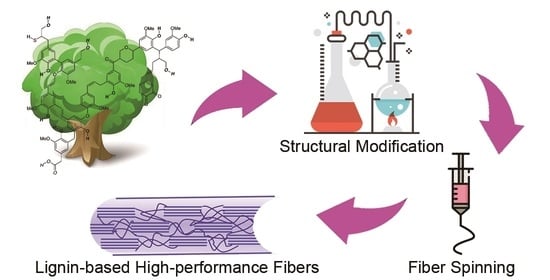

Lignin-Based High-Performance Fibers by Textile Spinning Techniques

Abstract

:1. Introduction

2. Lignin’s Structure and Properties

3. Mechanical Performance of Lignin-Based Fibers

3.1. Lignin-Based Carbon Fibers

3.1.1. Melt-Spun Lignin-Based Carbon Fibers

Structurally Modified Melt-Spun Lignin-Based Carbon Fibers

Melt-Spun Lignin/Polymer Blend Carbon Fibers

3.1.2. Solution-Spun Lignin-Based Carbon Fibers

Structurally Modified Solution-Spun Lignin-Based Carbon Fibers

Solution-Spun Lignin/Polymer Carbon Fibers

3.1.3. Electrospun Lignin-Based Carbon Nanofibers

Structurally Modified Electrospun Lignin-Based Carbon Nanofibers

Electrospun Lignin/Polymer Carbon Nanofibers

3.1.4. Centrifugal-Spun Lignin-Based Carbon Fibers

3.2. Lignin as Fiber Reinforcement

4. Future Directions

- Extraction or pretreatment resulting in lignin with different structural chemistries suitable for various fabrication techniques to manufacture lignin-based high-performance fibers should be more systematically studied to yield lignin with higher molecular weight and narrower PDI. Although efforts have been made to fabricate lignin/cellulose fibers [224,225,226] that resemble fibrils in plant cell walls, there is still a gap in the fundamental knowledge of the physics and chemistry of natural lignin and how it reinforces or provides strength in wood. The knowledge should be gained to potentially develop fiber biomimetics with good mechanical properties.

- The reported lignin grafting with CNTs [79] or PAN [163], RAFT polymerization [99], and copolymerization with AN [119,234] showed promising results. The future trend of lignin chemical modification should focus on increasing molecular weight and polymer linearity by grafting lignin onto different polymers or via polymerization or copolymerization of lignin with other monomers. For lignin/polymer blends, lignin modification should not be limited to the reduction of lignin’s hydroxyl groups to be compatible with hydrophobic polymers such as PET and PP [234]. More studies of lignin modification should also be conducted to enhance its compatibility with polar polymers.

- Lignin fiber spinning research is still in its infancy and requires more efforts in material and spinning technique development. Solution spinning of lignin-based fibers should be more thoroughly investigated as an alternative to traditional melt spinning [41]. Solution-spun fibers have higher molecular orientation along the fiber axis, which is vital to achieve high-strength and high-modulus lignin-based fibers. In particular, the optimization of spinning parameters (e.g., draw ratio, solvents, coagulation bath composition, and temperature) that aid the orientation of molecules should be conducted to achieve fibers with small diameter, high crystallinity, high orientation, and high mechanical properties.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Fernandes, E.M.; Pires, R.A.; Mano, J.F.; Reis, R.L. Bionanocomposites from lignocellulosic resources: Properties, applications and future trends for their use in the biomedical field. Prog. Polym. Sci. 2013, 38, 1415–1441. [Google Scholar] [CrossRef]

- Faruk, O.; Bledzki, A.K.; Fink, H.-P.; Sain, M. Biocomposites reinforced with natural fibers: 2000–2010. Prog. Polym. Sci. 2012, 37, 1552–1596. [Google Scholar] [CrossRef]

- Pinto, M.A.; Chalivendra, V.B.; Kim, Y.K.; Lewis, A.F. Effect of surface treatment and Z-axis reinforcement on the interlaminar fracture of jute/epoxy laminated composites. Eng. Fract. Mech. 2013, 114, 104–114. [Google Scholar] [CrossRef]

- Dobos, A.M.; Onofrei, M.-D.; Stoica, I.; Olaru, N.; Olaru, L.; Ioan, S. Rheological properties and microstructures of cellulose acetate phthalate/hydroxypropyl cellulose blends. Polym. Compos. 2012, 33, 2072–2083. [Google Scholar] [CrossRef]

- Necula, A.M.; Olaru, N.; Olaru, L.; Homocianu, M.; Ioan, S. Influence of the Substitution Degrees on the Optical Properties of Cellulose Acetates. J. Appl. Polym. Sci. 2010, 115, 1751–1757. [Google Scholar] [CrossRef]

- Dobos, A.M.; Stoica, I.; Olaru, N.; Olaru, L.; Ioanid, E.G.; Ioan, S. Surface properties and biocompatibility of cellulose acetates. J. Appl. Polym. Sci. 2012, 125, 2521–2528. [Google Scholar] [CrossRef]

- Thakur, V.K.; Thakur, M.K.; Raghavan, P.; Kessler, M.R. Progress in green polymer composites from lignin for multifunctional applications: A review. ACS Sustain. Chem. Eng. 2014, 2, 1072–1092. [Google Scholar] [CrossRef]

- Shah, D.U. Developing plant fibre composites for structural applications by optimising composite parameters: A critical review. J. Mater. Sci. 2013, 48, 6083–6107. [Google Scholar] [CrossRef]

- Graca, M.P.F.; Rudnitskaya, A.; Faria, F.A.C.; Evtuguin, D.V.; Gomes, M.T.S.R.; Oliveira, J.A.B.P.; Costa, L.C. Electrochemical impedance study of the lignin-derived conducting polymer. Electrochim. Acta 2012, 76, 69–76. [Google Scholar] [CrossRef]

- Rozite, L.; Varna, J.; Joffe, R.; Pupurs, A. Nonlinear behavior of PLA and lignin-based flax composites subjected to tensile loading. J. Compos. 2013, 26, 476–496. [Google Scholar] [CrossRef]

- Laurichesse, S.; Averous, L. Chemical modification of lignins: Towards biobased polymers. Prog. Polym. Sci. 2014, 39, 1266–1290. [Google Scholar] [CrossRef]

- Collins, M.N.; Nechifor, M.; Tanasa, F.; Zanoaga, M.; McLoughlin, A.; Strozyk, M.A.; Culebras, M.; Teaca, C.A. Valorization of lignin in polymer and composite systems for advanced engineering applications—A review. Int. J. Biol. Macromol. 2019, 131, 828–849. [Google Scholar] [CrossRef] [PubMed]

- Fang, W.; Yang, S.; Wang, X.L.; Yuan, T.Q.; Sun, R.C. Manufacture and application of lignin-based carbon fibers (LCFs) and lignin-based carbon nanofibers (LCNFs). Green Chem. 2017, 19, 1794–1827. [Google Scholar] [CrossRef]

- Mao, H.; Chen, X.; Huang, R.; Chen, M.; Yang, R.; Lan, P.; Zhou, M.; Zhang, F.; Yang, Y.; Zhou, X. Fast preparation of carbon spheres from enzymatic hydrolysis lignin: Effects of hydrothermal carbonization conditions. Sci. Rep. 2018, 8, 9501. [Google Scholar] [CrossRef] [Green Version]

- Thakur, V.K.; Thakur, M.K. Recent advances in green hydrogels from lignin: A review. Int. J. Biol. Macromol. 2015, 72, 834–847. [Google Scholar] [CrossRef] [PubMed]

- Ten, E.; Vermerris, W. Recent developments in polymers derived from industrial lignin. J. Appl. Polym. Sci. 2015, 132. [Google Scholar] [CrossRef] [Green Version]

- Feldman, D.; Banu, D.; Manley, R.S.J.; Zhu, H. Highly filled blends of a vinylic copolymer with plasticized lignin: Thermal and mechanical properties. J. Appl. Polym. Sci. 2003, 89, 2000–2010. [Google Scholar] [CrossRef]

- Le Digabel, F.; Avérous, L. Effects of lignin content on the properties of lignocellulose-based biocomposites. Carbohydr. Polym. 2006, 66, 537–545. [Google Scholar] [CrossRef]

- Erakovic, S.; Veljovic, D.; Diouf, P.N.; Stevanovic, T.; Mitric, M.; Milonjic, S.; Miskovic-Stankovic, V.B. Electrophoretic deposition of biocomposite lignin/hydroxyapatite coatings on titanium. Int. J. Chem. React. Eng. 2009, 7, 113–130. [Google Scholar] [CrossRef]

- Raschip, I.E.; Hitruc, E.G.; Vasile, C. Semi-interpenetrating polymer networks containing polysaccharides. II. Xanthan/lignin networks: A spectral and thermal characterization. High. Perform. Polym. 2011, 23, 219–229. [Google Scholar] [CrossRef]

- Cerrutti, B.M.; de Souza, C.S.; Castellan, A.; Ruggiero, R.; Frollini, E. Carboxymethyl lignin as stabilizing agent in aqueous ceramic suspensions. Ind. Crop. Prod. 2012, 36, 108–115. [Google Scholar] [CrossRef]

- Faria, F.A.C.; Evtuguin, D.V.; Rudnitskaya, A.; Gomes, M.T.S.R.; Oliveira, J.A.B.P.; Graca, M.P.F.; Costa, L.C. Lignin-based polyurethane doped with carbon nanotubes for sensor applications. Polym. Int. 2012, 61, 788–794. [Google Scholar] [CrossRef]

- Wang, H.; Zou, J.; Shen, Y.; Fei, G.; Mou, J. Preparation and colloidal properties of an aqueous acetic acid lignin containing polyurethane surfactant. J. Appl. Polym. Sci. 2013, 130, 1855–1862. [Google Scholar] [CrossRef]

- Wu, R.; Wang, X.; Li, F.; Li, H.; Wang, Y. Green composite films prepared from cellulose, starch and lignin in room-temperature ionic liquid. Bioresour. Technol. 2009, 100, 2569–2574. [Google Scholar] [CrossRef]

- Li, Y.; Cao, X.; Qian, X.; Chen, Y.; Liu, S.Q. Immobilization of laccase in N-doped carbon hollow spheres/chitosan composite film for electrochemical detection of kraft lignin. J. Electroanal Chem 2012, 686, 7–11. [Google Scholar] [CrossRef]

- Raschip, I.E.; Hitruc, G.E.; Vasile, C.; Popescu, M.C. Effect of the lignin type on the morphology and thermal properties of the xanthan/lignin hydrogels. Int. J. Biol. Macromol. 2013, 54, 230–237. [Google Scholar] [CrossRef]

- Otani, S.; Fukuoka, Y.; Igarashi, B.; Sasaki, K. Method for Producing Carbonized Lignin Fiber. U.S. Patent 3,461,082, 12 August 1969. [Google Scholar]

