Advantageous Implications of Reversed Austenite for the Tensile Properties of Super 13Cr Martensitic Stainless Steel

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Microstructures, Phases and Volume Fractions of Reversed Austenite

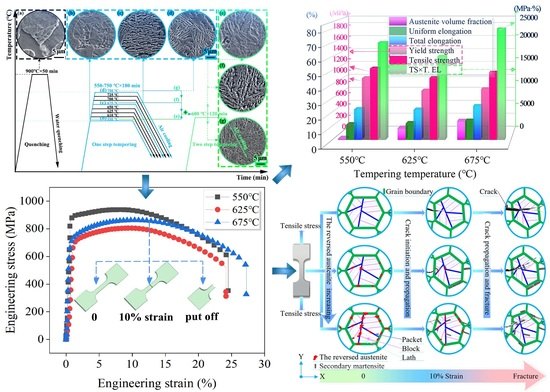

3.2. Effect of Reversed Austenite on Tensile Properties

4. Conclusions

- Reversed austenite is distributed along the boundary of martensite lath and bears the (11)γ//(011)α’ and [011]γ//[1]α’ Kurdjumov–Sachs (K–S) orientation relationship with the martensite.

- When tempered at 675 °C for 3 h for the first stage and 600 °C for 2 h for the second stage, the maximum volume fraction of reversed austenite is approximately 13.3%, achieving uniform elongation of 10.4% and total elongation of 27.2%. Moreover, the product of strength and elongation is 23.5 GPa·% higher than other samples.

- The outstanding combination of high strength and commendable plasticity has been achieved due to the secondary martensite formation assisted by the austenite reversion process and a striking ability to sustain a high strain hardening rate over a wide strain region.

- The TRIP effect, consuming a large amount of deformation work, alleviates local stress concentration. The reversed austenite consumes the plastic energy at the tip of the microcrack and makes the crack tip blunt, which hinders the further propagation of the crack, consequently increasing the total elongation and improving toughness.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zepon, G.; Nogueira, R.P.; Kiminami, C.S.; Botta, W.J.; Bolfarini, C. Electrochemical corrosion behavior of spray-formed boron-modified supermartensitic stainless steel. Metall. Mater. Trans. A 2017, 48, 2077–2089. [Google Scholar] [CrossRef]

- Zepon, G.; Nascimento, A.R.C.; Kasama, A.H.; Nogueira, R.P.; Kiminami, C.S.; Botta, W.J.; Bolfarini, C. Design of wear resistant boron-modified supermartensitic stainless steel by spray forming process. Mater. Des. 2015, 83, 214–223. [Google Scholar] [CrossRef]

- Han, J.; Lee, Y.K. The effects of the heating rate on the reverse transformation mechanism and the phase stability of reverted austenite in medium Mn steels. Acta Mater. 2014, 67, 354–361. [Google Scholar] [CrossRef]

- Da Silva, A.K.; Inden, G.; Kumar, A.; Ponge, D.; Gault, B.; Raabe, D. Competition between formation of carbides and reversed austenite during tempering of a medium-manganese steel studied by thermodynamic-kinetic simulations and atom probe tomography. Acta Mater. 2018, 147, 165–175. [Google Scholar] [CrossRef]

- Zhang, X.G.; Miyamoto, G.; Kaneshita, T.; Yoshida, Y.; Toji, Y.; Furuhara, T. Growth mode of austenite during reversion from martensite in Fe-2Mn-1.5 Si-0.3 C alloy: A transition in kinetics and morphology. Acta Mater. 2018, 154, 1–13. [Google Scholar] [CrossRef]

- Escobar, J.D.; Faria, G.A.; Wu, L.; Oliveira, J.P.; Mei, P.R.; Ramirez, A.J. Austenite reversion kinetics and stability during tempering of a Ti-stabilized supermartensitic stainless steel: Correlative in situ synchrotron x-ray diffraction and dilatometry. Acta Mater. 2017, 138, 92–99. [Google Scholar] [CrossRef]

- Hu, J.; Du, L.-X.; Sun, G.S.; Xie, H.; Misra, R.D.K. The determining role of reversed austenite in enhancing toughness of a novel ultra-low carbon medium manganese high strength steel. Scr. Mater. 2015, 104, 87–90. [Google Scholar] [CrossRef]

- Bojack, A.; Zhao, L.; Morris, P.F.; Sietsma, J. In-Situ determination of austenite and martensite formation in 13Cr6Ni2Mo supermartensitic stainless steel. Mater. Charact. 2012, 71, 77–86. [Google Scholar] [CrossRef]

