Sustainability in Geotechnics: The Use of Environmentally Friendly Materials

Printed Edition Available!

A printed edition of this Special Issue is available

here.

Share This Topical Collection

Editor

Dr. Castorina Silva Vieira

Dr. Castorina Silva Vieira

Dr. Castorina Silva Vieira

Dr. Castorina Silva Vieira

E-Mail

Website

Guest Editor

Faculty of Engineering, University of Porto, 4099-002 Porto, Portugal

Interests: sustainable geotechnics; management of construction and demolition waste; construction and demolition recycled materials; geosynthetic reinforced soil structures; soil–geosynthetic interaction; seismic behavior of geosynthetic reinforced systems

Topical Collection Information

Dear Colleagues,

Currently, one of the biggest challenges facing civil engineers is the design and construction of sustainable structures and infrastructures. Geotechnical engineering, as a branch of civil engineering, can significantly contribute to sustainable development in the construction industry implementing environmentally-friendly and cost-effective solutions.

The need to reduce the exploitation of nonrenewable resources is unquestionable today. Moreover, the increase in waste valorization and reuse of waste materials are undoubtedly important steps forward for environmental sustainability. Geotechnical design being part of typical civil engineering projects can play a major role in the sustainability of built environment. For all of these reasons, this Special Issue has been proposed, focusing on the use of environmentally-friendly materials in geotechnical solutions, highlighting the relevance of geotechnics in reducing our carbon footprint.

The purpose of this Special Issue of Sustainability is to collect and publish original research papers pointing out the use of sustainable materials in geotechnics.

Dr. Castorina Silva Vieira

Guest Editor

Manuscript Submission Information

Manuscripts should be submitted online at www.mdpi.com by registering and logging in to this website. Once you are registered, click here to go to the submission form. Manuscripts can be submitted until the deadline. All submissions that pass pre-check are peer-reviewed. Accepted papers will be published continuously in the journal (as soon as accepted) and will be listed together on the collection website. Research articles, review articles as well as short communications are invited. For planned papers, a title and short abstract (about 100 words) can be sent to the Editorial Office for announcement on this website.

Submitted manuscripts should not have been published previously, nor be under consideration for publication elsewhere (except conference proceedings papers). All manuscripts are thoroughly refereed through a single-blind peer-review process. A guide for authors and other relevant information for submission of manuscripts is available on the Instructions for Authors page. Sustainability is an international peer-reviewed open access semimonthly journal published by MDPI.

Please visit the Instructions for Authors page before submitting a manuscript.

The Article Processing Charge (APC) for publication in this open access journal is 2400 CHF (Swiss Francs).

Submitted papers should be well formatted and use good English. Authors may use MDPI's

English editing service prior to publication or during author revisions.

Keywords

- Sustainable geotechnics

- Sustainable reuse of waste materials

- Environmentally friendly geotechnical materials

- Construction and demolition waste

- Recycled aggregates

- Eco-friendly ground improvement techniques

- Industrial wastes for soil stabilization

- Sustainable solutions using geosynthetics

Published Papers (30 papers)

Open AccessArticle

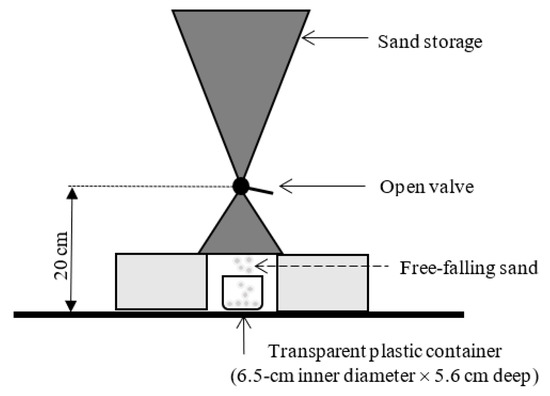

Enzymatic-Induced Calcite Precipitation (EICP) Method for Improving Hydraulic Erosion Resistance of Surface Sand Layer: A Laboratory Investigation

by

Seyed Mohammad Ali Zomorodian, Sodabeh Nikbakht, Hamideh Ghaffari and Brendan C. O’Kelly

Cited by 7 | Viewed by 2576

Abstract

As a bio-inspired calcite precipitation method, bio-grouting via enzymatic-induced calcite precipitation (EICP) uses free urease enzyme to catalyze the urea hydrolysis reaction. This soil stabilization approach is relatively new and insufficiently investigated, especially for applications involving surface layer stabilization of sandy soil deposits

[...] Read more.

As a bio-inspired calcite precipitation method, bio-grouting via enzymatic-induced calcite precipitation (EICP) uses free urease enzyme to catalyze the urea hydrolysis reaction. This soil stabilization approach is relatively new and insufficiently investigated, especially for applications involving surface layer stabilization of sandy soil deposits for increasing hydraulic erosion resistance. This paper presents a laboratory investigation on the surface erosion resistance improvements for compacted medium-gradation quartz sand specimens mediated using 10 different EICP treatment protocols. They involved single- and two-cycle injections of the urease enzyme (activity of 2400 U/L) and 0.5, 0.75, or 1.0-M urea–CaCl

2 cementation solution reagents. The urease enzyme was extracted from watermelon seeds. Erosion rates were determined for various hydraulic shear stresses applied using the erosion function apparatus. The spatial distribution and morphology of precipitated calcite within the pore-void spaces of the crustal sand layer were investigated with a scanning electron microscope. Compared to untreated sand, all 10 investigated EICP treatment protocols produced substantially improved erosion resistance, especially for the higher cementation solution concentration (1.0 M). Of these 10 EICP protocols, a single cycle of enzyme–1.0-M-cementation solutions injections was identified as the more pragmatic option for achieving near-optimum erosion resistance improvements. Highest and lowest amounts (18.8 and 5.0 wt%) of precipitated calcite corresponded to the best and worst performing EICP-treated specimens, although the calcite’s spatial distribution in treated specimens is another important factor.

Full article

►▼

Show Figures

Open AccessArticle

Reducing the Erodibility of Sandy Soils Engineered by Cyanobacteria Inoculation: A Laboratory Investigation

by

Asma Rabiei, Seyed Mohammad Ali Zomorodian and Brendan C. O’Kelly

Cited by 3 | Viewed by 1718

Abstract

Windblown and water-induced erosion cause substantial soil losses worldwide, especially for drylands. Any sustainable management program that increases soil organic matter and improves the stability of the crustal layer could considerably enhance soil productivity and the preservation of erosion-prone land. This paper presents

[...] Read more.

Windblown and water-induced erosion cause substantial soil losses worldwide, especially for drylands. Any sustainable management program that increases soil organic matter and improves the stability of the crustal layer could considerably enhance soil productivity and the preservation of erosion-prone land. This paper presents a laboratory investigation of cyanobacteria-inoculated medium sand and fine sand soils studied for severe runoff conditions that were simulated using an erosion function apparatus (EFA). Loosely deposited sand specimens prepared by air-pluviation were inoculated with a single native filamentous-cyanobacterium strain (investigating both

Nostoc sp. and

Calothrix sp.) and then incubated under high exposure to white light for 32- or 48-day periods. Well-developed bio-crusts were produced on the specimens’ top surface that achieved substantial improvements in erosion resistance, as was demonstrated for a wide range of hydraulic shear stress investigated using EFA experiments. Relative improvements in hydraulic erosion resistance were explained in terms of the nature of the cyanobacteria-developed microstructures (cyanobacteria filament infiltration of pore-void spaces and exopolysaccharide excretion), as were observed by scanning electron microscope examinations. The developed microstructure depended on the cyanobacterium strain employed and the nominal pore-void sizes that are related to the sand gradation and density state. The encouraging findings of this experimental investigation suggest a tailored approach (i.e., employing a suitable native cyanobacterium strain chosen for its compatibility with the soil’s physical properties) could lay the basis for developing a novel technology for soil protection.

Full article

►▼

Show Figures

Open AccessArticle

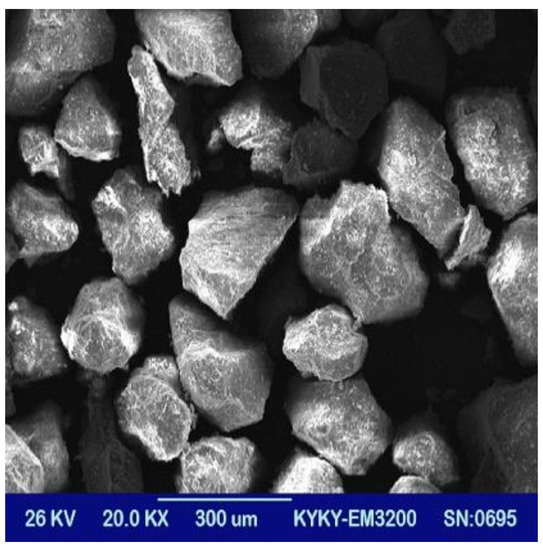

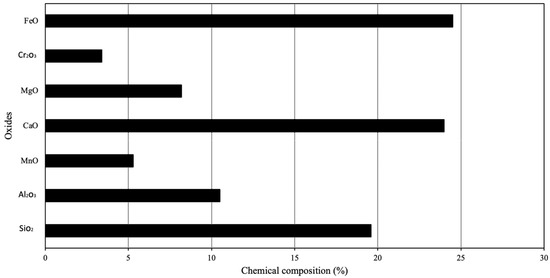

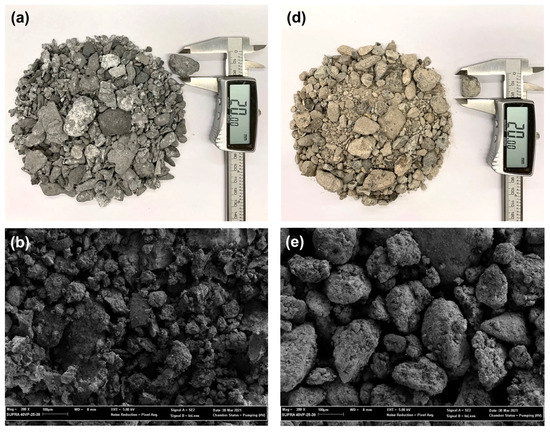

Mechanical Behaviour of Steel Slag–Rubber Mixtures: Laboratory Assessment

by

Rubens Alves, Sara Rios, Eduardo Fortunato, António Viana da Fonseca and Bruno Guimarães Delgado

