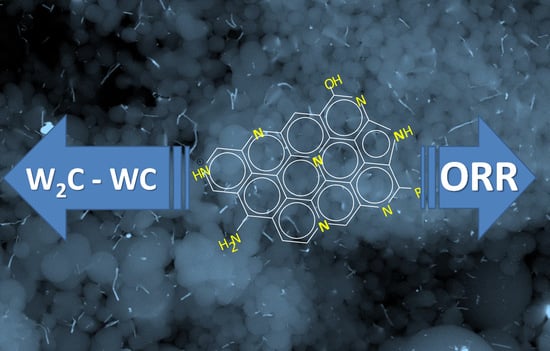

Growing Tungsten Nanophases on Carbon Spheres Doped with Nitrogen. Behaviour as Electro-Catalysts for Oxygen Reduction Reaction

Abstract

:1. Introduction

2. Materials and Methods

2.1. Synthesis of Materials

2.1.1. Hydrothermal Synthesis of the Polymeric Spheres

2.1.2. Impregnation with the Tungsten Precursor

2.1.3. Carbonization of the Polymeric Spheres and the Corresponding Obtainment of the Electro-Catalysts

2.2. Textural and Chemical Characterization

2.3. Electrochemical Measurements

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Barbir, F. PEM Fuel Cells: Theory and Practice; Academic Press: Cambridge, MA, USA, 2012; ISBN 0123877105. [Google Scholar]

- Kendall, K.; Pollet, B.G. Hydrogen and fuel cells in transport. In Comprehensive Renewable Energy; Elsevier: Amsterdam, The Netherlands, 2012; Volume 4, pp. 301–313. ISBN 9780080878737. [Google Scholar]

- Carrette, L.; Friedrich, K.A.; Stimming, U. Fuel Cells—Fundamentals and Applications. Fuel Cells 2002, 1, 5–39. [Google Scholar] [CrossRef]

- de Frank Bruijn, A.; Janssen, G.J.M. PEM Fuel Cell Materials: Costs, Performance, and Durability. In PEM Fuel Cells and Platinum-Based Electrocatalysts: A Volume in the Encyclopedia of Sustainability Science and Technology, 2nd ed.; Springer: New York, NY, USA, 2019; pp. 195–234. ISBN 978-1-4939-7788-8. [Google Scholar]

- Stambouli, A.B. Fuel cells: The expectations for an environmental-friendly and sustainable source of energy. Renew. Sustain. Energy Rev. 2011, 15, 4507–4520. [Google Scholar] [CrossRef]

- Zhang, S.; Chen, M.; Zhao, X.; Cai, J.; Yan, W.; Yen, J.C.; Chen, S.; Yu, Y.; Zhang, J. Advanced Noncarbon Materials as Catalyst Supports and Non-noble Electrocatalysts for Fuel Cells and Metal-Air Batteries. Electrochem. Energy Rev. 2021, 4, 336–381. [Google Scholar] [CrossRef]

- Sui, S.; Wang, X.; Zhou, X.; Su, Y.; Riffat, S.; Liu, C. A comprehensive review of Pt electrocatalysts for the oxygen reduction reaction: Nanostructure, activity, mechanism and carbon support in PEM fuel cells. J. Mater. Chem. A 2017, 5, 1808–1825. [Google Scholar] [CrossRef]

- Banham, D.; Ye, S.; Pei, K.; Ozaki, J.-I.; Kishimoto, T.; Imashiro, Y. A review of the stability and durability of non-precious metal catalysts for the oxygen reduction reaction in proton exchange membrane fuel cells. J. Power Sources 2015, 285, 334–348. [Google Scholar] [CrossRef]

- Jung, D.H.; Bae, S.J.; Kim, S.J.; Nahm, K.S.; Kim, P. Effect of the Pt precursor on the morphology and catalytic performance of Pt-impregnated on Pd/C for the oxygen reduction reaction in polymer electrolyte fuel cells. Int. J. Hydrogen Energy 2011, 36, 9115–9122. [Google Scholar] [CrossRef]

- Hossen, M.M.; Artyushkova, K.; Atanassov, P.; Serov, A. Synthesis and characterization of high performing Fe-NC cat-alyst for oxygen reduction reaction (ORR) in Alkaline Exchange Membrane Fuel Cells. J. Power Sources 2018, 375, 214–221. [Google Scholar] [CrossRef]