- Song, Y.Y.; Li, X.Y.; Rong, L.J.; Li, Y.Y.; Nagai, T. Reversed austenite in 0Cr13Ni4Mo martensitic stainless steels. Mater. Chem. Phys. 2014, 143, 728–734. [Google Scholar] [CrossRef]

- Song, Y.Y.; Li, X.Y.; Rong, L.J.; Ping, D.H.; Yin, F.X.; Li, Y.Y. Formation of the reversed austenite during intercritical tempering in a Fe–13% Cr–4% Ni–Mo martensitic stainless steel. Mater. Lett. 2010, 64, 1411–1414. [Google Scholar] [CrossRef]

- Song, P.C.; Liu, W.B.; Zhang, C.; Liu, L.; Yang, Z.G. Reversed Austenite Growth Behavior of a 13%Cr–5%Ni Stainless Steel during Intercritical Annealing. ISIJ Int. 2016, 56, 148–153. [Google Scholar] [CrossRef] [Green Version]

- Song, Y.Y.; Li, X.Y.; Rong, L.J.; Li, Y.Y. The influence of tempering temperature on the reversed austenite formation and tensile properties in Fe–13% Cr–4% Ni–Mo low carbon martensite stainless steels. Mater. Sci. Eng. A 2011, 528, 4075–4079. [Google Scholar] [CrossRef]

- Zhang, Y.W.; Zhang, C.; Yuan, X.M.; Li, D.K.; Yin, Y.D.; Li, S.Z. Microstructure evolution and orientation relationship of reverted austenite in 13Cr supermartensitic stainless steel during the tempering process. Materials 2019, 12, 589. [Google Scholar] [CrossRef] [Green Version]

- Clarke, A.J.; Speer, J.G.; Miller, M.K.; Hackenberg, R.E.; Edmonds, D.V.; Matlock, D.K.; Rizzo, F.C.; Moor, E.D. Carbon partitioning to austenite from martensite or bainite during the quench and partition (Q&P) process: A critical assessment. Acta Mater. 2008, 56, 16–22. [Google Scholar]

- Speer, J.; Matlock, D.K.; Cooman, B.C.D.; Schroth, J.G. Carbon partitioning into austenite after martensite transformation. Acta Mater. 2003, 51, 2611–2622. [Google Scholar] [CrossRef]

- He, B. On the factors governing austenite stability: Intrinsic versus extrinsic. Materials 2020, 13, 3440. [Google Scholar] [CrossRef]

- Lee, Y.K.; Shin, H.C.; Leem, D.S.; Choi, J.Y.; Jin, W.; Choi, C.S. Reverse transformation mechanism of martensite to austenite and amount of retained austenite after reverse transformation in Fe–3Si–13Cr–7Ni (wt-%) martensitic stainless steel. Mater. Sci. Technol. 2003, 19, 393–398. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhong, Y.; Lv, C.; Tan, L.; Yuan, X.; Li, S. Effect of carbon partition in the reverted austenite of supermartensitic stainless steel. Mater. Res. Express 2019, 6, 086518. [Google Scholar] [CrossRef]

- Zhang, S.H.; Wang, P.; Li, D.Z.; Li, Y.Y. Investigation of the evolution of retained austenite in Fe–13% Cr–4% Ni martensitic stainless steel during intercritical tempering. Mater. Des. 2015, 84, 385–394. [Google Scholar] [CrossRef]

- Yan, S.; Liu, X.H.; Liang, T.S.; Zhao, Y. The effects of the initial microstructure on microstructural evolution, mechanical properties and reversed austenite stability of intercritically annealed Fe-6.1 Mn-1.5 Si-0.12 C steel. Mater. Sci. Eng. A 2018, 712, 332–340. [Google Scholar] [CrossRef]

- Govindaraj, V.; Hodgson, P.; Singh, R.P.; Beladi, H. The effect of austenite reversion on the microstructure and mechanical properties of a 12Cr–3Ni–3Mn–3Cu-0.15 Nb–0.05 C maraging stainless steel. Mater. Sci. Eng. A 2021, 828, 142097. [Google Scholar] [CrossRef]

- Gong, P.; Wynne, B.P.; Knowles, A.J.; Turk, A.; Ma, L.; Galindo-Nava, E.I.; Rainforth, W.M. Effect of ageing on the microstructural evolution in a new design of maraging steels with carbon. Acta Mater. 2020, 196, 101–121. [Google Scholar] [CrossRef]