Cited by 5 | Viewed by 1880

Abstract

Slags and rubber from end-of-life tires represent a liability to the steel and tire industry, causing economic and environmental problems that are difficult to manage. Transport infrastructures can use these industrial by-products instead of extracting natural raw materials, but the adequate mechanical performance

[...] Read more.

Slags and rubber from end-of-life tires represent a liability to the steel and tire industry, causing economic and environmental problems that are difficult to manage. Transport infrastructures can use these industrial by-products instead of extracting natural raw materials, but the adequate mechanical performance of the materials needs to be assured. This paper addresses the mechanical behaviour of slag–rubber mixtures in the laboratory with CBR, monotonic and cyclic triaxial tests. In addition, light falling weight deflectometer tests were also performed in a physical model. The results were analysed to meet technical specifications from Brazil, Portugal and Australia using railway sub-ballast layers, capping layers or road pavement layers as the base and sub-base to identify the applicability range of slag–rubber mixtures for transport infrastructures. Concerning the analysed parameters, it was demonstrated that slag–rubber mixtures can show resilient behaviour and strength adequate for the support layers of transport infrastructures provided that the rubber content is below 5% in weight and that the slag is milled to comply with the grain size distribution ranges available in the technical specifications of the cited countries.

Full article

►▼

Show Figures

Open AccessArticle

Processing Coalmine Overburden Waste Rock as Replacement to Natural Sand: Environmental Sustainability Assessment

by

Anshumali Mishra, Sarat Kumar Das and Krishna R. Reddy

Cited by 10 | Viewed by 2428

Abstract

Waste rock dumped beside a surface coal mining site is termed coalmine overburden (OB) and is found suitable as a construction material. It requires preprocessing to be converted into the final construction material. The waste rock (cradle) processing to the final product (gate)

[...] Read more.

Waste rock dumped beside a surface coal mining site is termed coalmine overburden (OB) and is found suitable as a construction material. It requires preprocessing to be converted into the final construction material. The waste rock (cradle) processing to the final product (gate) involves transportation to the processing plant, crushing, screening, washing, and transportation from the processing plant to the client or project site. Preprocessing will cause environmental impacts. The present study performs a cradle-to-gate environmental impact assessment of waste rock to replace natural sand at a coal mine near Dhanbad, India. Life cycle environmental sustainability is assessed using the SimaPro

® CML-IA baseline V3.07/EU+3 2000 impact method with the Ecoinvent 3.0 inventory. The data used was collected from an operational plant in the nearby area. The layout of a typical processing plant is also proposed in the study. The environmental impacts are reported in terms of abiotic depletion, global warming potential, ozone depletion potential, terrestrial ecotoxicity, human toxicity, eutrophication, acidification, and eutrophication. The manufacture of overburden sand (OBS) using a sustainable fuel and energy mix is more environmentally friendly. The environmental impacts can be drastically reduced if crushing is carried out using an onsite or mobile crushing plant.

Full article

►▼

Show Figures

Open AccessArticle

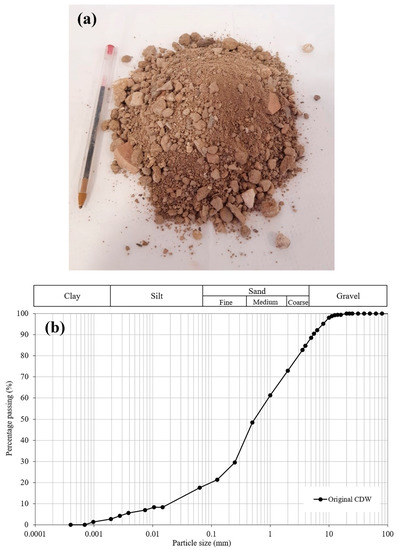

Geomechanical Behaviour of Recycled Construction and Demolition Waste Submitted to Accelerated Wear

by

Marina Paula Secco, Giovani Jordi Bruschi, Castorina S. Vieira and Nuno Cristelo

Cited by 5 | Viewed by 1846

Abstract

The construction industry is one of the most important sectors for economic and social development. However, it is responsible for more than 50% of the depletion of natural resources, for 40% of the energy consumption and construction and demolition waste (CDW) accounting for

[...] Read more.

The construction industry is one of the most important sectors for economic and social development. However, it is responsible for more than 50% of the depletion of natural resources, for 40% of the energy consumption and construction and demolition waste (CDW) accounting for 30–60% of the total municipal solid waste generated worldwide. In this sense, the recycling of CDW is considered a safe alternative to the current trend, which can produce environmental and economic benefits, namely the reduction of the depletion of natural resources and the volume of waste sent to landfills. Some studies have shown promising results in the use of recycled CDW as geotechnical materials. However, the degradation performance induced by the construction procedures and weather conditions on the geotechnical behaviour of recycled CDW is still a research gap, creating an obstacle for its regular use in general engineering practice. This work evaluated the mechanical performance of recycled CDW over time when subjected to wetting–drying degradation cycles under different temperature and pH conditions. The effects of such degradation were then evaluated qualitatively (changes in particle size distribution and Proctor parameters) and quantitatively (stress–strain response and permeability). The results showed that 10 wetting–drying cycles and different compaction energies have no change in the particle size distribution of CDW compared to the original CDW. The shear strength parameters were very similar for the different degradation conditions except when different pH values were used, which may have weakened the grains and decrease the friction angle of the material. Regarding the permeability, all tested samples were classified in the same hydraulic conductivity range (very low) without significant changes induced by the degradation mechanisms.

Full article

►▼

Show Figures

Open AccessArticle

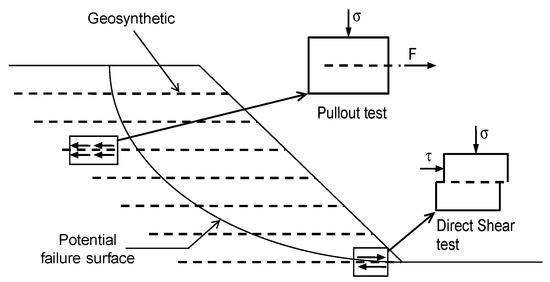

Influence of the Geosynthetic Type and Compaction Conditions on the Pullout Behaviour of Geosynthetics Embedded in Recycled Construction and Demolition Materials

by

Castorina S. Vieira and Paulo M. Pereira

Cited by 11 | Viewed by 2457

Abstract

The effects of the climate change that the planet has been experiencing, and the growing awareness of citizens that natural resources are finite, highlight the inevitability of making society more sustainable. Since the construction industry is responsible for a high consumption of natural

[...] Read more.

