Wood: Modifications, Coatings, Surfaces, and Interfaces

A topical collection in Coatings (ISSN 2079-6412). This collection belongs to the section "Thin Films".

Viewed by 9114Editors

Interests: wood processing; wood modification; discolorations of wood; coatings

Special Issues, Collections and Topics in MDPI journals

Interests: wood technology; adhesives and lacquer products; wood-based materials; technology; wood gluing; wood finishing

Special Issues, Collections and Topics in MDPI journals

Topical Collection Information

Dear Colleagues,

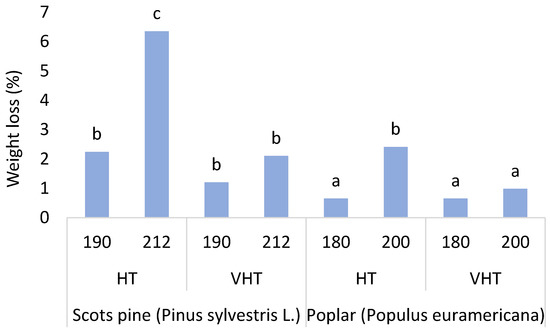

Wood has been used for centuries for many reasons due to its fibrous nature. It’s a raw material that can be used in indoor applications and, if treated efficiently, in outdoor application as well. However, wood has two main disadvantages which restrict its wider use: (1) susceptible to microbial or fungal degration/corrosion and (2) dimensional instability when subjected to a varied moisture content.

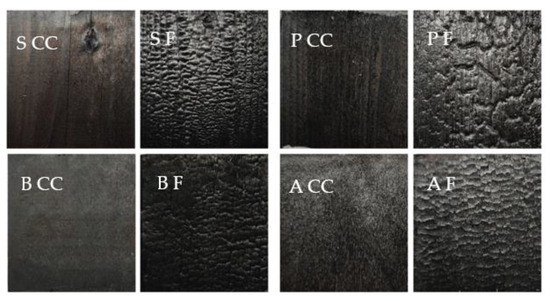

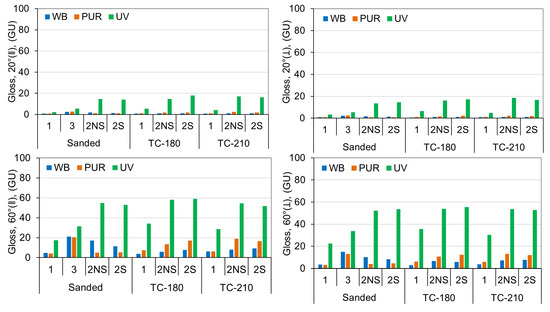

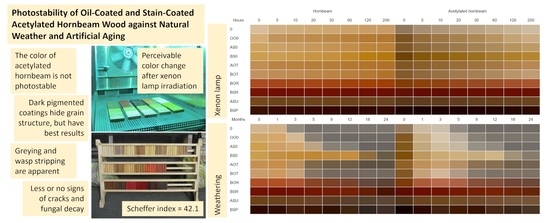

In light of these aspects, the preservation of wood quality is crucial in increasing its lifetime. From a practical point of view, the durability of protected surfaces to different factors is important. The most popular methods for wood preservation are heat treatment, impregnation, chemical modification and impregnation, or/and finishing. Among them, coatings and surface/interface modification are hot topics in recent years and are often discussed in many scientific groups. Some of the results from this scholarly activity have been presented in the Coatings journal.

This Topical Collection covers coatings, surfaces, and interfaces in the broader sense on wood science. Topics of interest include, but are not limited to, the following:

- exterior wood coatings;

- interior wood coatings;

- wood modification;

- wood finishing;

- weathering performance;

- UV cure coatings;

- engineered wood products;

- protection of ancient wooden buildings;

- weathering and durability.

Dr. Emilia-Adela Salca

Dr. Tomasz Krystofiak

Collection Editors

Manuscript Submission Information

Manuscripts should be submitted online at www.mdpi.com by registering and logging in to this website. Once you are registered, click here to go to the submission form. Manuscripts can be submitted until the deadline. All submissions that pass pre-check are peer-reviewed. Accepted papers will be published continuously in the journal (as soon as accepted) and will be listed together on the collection website. Research articles, review articles as well as short communications are invited. For planned papers, a title and short abstract (about 100 words) can be sent to the Editorial Office for announcement on this website.

Submitted manuscripts should not have been published previously, nor be under consideration for publication elsewhere (except conference proceedings papers). All manuscripts are thoroughly refereed through a single-blind peer-review process. A guide for authors and other relevant information for submission of manuscripts is available on the Instructions for Authors page. Coatings is an international peer-reviewed open access monthly journal published by MDPI.

Please visit the Instructions for Authors page before submitting a manuscript. The Article Processing Charge (APC) for publication in this open access journal is 2600 CHF (Swiss Francs). Submitted papers should be well formatted and use good English. Authors may use MDPI's English editing service prior to publication or during author revisions.