Power: 25 W |

| * Digital Scale | Fuzion | PT500 | Weighing Range: 0.03–500 g Resolution: 0.01 g |

| Material | Color | Chemical Composition (in ppm) | Size | Purity | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Nano Alumina (Brand: XF-NANO) | White | Al2O3 | Ca | Fe | K | Na | Mn | Si | 10–15 nm | 99.9% |

| 99.99% | ≤1 | ≤18 | ≤29 | ≤35 | ≤1.2 | ≤16 | ||||

| Color (concentrate) | Straw |

| Odor (concentrate) | Mild amine |

| Form (concentrate) | Liquid |

| Flash point (concentrate) | >160 °C (320 °F) |

| pH (concentrate as range) | 9.2–10.2 |

| pH (typical operating range) | 8.8–9.8 |

| Coolant refractometer factor | 1.2 |

| Lubricant 1 | Flood coolant |

| Lubricant 2 | Pure mineral oil |

| Lubricant 3 | 0.2% Al2O3 nanoparticles |

| Lubricant 4 | 0.5% Al2O3 nanoparticles |

| Lubricant 5 | 1% Al2O3 nanoparticles |

| Lubricant 6 | 2% Al2O3 nanoparticles |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

James, S.; Mazaheri, M. Study on High-Speed Machining of 2219 Aluminum Utilizing Nanoparticle-Enhanced Minimum Quantity Lubrication (MQL) Technique. Surfaces 2023, 6, 29-39. https://doi.org/10.3390/surfaces6010003

James S, Mazaheri M. Study on High-Speed Machining of 2219 Aluminum Utilizing Nanoparticle-Enhanced Minimum Quantity Lubrication (MQL) Technique. Surfaces. 2023; 6(1):29-39. https://doi.org/10.3390/surfaces6010003

Chicago/Turabian StyleJames, Sagil, and Mehrshad Mazaheri. 2023. "Study on High-Speed Machining of 2219 Aluminum Utilizing Nanoparticle-Enhanced Minimum Quantity Lubrication (MQL) Technique" Surfaces 6, no. 1: 29-39. https://doi.org/10.3390/surfaces6010003

APA StyleJames, S., & Mazaheri, M. (2023). Study on High-Speed Machining of 2219 Aluminum Utilizing Nanoparticle-Enhanced Minimum Quantity Lubrication (MQL) Technique. Surfaces, 6(1), 29-39. https://doi.org/10.3390/surfaces6010003