Lightweight Equipment Using Multiple Torches for Fast Speed Asphalt Roofing

Abstract

:1. Introduction

2. Design and Analysis

2.1. Mechanical Design and Analysis

2.2. Thermal Design

2.2.1. Requirement of Heat Power into the Roll

2.2.2. Heat Transferred and Thermal Insulation Cover

- The background boundary considers a zero static pressure and an infinite ambient temperature of 25 °C;

- The inlet boundary supplies air a certain input speed, vi, and input temperature Ti;

- The thermal insulation cover boundary is a solid–fluid interface line that links the thermal properties of adjacent fluids with the solid thermal conduction inside the rock wool (the fluid speed in this boundary shall be zero). This boundary is removed in the second simulation in order to quantify the improvement effect of the thermal insulation cover;

- The roll boundary is a solid–fluid interface line that links the thermal properties of adjacent fluids with the solid thermal conduction inside the asphalt (the fluid speed in this boundary shall be zero);

- The inner diameter of the roll is a thermal convective boundary with a free convective coefficient of 5 W/m2K, which evacuates the heat to 25 °C ambient temperature;

- The floor is a wall-type boundary, which means that the fluid speed in this boundary shall be zero.

3. Manufacturing and Assembly of the Prototype

4. Test Results and Discussion

4.1. Preliminary Laboratory Test

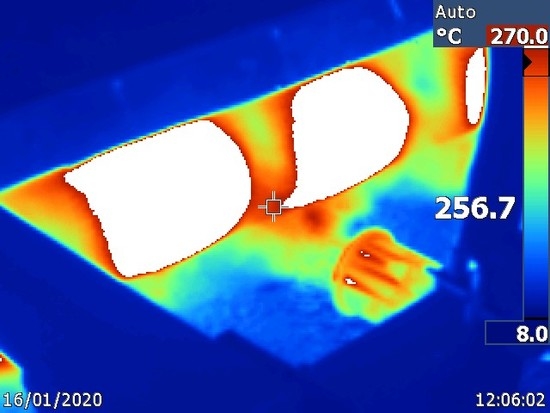

4.2. Outdoor Asphalt Temperature and Adhesion Test

4.3. Outdoor Installation Speed Test

4.4. Outdoor Installation Quality Test

5. Lessons Learned and Suggested Improvements

- The differences in temperature between the adjacent areas show that heat was not entirely uniformly distributed, as the spaces between torches affects the heat distribution. This is something that could be improved by adding more torches or using wider diffusors on each torch;

- As the roll gets installed and unrolled, the distance between the torches and the roll increases, negatively affecting the amount of heat transferred A simple cam-follower mechanism could be integrated between the torches and the roll in order to maintain the distance;

- Heat is lost through the lateral sides of the trolley. A special metallic lateral wall could prevent this loss in the same way that the thermal insulation cover prevents vertical heat losses;

- The lateral stops for the roll are very close to the ground level, and may collide with imperfectly flat areas of ground or surfaces. By elevating the lateral stops by 30–40 mm, these collisions could be avoided;

- If the roll is not perfectly aligned in the lateral sides it is hard to place, since the lateral margins are very small. The lateral stops should have a spring follower mechanism to allow the roll to be positioned in an easier way;

- The hot air flow becomes turbulent around the roll. Future CFD analysis should consider this;

- It is sometimes hard to slightly change the roll direction. By enabling the rotation of the rear wheels, the guidance of the trolley could be easier;

- Increasing the flow in the lateral torches and reducing it in the middle may reduce total consumption;

- Adding extra compaction drums all along the trolley will surely improve the adhesion in the middle without affecting the driving of the trolley;

- We detected slight differences in the flow, and thus on the applied heat, of the torch that was closer to the main pipeline in relation to the one at the other side. This may be due to differences in pressure decay along the pipeline. This difference could be avoided by adjusting the lateral torches and/or by connecting the main pipeline at the middle rather than at one side.

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Abuseif, M.; Gou, Z. A review of roofing methods: Construction features, heat reduction, payback period and climatic responsiveness. Energies 2018, 11, 3196. [Google Scholar] [CrossRef] [Green Version]

- Van Toor, A.C.; Bax, N.X.C. Method and Apparatus for Applying a Bituminous Sheet to a Substrate. Patent EP 0466249, 15 January 1993. [Google Scholar]

- Warren, A. Single Ply Roofing Applicator. U.S. Patent 4725328, 16 February 1988. [Google Scholar]

- Bessette, R. Membrane Applying Apparatus. U.S. Patent 2013228287, 5 September 2013. [Google Scholar]

- Unify-er-Produits. Available online: www.modbitapplicator.com/produits.php (accessed on 4 November 2019).