- Luhar, S.; Suntharalingam, T.; Navaratnam, S.; Luhar, I.; Thamboo, J.; Poologanathan, K.; Gatheeshgar, P. Sustainable and renewable bio-based natural fibres and its application for 3D printed concrete: A review. Sustainability 2020, 12, 10485. [Google Scholar] [CrossRef]

- Li, Q.; Serem, W.K.; Dai, W.; Yue, Y.; Naik, M.T.; Xie, S.X.; Karki, P.; Liu, L.; Sue, H.J.; Liang, H.; et al. Molecular weight and uniformity define the mechanical performance of lignin-based carbon fiber. J. Mater. Chem. A 2017, 5, 12740–12746. [Google Scholar] [CrossRef]

- Li, Q.; Xie, S.X.; Serem, W.K.; Naik, M.T.; Liu, L.; Yuan, J.S. Quality carbon fibers from fractionated lignin. Green Chem. 2017, 19, 1628–1634. [Google Scholar] [CrossRef]

- Zhang, M.; Ogale, A.A. Carbon fibers from dry-spinning of acetylated softwood kraft lignin. Carbon 2014, 69, 626–629. [Google Scholar] [CrossRef]

- Zhang, M.; Ogale, A.A. Effect of temperature and concentration of acetylated-lignin solutions on dry-spinning of carbon fiber precursors. J. Appl. Polym. Sci. 2016, 133. [Google Scholar] [CrossRef]

- Kubo, S.; Kadla, J.F. Lignin-based carbon fibers: Effect of synthetic polymer blending on fiber properties. J. Polym. Environ. 2005, 13, 97–105. [Google Scholar] [CrossRef]

- Schmack, G.; Tändler, B.; Optiz, G.; Vogel, R.; Komber, H.; Häußler, L.; Voigt, D.; Weinmann, S.; Heinemann, M.; Fritz, H.G. High-speed melt spinning of various grades of polylactides. J. Appl. Polym. Sci. 2004, 91, 800–806. [Google Scholar] [CrossRef]

- Hufenus, R.; Yan, Y.; Dauner, M.; Kikutani, T. Melt-spun fibers for textile applications. Materials 2020, 13, 4298. [Google Scholar] [CrossRef]

- Ogale, A.A.; Zhang, M.; Jin, J. Recent advances in carbon fibers derived from biobased precursors. J. Appl. Polym. Sci. 2016, 133. [Google Scholar] [CrossRef] [Green Version]

- Huang, X. Fabrication and properties of carbon fibers. Materials 2009, 2, 2369–2403. [Google Scholar] [CrossRef]

- Frank, E.; Steudle, L.M.; Ingildeev, D.; Sporl, J.M.; Buchmeiser, M.R. Carbon fibers: Precursor systems, processing, structure, and properties. Angew. Chem. Int. Ed. 2014, 53, 5262–5298. [Google Scholar] [CrossRef] [PubMed]

- Souto, F.; Calado, V.; Pereira, N. Lignin-based carbon fiber: A current overview. Mater. Res. Express 2018, 5, 072001. [Google Scholar] [CrossRef]

- Wang, S.; Bai, J.; Innocent, M.T.; Wang, Q.; Xiang, H.; Tang, J.; Zhu, M. Lignin-based carbon fibers: Formation, modification and potential applications. Green Energy Environ. 2021. [Google Scholar] [CrossRef]

- Baker, D.A.; Rials, T.G. Recent advances in low-cost carbon fiber manufacture from lignin. J. Appl. Polym. Sci. 2013, 130, 713–728. [Google Scholar] [CrossRef]

- Sagues, W.J.; Jain, A.; Brown, D.; Aggarwal, S.; Suarez, A.; Kollman, M.; Park, S.; Argyropoulos, D.S. Are lignin-derived carbon fibers graphitic enough? Green Chem. 2019, 21, 4253–4265. [Google Scholar] [CrossRef]

- Demiroğlu Mustafov, S.; Seydibeyoğlu, M.Ö. Surface Treatment of Lignin Sourced Carbon Fibers: Principles, Processes, and Challenges. In Sustainable Lignin for Carbon Fibers: Principles, Techniques, and Applications; Akpan, E.I., Adeosun, S.O., Eds.; Springer International Publishing: Cham, Swizerland, 2019; pp. 427–439. [Google Scholar]

- Svinterikos, E.; Zuburtikudis, I.; Al-Marzouqi, M. Electrospun lignin-derived carbon micro- and nanofibers: A review on precursors, properties, and applications. ACS Sustain. Chem. Eng. 2020, 8, 13868–13893. [Google Scholar] [CrossRef]

- Marisa, T.; Ounis, H.; Benchabane, A.; Sedira, L. Effect of lignin on the mechanical properties of a composite material based on date palm leaflets and expanded polystyrene wastes. Tecn. Ital. Ital. J. Eng. Sci. 2019, 63, 393–396. [Google Scholar]

- Doherty, W.O.S.; Mousavioun, P.; Fellows, C.M. Value-adding to cellulosic ethanol: Lignin polymers. Ind. Crop. Prod. 2011, 33, 259–276. [Google Scholar] [CrossRef] [Green Version]

- Chakar, F.S.; Ragauskas, A.J. Review of current and future softwood kraft lignin process chemistry. Ind. Crop. Prod. 2004, 20, 131–141. [Google Scholar] [CrossRef]

- Cheng, G.; Kent, M.S.; He, L.; Varanasi, P.; Dibble, D.; Arora, R.; Deng, K.; Hong, K.; Melnichenko, Y.B.; Simmons, B.A.; et al. Effect of ionic liquid treatment on the structures of lignins in solutions: Molecular subunits released from lignin. Langmuir 2012, 28, 11850–11857. [Google Scholar] [CrossRef]

- Qiu, X.; Kong, Q.; Zhou, M.; Yang, D. Aggregation behavior of sodium lignosulfonate in water solution. J. Phys. Chem. B 2010, 114, 15857–15861. [Google Scholar] [CrossRef]

- Deng, Y.; Feng, X.; Zhou, M.; Qian, Y.; Yu, H.; Qiu, X. Investigation of aggregation and assembly of alkali lignin using iodine as a probe. Biomacromolecules 2011, 12, 1116–1125. [Google Scholar] [CrossRef] [PubMed]

- Ragauskas, A.J.; Beckham, G.T.; Biddy, M.J.; Chandra, R.; Chen, F.; Davis, M.F.; Davison, B.H.; Dixon, R.A.; Gilna, P.; Keller, M.; et al. Lignin valorization: Improving lignin processing in the biorefinery. Science 2014, 344, 1246843. [Google Scholar] [CrossRef] [PubMed]

- Kai, D.; Tan, M.J.; Chee, P.L.; Chua, Y.K.; Yap, Y.L.; Loh, X.J. Towards lignin-based functional materials in a sustainable world. Green Chem. 2016, 18, 1175–1200. [Google Scholar] [CrossRef]

- Boerjan, W.; Ralph, J.; Baucher, M. Lignin biosynthesis. Annu. Rev. Plant Biol. 2003, 54, 519–546. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; He, H.; Dong, K.; Fan, M.; Zhang, S. A DFT study on lignin dissolution in imidazolium-based ionic liquids. RSC Adv. 2017, 7, 12670–12681. [Google Scholar] [CrossRef] [Green Version]

- Sen, S.; Patil, S.; Argyropoulos, D.S. Thermal properties of lignin in copolymers, blends, and composites: A review. Green Chem. 2015, 17, 4862–4887. [Google Scholar] [CrossRef]

- Windeisen, E.; Wegener, G. Lignin as Building Unit for Polymers. In Polymer Science: A Comprehensive Reference; Matyjaszewski, K., Möller, M., Eds.; Elsevier: Amsterdam, The Netherlands, 2012; pp. 255–265. [Google Scholar]

- Chatterjee, S.; Saito, T. Lignin-derived advanced carbon materials. ChemSusChem 2015, 8, 3941–3958. [Google Scholar] [CrossRef]

- Mei, Q.Q.; Shen, X.J.; Liu, H.Z.; Han, B.X. Selectively transform lignin into value-added chemicals. Chin. Chem. Lett. 2019, 30, 15–24. [Google Scholar] [CrossRef]

- Li, C.; Zhao, X.; Wang, A.; Huber, G.W.; Zhang, T. Catalytic Transformation of Lignin for the Production of Chemicals and Fuels. Chem. Rev. 2015, 115, 11559–11624. [Google Scholar] [CrossRef]

- Karhunen, P.; Rummakko, P.; Sipila, J.; Brunow, G.; Kilpelainen, I. Dibenzodioxocins—A novel type of linkage in softwood lignins. Tetrahedron Lett. 1995, 36, 169–170. [Google Scholar] [CrossRef]

- Choi, D.; Kil, H.S.; Lee, S. Fabrication of low-cost carbon fibers using economical precursors and advanced processing technologies. Carbon 2019, 142, 610–649. [Google Scholar] [CrossRef]

- Irvine, G.M. The significance of the glass transition of lignin in thermomechanical pulping. Wood Sci. Technol. 1985, 19, 139–149. [Google Scholar] [CrossRef]

- Hillis, W.E.; Rozsa, A.N. The softening temperatures of wood. Holzforschung 1978, 32, 68–73. [Google Scholar] [CrossRef]

- Holladay, J.E.; White, J.F.; Bozell, J.J.; Johnson, D. Top Value-Added Chemicals from Biomass—Volume II—Results of Screening for Potential Candidates from Biorefinery Lignin; Pacific Northwest National Lab (PNNL): Richland, WA, USA, 2007. [Google Scholar]

- Constantino, C.J.L.; Dhanabalan, A.; Curvelo, A.; Oliveira, O.N. Preparation and characterization of composite LB films of lignin and cadmium stearate. Thin Solid Films 1998, 327, 47–51. [Google Scholar] [CrossRef]

- Singha, A.S.; Thakur, V.K.; Mehta, I.K.; Shama, A.; Khanna, A.J.; Rana, R.K.; Rana, A.K. Surface-modified hibiscus sabdariffa fibers: Physicochemical, thermal, and morphological properties evaluation. Int. J. Polym. Anal. Charact. 2009, 14, 695–711. [Google Scholar] [CrossRef]

- Schutyser, W.; Renders, T.; Van den Bosch, S.; Koelewijn, S.F.; Beckham, G.T.; Sels, B.F. Chemicals from lignin: An interplay of lignocellulose fractionation, depolymerisation, and upgrading. Chem. Soc. Rev. 2018, 47, 852–908. [Google Scholar] [CrossRef] [PubMed]

- Vishtal, A.; Kraslawski, A. Challenges in industrial applications of technical lignins. Bioresources 2011, 6, 3547–3568. [Google Scholar] [CrossRef]