- De Knijf, D.; Petrov, R.; Föjer, C.; Kestens, L.A.I. Effect of fresh martensite on the stability of retained austenite in quenching and partitioning steel. Mater. Sci. Eng. A 2014, 615, 107–115. [Google Scholar] [CrossRef]

- Yang, K.; Li, Y.; Hong, Z.J.; Du, S.F.; Ma, T.; Liu, S.L. The dominating role of austenite stability and martensite transformation mechanism on the toughness and ductile-to-brittle-transition temperature of a quenched and partitioned steel. Mater. Sci. Eng. A 2021, 820, 141517. [Google Scholar] [CrossRef]

- Xiong, X.C.; Chen, B.; Huang, M.X.; Wang, J.F.; Wang, L. The effect of morphology on the stability of retained austenite in a quenched and partitioned steel. Script. Mater. 2013, 68, 321–324. [Google Scholar] [CrossRef]

- Bojack, A.; Zhao, L.; Morris, P.F.; Sietsma, J. Austenite Formation from Martensite in a 13Cr6Ni2Mo Supermartensitic Stainless Steel. Metall. Mater. Trans. A 2016, 47, 1996–2009. [Google Scholar] [CrossRef] [Green Version]

- Zhang, S.Y.; Terasaki, H.; Komizo, Y.I. In-Situ observation of martensite transformation and retained austenite in supermartensitic stainless steel. Trans. JWRI 2010, 39, 115–117. [Google Scholar] [CrossRef] [Green Version]

- Ma, X.P.; Wang, L.J.; Liu, C.M.; Subramanianb, S.V. Microstructure and properties of 13Cr5Ni1Mo0. 025Nb0. 09V0. 06N super martensitic stainless steel. Mater. Sci. Eng. A 2012, 539, 271–279. [Google Scholar] [CrossRef]

- Zhang, X.H.; Li, J.Y.; Gu, J.B.; Liao, L.H.; Deng, Y. Effect of nitrogen and tempering temperature on microstructure evolution and mechanical properties of 0Cr15Ni6Mo2 martensitic stainless steel. Ironmak. Steelmak. 2022, 49, 311–321. [Google Scholar] [CrossRef]

- Xu, N.; Yang, Z.M.; Mu, X.; Huang, Y.B.; Li, S.L.; Wang, Y.D. Effect of Al addition on the microstructures and deformation behaviors of non equiatomic FeMnCoCr metastable high entropy alloys. Appl. Phys. Lett. 2021, 119, 261902. [Google Scholar] [CrossRef]

- Tanaka, M.; Choi, C.S. The Effects of Carbon Contents and Ms Temperatures on the Hardness of Martensitic Fe-Ni-C Alloys. Trans. Iron Steel Inst. Jpn. 1972, 12, 16–25. [Google Scholar] [CrossRef]

- Zinsaz-Borujerdi, A.; Zarei-Hanzaki, A.; Abedi, H.R.; Karam-Abian, M.; Ding, H.; Han, D.; Kheradmand, N. Room temperature mechanical properties and microstructure of a low alloyed TRIP-assisted steel subjected to one-step and two-step quenching and partitioning process. Mater. Sci. Eng. A 2018, 725, 341–349. [Google Scholar] [CrossRef]

- Wang, P.; Xiao, N.M.; Lu, S.P.; Li, D.Z.; Li, Y.Y. Investigation of the mechanical stability of reversed austenite in 13%Cr-4%Ni martensitic stainless steel during the uniaxial tensile test. Mater. Sci. Eng. A 2013, 586, 292–300. [Google Scholar] [CrossRef]

- Du, P.; Chen, P.; Misra, M.D.K.; Wu, D.; Yi, H.L. Transformation-induced ductility of reverse austenite evolved by low-temperature tempering of martensite. Metals 2020, 10, 1343. [Google Scholar] [CrossRef]

- Wang, J.J.; Van, D.Z. Stabilization mechanisms of retained austenite in transformation-induced plasticity steel. Metall. Mater. Trans. A 2001, 32, 1527–1539. [Google Scholar] [CrossRef]

- Kim, S.J.; Lee, C.G.; Choi, I.; Lee, S. Effects of heat treatment and alloying elements on the microstructures and mechanical properties of 0.15 wt pct C transformation induced plasticity-aided cold-rolled steel sheets. Metall. Mater. Trans. A 2001, 32, 505–514. [Google Scholar] [CrossRef] [Green Version]

