Micromixers: Analysis, Design and Fabrication

A topical collection in Micromachines (ISSN 2072-666X). This collection belongs to the section "A:Physics".

Viewed by 18467

Share This Topical Collection

Editor

Topical Collection Information

Dear Colleagues,

Micromixers are an important component in micro-total analysis systems (μTAS) and lab-on-a-chip platforms which are widely used for sample preparation and analysis, drug delivery, and biological and chemical synthesis. The successful operation of microfluidic devices requires fast and adequate mixing, but mixing is a challenging task due to the laminar feature of flow at the microscale. Mixing in laminar flows relies on diffusion and requires a longer channel to achieve complete mixing due to the slow process compared with that in turbulent flows. Hence, it is crucial to overcome this challenge to improve the mixing performance. Based on their mixing mechanism, micromixers are classified into two types: active and passive. Passive micromixers are easy to fabricate and generally use geometry modification to cause chaotic advection or lamination to promote the mixing of fluid samples, unlike active micromixers, which use moving parts or some external agitation/energy for the mixing. This collection will highlight recent developments within new mechanisms, numerical and/or experimental mixing analysis, design, and fabrication of various micromixers.

Prof. Dr. Kwang-Yong Kim

Collection Editor

Manuscript Submission Information

Manuscripts should be submitted online at www.mdpi.com by registering and logging in to this website. Once you are registered, click here to go to the submission form. Manuscripts can be submitted until the deadline. All submissions that pass pre-check are peer-reviewed. Accepted papers will be published continuously in the journal (as soon as accepted) and will be listed together on the collection website. Research articles, review articles as well as short communications are invited. For planned papers, a title and short abstract (about 100 words) can be sent to the Editorial Office for announcement on this website.

Submitted manuscripts should not have been published previously, nor be under consideration for publication elsewhere (except conference proceedings papers). All manuscripts are thoroughly refereed through a single-blind peer-review process. A guide for authors and other relevant information for submission of manuscripts is available on the Instructions for Authors page. Micromachines is an international peer-reviewed open access monthly journal published by MDPI.

Please visit the Instructions for Authors page before submitting a manuscript.

The Article Processing Charge (APC) for publication in this open access journal is 2600 CHF (Swiss Francs).

Submitted papers should be well formatted and use good English. Authors may use MDPI's

English editing service prior to publication or during author revisions.

Keywords

- micromixer

- mixing

- microfluidic device

- analysis

- design

- fabrication

Published Papers (11 papers)

Open AccessArticle

Analysis of Entropy Generation for Mass and Thermal Mixing Behaviors in Non-Newtonian Nano-Fluids of a Crossing Micromixer

by

Ayache Lakhdar, Jribi Skander, Naas Toufik Tayeb, Telha Mostefa, Shakhawat Hossain and Sun Min Kim

Viewed by 488

Abstract

This work’s objective is to investigate the laminar steady flow characteristics of non-Newtonian nano-fluids in a developed chaotic microdevice known as a two-layer crossing channels micromixer (TLCCM). The continuity equation, the 3D momentum equations, and the species transport equations have been solved numerically

[...] Read more.

This work’s objective is to investigate the laminar steady flow characteristics of non-Newtonian nano-fluids in a developed chaotic microdevice known as a two-layer crossing channels micromixer (TLCCM). The continuity equation, the 3D momentum equations, and the species transport equations have been solved numerically at low Reynolds numbers with the commercial CFD software Fluent. A procedure has been verified for non-Newtonian flow in studied geometry that is continuously heated. Secondary flows and thermal mixing performance with two distinct intake temperatures of nano-shear thinning fluids is involved. For an extensive range of Reynolds numbers (0.1 to 25), the impact of fluid characteristics and various concentrations of Al

2O

3 nanoparticles on thermal mixing capabilities and pressure drop were investigated. The simulation for performance enhancement was run using a power-law index (

n) at intervals of different nanoparticle concentrations (0.5 to 5%). At high nano-fluid concentrations, our research findings indicate that hydrodynamic and thermal performances are considerably improved for all Reynolds numbers because of the strong chaotic flow. The mass fraction visualization shows that the suggested design has a fast thermal mixing rate that approaches 0.99%. As a consequence of the thermal and hydrodynamic processes, under the effect of chaotic advection, the creation of entropy governs the second law of thermodynamics. Thus, with the least amount of friction and thermal irreversibilities compared to other studied geometries, the TLCCM arrangement confirmed a significant enhancement in the mixing performance.