- De la Torre, M.J.; Moral, A.; Hernández, M.D.; Cabeza, E.; Tijero, A. Organosolv lignin for biofuel. Ind. Crop. Prod. 2013, 45, 58–63. [Google Scholar] [CrossRef]

- Hosseinaei, O.; Harper, D.P.; Bozell, J.J.; Rials, T.G. Role of Physicochemical Structure of Organosolv Hardwood and Herbaceous Lignins on Carbon Fiber Performance. ACS Sustain. Chem. Eng. 2016, 4, 5785–5798. [Google Scholar] [CrossRef]

- Shrotri, A.; Kobayashi, H.; Fukuoka, A. Catalytic Conversion of Structural Carbohydrates and Lignin to Chemicals. In Advances in Catalysis; Song, C., Ed.; Academic Press: Cambridge, MA, USA, 2017; Volume 60, pp. 59–123. [Google Scholar]

- Malkin, A.Y.; Isayev, A.I. Applications of rheology. In Rheology Concepts, Methods, and Applications; Malkin, A.Y., Isayev, A.I., Eds.; Elsevier: Oxford, UK, 2012; pp. 365–420. [Google Scholar]

- Afshari, M.; Kotek, R.; Tonelli, A.E.; Jung, D.W. Producing polyamide nanofibers by electrospinning. In Nanofibers and Nanotechnology in Textiles; Brown, P.J., Stevens, K., Eds.; Woodhead Publishing: Sawston, UK, 2007; pp. 71–89. [Google Scholar]

- Pedicini, A.; Farris, R.J. Thermally induced color change in electrospun fiber mats. J. Polym. Sci. Part B Polym. Phys. 2004, 42, 752–757. [Google Scholar] [CrossRef]

- Deitzel, J.M.; Kosik, W.; McKnight, S.H.; Tan, N.C.B.; DeSimone, J.M.; Crette, S. Electrospinning of polymer nanofibers with specific surface chemistry. Polymer 2002, 43, 1025–1029. [Google Scholar] [CrossRef]

- Fitzer, E.; Manocha, L.M. Carbon Reinforcements and Carbon/Carbon Composites; Springer Science & Business Media: Berlin, Germany, 2012. [Google Scholar]

- Wheatley, A.; Warren, D.; Das, S. Low-cost carbon fibre: Applications, performance and cost models. Adv. Compos. Mater. Automotive Appl. 2013, 405–434. [Google Scholar] [CrossRef]

- Sudo, K.; Shimizu, K. A new carbon-fiber from lignin. J. Appl. Polym. Sci. 1992, 44, 127–134. [Google Scholar] [CrossRef]

- Wang, S.; Zhou, Z.; Xiang, H.; Chen, W.; Yin, E.; Chang, T.; Zhu, M. Reinforcement of lignin-based carbon fibers with functionalized carbon nanotubes. Compos. Sci. Technol. 2016, 128, 116–122. [Google Scholar] [CrossRef]

- Wang, S.; Li, Y.; Xiang, H.; Zhou, Z.; Chang, T.; Zhu, M. Low cost carbon fibers from bio-renewable Lignin/Poly(lactic acid) (PLA) blends. Compos. Sci. Technol. 2015, 119, 20–25. [Google Scholar] [CrossRef]

- Alexy, P.; Kosikova, B.; Podstranska, G. The effect of blending lignin with polyethylene and polypropylene on physical properties. Polymer 2000, 41, 4901–4908. [Google Scholar] [CrossRef]

- Kadla, J.F.; Kubo, S.; Venditti, R.A.; Gilbert, R.D.; Compere, A.L.; Griffith, W. Lignin-based carbon fibers for composite fiber applications. Carbon 2002, 40, 2913–2920. [Google Scholar] [CrossRef]

- Thunga, M.; Chen, K.; Grewell, D.; Kessler, M.R. Bio-renewable precursor fibers from lignin/polylactide blends for conversion to carbon fibers. Carbon 2014, 68, 159–166. [Google Scholar] [CrossRef] [Green Version]

- Zhang, M.; Ogale, A.A. Carbon fibers derived from acetylated softwood kraft lignin. Polym. Precursor Deriv. Carbon 2014, 1173, 137–152. [Google Scholar]

- Sudo, K.; Shimizu, K.; Nakashima, N.; Yokoyama, A. A new modification method of exploded lignin for the preparation of a carbon fiber precursor. J. Appl. Polym. Sci. 1993, 48, 1485–1491. [Google Scholar] [CrossRef]

- Ziabicki, A. Studies on the orientation phenomena by fiber formation from polymer melts. Part II. Theoretical considerations. J. Appl. Polym. Sci. 1960, 4, 24–31. [Google Scholar] [CrossRef]

- Heuvel, H.M.; Huisman, R. Effect of winding speed on the physical structure of as-spun poly(ethylene terephthalate) fibers, including orientation-induced crystallization. J. Appl. Polym. Sci. 1978, 22, 2229–2243. [Google Scholar] [CrossRef]

- Jin, J.; Ding, J.; Klett, A.S.; Thies, M.C.; Ogale, A.A. Carbon fibers derived from fractionated–solvated lignin precursors for enhanced mechanical performance. ACS Sustain. Chem. Eng. 2018, 6, 14135–14142. [Google Scholar] [CrossRef]

- Yoon, H. Melt Spinning of High Performance Poly(ethylene terephthalate) (PET) Multifilament Yarn via Utilizing a Horizontal Isothermal Bath (HIB) in the Threadline; North Carolina State University: Raleigh, NC, USA, 2012. [Google Scholar]

- Compere, A.L.; Griffith, W.L.; Leitten, C.F.; Shaffer, J.T. Low cost carbon fiber from renewable resources. Adv. Afford. Mater. Technol. 2001, 33, 1306–1314. [Google Scholar]

- Qin, W.; Kadla, J.F. Carbon fibers based on pyrolytic lignin. J. Appl. Polym. Sci. 2012, 126, E204–E213. [Google Scholar] [CrossRef]

- Uraki, Y.; Kubo, S.; Nigo, N.; Sano, Y.; Sasaya, T. Preparation of carbon-fibers from organosolv lignin obtained by aqueous acetic-acid pulping. Holzforschung 1995, 49, 343–350. [Google Scholar] [CrossRef]

- Thielemans, W.; Wool, R.P. Lignin esters for use in unsaturated thermosets: Lignin modification and solubility modeling. Biomacromolecules 2005, 6, 1895–1905. [Google Scholar] [CrossRef]

- Culebras, M.; Beaucamp, A.; Wang, Y.; Clauss, M.M.; Frank, E.; Collins, M.N. Biobased Structurally Compatible Polymer Blends Based on Lignin and Thermoplastic Elastomer Polyurethane as Carbon Fiber Precursors. ACS Sustain. Chem. Eng. 2018, 6, 8816–8825. [Google Scholar] [CrossRef]

- Hosseinaei, O.; Harper, D.P.; Bozell, J.J.; Rials, T.G. Improving Processing and Performance of Pure Lignin Carbon Fibers through Hardwood and Herbaceous Lignin Blends. Int. J. Mol. Sci. 2017, 18, 1410. [Google Scholar] [CrossRef] [Green Version]

- Nordström, Y.; Norberg, I.; Sjöholm, E.; Drougge, R. A new softening agent for melt spinning of softwood kraft lignin. J. Appl. Polym. Sci. 2013, 129, 1274–1279. [Google Scholar] [CrossRef]

- Qu, W.; Liu, J.; Xue, Y.; Wang, X.; Bai, X. Potential of producing carbon fiber from biorefinery corn stover lignin with high ash content. J. Appl. Polym. Sci. 2018, 135, 45736. [Google Scholar] [CrossRef]

- Qu, W.; Xue, Y.; Gao, Y.; Rover, M.; Bai, X. Repolymerization of pyrolytic lignin for producing carbon fiber with improved properties. Biomass Bioenergy 2016, 95, 19–26. [Google Scholar] [CrossRef] [Green Version]

- Luo, Y.; Qu, W.; Cochran, E.; Bai, X. Enabling high-quality carbon fiber through transforming lignin into an orientable and melt-spinnable polymer. J. Clean. Prod. 2021, 307, 127252. [Google Scholar] [CrossRef]

- Kubo, S.; Uraki, Y.; Sano, Y. Preparation of carbon fibers from softwood lignin by atmospheric acetic acid pulping. Carbon 1998, 36, 1119–1124. [Google Scholar] [CrossRef]

- Chen, K. Bio-Renewable Fibers Extracted from Lignin/Polylactide (PLA) Blend; Iowa State University: Ames, IA, USA, 2012. [Google Scholar]

- Beaucamp, A.; Wang, Y.; Culebras, M.; Collins, M.N. Carbon fibres from renewable resources: The role of the lignin molecular structure in its blendability with biobased poly(ethylene terephthalate). Green Chem. 2019, 21, 5063–5072. [Google Scholar] [CrossRef]

- Lin, J.; Kubo, S.; Yamada, T.; Koda, K.; Uraki, Y. Chemical thermostabilization for the preparation of carbon fibers from softwood lignin. Bioresources 2012, 7, 13. [Google Scholar] [CrossRef]

- Kleinhans, H.; Salmén, L. Development of lignin carbon fibers: Evaluation of the carbonization process. J. Appl. Polym. Sci. 2016, 133. [Google Scholar] [CrossRef]

- Baker, D.A.; Gallego, N.C.; Baker, F.S. On the characterization and spinning of an organic-purified lignin toward the manufacture of low-cost carbon fiber. J. Appl. Polym. Sci. 2012, 124, 227–234. [Google Scholar] [CrossRef]

- Klett, A.S.; Chappell, P.V.; Thies, M.C. Recovering ultraclean lignins of controlled molecular weight from Kraft black-liquor lignins. Chem. Commun. 2015, 51, 12855–12858. [Google Scholar] [CrossRef] [PubMed]

- Klett, A.S.; Payne, M.; Thies, M.C. Continuous-flow process for the purification and fractionation of alkali and Organosolv lignins. ACS Sustain. Chem. Eng. 2016, 4, 6689–6694. [Google Scholar] [CrossRef]

- Thies, M.C.; Klett, A.S.; Bruce, D.A. Solvent and Recovery Process for Lignin. U.S. Patent 10,053,482, 21 August 2018. [Google Scholar]

- Liu, L.Y.; Hua, Q.; Renneckar, S. A simple route to synthesize esterified lignin derivatives. Green Chem. 2019, 21, 3682–3692. [Google Scholar] [CrossRef]

- Buono, P.; Duval, A.; Verge, P.; Averous, L.; Habibi, Y. New insights on the chemical modification of lignin: Acetylation versus silylation. ACS Sustain. Chem. Eng. 2016, 4, 5212–5222. [Google Scholar] [CrossRef]