- Ishii, T.; Maie, T.; Kimura, N.; Kobori, Y.; Imashiro, Y.; Ozaki, J.-I. Enhanced catalytic activity of nanoshell carbon co-doped with boron and nitrogen in the oxygen reduction reaction. Int. J. Hydrogen Energy 2017, 42, 5–12. [Google Scholar] [CrossRef]

- Chung, D.Y.; Yoo, J.M.; Sung, Y. Highly Durable and Active Pt-Based Nanoscale Design for Fuel-Cell Oxygen-Reduction Electrocatalysts. Adv. Mater. 2018, 30, 1704123. [Google Scholar] [CrossRef]

- Sarapuu, A.; Samolberg, L.; Kreek, K.; Koel, M.; Matisen, L.; Tammeveski, K. Cobalt- and iron-containing nitrogen-doped carbon aerogels as non-precious metal catalysts for electrochemical reduction of oxygen. J. Electroanal. Chem. 2015, 746, 9–17. [Google Scholar] [CrossRef]

- Elmouwahidi, A.; Bailón-García, E.; Pérez-Cadenas, A.F.; Castelo-Quibén, J.; Carrasco-Marín, F. Carbon-vanadium composites as non-precious catalysts for electro-reduction of oxygen. Carbon 2019, 144, 289–300. [Google Scholar] [CrossRef]

- Chen, Z.; Higgins, D.; Yu, A.; Zhang, L.; Zhang, J. A review on non-precious metal electrocatalysts for PEM fuel cells. Energy Environ. Sci. 2011, 4, 3167–3192. [Google Scholar] [CrossRef]

- Tang, L.; Xu, Q.; Zhang, Y.; Chen, W.; Wu, M. MOF/PCP-Based Electrocatalysts for the Oxygen Reduction Reaction; Springer: Singapore, 2021; ISBN 4191802100. [Google Scholar]

- Chen, T.; Kalimuthu, P.; Anushya, G.; Chen, S.; Ramachandran, R.; Mariyappan, V.; Muthumala, D.C. High-Efficiency of Bi-Functional-Based Perovskite Nanocomposite for Oxygen Evolution and Oxygen Reduction Reaction: An Overview. Materials 2021, 14, 2976. [Google Scholar] [CrossRef]

- Lee, K.; Ishihara, A.; Mitsushima, S.; Kamiya, N.; Ota, K.I. Transition metal carbides for new cathode material of polymer electrolyte fuel cell. ECS Proc. Vol. 2004, 2004, 213–221. [Google Scholar] [CrossRef]

- Shao, M.; Merzougui, B.; Shoemaker, K.; Stolar, L.; Protsailo, L.; Mellinger, Z.J.; Hsu, I.J.; Chen, J.G. Tungsten carbide modified high surface area carbon as fuel cell catalyst support. J. Power Sources 2011, 196, 7426–7434. [Google Scholar] [CrossRef]

- Liu, Y.; Kelly, T.G.; Chen, J.G.; Mustain, W.E. Metal carbides as alternative electrocatalyst supports. ACS Catal. 2013, 3, 1184–1194. [Google Scholar] [CrossRef] [Green Version]

- Moon, J.-S.; Lee, Y.-W.; Han, S.-B.; Kwak, D.-H.; Lee, K.-H.; Park, A.-R.; Sohn, J.I.; Cha, S.N.; Park, K.-W. Iron-itrogen-doped mesoporous tungsten carbide nanostructures as oxygen reduction electrocatalysts. Phys. Chem. Chem. Phys. 2014, 16, 14644–14650. [Google Scholar] [CrossRef]

- Xiong, L.; Zheng, L.; Liu, C.; Jin, L.; Liu, Q.; Xu, J. Tungsten carbide microspheres with high surface area as platinum catalyst supports for enhanced electrocatalytic activity. J. Electrochem. Soc. 2015, 162, F468–F473. [Google Scholar] [CrossRef]

- Huang, K.; Bi, K.; Xu, J.C.; Liang, C.; Lin, S.; Wang, W.J.; Yang, T.Z.; Du, Y.X.; Zhang, R.; Yang, H.J. Novel graphite-carbon encased tungsten carbide nanocomposites by solid-state reaction and their ORR electrocatalytic performance in alkaline medium. Electrochim. Acta 2015, 174, 172–177. [Google Scholar] [CrossRef]