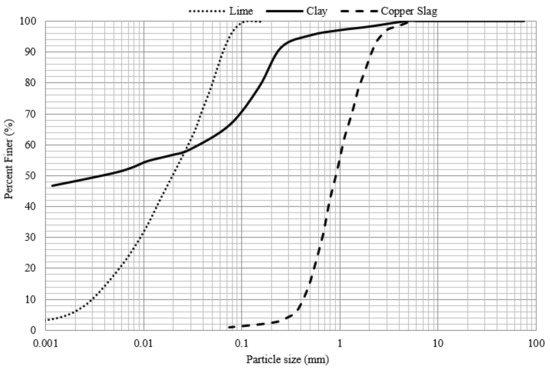

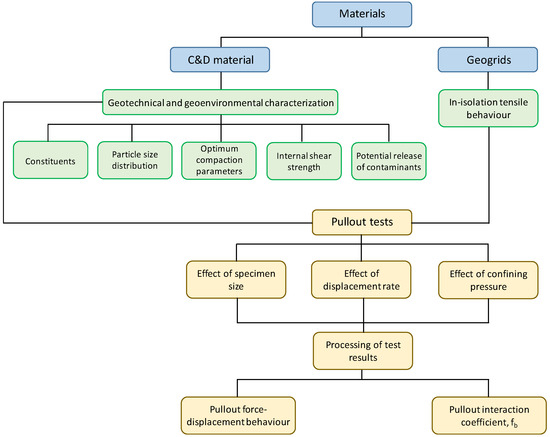

The effects of the climate change that the planet has been experiencing, and the growing awareness of citizens that natural resources are finite, highlight the inevitability of making society more sustainable. Since the construction industry is responsible for a high consumption of natural resources and it simultaneously produces high volumes of waste, it is of great importance to investigate the feasibility of using construction and demolition (C&D) wastes as alternatives to common natural materials. This paper investigates the feasibility of using fine-grain recycled C&D wastes as backfill material of geosynthetic reinforced steep slopes, through a laboratory study focused mainly on the pullout behaviour of two geosynthetics embedded in these alternative materials. The influence of the geosynthetic type, moisture content and compaction degree of the recycled C&D material on the pullout behaviour is assessed and discussed. The physical and mechanical characterization of the filling material is also presented. The pullout test results have pointed out that, although the two geosynthetics have similar tensile strength, the pullout resistance of the geogrid is higher than that of the geotextile and is achieved at lower frontal displacements. While the reduction of the compaction moisture content below the optimum value induced a slight decrease in the geogrid pullout resistance (ranging from 5% to 7%), conversely the pullout capacity of the geotextile increased up to 22%. The compaction degree of the recycled C&D material had the expected effect on the geotextile pullout resistance, reflected in an increase of about 20% when the degree of compaction rose from 80% to 90%. However, the expected trend was not observed on the geogrid pullout behaviour. The pullout interaction coefficient tended to decrease with the variation of the compaction moisture content around the optimum value (maximum decrease of 33% and 16% for the geogrid and the geotextile, respectively) and with an increase in the vertical confining pressure from 10 kPa up to 50 kPa (decrease around 25%). The average value of the pullout interaction coefficient, fb, ranged from 0.61 to 1.09 for the geogrid and from 0.67 to 1.25 for the geotextile. From all these findings it can be concluded that recycled C&D materials can be seen as an environmentally friendly alternatives to the natural resources commonly used in the construction of geosynthetic-reinforced embankments.

Full article

►▼

Show Figures

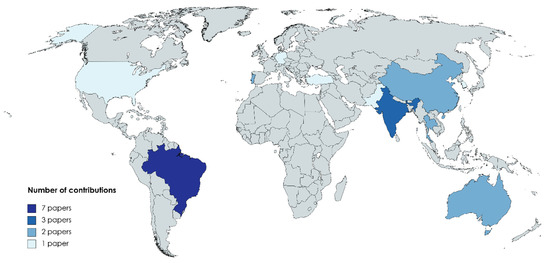

Open AccessEditorial

Sustainability in Geotechnics through the Use of Environmentally Friendly Materials

by

Castorina S. Vieira

Cited by 3 | Viewed by 2502

Abstract

The reduction in the exploitation of non-renewable natural resources is nowadays widely recognized as a pressing need for a more sustainable society [...]

Full article

►▼

Show Figures

Open AccessReview

Sustainable Solutions with Geosynthetics and Alternative Construction Materials—A Review

by

Ennio M. Palmeira, Gregório L. S. Araújo and Eder C. G. Santos

Cited by 22 | Viewed by 5320

Abstract

Geosynthetics have proven to provide sustainable solutions for geotechnical and geoenvironmental problems when used with natural materials. Therefore, the expected benefits to the environment when geosynthetics are associated with unconventional or alternative construction materials will be even greater. This paper addresses the use

[...] Read more.

Geosynthetics have proven to provide sustainable solutions for geotechnical and geoenvironmental problems when used with natural materials. Therefore, the expected benefits to the environment when geosynthetics are associated with unconventional or alternative construction materials will be even greater. This paper addresses the use of geosynthetics with wasted materials in different applications. The potential uses of alternative materials such as wasted tires, construction and demolition wastes, and plastic bottles are presented and discussed considering results from laboratory and field tests. Combinations of geosynthetics and alternative construction materials applied to reinforced soil structures, drainage systems for landfills, barriers, and stabilisation of embankments on soft grounds are discussed. The results show the feasibility of such combinations, and that they are beneficial to the environment and in line with the increasing trend towards a circular economy and sustainable development.

Full article

►▼

Show Figures

Open AccessArticle

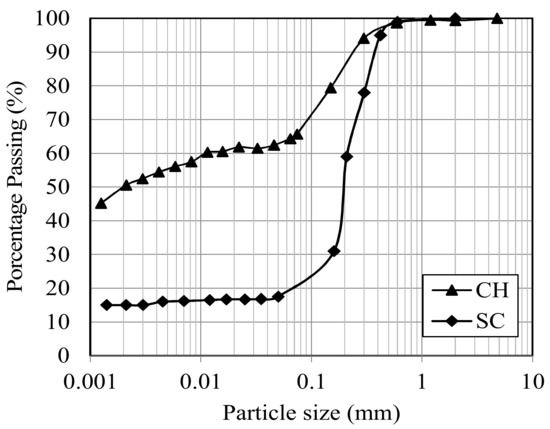

Effect of Polypropylene Fibers on the Shear Strength–Dilation Behavior of Compacted Lateritic Soils

by

Maitê Rocha Silveira, Sabrina Andrade Rocha, Natália de Souza Correia, Roger Augusto Rodrigues, Heraldo Luiz Giacheti and Paulo César Lodi

Cited by 9 | Viewed by 2834

Abstract

The stress–dilatancy relationship for fiber-reinforced soils has been the focus of recent studies. This relationship can be used as a foundation for the development of constitutive models for fiber-reinforced soils. The present study aims to investigate the effect of recycled polypropylene fibers on

[...] Read more.

The stress–dilatancy relationship for fiber-reinforced soils has been the focus of recent studies. This relationship can be used as a foundation for the development of constitutive models for fiber-reinforced soils. The present study aims to investigate the effect of recycled polypropylene fibers on the shear strength–dilation behavior of two lateritic soils using the stress–dilatancy relationship for direct shear tests. Results show that fibers improved the shear strength behavior of the composites, observed by increases in the friction angle. Fibers’ orientation at the sheared interface could be observed. The volumetric change during shearing was altered by the presence of fibers in both soils. Overall, results indicate that the stress–dilatancy relationship is affected by inclusions in the soil mix. Results can be used to implement constitutive modeling for fiber-reinforced soils.

Full article

►▼

Show Figures

Open AccessArticle

Substitute Building Materials in Geogrid-Reinforced Soil Structures

by

Sven Schwerdt, Dominik Mirschel, Tobias Hildebrandt, Max Wilke and Petra Schneider

Cited by 5 | Viewed by 1969

Abstract

The feasibility of substitute building materials (SBMs) in engineering applications was investigated within the project. A geogrid-reinforced soil structure (GRSS) was built using SBM as the fill material as well as vegetated soil for facing and on top of the construction. Four different

[...] Read more.

The feasibility of substitute building materials (SBMs) in engineering applications was investigated within the project. A geogrid-reinforced soil structure (GRSS) was built using SBM as the fill material as well as vegetated soil for facing and on top of the construction. Four different SBMs were used as fill material, namely blast furnace slag (BFS), electric furnace slag (EFS), track ballast (TB), and recycled concrete (RC). For the vegetated soil facing, a mixture of either recycled brick (RB) material or crushed lightweight concrete (LC) mixed with organic soil was used. The soil mechanical and chemical parameters for all materials were determined and assessed. In the next step, a GRSS was built as a pilot application consisting of three geogrid layers with a total height of 1.5 m and a slope angle of 60°. The results of the soil mechanical tests indicate that the used fill materials are similar or even better than primary materials, such as gravel. The results of the chemical tests show that some materials are qualified to be used in engineering constructions without or with minor restrictions. Other materials need a special sealing layer to prevent the material from leakage. The vegetation on the mixed SBM material grew successfully. Several ruderal and pioneer plants could be found even in the first year of the construction. The porous material (RB and LC) provide additional water storage capacity for plants especially during summer and/or heat periods. With regard to the results of the chemical analyses of the greening layers, they are usable under restricted conditions. Here special treatment is necessary. Finally, it can be stated that SBMs are feasible in GRSS, particularly as fill material but also as a mixture for the greenable soil.

Full article

►▼

Show Figures

Open AccessArticle

Improved Mechanical Properties of Cement-Stabilized Soft Clay Using Garnet Residues and Tire-Derived Aggregates for Subgrade Applications

by

Patimapon Sukmak, Gampanart Sukmak, Suksun Horpibulsuk, Sippakarn Kassawat, Apichat Suddeepong and Arul Arulrajah

Cited by 8 | Viewed by 2323

Abstract

The growth of the global economy in recent years has resulted in an increase in infrastructure projects worldwide and consequently, this has led to an increase in the quantity of waste generated. Two recycled materials, namely garnet residues (GR) and tire-derived aggregates (TDA),

[...] Read more.