Full article

►▼

Show Figures

Open AccessArticle

Independent Concentration Manipulation Using Sidewall-Driven Micromixer

by

Toshio Takayama and Hayato Maki

Viewed by 911

Abstract

Lab-on-a-chip technology has been developed to streamline biochemical experiments by providing experimental environments in microscopic areas. Due to the difficulty of mixing chemicals in such small channels, various micromixers have been created. Our proposed sidewall-driven micromixer offers easy fabrication and precise control over

[...] Read more.

Lab-on-a-chip technology has been developed to streamline biochemical experiments by providing experimental environments in microscopic areas. Due to the difficulty of mixing chemicals in such small channels, various micromixers have been created. Our proposed sidewall-driven micromixer offers easy fabrication and precise control over mixing concentrations. In our previous study, we successfully generated concentration gradients by simultaneously mixing multiple chambers using a single actuator. However, it is not possible to mix different chemicals in each chamber. In this study, we developed a sidewall-driven micromixer that enables independent mixing in each chamber by installing one actuator per chamber. Experimental results showed that different conditions were achieved in each chamber using both microbead-mixture water and colored water. Thus, this mixer can be used to manipulate concentrations regardless of whether the mixing targets are particles or fluids.

Full article

►▼

Show Figures

Open AccessArticle

Design and Mixing Analysis of a Passive Micromixer with Circulation Promoters

by

Makhsuda Juraeva and Dong-Jin Kang

Cited by 1 | Viewed by 982

Abstract

A novel passive micromixer equipped with circulation promoters is proposed, and its mixing performance is simulated over a broad range of Reynolds numbers (

). To evaluate the effectiveness of the circulation promoters, three different configurations are

[...] Read more.

A novel passive micromixer equipped with circulation promoters is proposed, and its mixing performance is simulated over a broad range of Reynolds numbers (

). To evaluate the effectiveness of the circulation promoters, three different configurations are analyzed in terms of the degree of mixing (DOM) at the outlet and the associated pressure drop. Compared to other typical passive micromixers, the circulation promoter is shown to significantly enhance mixing performance. Among the three configurations of circulation promoters, Case 3 demonstrates the best performance, with a DOM exceeding 0.96 across the entire range of Reynolds numbers. At Re = 1, the DOM of Case 3 is 3.7 times larger than that of a modified Tesla micromixer, while maintaining a comparable pressure drop. The mixing enhancement of the present micromixer is particularly significant in the low and intermediate ranges of Reynolds numbers (

In the low range of Reynolds numbers (

), the mixing enhancement is primarily due to circulation promoters directing fluid flow from a concave wall to the opposite convex wall. In the intermediate range of Reynolds numbers (

), the mixing enhancement results from fluid flowing from one concave wall to another concave wall on the opposite side.

Full article

►▼

Show Figures

Open AccessArticle

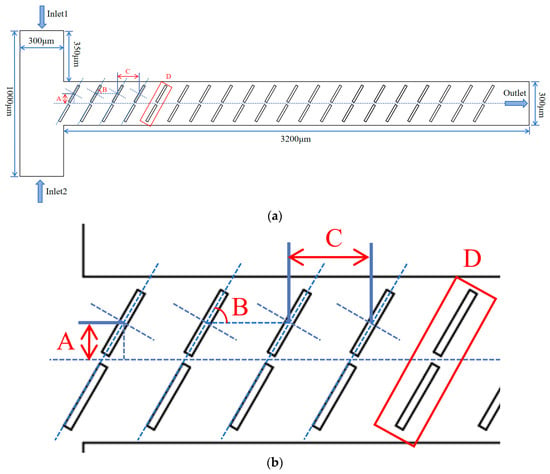

Mixing Performance Analysis and Optimal Design of a Novel Passive Baffle Micromixer

by

Yiwen Zheng, Yu Liu, Chaojun Tang, Bo Liu, Hongyuan Zou, Wei Li and Hongpeng Zhang

Viewed by 1669

Abstract

Micromixers, as crucial components of microfluidic devices, find widespread applications in the field of biochemistry. Due to the laminar flow in microchannels, mixing is challenging, and it significantly impacts the efficiency of rapid reactions. In this study, numerical simulations of four baffle micromixer

[...] Read more.