- Livitsanos, C.P.; Thomson, P.F. The effect of temperature and deformation rate on transformation-dependent ductility of a metastable austenitic stainless steel. Mater. Sci. Eng. A 1977, 30, 93–98. [Google Scholar] [CrossRef]

- Sohn, S.S.; Lee, B.J.; Lee, S.; Kim, N.J.; Kwak, J.H. Effect of annealing temperature on microstructural modification and tensile properties in 0.35 C–3.5 Mn–5.8 Al lightweight steel. Acta Mater. 2013, 61, 5050–5066. [Google Scholar] [CrossRef]

- Moshtaghi, M.; Safyari, M. Effect of Work-Hardening Mechanisms in Asymmetrically Cyclic-Loaded Austenitic Stainless Steels on Low-Cycle and High-Cycle Fatigue Behavior. Steel Res. Int. 2021, 92, 2000242. [Google Scholar] [CrossRef]

- Zhang, J.; Di, H.; Deng, Y.; Misra, R.D.K. Effect of martensite morphology and volume fraction on strain hardening and fracture behavior of martensite-ferrite dual phase steel. Mater. Sci. Eng. A 2015, 627, 230–240. [Google Scholar] [CrossRef]

- Ding, Y.; Cao, R.; Yan, Y. Effects of heat treatment on fracture mechanism of martensite/austenite MLS composite plates by hot roll bonding. Mater. Sci. Eng. A 2020, 773, 138727. [Google Scholar] [CrossRef]

- Wang, M.; Huang, M. Abnormal TRIP effect on the work hardening behavior of a quenching and partitioning steel at high strain rate. Acta Mater. 2020, 188, 551–559. [Google Scholar] [CrossRef]

- Wang, M.M.; Tasan, C.C.; Ponge, D.; Dippel, A.C.; Raabe, D. Nanolaminate transformation-induced plasticity-twinning-induced plasticity steel with dynamic strain partitioning and enhanced damage resistance. Acta Mater. 2015, 85, 216–228. [Google Scholar] [CrossRef]

- Ungár, T.; Dragomir, I.; Révész, Á.; Borbély, A. The contrast factors of dislocations in cubic crystals: The dislocation model of strain anisotropy in practice. J. Appl. Crystallogr. 1999, 32, 992–1002. [Google Scholar] [CrossRef] [Green Version]

- Nakanishi, D.; Kawabata, T.; Aihara, S. Effect of dispersed retained γ-Fe on brittle crack arrest toughness in 9% Ni steel in cryogenic temperatures. Mater. Sci. Eng. A 2018, 723, 238–246. [Google Scholar] [CrossRef]

| C | Cr | Ni | Mo | Mn | Al | V | Si | P | S | Fe |

|---|---|---|---|---|---|---|---|---|---|---|

| 0.01 | 13.2 | 5.06 | 1.98 | 0.66 | 0.015 | 0.07 | 0.25 | 0.0065 | 0.0064 | Bal. |

| No. | Austenite Volume Fraction (%) | Yield Strength (MPa) | Ultimate Tensile Strength (MPa) | Uniform Elongation (%) | Total Elongation (%) | PSE GPa•% |

|---|---|---|---|---|---|---|

| Sample 1 | 0.9 | 881.2 | 938.6 | 8.5 | 24.1 | 22.6 |

| Sample 2 | 8.3 | 714.7 | 803.8 | 10.3 | 23.7 | 19.1 |

| Sample 3 | 13.3 | 721 | 862.5 | 10.4 | 27.2 | 23.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, P.; Zheng, W.; Yu, X.; Wang, Y. Advantageous Implications of Reversed Austenite for the Tensile Properties of Super 13Cr Martensitic Stainless Steel. Materials 2022, 15, 7697. https://doi.org/10.3390/ma15217697

Wang P, Zheng W, Yu X, Wang Y. Advantageous Implications of Reversed Austenite for the Tensile Properties of Super 13Cr Martensitic Stainless Steel. Materials. 2022; 15(21):7697. https://doi.org/10.3390/ma15217697

Chicago/Turabian StyleWang, Peng, Weiwei Zheng, Xinpan Yu, and Yanli Wang. 2022. "Advantageous Implications of Reversed Austenite for the Tensile Properties of Super 13Cr Martensitic Stainless Steel" Materials 15, no. 21: 7697. https://doi.org/10.3390/ma15217697

APA StyleWang, P., Zheng, W., Yu, X., & Wang, Y. (2022). Advantageous Implications of Reversed Austenite for the Tensile Properties of Super 13Cr Martensitic Stainless Steel. Materials, 15(21), 7697. https://doi.org/10.3390/ma15217697