The growth of the global economy in recent years has resulted in an increase in infrastructure projects worldwide and consequently, this has led to an increase in the quantity of waste generated. Two recycled materials, namely garnet residues (GR) and tire-derived aggregates (TDA), were used to improve mechanical properties of soft clay (SC) subgrade in this study. GR was evaluated as a replacement material in SC prior to Type I Portland cement stabilization. TDA was also studied as an elastic material in cement-stabilized SC–GR. The laboratory tests on the cement–TDA-stabilized SC–GR included unconfined compressive strength (UCS), indirect tensile stress (ITS) and indirect tensile fatigue (ITF). Microstructural analysis on the cement–TDA-stabilized SC–GR was also performed to illustrate the role of GR and TDA contents on the degree of hydration. The UCS of cement-stabilized SC–GR increased when cement content increased from 0% to 2%. Beyond 2% cement content, the UCS development was slightly slower, possibly due to the presence of insufficient water for hydration. The GR reduces the specific surface and particle contacts of the SC–GR blends to be bonded with cementitious products. The optimum SC:GR providing the highest UCS was found to be 90:10 for all cement contents. Increased amounts of GR led to a reduction in UCS values due to its high water absorption, resulting in the insufficient water for the cement hydration. Moreover, the excessive GR replacement ratio weakened the interparticle bond strength due to its smooth and round particles. The TDA addition can enhance the fatigue resistance of the cement-stabilized SC–GR. The maximum fatigue life was found at 2% TDA content. The excessive TDA caused large amounts of micro-cracks in cement–TDA-stabilized SC–GR due to the low adhesion property of TDA. The SC:GR = 90:10, cement content = 2% and TDA content = 2% were suggested as the optimum ingredients. The outcome of this research will promote the usage of GR and TDA to develop a green high-fatigue-resistant subgrade material.

Full article

►▼

Show Figures

Open AccessArticle

Engineering Characteristics and Environmental Risks of Utilizing Recycled Aluminum Salt Slag and Recycled Concrete as a Sustainable Geomaterial

by

Youli Lin, Farshid Maghool, Arul Arulrajah and Suksun Horpibulsuk

Cited by 11 | Viewed by 2879

Abstract

Recycled aluminum salt slag (RASS) is an industrial by-product generated from the melting of white dross and aluminum scraps during the secondary smelter process. Insufficient knowledge in the aspects of engineering characteristics, and the environmental risks associated with RASS, is the primary barrier

[...] Read more.

Recycled aluminum salt slag (RASS) is an industrial by-product generated from the melting of white dross and aluminum scraps during the secondary smelter process. Insufficient knowledge in the aspects of engineering characteristics, and the environmental risks associated with RASS, is the primary barrier to the utilization of RASS as a substitute material for natural quarry materials in the field of geotechnical construction. In this research, comprehensive geotechnical and environmental engineering tests were conducted to evaluate the feasibility of utilizing RASS as a sustainable geomaterial. This was undertaken by comparing the laboratory testing results for RASS with a well-known recycled material, namely recycled concrete aggregate (RCA), and the relevant specifications set forth by the local road authority. The geotechnical engineering assessment included particle size distribution, flakiness index, organic content, pH, particle density, water absorption, modified Proctor compaction, aggregate impact value, Los Angeles (LA) abrasion, hydraulic conductivity, and California bearing ratio (CBR). The CBR results of the RASS samples satisfied the minimum CBR value (>80%) for usage as pavement subbase material in road construction. In addition, the repeated load triaxial (RLT) tests were carried out on the RASS samples to assess the response of the RASS under cyclic loading conditions. Furthermore, a range of chemical tests, consisting of leaching and polycyclic aromatic hydrocarbon tests, were also performed on the RASS to address the environmental concerns. Comparing the chemical test results with the environmental protection authorities’ guidelines provided satisfactory evidence that RASS will not pose any environmental and health issues throughout its service life as a geotechnical construction material.

Full article

►▼

Show Figures

Open AccessArticle

Generalized Interface Shear Strength Equation for Recycled Materials Reinforced with Geogrids

by

Artit Udomchai, Menglim Hoy, Apichat Suddeepong, Amornrit Phuangsombat, Suksun Horpibulsuk, Arul Arulrajah and Nguyen Chi Thanh

Cited by 5 | Viewed by 2225

Abstract

In this research, large direct shear tests were conducted to evaluate the interface shear strength between reclaimed asphalt pavement (RAP) and kenaf geogrid (RAP–geogrid) and to also assess their viability as an environmentally friendly base course material. The influence of factors such as

[...] Read more.

In this research, large direct shear tests were conducted to evaluate the interface shear strength between reclaimed asphalt pavement (RAP) and kenaf geogrid (RAP–geogrid) and to also assess their viability as an environmentally friendly base course material. The influence of factors such as the gradation of RAP particles and aperture sizes of geogrid (

D) on interface shear strength of the RAP–geogrid interface was evaluated under different normal stresses. A critical analysis was conducted on the present and previous test data on geogrids reinforced recycled materials. The

D/

FD, in which

FD is the recycled materials’ particle content finer than the aperture of geogrid, was proposed as a prime parameter governing the interface shear strength. A generalized equation was proposed for predicting the interface shear strength of the form:

α =

a(

D/

FD) +

b, where

α is the interface shear strength coefficient, which is the ratio of the interface shear strength to the shear strength of recycled material, and

a and

b are constants. The constant values of

a and

b were found to be dependent upon types of recycled material, irrespective of types of geogrids. A stepwise procedure to determine variable

a, which is required for analysis and design of geogrids reinforced recycled materials in roads with various gradations was also suggested.

Full article

►▼

Show Figures

Open AccessEditor’s ChoiceArticle

Modeling the Compaction Characteristics of Fine-Grained Soils Blended with Tire-Derived Aggregates

by

Amin Soltani, Mahdieh Azimi and Brendan C. O’Kelly

Cited by 11 | Viewed by 2845

Abstract

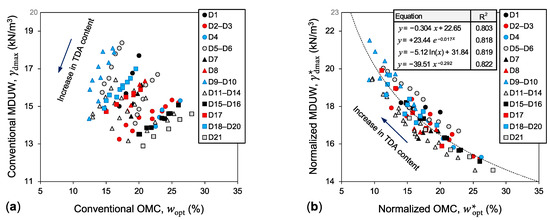

This study aims at modeling the compaction characteristics of fine-grained soils blended with sand-sized (0.075–4.75 mm) recycled tire-derived aggregates (TDAs). Model development and calibration were performed using a large and diverse database of 100 soil–TDA compaction tests (with the TDA-to-soil dry mass ratio

[...] Read more.

This study aims at modeling the compaction characteristics of fine-grained soils blended with sand-sized (0.075–4.75 mm) recycled tire-derived aggregates (TDAs). Model development and calibration were performed using a large and diverse database of 100 soil–TDA compaction tests (with the TDA-to-soil dry mass ratio ≤ 30%) assembled from the literature. Following a comprehensive statistical analysis, it is demonstrated that the optimum moisture content (OMC) and maximum dry unit weight (MDUW) for soil–TDA blends (across different soil types, TDA particle sizes and compaction energy levels) can be expressed as universal power functions of the OMC and MDUW of the unamended soil, along with the soil to soil–TDA specific gravity ratio. Employing the Bland–Altman analysis, the 95% upper and lower (water content) agreement limits between the predicted and measured OMC values were, respectively, obtained as +1.09% and −1.23%, both of which can be considered negligible for practical applications. For the MDUW predictions, these limits were calculated as +0.67 and −0.71 kN/m

3, which (like the OMC) can be deemed acceptable for prediction purposes. Having established the OMC and MDUW of the unamended fine-grained soil, the empirical models proposed in this study offer a practical procedure towards predicting the compaction characteristics of the soil–TDA blends without the hurdles of performing separate laboratory compaction tests, and thus can be employed in practice for preliminary design assessments and/or soil–TDA optimization studies.

Full article

►▼

Show Figures

Open AccessArticle

Examining Energy Consumption and Carbon Emissions of Microbial Induced Carbonate Precipitation Using the Life Cycle Assessment Method

by

Xuejie Deng, Yu Li, Hao Liu, Yile Zhao, Yinchao Yang, Xichen Xu, Xiaohui Cheng and Benjamin de Wit

Cited by 36 | Viewed by 4399

Abstract

Microbial induced carbonate precipitation (MICP) is a new geotechnical engineering technology used to strengthen soils and other materials. Although it is considered to be environmentally friendly, there is a lack of quantitative data and objective evaluation to support conclusions about its environmental impact.

[...] Read more.

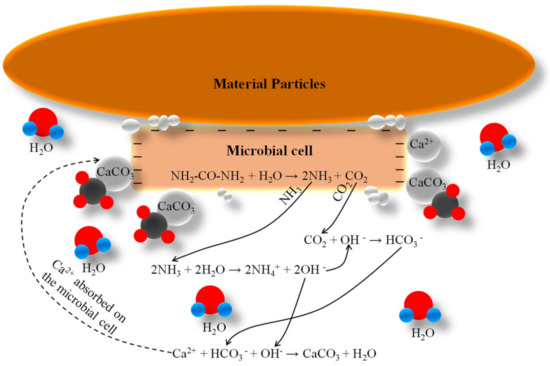

Microbial induced carbonate precipitation (MICP) is a new geotechnical engineering technology used to strengthen soils and other materials. Although it is considered to be environmentally friendly, there is a lack of quantitative data and objective evaluation to support conclusions about its environmental impact. In this paper, the energy consumption and carbon emissions of MICP technology are quantitatively analyzed by using the life cycle assessment (LCA) method. The environmental effects of MICP technology are evaluated from the perspectives of resource consumption and environmental impact. The results show that for each tonne of calcium carbonate produced by MICP technology, 1.8 t standard coal is consumed and 3.4 t CO

2 is produced, among which 80.4% of the carbon emissions and 96% of the energy consumption come from raw materials. Comparing using MICP with cement, lime, and sintered brick, the current MICP application process consumes less non-renewable resources but has a greater environmental impact. The major environmental impact that MICP has is the production of smoke and ash, with secondary impacts being global warming, photochemical ozone creation, acidification, and eutrophication. In five potential application scenarios of MICP, including concrete, sintered brick, lime mortar, mine cemented backfill, and foundation reinforcement, the carbon emissions of MICP are 3 to 7 times greater than the emissions of traditional technologies. The energy consumption is 15 to 23 times. Based on the energy consumption and carbon emissions characteristics of MICP technology at the current condition, suggestions are given for the future research of MICP.