- Soutis, C. Carbon fiber reinforced plastics in aircraft construction. Mater. Sci. Eng. 2005, 412, 171–176. [Google Scholar] [CrossRef]

- Kadla, J.F.; Kubo, S. Lignin-based polymer blends: Analysis of intermolecular interactions in lignin–synthetic polymer blends. Compos. Part A Appl. Sci. Manuf. 2004, 35, 395–400. [Google Scholar] [CrossRef]

- Kadla, J.F.; Kubo, S.; Venditti, R.A.; Gilbert, R.D. Novel hollow core fibers prepared from lignin polypropylene blends. J. Appl. Polym. Sci. 2002, 85, 1353–1355. [Google Scholar] [CrossRef]

- Baker, F.; Menchhofer, P. Carbon Nanotube (CNT) Enhanced Precursor for Carbon Fiber Production and Method of Making a CNT Enhanced Continuous Lignin Fiber. U.S. Patent 2011285049, 24 November 2011. [Google Scholar]

- Kubo, S.; Yoshida, T.; Kadla, J.F. Surface porosity of lignin/PP Blend carbon fibers. J. Wood Chem. Technol. 2007, 27, 257–271. [Google Scholar] [CrossRef]

- Zhang, M.; Jin, J.; Ogale, A. Carbon fibers from UV-assisted stabilization of lignin-based precursors. Fibers 2015, 3, 184–196. [Google Scholar] [CrossRef]

- Oroumei, A.; Lynch, P.; Tobin, M.; Naebe, M. Synchrotron X-ray scattering and IR-mapping studies of wet-spun lignin-derived carbon fibre precursor. Compos. Sci. Technol. 2018, 163, 151–161. [Google Scholar] [CrossRef]

- Dong, X.; Lu, C.; Zhou, P.; Zhang, S.; Wang, L.; Li, D. Polyacrylonitrile/lignin sulfonate blend fiber for low-cost carbon fiber. RSC Adv. 2015, 5, 42259–42265. [Google Scholar] [CrossRef]

- Maradur, S.P.; Kim, C.H.; Kim, S.Y.; Kim, B.H.; Kim, W.C.; Yang, K.S. Preparation of carbon fibers from a lignin copolymer with polyacrylonitrile. Synth. Met. 2012, 162, 453–459. [Google Scholar] [CrossRef]

- Blades, H. Dry Jet Wet Spinning Process. U.S. Patent 3,767,756, 23 October 1973. [Google Scholar]

- Khayyam, H.; Jazar, R.N.; Nunna, S.; Golkarnarenji, G.; Badii, K.; Fakhrhoseini, S.M.; Kumar, S.; Naebe, M. PAN precursor fabrication, applications and thermal stabilization process in carbon fiber production: Experimental and mathematical modelling. Prog. Mater. Sci. 2020, 107, 100575. [Google Scholar] [CrossRef]

- Lewin, M. Handbook of Fiber Chemistry; CRC Press: Boca Raton, FL, USA, 2006. [Google Scholar]

- Liu, H.; Chien, A.T.; Newcomb, B.A.; Liu, Y.; Kumar, S. Processing, structure, and properties of lignin- and CNT-incorporated polyacrylonitrile-based carbon fibers. ACS Sustain. Chem. Eng. 2015, 3, 1943–1954. [Google Scholar] [CrossRef]

- Lu, C.; Blackwell, C.; Ren, Q.; Ford, E. Effect of the coagulation bath on the structure and mechanical properties of gel-spun lignin/poly(vinyl alcohol) fibers. ACS Sustain. Chem. Eng. 2017, 5, 2949–2959. [Google Scholar] [CrossRef]

- Lu, C.; Rawat, P.; Louder, N.; Ford, E. Properties and structural anisotropy of gel-spun lignin/poly(vinyl alcohol) fibers due to gel aging. ACS Sustain. Chem. Eng. 2018, 6, 679–689. [Google Scholar] [CrossRef]

- Liu, H.; Luo, J.; Chang, H.; Davijani, A.A.B.; Wang, P.; Kumar, S. Polyacrylonitrile sheath and polyacrylonitrile/lignin core bi-component carbon fibers. Carbon 2019, 149, 165–172. [Google Scholar] [CrossRef] [Green Version]

- Smith, P.; Lemstra, P.J.; Booij, H.C. Ultradrawing of high-molecular-weight polyethylene cast from solution. II. Influence of initial polymer concentration. J. Polym. Sci. Polym. Phys. Ed. 1981, 19, 877–888. [Google Scholar] [CrossRef] [Green Version]

- Kuo, C.J.; Lan, W.L. Gel spinning of synthetic polymer fibres. In Advances in Filament Yarn Spinning of Textiles and Polymers; Zhang, D., Ed.; Woodhead Publishing: Sawston, UK, 2014; pp. 100–112. [Google Scholar]

- Chen, H.; Du, W.; Ye, W.; Pan, D. Structure of PAN precursor in thermal-induced gel spinning. J. Appl. Polym. Sci. 2011, 122, 1176–1181. [Google Scholar] [CrossRef]

- Le, N.D.; Trogen, M.; Varley, R.J.; Hummel, M.; Byrne, N. Effect of boric acid on the stabilisation of cellulose-lignin filaments as precursors for carbon fibres. Cellulose 2021, 28, 729–739. [Google Scholar] [CrossRef]

- Xia, K.; Ouyang, Q.; Chen, Y.; Wang, X.; Qian, X.; Wang, L. Preparation and characterization of lignosulfonate–acrylonitrile copolymer as a novel carbon fiber precursor. ACS Sustain. Chem. Eng. 2015, 4, 159–168. [Google Scholar] [CrossRef]

- Ouyang, Q.; Xia, K.; Liu, D.; Jiang, X.; Ma, H.; Chen, Y. Fabrication of partially biobased carbon fibers from novel lignosulfonate–acrylonitrile copolymers. J. Mater. Sci. 2017, 52, 7439–7451. [Google Scholar] [CrossRef]

- Husman, G. Development and Commercialization of a Novel Low-Cost Carbon Fiber. Presentation at 2014 DOE Hydrogen and Fuel Cells Program and Vehicle Technologies Program Annual Merit Review and Peer Evaluation Meeting. 17 June 2014. Available online: https://www.energy.gov/sites/prod/files/2014/07/f17/lm048_husman_2014_o_0.pdf (accessed on 1 May 2021).

- Park, C.W.; Youe, W.J.; Han, S.Y.; Kim, Y.S.; Lee, S.H. Solubility of kraft lignin-g-polyacrylonitrile copolymer in various ionic liquids and characterization of its solution. Wood Sci. Technol. 2017, 51, 151–163. [Google Scholar] [CrossRef]

- Jin, J.; Ogale, A.A. Carbon fibers derived from wet-spinning of equi-component lignin/polyacrylonitrile blends. J. Appl. Polym. Sci. 2018, 135. [Google Scholar] [CrossRef]

- Bengtsson, A.; Bengtsson, J.; Olsson, C.; Sedin, M.; Jedvert, K.; Theliander, H.; Sjoholm, E. Improved yield of carbon fibres from cellulose and kraft lignin. Holzforschung 2018, 72, 1007–1016. [Google Scholar] [CrossRef]

- Follmer, M.; Jestin, S.; Neri, W.; Derre, A.; Bentaleb, A.; Mercader, C.; Poulin, P. Structuration of lignin-graphene oxide based carbon materials through liquid crystallinity. Carbon 2019, 149, 297–306. [Google Scholar] [CrossRef]

- Follmer, M.; Jestin, S.; Neri, W.; Vo, V.; Derre, A.; Mercader, C.; Poulin, P. Wet-spinning and carbonization of lignin-polyvinyl alcohol precursor fibers. Adv. Sustain. Syst. 2019, 3, 1900082. [Google Scholar] [CrossRef]

- Trogen, M.; Le, N.D.; Sawada, D.; Guizani, C.; Lourencon, T.V.; Pitkanen, L.; Sixta, H.; Shah, R.; O’Neill, H.; Balakshin, M.; et al. Cellulose-lignin composite fibres as precursors for carbon fibres. Part 1—Manufacturing and properties of precursor fibres. Carbohydr. Polym. 2021, 252, 117133. [Google Scholar] [CrossRef]

- Bengtsson, A.; Hecht, P.; Sommertune, J.; Ek, M.; Sedin, M.; Sjöholm, E. Carbon fibers from lignin–cellulose precursors: Effect of carbonization conditions. ACS Sustain. Chem. Eng. 2020, 8, 6826–6833. [Google Scholar] [CrossRef]

- Nypelo, T.; Asaadi, S.; Kneidinger, G.; Sixta, H.; Konnerth, J. Conversion of wood-biopolymers into macrofibers with tunable surface energy via dry-jet wet-spinning. Cellulose 2018, 25, 5297–5307. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ramasubramanian, G. Influence of Lignin Modification on PAN-Lignin Copolymers as Potential Carbon Fiber Precursors; Iowa State University: Ames, IA, USA, 2013. [Google Scholar]

- Husman, G. Development and Commercialization of a Novel Low-Cost Carbon Fiber. Presentation at 2013 DOE Hydrogen and Fuel Cells Program and Vehicle Technologies Program Annual Merit Review and Peer Evaluation Meeting. 15 May 2013. Available online: https://www.energy.gov/sites/prod/files/2014/03/f10/lm048_husman_2013_o_0.pdf (accessed on 1 May 2021).

