New Frontiers in Production Engineering

A topical collection in Sustainability (ISSN 2071-1050). This collection belongs to the section "Sustainable Engineering and Science".

Viewed by 82287Editors

Interests: industrial management; lean; six-sigma; processes improvement; safety; sustainability

Special Issues, Collections and Topics in MDPI journals

Interests: tribology; coatings; manufacturing processes

Special Issues, Collections and Topics in MDPI journals

Interests: innovation; innovative technologies; patents; quality management; sustainability

Special Issues, Collections and Topics in MDPI journals

Interests: industrial simulation; manufacturing; industry 4.0

Special Issues, Collections and Topics in MDPI journals

Topical Collection Information

Dear Colleagues,

Climate change is increasingly present in our daily lives. Industry has been one of the main generators of pollution and greenhouse gases, which have led to the situation we are currently facing. Effective efforts are needed to improve production systems in order to minimise their environmental and social impact, without forgetting the economic factor. Tools from various sectors have converged in order to improve this situation. Many tools that promote the reduction in natural resources and their reuse and recovery are tools that also create better conditions for competitiveness.

Smart manufacturing represents the implementation of Industry 4.0 on the manufacturing floor and has the potential to revolutionize the efficiency and responsiveness of production systems. The Internet of Things (IoT), big data, machine learning, cyberphysical systems, virtual/augmented reality, additive manufacturing, and robotics are some of the key disruptive technologies of this revolution, which also converge in aiming to improve safety and ergonomics at work, reduce the consumption of natural resources, and integrate information from various systems, significantly improving competitiveness, quality, safety, and environmental sustainability.

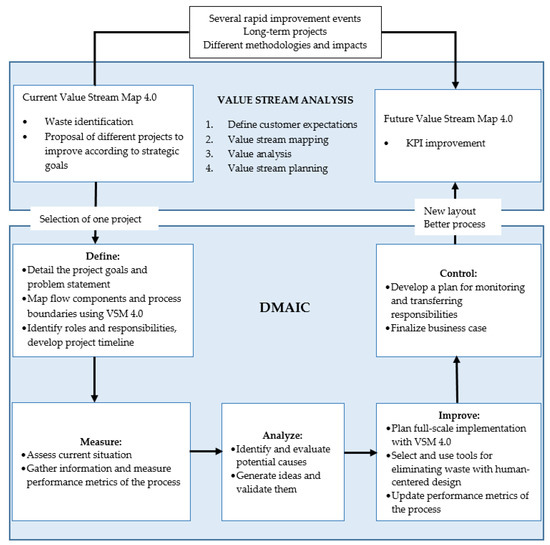

Lean-green manufacturing combines lean practices focused on customers’ demand, and green practices focused on reducing the manufacturing environmental impact. Lean and Six-Sigma promotes better safety conditions and eliminates waste in terms of materials and other natural resources, such as energy. In fact, methodologies such as DMAIC and DMADV also promote continuous improvement, from the product design stage to the various iterations aimed at improving its quality and manufacturing process toward value creation and, simultaneously, sustainability.

The Physical Internet is the new supply chain and logistics paradigm, supported on I4.0 technologies, aiming to improve economic, environmental, and societal efficiency and sustainability.

This Special Issue intends to collect and disseminate cutting-edge research with very high quality that is able to bring new insights into how Industry 4.0 can contribute to a more sustainable production environment. The Special Issue also intends to collect practical insights through highly relevant case studies able to bring new ideas to scholars and industry able to effectively reduce concerns about sustainability, environmental impacts, safety, and quality, maintaining competitiveness. Disseminating these cutting-edge studies, this Special Issue intends to extend the previous knowledge in deeply researched items, such as Lean and Six-Sigma, regarding the new paradigms of Industry 4.0, making the corresponding linkage to sustainable production.

Thus, this Special Issue on “New Frontiers in Production Engineering” aims to collect and disseminate cutting-edge research applied to industrial processes and systems with the main focus in Industry 4.0, or smart manufacturing, in Sustainability. The scope of this Special Issue covers but is not limited to the following topics:

- Lean Production and Industry 4.0

- Six-Sigma in Industry 4.0

- Quality in Industry 4.0

- Safety in Industry 4.0

- Sustainability in manufacturing

- Reduce, reuse, recycle, recover

- Lean-green

- Cleaner production

- Green automation

- Energy saving

- Sustainable smart manufacturing

- Sustainable maintenance

- Maintenance in Industry 4.0

- Logistics in Industry 4.0

- Manufacturing simulation and optimization

- Process digitalization

- Circular Economy

- Integrated management systems

- Innovation

- Value creation

- Simulation in Industry 4.0

- Physical Internet

- Education for Sustainability/Education 4.0

Prof. Dr. José Carlos Sá

Prof. Dr. Francisco J. G. Silva

Prof. Dr. Gilberto Santos

Prof. Dr. Luís Pinto Ferreira

Collection Editors

Manuscript Submission Information

Manuscripts should be submitted online at www.mdpi.com by registering and logging in to this website. Once you are registered, click here to go to the submission form. Manuscripts can be submitted until the deadline. All submissions that pass pre-check are peer-reviewed. Accepted papers will be published continuously in the journal (as soon as accepted) and will be listed together on the collection website. Research articles, review articles as well as short communications are invited. For planned papers, a title and short abstract (about 100 words) can be sent to the Editorial Office for announcement on this website.

Submitted manuscripts should not have been published previously, nor be under consideration for publication elsewhere (except conference proceedings papers). All manuscripts are thoroughly refereed through a single-blind peer-review process. A guide for authors and other relevant information for submission of manuscripts is available on the Instructions for Authors page. Sustainability is an international peer-reviewed open access semimonthly journal published by MDPI.

Please visit the Instructions for Authors page before submitting a manuscript. The Article Processing Charge (APC) for publication in this open access journal is 2400 CHF (Swiss Francs). Submitted papers should be well formatted and use good English. Authors may use MDPI's English editing service prior to publication or during author revisions.

Keywords

- manufacturing

- smart manufacturing

- automated production

- Industry 4.0

- lean

- green

- cleaner production

- lean safety

- sustainability

- logistics

- sustainable maintenance

- safety

- Six-Sigma

- quality

- innovation

- value creation

- manufacturing simulation