- Song, L.; Wang, T.; Wang, Y.; Xue, H.; Fan, X.; Guo, H.; Xia, W.; Gong, H.; He, J. Porous iron-tungsten carbide electro-catalyst with high activity and stability toward oxygen reduction reaction: From the self-assisted synthetic mechanism to its active-species probing. ACS Appl. Mater. Interfaces 2017, 9, 3713–3722. [Google Scholar] [CrossRef] [PubMed]

- Zhu, H.; Sun, Z.; Chen, M.; Cao, H.; Li, K.; Cai, Y.; Wang, F. Highly porous composite based on tungsten carbide and N-doped carbon aerogels for electrocatalyzing oxygen reduction reaction in acidic and alkaline media. Electrochim. Acta 2017, 236, 154–160. [Google Scholar] [CrossRef]

- Sohn, Y.; Jung, J.Y.; Kim, P. Facile synthesis of tungsten carbide-carbon composites for oxygen reduction reaction. Korean J. Chem. Eng. 2017, 34, 2162–2168. [Google Scholar] [CrossRef]

- Bott-Neto, J.L.; Beck, W., Jr.; Varanda, L.C.; Ticianelli, E.A. Electrocatalytic activity of platinum nanoparticles supported on different phases of tungsten carbides for the oxygen reduction reaction. Int. J. Hydrogen Energy 2017, 42, 20677–20688. [Google Scholar] [CrossRef]

- do Rêgo, U.A.; Lopes, T.; Bott-Neto, J.L.; Tanaka, A.A.; Ticianelli, E.A. Oxygen reduction electrocatalysis on transition metal-nitrogen modified tungsten carbide nanomaterials. J. Electroanal. Chem. 2018, 810, 222–231. [Google Scholar] [CrossRef]

- Zhang, J.; Chen, J.; Jiang, Y.; Zhou, F.; Wang, G.; Wang, R. Tungsten carbide encapsulated in nitrogen-doped carbon with iron/cobalt carbides electrocatalyst for oxygen reduction reaction. Appl. Surf. Sci. 2016, 389, 157–164. [Google Scholar] [CrossRef]

- Zhong, G.; Wang, H.; Yu, H.; Peng, F. A Novel Carbon-Encapsulated Cobalt-Tungsten Carbide as Electrocatalyst for Oxygen Reduction Reaction in Alkaline Media. Fuel Cells 2013, 13, 387–391. [Google Scholar] [CrossRef]

- Stöber, W.; Fink, A.; Bohn, E. Controlled growth of monodisperse silica spheres in the micron size range. J. Colloid Interface Sci. 1968, 26, 62–69. [Google Scholar] [CrossRef]

- Moreno-Castilla, C.; García-Rosero, H.; Carrasco-Marín, F. Synthesis and characterization of solid polymer and carbon spheres derived from an emulsion polymerization reaction of different phenolic compounds with formaldehyde. Colloids Surfaces A Physicochem. Eng. Asp. 2017, 520, 488–496. [Google Scholar] [CrossRef]

- Maldonado-Hódar, F.J.; Pérez-Cadenas, A.F.; Moreno-Castilla, C. Morphology of heat-treated tunsgten doped monolithic carbon aerogels. Carbon 2003, 41, 1291–1299. [Google Scholar] [CrossRef]

- Pérez-Cadenas, M.; Moreno-Castilla, C.; Carrasco-Marín, F.; Pérez-Cadenas, A.F. Surface chemistry, porous texture, and morphology of N-doped carbon xerogels. Langmuir 2008, 25, 466–470. [Google Scholar] [CrossRef]

- Zapata-Benabithe, Z.; Carrasco-Marín, F.; Moreno-Castilla, C. Preparation, surface characteristics, and electrochemical double-layer capacitance of KOH-activated carbon aerogels and their O- and N-doped derivatives. J. Power Sources 2012, 219, 80–88. [Google Scholar] [CrossRef]

- Geng, D.; Chen, Y.; Chen, Y.; Li, Y.; Li, R.; Sun, X.; Ye, S.; Knights, S. High oxygen-reduction activity and durability of nitrogen-doped graphene. Energy Environ. Sci. 2011, 4, 760–764. [Google Scholar] [CrossRef]

- Chen, Y.; Ji, S.; Wang, Y.; Dong, J.; Chen, W.; Li, Z.; Shen, R.; Zheng, L.; Zhuang, Z.; Wang, D.; et al. Isolated Single Iron Atoms Anchored on N-Doped Porous Carbon as an Efficient Electrocatalyst for the Oxygen Reduction Reaction. Angew. Chem. Int. Ed. 2017, 56, 6937–6941. [Google Scholar] [CrossRef]