Full article

►▼

Show Figures

Open AccessArticle

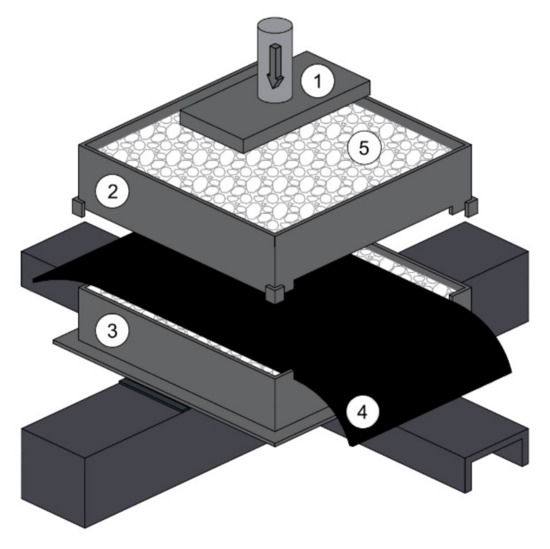

Evaluation of Changes in the Permeability Characteristics of a Geotextile–Polynorbornene Liner for the Prevention of Pollutant Diffusion in Oil-Contaminated Soils

by

Jeongjun Park

Cited by 5 | Viewed by 2356

Abstract

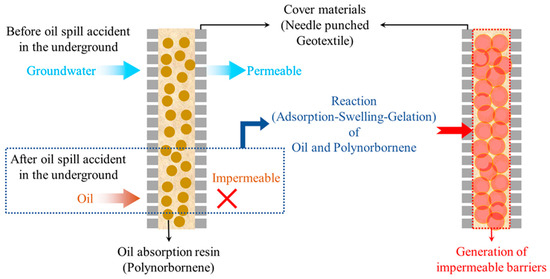

In this study, changes in the permeability characteristics of a geotextile–polynorbornene liner at different oil pollutant contact times were evaluated. Experiments and numerical analyses were performed, and ASTM D5887 and ASTM D6766 were applied as test methods. The test results show that, when

[...] Read more.

In this study, changes in the permeability characteristics of a geotextile–polynorbornene liner at different oil pollutant contact times were evaluated. Experiments and numerical analyses were performed, and ASTM D5887 and ASTM D6766 were applied as test methods. The test results show that, when the pollutant contact time and pressure head were 4 h and 75 kPa, the reaction between the geotextile–polynorbornene liner and the pollutant was almost complete. Moreover, a numerical analysis was used to measure the ratio of the concentration of the pollutant that permeated through the geotextile–polynorbornene liner to the initial pollutant concentration at different pollutant contact times. The ratio was between 70 and 83% after a pollutant contact time of 0.5 h and between 0.1 and 1.0% after 4 h. The test and numerical analysis results confirm that, as a reactive medium, the geotextile–polynorbornene liner can effectively prevent the diffusion of oil pollutants by changing its permeability characteristics.

Full article

►▼

Show Figures

Open AccessArticle

Sustainability Benefits Assessment of Metakaolin-Based Geopolymer Treatment of High Plasticity Clay

by

Rinu Samuel, Anand J. Puppala and Miladin Radovic

Cited by 27 | Viewed by 3658

Abstract

Expansive soils are prevalent world over and cause significant hazards and monetary losses due to infrastructure damages caused by their swelling and shrinking behavior. Expansive soils have been conventionally treated using chemical additives such as lime and cement, which are known to significantly

[...] Read more.

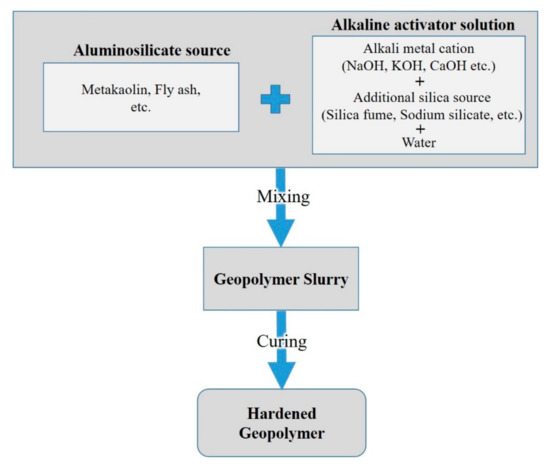

Expansive soils are prevalent world over and cause significant hazards and monetary losses due to infrastructure damages caused by their swelling and shrinking behavior. Expansive soils have been conventionally treated using chemical additives such as lime and cement, which are known to significantly improve their strength and volume-change properties. The production of lime and cement is one of the highest contributors of greenhouse gas emissions worldwide, because of their energy-intensive manufacturing processes. Hence, there is a pressing need for sustainable alternative chemical binders. Geopolymers are a relatively new class of aluminosilicate polymers that can be synthesized from industrial by-products at ambient temperatures. Geopolymer-treated soils are known to have comparable strength and stiffness characteristics of lime and cement-treated soils. This study evaluates the sustainability benefits of a metakaolin-based geopolymer treatment for an expansive soil and compares its results with lime treatment. Test results have shown that geopolymers have significantly improved strength, stiffness, and volume-change properties of expansive soils. Increased dosages and curing periods have resulted in further property enhancements. Swell and shrinkage studies also indicated reductions in these strains when compared to control conditions. The sustainability benefits of both geopolymer and lime treatment methods are evaluated using a framework that incorporates resource consumption, environmental, and socio-economic concerns. This study demonstrates geopolymer treatment of expansive soils as a more sustainable alternative for expansive soil treatments, primarily due to metakaolin source material. Overall results indicated that geopolymers can be viable additives or co-additives for chemical stabilization of problematic expansive soils.

Full article

►▼

Show Figures

Open AccessArticle

Effect of Fiber and Cement Additives on the Small-Strain Stiffness Behavior of Toyoura Sand

by

Muhammad Safdar, Tim Newson, Colin Schmidt, Kenichi Sato, Takuro Fujikawa and Faheem Shah

Cited by 9 | Viewed by 2687

Abstract

The disposal of 2011 Japan earthquake waste has become an important issue in Japan and it is not realistic or economical to send all of these wastes to landfill sites, due to limited space, high costs, and related environmental issues. In sustainable geotechnical

[...] Read more.

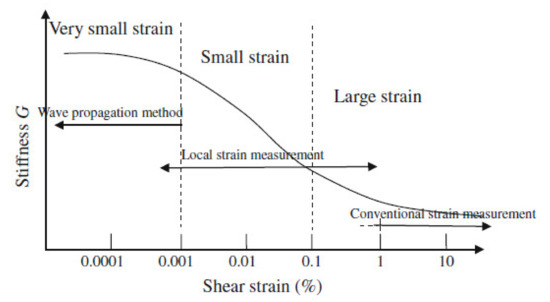

The disposal of 2011 Japan earthquake waste has become an important issue in Japan and it is not realistic or economical to send all of these wastes to landfill sites, due to limited space, high costs, and related environmental issues. In sustainable geotechnical applications, mixing of the separated soils from disaster wastes with additives (e.g., cement and fiber) is required to improve their strength and stiffness characteristics. In this study, monotonic triaxial drained compression tests are performed on medium dense specimens of Toyoura sand-cement-fiber mixtures with different percentages of fiber and cement (e.g., 0–3%) additives. The experimental results indicate that behavior of the mixtures is significantly affected by the concentration of fiber and cement additives. Based on a comprehensive set of test results, modifications to the series of equations were developed that can be used to evaluate the shear modulus and mobilized stress curves at small-strain levels. The experimental results and model comparison show that the elastic threshold strain (

), reference strain (

), increases with fiber and cement additives. In addition, the range of curvature parameter, from 0.88 to 1.0, provides a good comparison with the results of small-strain measurements. Overall, the comparison of the results and model shows that the small-strain measurements obtained using local strain transducers fall within the range of model upper and lower bound curves. The results of the unreinforced, fiber, and cemented sand shows a close agreement with the model mean curve, but fiber-reinforced cemented sand shows a good comparison with model upper bound.

Full article

►▼

Show Figures

Open AccessArticle

Effect of Recycled Polyethylene Terephthalate Strips on the Mechanical Properties of Cement-Treated Lateritic Sandy Soil

by

Maitê Rocha Silveira, Paulo César Lodi, Natália de Souza Correia, Roger Augusto Rodrigues and Heraldo Luiz Giacheti

Cited by 6 | Viewed by 2253

Abstract

The civil engineering construction industry is nowadays one of the largest consumers of natural resources. Therefore, the proposal of using alternative materials that seek to reduce waste production or the use of previously generated waste is becoming increasingly necessary. This paper evaluated the

[...] Read more.