- Jiang, X.; Ouyang, Q.; Liu, D.; Huang, J.; Ma, H.; Chen, Y.; Wang, X.; Sun, W. Preparation of low-cost carbon fiber precursors from blends of wheat straw lignin and commercial textile-grade polyacrylonitrile (PAN). Holzforschung 2018, 72, 727–734. [Google Scholar] [CrossRef]

- Zhang, B.; Lu, C.; Liu, Y.; Zhou, P. Wet spun polyacrylontrile-based hollow fibers by blending with alkali lignin. Polymer 2018, 149, 294–304. [Google Scholar] [CrossRef]

- Jia, Z.; Lu, C.; Liu, Y.; Zhou, P.; Wang, L. Lignin/polyacrylonitrile composite hollow fibers prepared by wet spinning method. ACS Sustain. Chem. Eng. 2016, 4, 2838–2842. [Google Scholar] [CrossRef]

- He, Q.; Zhou, P.; Hao, J.; Lu, C.; Liu, Y. Incorporation of alkali lignin in polyacrylonitrile: Phase separation, coagulation, and cyclization kinetics. ACS Omega 2019, 4, 11346–11353. [Google Scholar] [CrossRef] [Green Version]

- Porkodi, P.; Abhilash, J.K.; Shukla, H.K.; Rawat, J. Rheological properties of concentrated polyacrylonitrile co-polymer and lignin blend solution. Polym. Bull. 2020, 77, 3937–3951. [Google Scholar] [CrossRef]

- Liu, H.C.; Tuan, C.C.; Davijani, A.A.B.; Wang, P.H.; Chang, H.; Wong, C.P.; Kumar, S. Rheological behavior of polyacrylonitrile and polyacrylonitrile/lignin blends. Polymer 2017, 111, 177–182. [Google Scholar] [CrossRef]

- Song, L.; Ouyang, Q.; Huang, X.; Ma, H.; Chen, P.; Shen, L.; Wang, X. Carbon fibers with low cost and uniform disordered structure derived from lignin/polyacrylonitrile composite precursors. Fibers Polym. 2021, 22, 240–248. [Google Scholar] [CrossRef]

- Cha, W.I.; Hyon, S.H.; Ikada, Y. Gel spinning of poly(vinyl alcohol) from dimethyl sulfoxide/water mixture. J. Polym. Sci. Pol. Phys. 1994, 32, 297–304. [Google Scholar] [CrossRef]

- Yamaura, K.; Tanigami, T.; Hayashi, N.; Kosuda, K.; Okuda, S.; Takemura, Y.; Itoh, M.; Matsuzawa, S. Preparation of high modulus poly(vinyl alcohol) by drawing. J. Appl. Polym. Sci. 1990, 40, 905–916. [Google Scholar] [CrossRef]

- Bengtsson, A.; Bengtsson, J.; Sedin, M.; Sjoholm, E. Carbon fibers from lignin-cellulose precursors: Effect of stabilization conditions. ACS Sustain. Chem. Eng. 2019, 7, 8440–8448. [Google Scholar] [CrossRef] [Green Version]

- Olsson, C.; Sjöholm, E.; Reimann, A. Carbon fibres from precursors produced by dry-jet wet-spinning of kraft lignin blended with kraft pulps. Holzforschung 2017, 71, 275–283. [Google Scholar] [CrossRef]

- Le, N.D.; Trogen, M.; Ma, Y.; Varley, R.J.; Hummel, M.; Byrne, N. Cellulose-lignin composite fibers as precursors for carbon fibers: Part 2—The impact of precursor properties on carbon fibers. Carbohydr. Polym. 2020, 250, 116918. [Google Scholar] [CrossRef]

- Le, N.D.; Trogen, M.; Ma, Y.B.; Varley, R.J.; Hummel, M.; Byrne, N. Understanding the influence of key parameters on the stabilisation of cellulose-lignin composite fibres. Cellulose 2021, 28, 911–919. [Google Scholar] [CrossRef]

- Byrne, N.; De Silva, R.; Ma, Y.; Sixta, H.; Hummel, M. Enhanced stabilization of cellulose-lignin hybrid filaments for carbon fiber production. Cellulose 2018, 25, 723–733. [Google Scholar] [CrossRef] [Green Version]

- Svenningsson, L.; Bengtsson, J.; Jedvert, K.; Schlemmer, W.; Theliander, H.; Evenas, L. Disassociated molecular orientation distributions of a composite cellulose-lignin carbon fiber precursor: A study by rotor synchronized NMR spectroscopy and X-ray scattering. Carbohydr. Polym. 2021, 254, 117293. [Google Scholar] [CrossRef]

- Wang, L.; Ago, M.; Borghei, M.; Ishaq, A.; Papageorgiou, A.C.; Lundahl, M.; Rojas, O.J. Conductive carbon microfibers derived from wet-spun lignin/nanocellulose hydrogels. ACS Sustain. Chem. Eng. 2019, 7, 6013–6022. [Google Scholar] [CrossRef] [Green Version]

- Vincent, S.; Prado, R.; Kuzmina, O.; Potter, K.; Bhardwaj, J.; Wanasekara, N.D.; Harniman, R.L.; Koutsomitopoulou, A.; Eichhorn, S.J.; Welton, T.; et al. Regenerated cellulose and willow lignin blends as potential renewable precursors for carbon fibers. ACS Sustain. Chem. Eng. 2018, 6, 5903–5910. [Google Scholar] [CrossRef]

- Torres-Canas, F.; Bentaleb, A.; Follmer, M.; Roman, J.; Neri, W.; Ly, I.; Derre, A.; Poulin, P. Improved structure and highly conductive lignin-carbon fibers through graphene oxide liquid crystal. Carbon 2020, 163, 120–127. [Google Scholar] [CrossRef]

- Svinterikos, E.; Zuburtikudis, I. Carbon nanofibers from renewable bioresources (lignin) and a recycled commodity polymer [poly(ethylene terephthalate)]. J. Appl. Polym. Sci. 2016, 133. [Google Scholar] [CrossRef]

- Youe, W.J.; Lee, S.M.; Lee, S.S.; Lee, S.H.; Kim, Y.S. Characterization of carbon nanofiber mats produced from electrospun lignin-g-polyacrylonitrile copolymer. Int. J. Biol. Macromol. 2016, 82, 497–504. [Google Scholar] [CrossRef]

- Ruiz-Rosas, R.; Bedia, J.; Lallave, M.; Loscertales, I.G.; Barrero, A.; Rodriguez-Mirasol, J.; Cordero, T. The production of submicron diameter carbon fibers by the electrospinning of lignin. Carbon 2010, 48, 696–705. [Google Scholar] [CrossRef]

- Xu, X.; Zhou, J.; Jiang, L.; Lubineau, G.; Payne, S.A.; Gutschmidt, D. Lignin-based carbon fibers: Carbon nanotube decoration and superior thermal stability. Carbon 2014, 80, 91–102. [Google Scholar] [CrossRef] [Green Version]

- Svinterikos, E.; Zuburtikudis, I.; Al-Marzouqi, M. The nanoscale dimension determines the carbonization outcome of electrospun lignin/recycled-PET fibers. Chem. Eng. Sci. 2019, 202, 26–35. [Google Scholar] [CrossRef]

- Li, Q.; Naik, M.T.; Lin, H.S.; Hu, C.; Serem, W.K.; Liu, L.; Karki, P.; Zhou, F.; Yuan, J. Tuning hydroxyl groups for quality carbon fiber of lignin. Carbon 2018, 139, 500–511. [Google Scholar] [CrossRef]

- Wang, S.; Innocent, M.T.; Chen, J.; Wang, Q.; Ma, W.; Tang, J. Tuning the microstructure and electrochemical behavior of lignin-based ultrafine carbon fibers via hydrogen-bonding interaction. Int. J. Biol. Macromol. 2020, 157, 706–714. [Google Scholar] [CrossRef]

- Ding, R.; Wu, H.; Thunga, M.; Bowler, N.; Kessler, M.R. Processing and characterization of low-cost electrospun carbon fibers from organosolv lignin/polyacrylonitrile blends. Carbon 2016, 100, 126–136. [Google Scholar] [CrossRef]

- Lallave, M.; Bedia, J.; Ruiz-Rosas, R.; Rodriguez-Mirasol, J.; Cordero, T.; Otero, J.C.; Marquez, M.; Barrero, A.; Loscertales, I.G. Filled and hollow carbon nanofibers by coaxial electrospinning of Alcell lignin without binder polymers. Adv. Mater. 2007, 19, 4292–4296. [Google Scholar] [CrossRef]

- Deitzel, J.M.; Kleinmeyer, J.; Harris, D.; Tan, N.C.B. The effect of processing variables on the morphology of electrospun nanofibers and textiles. Polymer 2001, 42, 261–272. [Google Scholar] [CrossRef]

- Prabu, G.T.V.; Dhurai, B. A novel profiled multi-pin electrospinning system for nanofiber production and encapsulation of nanoparticles into nanofibers. Sci. Rep. 2020, 10, 4302. [Google Scholar] [CrossRef] [Green Version]

- Garcia-Mateos, F.J.; Ruiz-Rosas, R.; Rosas, J.M.; Rodriguez-Mirasol, J.; Cordero, T. Controlling the composition, morphology, porosity, and surface chemistry of lignin-based electrospun carbon materials. Front. Mater. 2019, 6, 114. [Google Scholar] [CrossRef] [Green Version]

- Li, Z.; Wang, C. Effects of working parameters on electrospinning. In One-Dimensional Nanostructures: Electrospinning Technique and Unique Nanofibers; Li, Z., Wang, C., Eds.; Springer: Berlin/Heidelberg, Germany, 2013; pp. 15–28. [Google Scholar]

- Teo, W.E.; Inai, R.; Ramakrishna, S. Technological advances in electrospinning of nanofibers. Sci. Technol. Adv. Mater. 2011, 12, 013002. [Google Scholar] [CrossRef] [Green Version]

- Han, D.; Steckl, A.J. Coaxial electrospinning formation of complex polymer fibers and their applications. ChemPlusChem 2019, 84, 1453–1497. [Google Scholar] [CrossRef] [PubMed]

- Liu, L.; Xu, W.H.; Ding, Y.C.; Agarwal, S.; Greiner, A.; Duan, G.G. A review of smart electrospun fibers toward textiles. Compos. Commun. 2020, 22, 100506. [Google Scholar] [CrossRef]

- Azwar, E.; Wan Mahari, W.A.; Chuah, J.H.; Vo, D.V.N.; Ma, N.L.; Lam, W.H.; Lam, S.S. Transformation of biomass into carbon nanofiber for supercapacitor application—A review. Int. J. Hydrog. Energ. 2018, 43, 20811–20821. [Google Scholar] [CrossRef]

- Dallmeyer, I.; Ko, F.; Kadla, J.F. Electrospinning of technical Lignins for the production of fibrous networks. J. Wood Chem. Technol. 2010, 30, 315–329. [Google Scholar] [CrossRef]

- Poursorkhabi, V.; Abdelwahab, M.A.; Misra, M.; Khalil, H.; Gharabaghi, B.; Mohanty, A.K. Processing, carbonization, and characterization of lignin based electrospun carbon Fibers: A review. Front. Energy Res. 2020, 8. [Google Scholar] [CrossRef]

- Garcia-Mateos, F.J.; Cordero-Lanzac, T.; Berenguer, R.; Morallon, E.; Cazorla-Amoros, D.; Rodriguez-Mirasol, J.; Cordero, T. Lignin-derived Pt supported carbon (submicron)fiber electrocatalysts for alcohol electro-oxidation. Appl. Catal. B Environ. 2017, 211, 18–30. [Google Scholar] [CrossRef]

- Garcia-Mateos, F.J.; Berenguer, R.; Valero-Romero, M.J.; Rodriguez-Mirasol, J.; Cordero, T. Phosphorus functionalization for the rapid preparation of highly nanoporous submicron-diameter carbon fibers by electrospinning of lignin solutions. J. Mater. Chem. A 2018, 6, 1219–1233. [Google Scholar] [CrossRef]