- Ferrero, G.A.; Preuss, K.; Fuertes, A.B.; Sevilla, M.; Titirici, M.M. The influence of pore size distribution on the oxygen reduction reaction performance in nitrogen doped carbon microspheres. J. Mater. Chem. A 2016, 4, 2581–2589. [Google Scholar] [CrossRef] [Green Version]

| Sample | SBET (m2·g−1) | V0 (cm3·g−1) | L0 (nm) | VMESO (cm3·g−1) | WTOTAL-TGA (%) |

|---|---|---|---|---|---|

| S | n.d. | - | - | - | 0.0 |

| CS | 41 | 0.012 | 2.9 | 0.199 | 0.0 |

| CSW2 | 254 | 0.107 | 2.7 | 0.191 | 2.7 |

| CSW5 | 374 | 0.165 | 1.5 | 0.105 | 5.6 |

| CSW10 | 96 | 0.043 | 2.4 | 0.087 | 10.0 |

| Sample | % CXPS | % OXPS | % NXPS | % WXPS |

|---|---|---|---|---|

| CS | 76.9 | 16.3 | 6.8 | 0.0 |

| CSW2 | 92.3 | 4.0 | 1.5 | 2.2 |

| CSW5 | 91.4 | 4.0 | 1.3 | 3.2 |

| CSW10 | 83.4 | 4.9 | 1.6 | 10.1 |

| Sample | % NXPS Total | % N-6 | % N-Q | % N-X |

|---|---|---|---|---|

| CS | 6.8 | 25 | 55 | 22 |

| CSW2 | 1.5 | 18 | 66 | 16 |

| CSW5 | 1.3 | 23 | 57 | 20 |

| CSW10 | 1.6 | 25 | 53 | 22 |

| B.E. (eV) | N1s | 398.5 | 401.0 | 402.5 |

| Sample | % WXPS Total | % WC | % WO3 |

|---|---|---|---|

| CS | 0.0 | - | - |

| CSW2 | 2.2 | 44 | 56 |

| CSW5 | 3.2 | 57 | 43 |

| CSW10 | 10.1 | 68 | 32 |

| B.E. (eV) | W4f7/2 | 32.0 | 35.7 |

| Sample | d (nm) | ||

|---|---|---|---|

| WC | W2C | W0 | |

| CSW2 | 11.4 | 14.1 | - |

| CSW5 | 12.2 | 13.6 | 18.1 |

| CSW10 | 7.1 | - | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Briz-Amate, T.; Castelo-Quibén, J.; Bailón-García, E.; Abdelwahab, A.; Carrasco-Marín, F.; Pérez-Cadenas, A.F. Growing Tungsten Nanophases on Carbon Spheres Doped with Nitrogen. Behaviour as Electro-Catalysts for Oxygen Reduction Reaction. Materials 2021, 14, 7716. https://doi.org/10.3390/ma14247716

Briz-Amate T, Castelo-Quibén J, Bailón-García E, Abdelwahab A, Carrasco-Marín F, Pérez-Cadenas AF. Growing Tungsten Nanophases on Carbon Spheres Doped with Nitrogen. Behaviour as Electro-Catalysts for Oxygen Reduction Reaction. Materials. 2021; 14(24):7716. https://doi.org/10.3390/ma14247716

Chicago/Turabian StyleBriz-Amate, Teresa, Jesica Castelo-Quibén, Esther Bailón-García, Abdalla Abdelwahab, Francisco Carrasco-Marín, and Agustín F. Pérez-Cadenas. 2021. "Growing Tungsten Nanophases on Carbon Spheres Doped with Nitrogen. Behaviour as Electro-Catalysts for Oxygen Reduction Reaction" Materials 14, no. 24: 7716. https://doi.org/10.3390/ma14247716

APA StyleBriz-Amate, T., Castelo-Quibén, J., Bailón-García, E., Abdelwahab, A., Carrasco-Marín, F., & Pérez-Cadenas, A. F. (2021). Growing Tungsten Nanophases on Carbon Spheres Doped with Nitrogen. Behaviour as Electro-Catalysts for Oxygen Reduction Reaction. Materials, 14(24), 7716. https://doi.org/10.3390/ma14247716