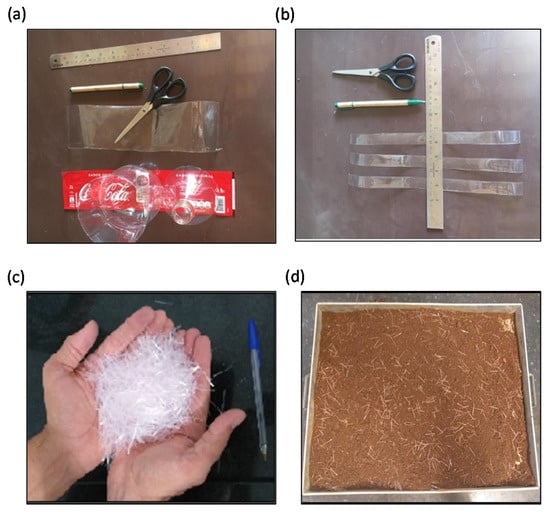

The civil engineering construction industry is nowadays one of the largest consumers of natural resources. Therefore, the proposal of using alternative materials that seek to reduce waste production or the use of previously generated waste is becoming increasingly necessary. This paper evaluated the effect of recycled polyethylene terephthalate (PET) strips on the mechanical properties of a cement-treated lateritic sandy soil. Unconfined compression strength (UCS) tests were conducted in natural and PET strips mixtures in different strips lengths and contents. In addition to UCS tests, compaction tests were also conducted in order to analyze the effect of these inclusions on the properties of a lateritic sandy soil. Lastly, direct shear tests were conducted on natural soil-strip, soil-cement, and soil-cement-strip composites using optimum UCS results. The addition of strips to the soil-cement composite showed an increase in the soil cohesion parameter. The inclusion of strips also provided a more ductile behavior to the soil, presenting greater deformations with fewer stress peaks. Results showed that the recycled strips’ inclusion in soil-cement can provide a material with high strength, ductility, and a highly sustainable alternative.

Full article

►▼

Show Figures

Open AccessArticle

Reinforcing Effect of Polypropylene Waste Strips on Compacted Lateritic Soils

by

Régis Marçal, Paulo César Lodi, Natália de Souza Correia, Heraldo Luiz Giacheti, Roger Augusto Rodrigues and John S. McCartney

Cited by 12 | Viewed by 2863

Abstract

This study evaluated the strength properties of compacted lateritic soils reinforced with polypropylene (PP) waste strips cut from recycled plastic packing with the goal of promoting sustainability through using local materials for engineering work and reusing waste materials as low-cost reinforcements. Waste PP

[...] Read more.

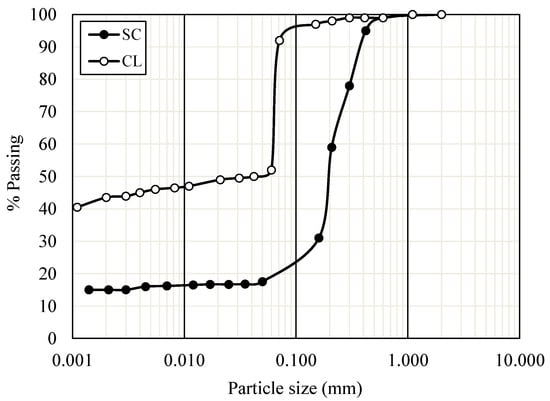

This study evaluated the strength properties of compacted lateritic soils reinforced with polypropylene (PP) waste strips cut from recycled plastic packing with the goal of promoting sustainability through using local materials for engineering work and reusing waste materials as low-cost reinforcements. Waste PP strips with widths of 15 mm and different lengths were uniformly mixed with clayey sand (SC) and clay (CL) soils with the goal of using these materials as low-cost fiber reinforcements. The impact of different PP strip contents (0.25% to 2.0%) and lengths (10, 15, 20, and 30 mm) on the unconfined compressive strength (UCS) of the soils revealed an optimum combination of PP strip content and length. Statistical analysis showed that PP strip content has a greater effect than the PP strip length on the UCS for both soils. Results led to the definition of an empirical equation to estimate the UCS of strip-reinforced soils. The results from direct shear tests indicate that the SC soil showed an increase in both apparent cohesion and friction angle after reinforcement, while the CL soil only showed an increase in friction angle after reinforcement. California bearing ratio (CBR) tests indicate that the SC soil experienced a 70% increase in CBR after reinforcement, while the CBR of the CL soil was not affected by strip inclusion.

Full article

►▼

Show Figures

Open AccessArticle

Use of Incinerator Bottom Ash as a Recycled Aggregate in Contact with Nonwoven Geotextiles: Evaluation of Mechanical Damage Upon Installation

by

Filipe Almeida, José Ricardo Carneiro and Maria de Lurdes Lopes

Cited by 7 | Viewed by 2514

Abstract

The recycling and reuse of materials is crucial to reducing the amount of generated waste and the exploitation of natural resources, contributing to achieving environmental sustainability. During the incineration process of municipal solid waste, a residue known as incinerator bottom ash is generated

[...] Read more.

The recycling and reuse of materials is crucial to reducing the amount of generated waste and the exploitation of natural resources, contributing to achieving environmental sustainability. During the incineration process of municipal solid waste, a residue known as incinerator bottom ash is generated in considerable amounts, being important the development of solutions for its valorization. In this work, three nonwoven geotextiles were submitted to mechanical damage under repeated loading tests with incinerator bottom ash and, for comparison purposes, with three natural aggregates (sand 0/4, gravel 4/8 and

tout-venant) and a standard aggregate (

corundum). Damage assessment was carried out by monitoring the changes that occurred in the short-term tensile and puncture behaviors of the geotextiles. Results showed that the damage induced by incinerator bottom ash on the short-term mechanical behavior of the geotextiles tended to be lower than the damage induced by the natural aggregates or by the standard aggregate. Therefore, concerning the mechanical damage caused on geotextiles, there are good prospects for the use of incinerator bottom ash as a filling material in contact with those construction materials, thereby promoting its valorization.

Full article

►▼

Show Figures

Open AccessArticle

HDPE Geomembranes for Environmental Protection: Two Case Studies

by

Fernando Luiz Lavoie, Clever Aparecido Valentin, Marcelo Kobelnik, Jefferson Lins da Silva and Maria de Lurdes Lopes

Cited by 17 | Viewed by 4531

Abstract

High-density polyethylene (HDPE) geomembranes have been used for different applications in engineering including sanitation, such as landfills and waste liquid ponds. For these applications, the material can be exposed to aging mechanisms as thermal and chemical degradation, even to UV radiation and biological

[...] Read more.

High-density polyethylene (HDPE) geomembranes have been used for different applications in engineering including sanitation, such as landfills and waste liquid ponds. For these applications, the material can be exposed to aging mechanisms as thermal and chemical degradation, even to UV radiation and biological contact, which can degrade the geomembrane and decrease the material’s durability. This paper aims to present an experimental evaluation of two exhumed HDPE geomembranes, the first was used for 2.75 years in a sewage treatment aeration pond (LTE sample) and another was used for 5.17 years in a municipal landfill leachate pond (LCH sample). Physical and thermal analyses were used such as thermogravimetry (TG), differential thermal analysis (DTA), differential scanning calorimetry (DSC) and dynamic mechanic analysis (DMA). The thermogravimetric analyses showed significant changes in the LCH sample’s thermal decomposition probably caused by the interaction reactions between the polymer and the leachate. For the DSC analyses, the behavior seen in the LTE sample was not observed in the LCH sample. In the DMA analyses, the behavior of the LTE sample storage module shows which LCH sample is less brittle. The LTE sample presented low stress cracking resistance and low tensile elongation at break, following the DMA results.

Full article

►▼

Show Figures

Open AccessArticle

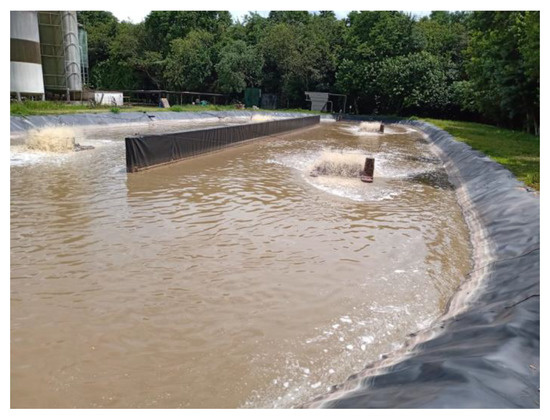

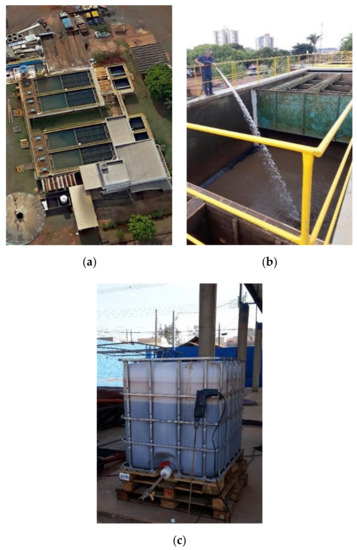

Geotextile Tube Dewatering Performance Assessment: An Experimental Study of Sludge Dewatering Generated at a Water Treatment Plant

by

Maria Alejandra Aparicio Ardila, Samira Tessarolli de Souza, Jefferson Lins da Silva, Clever Aparecido Valentin and Angela Di Bernardo Dantas

Cited by 14 | Viewed by 3975

Abstract

Using geotextile tubes as dewatering technology may significantly contribute to sustainable treatment of sludge generated in different industries, such as the water industry. This is an economical alternative for dewatering sludge from a Water Treatment Plant (WTP), which prevents sludge from being directly

[...] Read more.