- Trumbore, D.; Jankousky, A.; Hockman, E.L.; Sanders, R.; Calkin, J.; Szczepanik, S.; Owens, R. Emission factors for asphalt-related emissions in roofing manufacturing. Environ. Prog. 2005, 24, 268–278. [Google Scholar] [CrossRef]

- Vaz, W.; Sheffield, J. Preliminary assessment of greenhouse gas emissions for atactic polypropylene (APP) modified asphalt membrane roofs. Build. Environ. 2014, 78, 95–102. [Google Scholar] [CrossRef]

- EL-Mesery, H.S.; Abomohra, A.E.-F.; Kang, C.-U.; Cheon, J.-K.; Basak, B.; Jeon, B.-H. Evaluation of Infrared Radiation Combined with Hot Air Convection for Energy-Efficient Drying of Biomass. Energies 2019, 12, 2818. [Google Scholar] [CrossRef] [Green Version]

- Young-Corbett, D.E. Prevention through Design: Health Hazards in Asphalt Roofing. J. Constr. Eng. Manag. 2014, 140, 06014007. [Google Scholar] [CrossRef]

- Díez-Jiménez, E.; Vidal-Sánchez, A.; Barragán-García, A.; Fernández-Muñoz, M.; Mallol-Poyato, R. Lightweight equipment for the fast installation of asphalt roofing based on infrared heaters. Energies 2019, 12, 4253. [Google Scholar] [CrossRef] [Green Version]

- Díez-Jiménez, E.; Vidal-Sánchez, A.; Corral-Abad, E.; Gómez-García, M.J. Mecanismo Ligero para la Puesta Rápida de Láminas Bituminosas en Impermeabilizaciones de Cubiertas Planas. Patent P 201830702, 13 July 2018. [Google Scholar]

- Alade, O.; Al Shehri, D.; Mahmoud, M.; Sasaki, K. Viscosity-temperature-pressure relationship of extra-heavy oil (bitumen): Empirical modelling versus artificial neural network (ANN). Energies 2019, 12, 2390. [Google Scholar] [CrossRef] [Green Version]

- Ministerio de Industria, Gobierno de España. Código Técnico de la Edificación, 1st ed.; Garceta Grupo Editorial: Madrid, Spain, 2009; ISBN 9788493720896. [Google Scholar]

- Haynes, W.M. CRC Handbook of Chemistry and Physics; Apple Academic Press: Palm Bay, FL, USA, 2014; ISBN 9781482208672. [Google Scholar]

- Musavi, Z.; Kusar, H.; Andersson, R.; Engvall, K. Modelling and Optimization of a Small Diesel Burner for Mobile Applications. Energies 2018, 11, 2904. [Google Scholar] [CrossRef] [Green Version]

| Property | Asphalt | Rock Wool |

|---|---|---|

| Heat capacity (Cp) | 1014 J/kg∙°C | 840 J/kg∙°C |

| Thermal conductivity (k) | 0.5 W/m∙K | 0.035 W/m∙K |

| Density (ρ) | 1700 kg/m3 | 40 kg/m3 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Barragán-García, A.; Fernández-Muñoz, M.; Díez-Jiménez, E. Lightweight Equipment Using Multiple Torches for Fast Speed Asphalt Roofing. Energies 2020, 13, 2216. https://doi.org/10.3390/en13092216

Barragán-García A, Fernández-Muñoz M, Díez-Jiménez E. Lightweight Equipment Using Multiple Torches for Fast Speed Asphalt Roofing. Energies. 2020; 13(9):2216. https://doi.org/10.3390/en13092216

Chicago/Turabian StyleBarragán-García, Alberto, Miguel Fernández-Muñoz, and Efrén Díez-Jiménez. 2020. "Lightweight Equipment Using Multiple Torches for Fast Speed Asphalt Roofing" Energies 13, no. 9: 2216. https://doi.org/10.3390/en13092216

APA StyleBarragán-García, A., Fernández-Muñoz, M., & Díez-Jiménez, E. (2020). Lightweight Equipment Using Multiple Torches for Fast Speed Asphalt Roofing. Energies, 13(9), 2216. https://doi.org/10.3390/en13092216