- Mikes, P.; Baker, D.A.; Uhlin, A.; Lukas, D.; Kuzelova-Kostakova, E.; Vidrich, A.; Valtera, J.; Koprivova, B.; Asatiani, N.; Salmen, L.; et al. The mass production of lignin fibres by means of needleless electrospinning. J. Polym. Environ. 2021. [Google Scholar] [CrossRef]

- You, X.; Koda, K.; Yamada, T.; Uraki, Y. Preparation of electrode for electric double layer capacitor from electrospun lignin fibers. Holzforschung 2015, 69, 1097–1106. [Google Scholar] [CrossRef] [Green Version]

- Schlee, P.; Hosseinaei, O.; Baker, D.; Landmer, A.; Tomani, P.; Mostazo-Lopez, M.J.; Cazorla-Amoros, D.; Herou, S.; Titirici, M.M. From waste to wealth: From Kraft lignin to free-standing supercapacitors. Carbon 2019, 145, 470–480. [Google Scholar] [CrossRef]

- Lai, C.; Zhou, Z.; Zhang, L.; Wang, X.; Zhou, Q.; Zhao, Y.; Wang, Y.; Wu, X.; Zhu, Z.; Fong, H. Free-standing and mechanically flexible mats consisting of electrospun carbon nanofibers made from a natural product of alkali lignin as binder-free electrodes for high-performance supercapacitors. J. Power Sources 2014, 247, 134–141. [Google Scholar] [CrossRef]

- Shi, X.; Wang, X.; Tang, B.; Dai, Z.; Chen, K.; Zhou, J. Impact of lignin extraction methods on microstructure and mechanical properties of lignin-based carbon fibers. J. Appl. Polym. Sci. 2018, 135, 45580. [Google Scholar] [CrossRef]

- Shi, X.; Dai, Z.; Cao, Q.; Chen, K.; Zhou, J. Stepwise fractionation extracted lignin for high strength lignin-based carbon fibers. New J. Chem. 2019, 43, 18868–18875. [Google Scholar] [CrossRef]

- Cho, M.J.; Karaaslan, M.A.; Renneckar, S.; Ko, F. Enhancement of the mechanical properties of electrospun lignin-based nanofibers by heat treatment. J. Mater. Sci. 2017, 52, 9602–9614. [Google Scholar] [CrossRef]

- Dallmeyer, I.; Lin, L.T.; Li, Y.; Ko, F.; Kadla, J.F. Preparation and characterization of interconnected, kraft lignin-based carbon fibrous materials by electrospinning. Macromol. Mater. Eng. 2014, 299, 540–551. [Google Scholar] [CrossRef]

- Ghosh, T.; Chen, J.W.; Kumar, A.; Tang, T.; Ayranci, C. Bio-cleaning improves the mechanical properties of lignin-based carbon fibers. RSC Adv. 2020, 10, 22983–22995. [Google Scholar] [CrossRef]

- Cho, M.; Karaaslan, M.; Chowdhury, S.; Ko, F.; Renneckar, S. Skipping oxidative thermal stabilization for lignin-based carbon nanofibers. ACS Sustain. Chem. Eng. 2018, 6, 6434–6444. [Google Scholar] [CrossRef]

- Liu, H.; Dai, Z.; Cao, Q.; Shi, X.J.; Wang, X.; Li, H.; Han, Y.; Li, Y.; Zhou, J. Lignin/polyacrylonitrile carbon fibers: The effect of fractionation and purification on properties of derived carbon fibers. ACS Sustain. Chem. Eng. 2018, 6, 8554–8562. [Google Scholar] [CrossRef]

- Dai, Z.; Shi, X.; Liu, H.; Li, H.; Han, Y.; Zhou, J. High-strength lignin-based carbon fibers via a low-energy method. RSC Adv. 2018, 8, 1218–1224. [Google Scholar] [CrossRef] [Green Version]

- Zhang, R.; Du, Q.; Wang, L.; Zheng, Z.; Guo, L.; Zhang, X.; Yang, X.; Yu, H. Unlocking the response of lignin structure for improved carbon fiber production and mechanical strength. Green Chem. 2019, 21, 4981–4987. [Google Scholar] [CrossRef]

- Zhang, X.; Dong, S.; Wu, W.; Yang, J.; Li, J.; Shi, K.; Liu, H. Influence of lignin units on the properties of lignin/PAN-derived carbon fibers. J. Appl. Polym. Sci. 2020, 137, 49274. [Google Scholar] [CrossRef]

- Dai, Z.; Ren, P.G.; An, Y.L.; Zhang, H.; Ren, F.; Zhang, Q. Nitrogen-sulphur co-doped graphenes modified electrospun lignin/polyacrylonitrile-based carbon nanofiber as high performance supercapacitor. J. Power Sources 2019, 437, 226937. [Google Scholar] [CrossRef]

- Park, C.W.; Youe, W.J.; Han, S.Y.; Kim, Y.S.; Lee, S.H. Characteristics of carbon nanofibers produced from lignin/polyacrylonitrile (PAN)/kraft lignin-g-PAN copolymer blends electrospun nanofibers. Holzforschung 2017, 71, 743–750. [Google Scholar] [CrossRef]

- Du, B.; Chen, C.; Sun, Y.; Yu, M.; Liu, B.; Wang, X.; Zhou, J. Lignin bio-oil-based electrospun nanofibers with high substitution ratio property for potential carbon nanofibers applications. Polym. Test. 2020, 89, 106591. [Google Scholar] [CrossRef]

- Beck, R.J.; Zhao, Y.; Fong, H.; Menkhaus, T.J. Electrospun lignin carbon nanofiber membranes with large pores for highly efficient adsorptive water treatment applications. J. Water Process. Eng. 2017, 16, 240–248. [Google Scholar] [CrossRef]

- Roman, J.; Neri, W.; Derre, A.; Poulin, P. Electrospun lignin-based twisted carbon nanofibers for potential microelectrodes applications. Carbon 2019, 145, 556–564. [Google Scholar] [CrossRef]

- Schreiber, M.; Vivekanandhan, S.; Mohanty, A.K.; Misra, M. Iodine treatment of lignin–cellulose acetate electrospun fibers: Enhancement of green fiber carbonization. ACS Sustain. Chem. Eng. 2014, 3, 33–41. [Google Scholar] [CrossRef]

- Xu, X.; Zhou, J.; Jiang, L.; Lubineau, G.; Chen, Y.; Wu, X.F.; Piere, R. Porous core-shell carbon fibers derived from lignin and cellulose nanofibrils. Mater. Lett. 2013, 109, 175–178. [Google Scholar] [CrossRef]

- Ma, C.; Li, Z.; Li, J.; Fan, Q.; Wu, L.; Shi, J.; Song, Y. Lignin-based hierarchical porous carbon nanofiber films with superior performance in supercapacitors. Appl. Surf. Sci. 2018, 456, 568–576. [Google Scholar] [CrossRef]

- Cao, M.; Cheng, W.; Ni, X.; Hu, Y.; Han, G. Lignin-based multi-channels carbon nanofibers @ SnO2 nanocomposites for high-performance supercapacitors. Electrochim. Acta 2020, 345, 136172. [Google Scholar] [CrossRef]

- Badrossamay, M.R.; McIlwee, H.A.; Goss, J.A.; Parker, K.K. Nanofiber assembly by rotary jet-spinning. Nano Lett. 2010, 10, 2257–2261. [Google Scholar] [CrossRef] [Green Version]

- Sarkar, K.; Gomez, C.; Zambrano, S.; Ramirez, M.; de Hoyos, E.; Vasquez, H.; Lozano, K. Electrospinning to forcespinning™. Mater. Today 2010, 13, 12–14. [Google Scholar] [CrossRef]

- Stojanovska, E.; Kurtulus, M.; Abdelgawad, A.; Candan, Z.; Kilic, A. Developing lignin-based bio-nanofibers by centrifugal spinning technique. Int. J. Biol. Macromol. 2018, 113, 98–105. [Google Scholar] [CrossRef]

- Wong, E.W.; Sheehan, P.E.; Lieber, C.M. Nanobeam mechanics: Elasticity, strength, and toughness of nanorods and nanotubes. Science 1997, 277, 1971–1975. [Google Scholar] [CrossRef]

- Yu, M.F.; Lourie, O.; Dyer, M.J.; Moloni, K.; Kelly, T.F.; Ruoff, R.S. Strength and breaking mechanism of multiwalled carbon nanotubes under tensile load. Science 2000, 287, 637–640. [Google Scholar] [CrossRef] [Green Version]

- Lee, C.; Wei, X.; Kysar, J.W.; Hone, J. Measurement of the elastic properties and intrinsic strength of monolayer graphene. Science 2008, 321, 385–388. [Google Scholar] [CrossRef]

- Tian, D.; Hu, J.; Bao, J.; Chandra, R.P.; Saddler, J.N.; Lu, C. Lignin valorization: Lignin nanoparticles as high-value bio-additive for multifunctional nanocomposites. Biotechnol. Biofuels 2017, 10, 192. [Google Scholar] [CrossRef] [Green Version]

- Hu, M.; Chen, Z.; Luo, S.; Yang, X.; Ye, R.; Zheng, M.; Chen, P. Preparation of graphene oxide and alkali lignin nanohybrids and its application to reinforcing polymer. Wood Sci. Technol. 2019, 53, 649–664. [Google Scholar] [CrossRef]

- Zhao, G.; Ni, H.; Ren, S.; Fang, G. Correlation between Solubility Parameters and Properties of Alkali Lignin/PVA Composites. Polymers 2018, 10, 290. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rejmontova, P.; Kovalcik, A.; Humpolicek, P.; Capakova, Z.; Wrzecionko, E.; Saha, P. The use of fractionated Kraft lignin to improve the mechanical and biological properties of PVA-based scaffolds. RSC Adv. 2019, 9, 12346–12353. [Google Scholar] [CrossRef] [Green Version]

- Kwak, H.W.; Woo, H.; Kim, E.H.; Lee, K.H. Water-resistant Lignin/Poly(vinyl alcohol) Blend Fibers for Removal of Hexavalent Chromium. Fibers Polym. 2018, 19, 1175–1183. [Google Scholar] [CrossRef]

- Porkodi, P.; Abhilash, J.K.; Sunil, S.; Pardhi, T.K.; Shukla, H.K.; Shete, S.K.; Kumar, A. Lignin addition to polyacrylonitrile copolymer solution and its effect on the properties of carbon fiber precursor. J. Polym. Res. 2021, 28, 1–9. [Google Scholar] [CrossRef]