Micromixers, as crucial components of microfluidic devices, find widespread applications in the field of biochemistry. Due to the laminar flow in microchannels, mixing is challenging, and it significantly impacts the efficiency of rapid reactions. In this study, numerical simulations of four baffle micromixer structures were carried out at different Reynolds numbers (Re = 0.1, Re = 1, Re = 10, and Re = 100) in order to investigate the flow characteristics and mixing mechanism under different structures and optimize the micromixer by varying the vertical displacement of the baffle, the rotation angle, the horizontal spacing, and the number of baffle, and by taking into account the mixing intensity and pressure drop. The results indicated that the optimal mixing efficiency was achieved when the baffle’s vertical displacement was 90 μm, the baffle angle was 60°, the horizontal spacing was 130 μm, and there were 20 sets of baffles. At Re = 0.1, the mixing efficiency reached 99.4%, and, as Re increased, the mixing efficiency showed a trend of, first, decreasing and then increasing. At Re = 100, the mixing efficiency was 97.2%. Through simulation analysis of the mixing process, the structure of the baffle-type micromixer was effectively improved, contributing to enhanced fluid mixing efficiency and reaction speed.

Full article

►▼

Show Figures

Open AccessArticle

A Novel Micromixer That Exploits Electrokinetic Vortices Generated on a Janus Droplet Surface

by

Chengfa Wang and Yehui He

Viewed by 1436

Abstract

Micromixers play a crucial role as essential components in microfluidic analysis systems. This paper introduces a novel micromixer designed by harnessing electrokinetic vortices arising on the surface of a Janus droplet within a microchannel. The Janus droplet is characterized by different polarities of

[...] Read more.

Micromixers play a crucial role as essential components in microfluidic analysis systems. This paper introduces a novel micromixer designed by harnessing electrokinetic vortices arising on the surface of a Janus droplet within a microchannel. The Janus droplet is characterized by different polarities of charges on its two sides (upstream part and downstream part). In the presence of a direct current electric field, the droplet’s surface generates electroosmotic flows in opposite directions, resulting in the formation of vortices and facilitating solution mixing. Results from numerical simulations suggest that a better mixing performance of the micromixer is associated with both a higher absolute value of the zeta potential ratio between the downstream and upstream surfaces of the Janus droplet and a larger downstream surface area. Additionally, this study reveals that microchannel dimensions significantly influence the performance of the micromixer. Smaller microchannel widths and heights correspond to a larger mixing index for the micromixer. The micromixer presented in this study features a simple structure, easy fabrication, and holds promising application potential.

Full article

►▼

Show Figures

Open AccessArticle

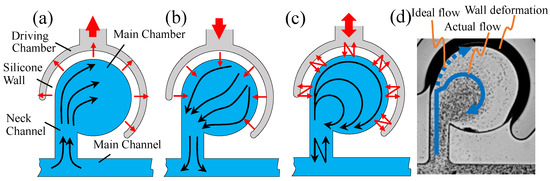

Design Optimization Method for Large-Size Sidewall-Driven Micromixer to Generate Powerful Swirling Flow

by

Daichi Yamamoto and Toshio Takayama

Viewed by 1192

Abstract

Microfluidic devices, which miniaturize cell culture and chemical experiments from lab-scale to microchip dimensions, have gained significant attention in recent years. Extensive research has been conducted on microfluidic mixers, which facilitate the mixing and agitation of chemicals. The “Sidewall-Driven Micromixer” that we are

[...] Read more.

Microfluidic devices, which miniaturize cell culture and chemical experiments from lab-scale to microchip dimensions, have gained significant attention in recent years. Extensive research has been conducted on microfluidic mixers, which facilitate the mixing and agitation of chemicals. The “Sidewall-Driven Micromixer” that we are currently developing employs a unique mechanism; it induces a swirling flow within the main chamber by vibrating the silicone wall situated between the main and driving chambers using pressure fluctuations. In an earlier study, we found that Sidewall-Driven Micromixers of a size suitable for small cells could indeed produce this swirling flow. Furthermore, we successfully established concentration gradients within each mixer. However, when attempting to upscale the mixer while maintaining conventional proportions to accommodate larger cell aggregates such as spheroids, the desired swirling flow was not achieved. To address this challenge, we made adjustments to the wall dimensions, aiming to amplify wall deformation and thereby enhance the mixer’s driving force. Concurrently, we modified the mixer’s shape to ensure that the increased wall deformation would not hinder the fluid flow. These alterations not only improved the mixer’s performance but also provided valuable insights for positioning the mixer’s neck channel, considering the extent of wall deformation.