Using geotextile tubes as dewatering technology may significantly contribute to sustainable treatment of sludge generated in different industries, such as the water industry. This is an economical alternative for dewatering sludge from a Water Treatment Plant (WTP), which prevents sludge from being directly deposited in water bodies and makes it possible to then transfer the sludge to landfills. This paper presents a laboratory study and a statistical analysis, carried out to evaluate the geotextile tube dewatering of sludge from a WTP, discussing the relation between the independent variables (initial Total Solids (TS) of the sludge and polymer dosing) and dependent variables (performance indices used in the literature) evaluated using semi-performance tests. Sludge from a WTP and three different types of geotextiles bags were used. Changes in the geotextiles’ characteristics after dewatering were also evaluated, quantitatively using permittivity tests and qualitatively by Scanning Electron Microscopy (SEM). The results indicated turbidity of effluent that met the Brazilian regulations for the discharge of effluents into Class 2 water bodies, as well as higher percent-solids than those obtained with mechanical dewatering technologies. This study underscores the importance of semi-performance tests to understand dewatering in geotextile tubes.

Full article

►▼

Show Figures

Open AccessArticle

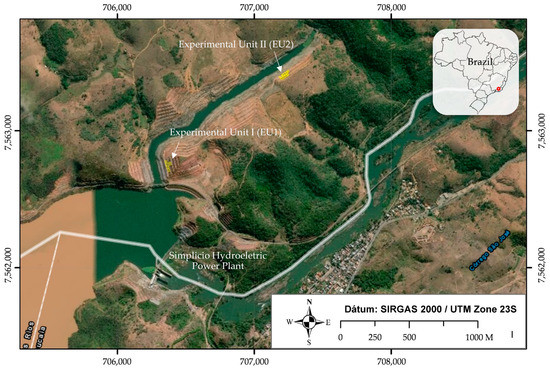

Bioengineering Techniques Adopted for Controlling Riverbanks’ Superficial Erosion of the Simplício Hydroelectric Power Plant, Brazil

by

Vinicius F. Vianna, Mateus P. Fleury, Gustavo B. Menezes, Arnaldo T. Coelho, Cecília Bueno, Jefferson Lins da Silva and Marta P. Luz

Cited by 12 | Viewed by 4110

Abstract

Controlling and preventing soil erosion on slope surfaces is a pressing concern worldwide, and at the same time, there is a growing need to incorporate sustainability into our engineering works. This study evaluates the efficiency of bioengineering techniques in the development of vegetation

[...] Read more.

Controlling and preventing soil erosion on slope surfaces is a pressing concern worldwide, and at the same time, there is a growing need to incorporate sustainability into our engineering works. This study evaluates the efficiency of bioengineering techniques in the development of vegetation in soil slopes located near a hydroelectric power plant in Brazil. For this purpose, twelve different bioengineering techniques were evaluated, in isolation and in combination, in the slopes (10 m high) of two experimental units (approximately 70 m long each) located next to the Paraíba do Sul riverbanks, in Brazil. High-resolution images of the slopes’ frontal view were taken in 15-day interval visits in all units for the first 90 days after implantation, followed by monthly visits up to 27 months after the works were finished. The images were treated and analyzed in a computer algorithm that, based on three-color bands (red–green–blue scale), helps to assess the temporal evolution of the vegetative cover index for each technique adopted. The results showed that most of the solutions showed a deficiency in vegetation establishment and were sensitive to climatological conditions, which induced changes in the vegetation phytosanitary aspects. Techniques which provided a satisfactory vegetative cover index throughout the investigated period are pointed out.

Full article

►▼

Show Figures

Open AccessArticle

Efficacy of Enzymatically Induced Calcium Carbonate Precipitation in the Retention of Heavy Metal Ions

by

Arif Ali Baig Moghal, Mohammed Abdul Lateef, Syed Abu Sayeed Mohammed, Kehinde Lemboye, Bhaskar C. S. Chittoori and Abdullah Almajed

Cited by 59 | Viewed by 5225

Abstract

This study evaluated the efficacy of enzyme induced calcite precipitation (EICP) in restricting the mobility of heavy metals in soils. EICP is an environmentally friendly method that has wide ranging applications in the sustainable development of civil infrastructure. The study examined the desorption

[...] Read more.

This study evaluated the efficacy of enzyme induced calcite precipitation (EICP) in restricting the mobility of heavy metals in soils. EICP is an environmentally friendly method that has wide ranging applications in the sustainable development of civil infrastructure. The study examined the desorption of three heavy metals from treated and untreated soils using ethylene diamine tetra-acetic acid (EDTA) and citric acid (C

6H

8O

7) extractants under harsh conditions. Two natural soils spiked with cadmium (Cd), nickel (Ni), and lead (Pb) were studied in this research. The soils were treated with three types of enzyme solutions (ESs) to achieve EICP. A combination of urea of one molarity (M), 0.67 M calcium chloride, and urease enzyme (3 g/L) was mixed in deionized (DI) water to prepare enzyme solution 1 (ES1); non-fat milk powder (4 g/L) was added to ES1 to prepare enzyme solution 2 (ES2); and 0.37 M urea, 0.25 M calcium chloride, 0.85 g/L urease enzyme, and 4 g/L non-fat milk powder were mixed in DI water to prepare enzyme solution 3 (ES3). Ni, Cd, and Pb were added with load ratios of 50 and 100 mg/kg to both untreated and treated soils to study the effect of EICP on desorption rates of the heavy metals from soil. Desorption studies were performed after a curing period of 40 days. The curing period started after the soil samples were spiked with heavy metals. Soils treated with ESs were spiked with heavy metals after a curing period of 21 days and then further cured for 40 days. The amount of CaCO

3 precipitated in the soil by the ESs was quantified using a gravimetric acid digestion test, which related the desorption of heavy metals to the amount of precipitated CaCO

3. The order of desorption was as follows: Cd > Ni > Pb. It was observed that the average maximum removal efficiency of the untreated soil samples (irrespective of the load ratio and contaminants) was approximately 48% when extracted by EDTA and 46% when extracted by citric acid. The soil samples treated with ES2 exhibited average maximum removal efficiencies of 19% and 10% when extracted by EDTA and citric acid, respectively. It was observed that ES2 precipitated a maximum amount of calcium carbonate (CaCO

3) when compared to ES1 and ES3 and retained the maximum amount of heavy metals in the soil by forming a CaCO

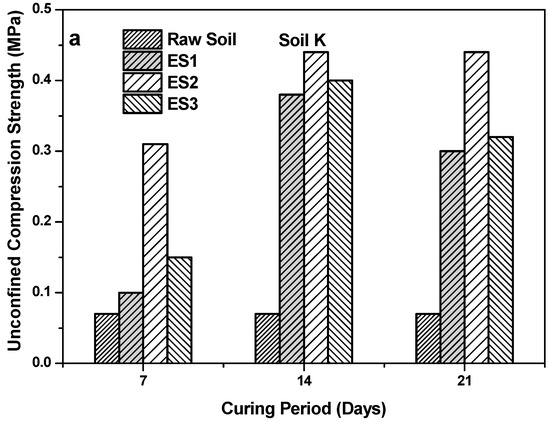

3 shield on the heavy metals, thus decreasing their mobility. An approximate improvement of 30% in the retention of heavy metal ions was observed in soils treated with ESs when compared to untreated soil samples. Therefore, the study suggests that ESs can be an effective alternative in the remediation of soils contaminated with heavy metal ions.

Full article

►▼

Show Figures

Open AccessArticle

Sustainable Perspective of Low-Lime Stabilized Fly Ashes for Geotechnical Applications: PROMETHEE-Based Optimization Approach

by

Arif Ali Baig Moghal, Ateekh Ur Rehman, K Venkata Vydehi and Usama Umer

Cited by 7 | Viewed by 2530

Abstract

In the present scenario of global green environmental and sustainable management, the disposal of large volumes of coal-based ashes (fly ashes) generate significant environmental stress. The aim is to exploit these fly ashes for bulk civil engineering applications to solve societal-environmental issues employing

[...] Read more.

In the present scenario of global green environmental and sustainable management, the disposal of large volumes of coal-based ashes (fly ashes) generate significant environmental stress. The aim is to exploit these fly ashes for bulk civil engineering applications to solve societal-environmental issues employing sustainable measures. In this study, the addition of lime and/or gypsum in improving the geotechnical properties (hydraulic conductivity, compressibility, unconfined compression strength, lime leachability, and California bearing ratio) of fly ashes was investigated. To assist the practicing engineers in selecting the right mix of lime and/or gypsum for a given amount of fly ash for a specific application, a multi-criteria approach was adopted. The possible alternatives investigated included untreated fly ash, fly ash treated with lime (1%, 2.5%, 5%, or 10%), and a variation in gypsum dosage (1% or 2.5%) in the presence of lime. Sensitivity analysis was performed to recognize and resolve the conflicting advantages and disadvantages when mixing lime and gypsum. The study revealed that to derive the potential benefits of fly ash, it is essential to combine the lime dosage with gypsum for pavement and liner applications where bulk quantities of fly ash are employed.

