Thermal Characterization of Polymers and Polymer Composites

A topical collection in Polymers (ISSN 2073-4360). This collection belongs to the section "Polymer Analysis and Characterization".

Viewed by 16064Editor

Interests: cold-cured adhesives and matrices for FRP employed in constructions; polymeric nanostructured adhesives and coatings; hydrophobic coatings for stone conservation and wood protection; durability of polymers, adhesives and coatings; eco-efficient materials for construction and cultural heritage

Special Issues, Collections and Topics in MDPI journals

Topical Collection Information

Dear Colleagues,

Thermal analyses (TA) are a set of analytical techniques able to measure and analyze the properties, or their changes, of (synthetic/biobased) polymers, polymeric composites, and of other materials containing a polymeric phase as a function of the temperature (or time) when the material under investigation is subjected to a controlled temperature program.

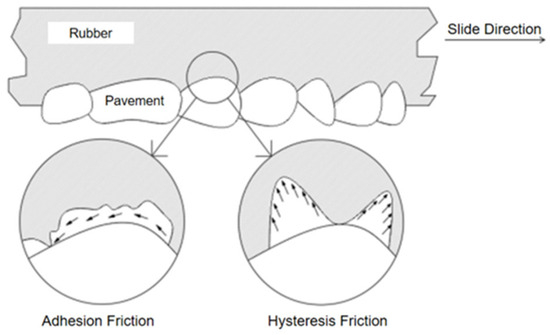

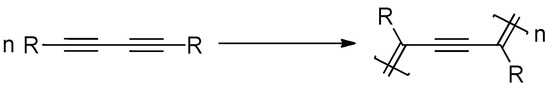

In the field of polymer science, TA represent an extraordinary useful tool to characterize polymeric materials in a simple and fast way and to investigate a wide variety of their properties during thermal events. It is possible to relate these latter properties to the compositional modifications (polymer blends, presence of fillers, additives, plasticizers, etc.) and to the conditions used for their processing, gaining invaluable information for their production, usage, durability, recycling, and degradation.

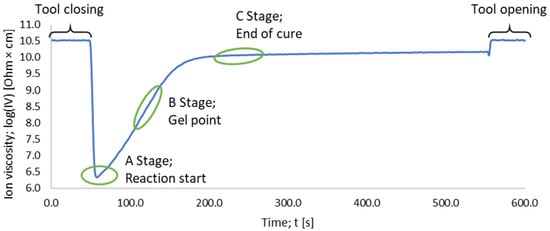

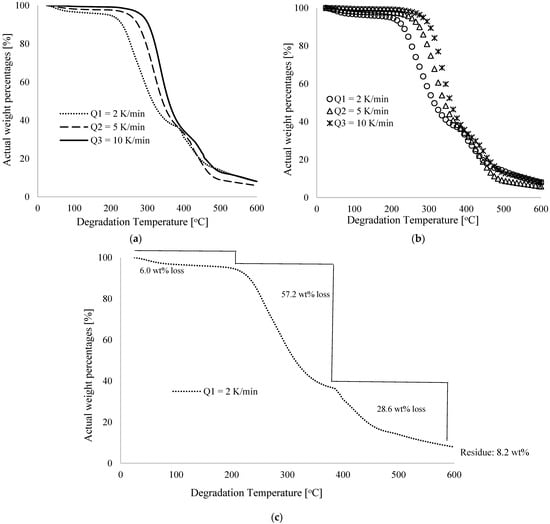

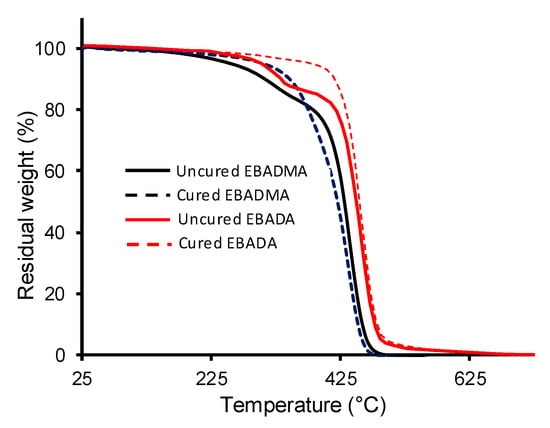

Different thermal analysis methods are available for several examination purposes. Among the most commonly employed TA for polymer characterization, there is differential scanning calorimetry (DSC), differential thermal analysis (DTA), thermogravimetric analysis (TGA), dynamic mechanical thermal analysis (DMTA), thermal mechanical analysis (TMA), and dielectric analysis (DEA).

The described techniques, frequently available in most industrial and research laboratories, also have strong potential and wide versatile applications in emerging fields of polymer research, such as polymer-based nanocomposites, polymers for energy applications, biodegradation of polymers, and high-performance polymer composites.

With TA techniques, it is possible to analyze chemical and physical processes related to thermal effects, including glass transition, melting, crystallization, curing reactions, physical aging, evaporation and decomposition processes, stability, interactions with environmental agents, fire retardancy, viscoelastic effects, volumetric and geometrical modifications, and changes in mechanical properties. Modeling and simulation of complex phenomena can be accomplished on the basis of TA data.

This Topical Collection focuses on the thermal analysis and characterization of polymers and polymer composites, on the information that these techniques can provide for optimal production/use/disposal of such materials, and on novel testing methods proposed to highlight properties and features of traditional as well as innovative polymer materials.

Prof. Dr. Mariaenrica Frigione

Collection Editor

Manuscript Submission Information

Manuscripts should be submitted online at www.mdpi.com by registering and logging in to this website. Once you are registered, click here to go to the submission form. Manuscripts can be submitted until the deadline. All submissions that pass pre-check are peer-reviewed. Accepted papers will be published continuously in the journal (as soon as accepted) and will be listed together on the collection website. Research articles, review articles as well as short communications are invited. For planned papers, a title and short abstract (about 100 words) can be sent to the Editorial Office for announcement on this website.

Submitted manuscripts should not have been published previously, nor be under consideration for publication elsewhere (except conference proceedings papers). All manuscripts are thoroughly refereed through a single-blind peer-review process. A guide for authors and other relevant information for submission of manuscripts is available on the Instructions for Authors page. Polymers is an international peer-reviewed open access semimonthly journal published by MDPI.

Please visit the Instructions for Authors page before submitting a manuscript. The Article Processing Charge (APC) for publication in this open access journal is 2700 CHF (Swiss Francs). Submitted papers should be well formatted and use good English. Authors may use MDPI's English editing service prior to publication or during author revisions.

Keywords

- calorimetry

- differential scanning calorimetry

- differential thermal analysis

- dynamic mechanical thermal analysis

- modeling

- thermal analysis

- thermal characterization

- thermal events

- thermal-mechanical analysis

- thermogravimetric analysis