Full article

►▼

Show Figures

Open AccessArticle

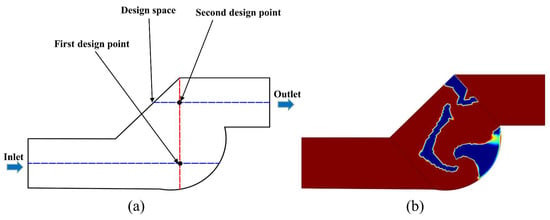

Topology-Optimized Micromixer Design with Enhanced Reverse Flow to Increase Mixing Efficiency

by

Qiang Fu, Zenghao Liu, Shuaiqi Cao, Zhe Wang and Guojun Liu

Cited by 4 | Viewed by 1364

Abstract

In this work, a serpentine mixing unit model based on topology optimization is proposed to enhance the reverse flow in both horizontal and vertical directions. The increase in reverse flow in both directions can enhance the chaotic advection phenomenon, leading to a rapid

[...] Read more.

In this work, a serpentine mixing unit model based on topology optimization is proposed to enhance the reverse flow in both horizontal and vertical directions. The increase in reverse flow in both directions can enhance the chaotic advection phenomenon, leading to a rapid increase in the mixing index. The proposed mixing unit model is applied in a T-shaped micromixer to create a new micromixer design, named TOD. Numerical simulations of TOD are performed using Comsol Multiphysics software to analyze the characteristics of the liquid flow, mixing surface, and pressure drop. The simulation results confirm that TOD has an outstanding mixing performance. By widening the surface area of contact and enhancing the chaotic advection phenomenon, TOD shows an excellent mixing performance at both a high and low Reynolds number, making it a promising micromixer design. For Re > 5, the mixing indexes of TOD are all beyond 90%.

Full article

►▼

Show Figures

Open AccessArticle

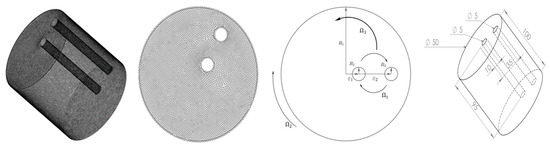

A Flexible Kenics Mixer for Applications in Liquid Chromatography

by

Prachet Dsk, Petru S. Fodor and Chandrasekhar R. Kothapalli

Viewed by 1544

Abstract

Miniaturization of liquid chromatography could help enhance sensitivity, reduce solvent usage, and detect small quantities of peptides. However, it demands better sample homogenization of the mobile phase. We here developed a mixer design based on the inline Kenics geometry, consisting of a periodic

[...] Read more.

Miniaturization of liquid chromatography could help enhance sensitivity, reduce solvent usage, and detect small quantities of peptides. However, it demands better sample homogenization of the mobile phase. We here developed a mixer design based on the inline Kenics geometry, consisting of a periodic arrangement of twisted blades placed inside a cylindrical capillary that repeatedly cut and stack fluid elements to achieve rapid mixing in laminar flow regimes. The mixer design was optimized with respect to the twist angle and aspect ratio of the mixing units to achieve complete mixing at minimum pressure load cost. Results suggest that for optimal designs, for a mixer volume of ~70 μL, complete mixing is achieved within a distance smaller than 4 cm for a broad set of flow rate conditions ranging from 75 μL·min

−1 to 7.5 mL·min

−1. A salient feature that we introduce and test for the first time is the physical flexibility of the cylindrical capillary. The performance of the design remained robust when the mixing section was not rigid and bent in different topologies, as well as when changing the chemical composition of the mobile phase used.