Full article

►▼

Show Figures

Open AccessArticle

Mechanical Characteristics of Soda Residue Soil Incorporating Different Admixture: Reuse of Soda Residue

by

Jiaxiao Ma, Nan Yan, Mingyi Zhang, Junwei Liu, Xiaoyu Bai and Yonghong Wang

Cited by 19 | Viewed by 3330

Abstract

Soda residue (SR), a waste by-product of sodium carbonate production, occupies land resources and pollutes the environment seriously. To promote the resource reusing of waste SR, this paper studies the feasibility of utilizing SR for the preparation of soda residue soil (SRS) through

[...] Read more.

Soda residue (SR), a waste by-product of sodium carbonate production, occupies land resources and pollutes the environment seriously. To promote the resource reusing of waste SR, this paper studies the feasibility of utilizing SR for the preparation of soda residue soil (SRS) through laboratory and field tests. The SR and fly ash (FA) were mixed with six different proportions (SR:FA is 1:0, 10:1, 8:1, 6:1, 3:1, 1:1) to prepare SRS, and the optimum water content, maximum dry density, shear strength, and unconfined compression strength of the SRS were measured. The representative SRS (SR:FA is 10:1) was selected to investigate the compression performance and collapsibility. The preparation and filling method of SRS in the field was proposed, and the effects of gravel, sand, and lime on the mechanical properties of SRS were studied through field tests. The results show that the addition of FA contributed to the strength development of SR, and the addition of lime, sand and rubble have a significant effect on the subgrade bearing capacity of SRS. The subgrade bearing capacity and deformation modulus of SRS in field tests is more than 210 kPa and 34.48 MPa, respectively. The results provide experimental basis and reference for the preparation of SRS, the scientific application of SRS in geotechnical engineering to promote sustainable development.

Full article

►▼

Show Figures

Open AccessArticle

Triple-Binder-Stabilized Marine Deposit Clay for Better Sustainability

by

Mohamad Hanafi, Abdullah Ekinci and Ertug Aydin

Cited by 24 | Viewed by 2970

Abstract

Marine clay deposits are commonly found worldwide. Considering the cost of dumping and related environmental concerns, an alternative solution involving the reuse of soils that have poor conditions is crucial. In this research, the authors examined the strength, microstructure, and wet–dry resistance of

[...] Read more.

Marine clay deposits are commonly found worldwide. Considering the cost of dumping and related environmental concerns, an alternative solution involving the reuse of soils that have poor conditions is crucial. In this research, the authors examined the strength, microstructure, and wet–dry resistance of triple-binder composites of marine-deposited clays and compiled a corresponding database. In order to evaluate the wetting–drying resistance of the laboratory-produced samples, the accumulated mass loss (ALM) was calculated. The use of slag alone as a binder, at any percentage, increased the ALM up to 2%. However, the use of lime as the third binder seemed to accelerate the chemical reactions associated with the hydration of clay and cementitious material and to enhance the chemical stability, i.e., specimens that included both lime and slag experienced the same ALM as specimens treated with cement only. Scanning electron microscopy analysis confirmed the durability improvements of these clays. The proposed unconfined compressive strength–porosity and accumulated mass loss relationship yielded practical approximation for the fine- and coarse-grained soils blended with up to three binders until 60 days of curing. The laboratory-produced mixes showed reduction of embodied energy and embodied carbon dioxide (eCO

2) emissions for the proposed models.

Full article

►▼

Show Figures

Open AccessArticle

Pullout Behaviour of Geogrids Embedded in a Recycled Construction and Demolition Material. Effects of Specimen Size and Displacement Rate

by

Castorina Silva Vieira, Paulo Pereira, Fernanda Ferreira and Maria de Lurdes Lopes

Cited by 25 | Viewed by 3420

Abstract

In recent years, environmental concerns related to the overexploitation of natural resources and the need to manage large amounts of wastes arising from construction activities have intensified the pressure on the civil engineering industry to adopt sustainable waste recycling and valorisation measures. The

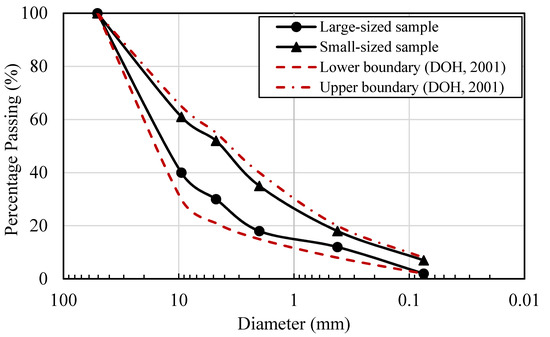

[...] Read more.

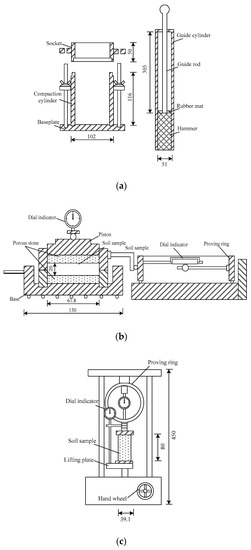

In recent years, environmental concerns related to the overexploitation of natural resources and the need to manage large amounts of wastes arising from construction activities have intensified the pressure on the civil engineering industry to adopt sustainable waste recycling and valorisation measures. The use of recycled construction and demolition (C&D) wastes as alternative backfill for geosynthetic-reinforced structures may significantly contribute towards sustainable civil infrastructure development. This paper presents a laboratory study carried out to characterise the interaction between a fine-grained C&D material and two different geogrids (a polyester (PET) geogrid and an extruded uniaxial high-density polyethylene (HDPE) geogrid) through a series of large-scale pullout tests. The effects of the geogrid specimen size, displacement rate and vertical confining pressure on the pullout resistance of the geogrids are evaluated and discussed, aiming to assess whether they are in line with the current knowledge about the pullout resistance of geogrids embedded in soils. Test results have shown that the measured peak pullout resistance of the geogrid increases with the specimen size, imposed displacement rate and confining pressure. However, the pullout interaction coefficient has exhibited the opposite trend with the specimen size and confining pressure. The pullout interaction coefficients ranged from 0.79 and 1.57 and were generally greater than or equal to the values reported in the literature for soil-geogrid and recycled material-geogrid interfaces.

Full article

►▼

Show Figures

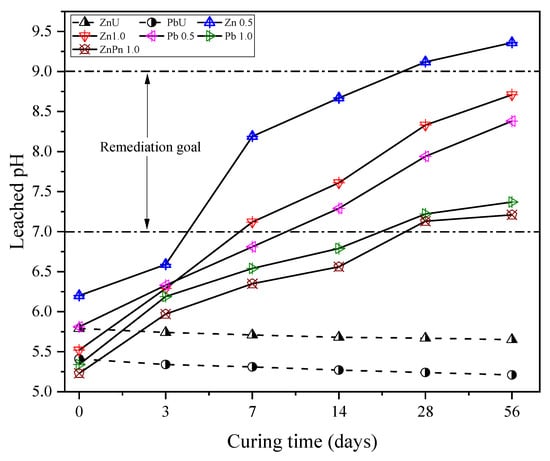

Open AccessFeature PaperArticle

Stabilization/Solidification of Zinc- and Lead-Contaminated Soil Using Limestone Calcined Clay Cement (LC3): An Environmentally Friendly Alternative

by

Vemula Anand Reddy, Chandresh H. Solanki, Shailendra Kumar, Krishna R. Reddy and Yan-Jun Du

Cited by 23 | Viewed by 5397

Abstract

Due to increased carbon emissions, the use of low-carbon and low-cost cementitious materials that are sustainable and effective are gaining considerable attention recently for the stabilization/solidification (S/S) of contaminated soils. The current study presents the laboratory investigation of low-carbon/cost cementitious material known as

[...] Read more.

Due to increased carbon emissions, the use of low-carbon and low-cost cementitious materials that are sustainable and effective are gaining considerable attention recently for the stabilization/solidification (S/S) of contaminated soils. The current study presents the laboratory investigation of low-carbon/cost cementitious material known as limestone-calcined clay cement (LC

3) for the potential S/S of Zn- and Pb-contaminated soils. The S/S performance of the LC

3 binder on Zn- and Pb-contaminated soil was determined via pH, compressive strength, toxicity leaching, chemical speciation, and X-ray powder diffraction (XRPD) analyses. The results indicate that immobilization efficiency of Zn and Pb was solely dependent on the pH of the soil. In fact, with the increase in the pH values after 14 days, the compressive strength was increased to 2.5–3 times compared to untreated soil. The S/S efficiency was approximately 88% and 99%, with increase in the residual phases up to 67% and 58% for Zn and Pb, respectively, after 28 days of curing. The increase in the immobilization efficiency and strength was supported by the XRPD analysis in forming insoluble metals hydroxides such as zincwoodwardite, shannonite, portlandite, haturite, anorthite, ettringite (Aft), and calcite. Therefore, LC

3 was shown to offer green and sustainable remediation of Zn- and Pb-contaminated soils, while the treated soil can also be used as safe and environmentally friendly construction material.

Full article

►▼

Show Figures