- Al Aiti, M.; Das, A.; Kanerva, M.; Jarventausta, M.; Johansson, P.; Scheffler, C.; Gobel, M.; Jehnichen, D.; Brunig, H.; Wulff, L.; et al. Dry-jet wet spinning of thermally stable lignin-textile grade polyacrylonitrile fibers regenerated from chloride-based ionic liquids compounds. Materials 2020, 13, 3687. [Google Scholar] [CrossRef]

- Zhang, B.; Lu, C.; Liu, Y.; Zhou, P.; Yu, Z.; Yuan, S. Wet spun polyacrylonitrile-based hollow-mesoporous fibers with different draw ratios. Polymer 2019, 179, 121618. [Google Scholar] [CrossRef]

- Pouteau, C.; Baumberger, S.; Cathala, B.; Dole, P. Lignin-polymer blends: Evaluation of compatibility by image analysis. Comptes Rendus Biol. 2004, 327, 935–943. [Google Scholar] [CrossRef]

- Kubo, S.; Kadla, J.F. The formation of strong intermolecular interactions in immiscible blends of poly(vinyl alcohol) (PVA) and lignin. Biomacromolecules 2003, 4, 561–567. [Google Scholar] [CrossRef]

- Lu, C.; Ford, E. Antiplasticizing behaviors of glucarate and lignin bio-based derivatives on the properties of gel-spun polyvinyl alcohol) fibers. Macromol. Mater. Eng. 2018, 303, 1700523. [Google Scholar] [CrossRef]

- Jin, Y.; Jing, Y.; Hu, W.; Lin, J.; Cheng, Y.; Yang, X.; Zhang, K.; Lu, C. Regulation mechanism of graphene oxide on the structure and mechanical properties of bio-based gel-spun lignin/poly (vinyl alcohol) fibers. Cellulose 2021, 28, 4745–4760. [Google Scholar] [CrossRef]

- Ma, Y.; Asaadi, S.; Johansson, L.S.; Ahvenainen, P.; Reza, M.; Alekhina, M.; Rautkari, L.; Michud, A.; Hauru, L.; Hummel, M.; et al. High-strength composite fibers from cellulose-lignin blends regenerated from ionic liquid solution. ChemSusChem 2015, 8, 4030–4039. [Google Scholar] [CrossRef] [PubMed]

- Protz, R.; Lehmann, A.; Ganster, J.; Fink, H.P. Solubility and spinnability of cellulose-lignin blends in aqueous NMMO. Carbohydr. Polym. 2021, 251, 117027. [Google Scholar] [CrossRef]

- Bengtsson, J.; Jedvert, K.; Kohnke, T.; Theliander, H. The challenge of predicting spinnability: Investigating benefits of adding lignin to cellulose solutions in air-gap spinning. J. Appl. Polym. Sci. 2021, 138, 50629. [Google Scholar] [CrossRef]

- Bengtsson, J.; Jedvert, K.; Hedlund, A.; Kohnke, T.; Theliander, H. Mass transport and yield during spinning of lignin-cellulose carbon fiber precursors. Holzforschung 2019, 73, 509–516. [Google Scholar] [CrossRef]

- Mikkila, J.; Trogen, M.; Koivu, K.A.Y.; Kontro, J.; Kuuskeri, J.; Maltari, R.; Dekere, Z.; Kemell, M.; Makela, M.R.; Nousiainen, P.A.; et al. Fungal treatment modifies Kraft lignin for lignin- and cellulose-based carbon fiber precursors. ACS Omega 2020, 5, 6130–6140. [Google Scholar] [CrossRef]

- Ago, M.; Okajima, K.; Jakes, J.E.; Park, S.; Rojas, O.J. Lignin-based electrospun nanofibers reinforced with cellulose nanocrystals. Biomacromolecules 2012, 13, 918–926. [Google Scholar] [CrossRef] [PubMed]

- Ago, M.; Jakes, J.E.; Johansson, L.S.; Park, S.; Rojas, O.J. Interfacial properties of lignin-based electrospun nanofibers and films reinforced with cellulose nanocrystals. ACS Appl. Mater. Interfaces 2012, 4, 6849–6856. [Google Scholar] [CrossRef] [PubMed]

- Ago, M.; Jakes, J.E.; Rojas, O.J. Thermomechanical properties of lignin-based electrospun nanofibers and films reinforced with cellulose nanocrystals: A dynamic mechanical and nanoindentation study. ACS Appl. Mater. Interfaces 2013, 5, 11768–11776. [Google Scholar] [CrossRef] [PubMed]

- Fang, W.; Yang, S.; Yuan, T.Q.; Charlton, A.; Sun, R.C. Effects of various surfactants on alkali lignin electrospinning ability and spun fibers. Ind. Eng. Chem. Res. 2017, 56, 9551–9559. [Google Scholar] [CrossRef] [Green Version]

- Chee, P.L.; Yew, P.Y.M.; Kai, D.; Loh, X.J. Reinforcement of aligned cellulose fibers by lignin-polyester copolymers. Mater. Today Chem. 2020, 18, 100358. [Google Scholar] [CrossRef]

- Koivu, K.A.Y.; Sadeghifar, H.; Nousiainen, P.A.; Argyropoulos, D.S.; Sipila, J. Effect of Fatty Acid esterification on the Thermal Properties of Softwood Kraft Lignin. ACS Sustain. Chem. Eng. 2016, 4, 5238–5247. [Google Scholar] [CrossRef]

| Modification/ Fractionation | Lignin/Polymer (Mass Ratio) and Reference | Processing Temperature (°C) | Thermal Treatment Stabilization/Carbonization | Diameter (μm) | Mechanical Properties | |

|---|---|---|---|---|---|---|

| TS (MPa) | TM (GPa) | |||||

| Unmodified lignin | Hardwood Kraft lignin [82] | 195–228 | 250 °C, 12~180 °C/h, 1 h, air 1000 °C, 180 °C/h, nitrogen | 46 ± 8 | 422 ± 80 | 40 ± 11 |

| Hardwood Kraft lignin/PEO (97/3) [82] | 189–228 | 250 °C, 12~180 °C/h, 1 h, air 1000 °C, 180 °C/h, nitrogen | 33 ± 2 | 458 ± 97 | 59 ± 8 | |

| Pyrolytic lignin [91] | 105/125 | 250 °C, 0.5 °C/min, 1 h, air 1000 °C, 3 °C/min, 1 h, nitrogen | 49 ± 2 | 370 ± 38 | 36 ± 1 | |

| Organosolv lignin [92] | 210 | 250 °C, 0.5 °C/min, 1 h, air 1000 °C, 3 °C/min, 1 h, nitrogen | 14 ± 1 | 355 ± 53 | 39.1 ± 13.3 | |

| Hardwood Kraft lignin/PET (75/25) [33] | 130–240 | 250 °C, 0.2–3 °C/min, 1 h, air 1000 °C, 3 °C/min, nitrogen | 34 ± 5 | 703 | 94 | |

| Hardwood Kraft lignin/PP (87.5/12.5) [93] | 130–240 | 250 °C, 0.2–3 °C/min, 1 h, air 1000 °C, 3 °C/min, nitrogen | 44 ± 5 | 437 | 54 | |

| Lignin/PLA (80/20) [80] | 220–240 | 280 °C, 0.25 °C/min, 1 h, air 1000 °C, nitrogen | 30–60 | 159.2 | 11.6 | |

| Organosolv yellow polar lignin [70] | N/A | 250 °C, 0.05 °C/min, 30 min, air Stepwise: 600 °C, 3 °C/min, 5 min; 1000 °C, 5 °C/min, 15 min, itrogen | 17.1 ± 1.59 | 544 ± 96 | 36.5 ± 2.81 | |

| Alcell organosolv hardwood lignin/TPU (50/50) [94] | 155/180/190/180 | 250 °C, 0.1 °C/min, 1 h, air 1000 °C, 10 °C/min, 0.5 h, nitrogen | 31 ± 2 | 1100 ± 100 | 80 ± 10 | |

| Organosolv lignin from yellow poplar/organosolv lignin from switchgrass (85/15) [95] | 180 | 250 °C, 0.05, 0.1, 0.2 and 0.5 °C/min, 30 min, air Stepwise: 600 °C, 3 °C/min, 5 min; 1000 °C, 5 °C/min, 15 min, nitrogen | 15.7 ± 1.1 | 747 ± 208 | 41.8 ± 3.9 | |

| Softwood Kraft lignin/hardwood Kraft lignin (90/10) [96] | 140–250 | 250 °C, 0.2 °C/min, 1 h, air Stepwise: 600 °C, 1 °C/min; 1000 °C, 3 °C/min, nitrogen | 21.4 | N/A | N/A | |

| Fractionation with methanol; acetylation | Modifed organosolv lignin [97] | 130 | 250 °C, 0.1 °C/min, 1 h, air 1000 °C, 3 °C/min, 1 h, argon | 39.1 ± 5.4 | 454 ± 98 | 62 ± 14 |

| Repolymerization | Repolymerized pyrolytic lignin [98] | 115–120 | 280 °C, 0.3 °C/min, 1 h, air 1000 °C, 3 °C/min, 1 h, argon | 29–50 | 855 ± 159 | 85 ± 37 |

| Hydrogenation | Modidified steam-exploded lignin [78] | 155–180 | 210 °C, 0.5–2 °C/min, air 1000 °C, 5 °C/min, 20 min, nitrogen | 7.6 ± 2.7 | 660 ± 230 | 40.7 ± 6.3 |

| Phenolyzation | Modidified steam-exploded lignin [85] | 155–180 | 210 °C, 0.5–2 °C/min, air 1000 °C, 5 °C/min, 20 min, nitrogen | N/A | 455 | N/A |

| Stepwise: acrylation, acetylation, and RAFT polymerization | Modified red oak lignin bio-oil [99] | 25–280 | 250 °C, 7 °C/min, air 1000 °C, 3 °C/min, 1 h, argon | 5.1 | 1700 | 182 |

| Fractionation with acetic acid (AcOH) | Fractionated softwood acetic acid lignin [100] | N/A | 250 °C, 0.5 °C/min, 1 h, air 1000 °C, 3 °C/min, nitrogen | 84 ± 15 | 26.4 ± 3.1 | 3.59 ± 0.43 |

| Butyration | Butyrated lignin/PLA (75/25) [83,101] | 180 | 250 °C, 0.25 °C/min, 5 h, oxygen 1000 °C, 3 °C/min, nitrogen | 122 ± 29 | N/A | 1.94 ± 0.11 |

| Fractionation with isopropyl alcohol | Fractionated organosolv hardwood lignin/PET (75/25) [102] | 170/230/252 | 250 °C, 0.1 °C/min, 1 h, air 1000 °C, 10 °C/min, 30 min, nitrogen | 120 ± 27 | N/A | N/A |