Full article

►▼

Show Figures

Open AccessArticle

A Modified-Herringbone Micromixer for Assessing Zebrafish Sperm (MAGS)

by

Jorge A. Belgodere, Mustafa Alam, Valentino E. Browning, Jason Eades, Jack North, Julie A. Armand, Yue Liu, Terrence R. Tiersch and W. Todd Monroe

Cited by 1 | Viewed by 1990

Abstract

Sperm motility analysis of aquatic model species is important yet challenging due to the small sample volume, the necessity to activate with water, and the short duration of motility. To achieve standardization of sperm activation, microfluidic mixers have shown improved reproducibility over activation

[...] Read more.

Sperm motility analysis of aquatic model species is important yet challenging due to the small sample volume, the necessity to activate with water, and the short duration of motility. To achieve standardization of sperm activation, microfluidic mixers have shown improved reproducibility over activation by hand, but challenges remain in optimizing and simplifying the use of these microdevices for greater adoption. The device described herein incorporates a novel micromixer geometry that aligns two sperm inlet streams with modified herringbone structures that split and recombine the sample at a 1:6 dilution with water to achieve rapid and consistent initiation of motility. The polydimethylsiloxane (PDMS) chip can be operated in a positive or negative pressure configuration, allowing a simple micropipettor to draw samples into the chip and rapidly stop the flow. The device was optimized to not only activate zebrafish sperm but also enables practical use with standard computer-assisted sperm analysis (CASA) systems. The micromixer geometry could be modified for other aquatic species with differing cell sizes and adopted for an open hardware approach using 3D resin printing where users could revise, fabricate, and share designs to improve standardization and reproducibility across laboratories and repositories.

Full article

►▼

Show Figures

Open AccessArticle

Serpentine Micromixers Using Extensional Mixing Elements

by

George Tomaras, Chandrasekhar R. Kothapalli and Petru S. Fodor

Cited by 5 | Viewed by 2478

Abstract

Computational fluid dynamics modeling was used to characterize the effect of the integration of constrictions defined by the vertices of hyperbolas on the flow structure in microfluidic serpentine channels. In the new topology, the Dean flows characteristic of the pressure-driven fluid motion along

[...] Read more.

Computational fluid dynamics modeling was used to characterize the effect of the integration of constrictions defined by the vertices of hyperbolas on the flow structure in microfluidic serpentine channels. In the new topology, the Dean flows characteristic of the pressure-driven fluid motion along curved channels are combined with elongational flows and asymmetric longitudinal eddies that develop in the constriction region. The resulting complex flow structure is characterized by folding and stretching of the fluid volumes, which can promote enhanced mixing. Optimization of the geometrical parameters defining the constriction region allows for the development of an efficient micromixer topology that shows robust enhanced performance across a broad range of Reynolds numbers from

Re = 1 to 100.

Full article

►▼

Show Figures

Open AccessArticle

Kinematic Properties of a Twisted Double Planetary Chaotic Mixer: A Three-Dimensional Numerical Investigation

by

Telha Mostefa, Aissaoui Djamel Eddine, Naas Toufik Tayeb, Shakhawat Hossain, Arifur Rahman, Bachiri Mohamed and Kwang-Yong Kim

Cited by 1 | Viewed by 2364

Abstract

In this study, a numerical investigation based on the CFD method is carried out to study the unsteady laminar flow of Newtonian fluid with a high viscosity in a three-dimensional simulation of a twisted double planetary mixer, which is composed of two agitating

[...] Read more.

In this study, a numerical investigation based on the CFD method is carried out to study the unsteady laminar flow of Newtonian fluid with a high viscosity in a three-dimensional simulation of a twisted double planetary mixer, which is composed of two agitating rods inside a moving tank. The considered stirring protocol is a “Continuous sine squared motion” by using the dynamic mesh model and user-defined functions (UDFs)to define the velocity profiles. The chaotic advection is obtained in our active mixers by the temporal modulation of rotational velocities of the moving walls in order to enhance the mixing of the fluid for a low Reynolds number and a high Peclet number. For this goal, we applied the Poincaré section and Lyapunov exponent as reliable mathematic tools for checking mixing quality by tracking a number of massless particles inside the fluid domain. Additionally, we investigated the development of fluid kinematics proprieties, such as vorticity, helicity, strain rate and elongation rate, at various time periods in order to view the impact of temporal modulation on the flow properties. The results of the mentioned simulation showed that it is possible to obtain a chaotic advection after a relatively short time, which can deeply enhance mixing fluid efficiency.

Full article

►▼

Show Figures