| Grafting with PEG | PEG grafted with softwood lignin [103] | 145–172 | 250 °C, 0.1–0.5 °C/min, 1 h, air 1000 °C, 3 °C/min, 1 h, nitrogen | 10.4 ± 1.3 | 457 ± 188 | 26.2 ± 13.3 |

| Hydroxypropyl modification | Hydroxypropyl modified kraft hardwood lignin/TPU (50/50) [94] | 175/190/200/190 | 250 °C, 0.1 °C/min,1 h, air 1000 °C, 10 °C/min, 0.5 h, nitrogen | 30 ± 1 | 800 ± 100 | 66 ± 10 |

| Grafting with CNTs | CNTs grafted with lignin (CNTs-g-L) (0.5/99.5) [79] | 225 | 280 °C, 0.25 °C/min,1 h, air 1000 °C, nitrogen | N/A | 289.3 | 18 |

| Spinning Technique | Lignin Type/Polymer (Mass Ratio)/Solvent and Reference | Modification/Coagulation Condition | Thermal Treatment Stabilization/Carbonization | Diameter (μm) | Maximum Mechanical Properties | |

|---|---|---|---|---|---|---|

| TS (GPa) | TM (GPa) | |||||

| Dry spinning | Lignin/alkaline solution [27] | NA | 150 °C, 5 °C/min, 10 h; 700 °C, 10 min | 20–30 | 0.8 | N/A |

| Modified softwood Kraft lignin/acetone [31] | Acetylation with acetic anhydride | 200 °C, 0.2 °C/min; 1000 °C, 4.5 °C/min | ~7 | 1.04 | 52 | |

| Modified softwood Kraft lignin/acetone [116] | Acetylation with acetic anhydride | UV treatment 250 °C; 1000 °C | N/A | 0.9 ± 0.1 | 34 ± 2 | |

| Softwood Kraft lignin/acetic acid–water (H2O) [88] | NA | 250 °C, 1 h; 1000 °C | 6–7 | 1.39 | 98 | |

| Beech organosolv lignin/cellulose (30/70, 50/50)/[DBNH]OAc [130] | NA | Stepwise: 240, 250, 260, 270 °C, line speed of 15.6 m/h, 23 min in each stabilization zone; 450, 600, 800, 1200, 1500 °C, line speed of 15.6 m/h, 5.5 min in each carbonization furnace | 4–11 | ~0.48 | ~26 | |

| Wet spinning | Hardwood lignin/DMSO [119] | Copolymerization with AN Coagulation bath: H2O | 280 °C, 1 h; 800 °C, 5 °C/min | 11 | N/A | N/A |

| Modified lignosulfonate/DMSO [131] | Esterification with acryloyl chloride, then copolymerization with AN (mass ratio of esterified lignin/AN:30/70) Coagulation bath: DMSO/H2O | 250 °C, 10 °C/min, 1 h; 1400 °C, 10 °C/min | 10–20 | 1.1 | N/A | |

| Modified lignosulfonate/DMSO [132] | Esterification with acryloyl chloride, then copolymerization with AN (mass ratio of esterified lignin/AN: 10/90, 15/85, 20/80, 25/75,30/70) Coagulation bath: DMSO/H2O (60/40 w/w), 60 °C | 250 °C, 10 °C/min, 1 h; 1400 °C, 10 °C/min, 10 min | 19–35 | 0.65 ± 0.05 | N/A | |

| Wheat straw lignin/PAN (1, 3.53, 5, 8.6, 13.3/20)/DMSO [133] | Coagulation bath: H2O | 250 °C, 1 °C/min, 0.5 h; 1400 °C, 10 °C/min, 20 min | 20–50 | 0.3–0.5 | <100 | |

| Softwood Kraft lignin/PAN (50/50)/DMSO [134] | Coagulation bath: DMSO/H2O (65/35 w/w), 0.2 wt.% of lignin were added into coagulant bath to control out-diffusion | 300 °C, 1 °C/min, 1 h; 1200 °C, 7 °C/min, 1 h | 7.0 ± 0.3 | 1.2 | 130 | |

| Lignin/PAN (37/20)/DMSO [135] | Coagulation bath: DMSO/H2O (60/40 w/w), 60 °C | 250 °C, 10 °C/min, 10 min; Stepwise: 700 °C, 10 °C/min, 10 min, then 1200 °C, 7 °C/min, 30 min | 13.5 | 2.1 | 224 | |

| Softwood Kraft lignin/cellulose (70/30)/[EMIm][OAc] [136] | Coagulation bath: H2O, 5 ± 2 °C | 250 °C, 0.2 °C/min, 1 h; Stepwise: 600 °C, 1 °C/min, then 1000 °C, 3 °C/min | < 10 | 1.07 | 76 | |

| Kraft lignin/PVA/GO (66/29/5)/DMSO [137] | Coagulation bath: isopropanol | 300 °C, 2 °C/min, 1 h; Stepwise: 500 °C, 2 °C/min, then 1000 °C, 5 °C/min | N/A | 0.763 | 52 | |

| Kraft lignin/PVA (70:30)/DMSO [138] | Coagulation bath: 2-propanol | 250 °C; 1000 °C, 5 °C/min | 37 | 0.351 ± 0.108 | 44.5 ± 9.6 | |

| Softwood Kraft lignin/cellulose (70/30)/[EMIm] [OAc] [139] | Coagulation bath: H2O, 5 ± 2 °C | Stepwise: 250 °C, 5 °C/min, 60 min, 600 °C, 1 °C/min; 800, 1000, 1200, 1400, 1600 °C, 3 °C/min | N/A | 1.1 (Carbonization at 1000 °C) | 77 (Carbonization at 1600 °C) | |

| Softwood Kraft lignin/cellulose (70/30)/[EMIm] [OAc] [140] | Coagulation bath: H2O, 15 °C | Stepwise: 200 °C, 0.2 °C/min, 250 °C, 1 °C/min; Stepwise: 600 °C, 1 °C/min, 1000 °C, 3 °C/min | 14–15 | 0.88 | 67 | |

| Softwood kraft lignin/cellulose (70/30)/[EMIm] [OAc] [136] | Coagulation bath: H2O, 5 ± 2 °C | Stepwise: 200 °C, 0.2 °C/min, 250 °C, 1, 5 °C/min, 1, 5, 10 h; Stepwise: 600 °C, 1 °C/min, 1000 °C, 3 °C/min | 6–8 | 1.07 | 76 | |

| Lignin/cellulose (25/75)/[EMIm] [OAc] [141] | Coagulation bath: H2O, room temperature | Stepwise: 240 °C, 5 °C/min, 30 min; 1000 °C, 10 °C/min, 60 min | 92.9 ± 2.7 | 0.12 | 5.9 | |

| Lignin/PAN(31/69)/DMF [126] | Coagulation bath: methanol, −50 °C | Stepwise: 265 °C, 3 °C/min, 158, 170, 182, 230, 255 min, 305 °C, 3 °C/min, 10 min; 1000, 1200, 1300 °C, 10 °C/min, 10 min | 8–9 | 2.1 (Carbonized at 1200 °C) | 274 (Carbonized at 1300 °C) | |

| Gel spinning | Soda lignin/PAN (30/70)/DMAc [123] | Coagulation bath: methanol, −50 °C | Stepwise: 255 °C, 3 °C/min, 400 min, 315 °C, 3 °C/min; 1100 °C, 5 °C/min, | 11.0 ± 1.1 | 1.72 | 230 |

| Soda lignin/PAN/CNT (70/30/3)/DMAc [123] | Coagulation bath: methanol, −50 °C | Stepwise: 255 °C, 3 °C/min, 400 min, 315 °C, 3 °C/min; 1100 °C, 5 °C/min | 8.8 ± 0.3 | 1.4 | 200 | |

| Lignin/Polymer (Mass Ratio)/Solvent and Reference | Processing Parameters | Carbonization Temperature (°C) | Diameter (nm) | Tensile Strength (MPa) | Young’s Modulus (GPa) |

|---|---|---|---|---|---|

| Lignin/PEO (95/5)/DMF [188] | Voltage: 20 kV Flow rate: 0.8 mL/h | 1000 | 867 ± 212 | 40 ± 3 | 6.1 ± 0.3 |

| Lignin/PEO (95/5)/DMF [187] | Voltage: 20 kV Flow rate: 0.5 mL/h Distance: 20 cm | 1000 | 1007 ± 70 | 15.58 ± 2.10 | 24.54 ± 3.29 |

| Lignin/PEO (28/0.2)/DMF [190] | Voltage: 15 kV Flow rate: 0.02 mL/min | 1000 | 634 ± 87 | 32 ± 9 | 4.8 ± 0.6 |

| Lignin/PEO (95/5–99.9/0.1)/DMF [191] | Flow rate: 0.42 μL/s | 1000 | 465 ± 76 | 11.64 ± 6.94 | 2.37 ± 0.78 |

| Lignin/PEO (99/1)/DMF [192] | Voltage: 20 kV Flow rate: 0.01 mL/min Distance: 25 cm | 800, 900, 1000 | 500 ± 150 | 33.7 ± 6 | 8.0 ± 1.4 |

| Lignin/PAN (50/50)/DMF [193] | Voltage: 25 kV Flow rate: 0.8 mL/h Distance: 20 cm | 1000 | 190 ± 18 | 21.21 ± 3 | 4.64 ± 0.1 |

| Lignin/PAN (50/50)/DMF [169] | Voltage: 15 kV Flow rate: 5μL/min Distance: 20 cm | 1000 | 1920 ± 150 | 22 ± 1 | 2.4 ± 0.2 |

| Lignin/PAN (50/50)/DMF [194] | Voltage: 20 kV Flow rate: 1.0 mL/h Distance: 20 cm | 1400 | N/A | 56 ± 2 | 3.2 ± 0.4 |

| Lignin/PAN (0.25/1)/DMF [195] | N/A | 1000 | 208 | 142 ± 8 | 10.0 ± 0.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jin, Y.; Lin, J.; Cheng, Y.; Lu, C. Lignin-Based High-Performance Fibers by Textile Spinning Techniques. Materials 2021, 14, 3378. https://doi.org/10.3390/ma14123378

Jin Y, Lin J, Cheng Y, Lu C. Lignin-Based High-Performance Fibers by Textile Spinning Techniques. Materials. 2021; 14(12):3378. https://doi.org/10.3390/ma14123378

Chicago/Turabian StyleJin, Yanhong, Jiaxian Lin, Yu Cheng, and Chunhong Lu. 2021. "Lignin-Based High-Performance Fibers by Textile Spinning Techniques" Materials 14, no. 12: 3378. https://doi.org/10.3390/ma14123378

APA StyleJin, Y., Lin, J., Cheng, Y., & Lu, C. (2021). Lignin-Based High-Performance Fibers by Textile Spinning Techniques. Materials, 14(12), 3378. https://doi.org/10.3390/ma14123378