New Partially Water-Soluble Feedstocks for Additive Manufacturing of Ti6Al4V Parts by Material Extrusion

Abstract

:1. Introduction

- Feedstock compounding of using suitable binders, additives and a huge solid load (ceramics: ≥50 vol%; metals: ≥60 vol%) considering spherical fillers ideally;

- Printing via MEX techniques;

- Debinding, often a combination of liquid pre-debinding with thermal debinding;

- Sintering with conditions depending on the filler’s properties.

2. Materials and Methods

2.1. Polar Feedstock Development

- Particle size distribution;

- Specific surface area;

- Particle density;

- Particle morphology.

2.2. Feedstock Preparation

2.3. Rheological Characterization

2.4. Material Extrusion (MEX)

2.4.1. Fused Filament Fabrication (FFF)

2.4.2. Fused Feedstock Deposition (FFD)

2.5. Debinding, Sintering and Hot Isostatic Pressing

2.6. Characterization of Sintered Samples

3. Results and Discussion

3.1. Material Characterization

3.2. Feedstock Compounding

3.2.1. PEG/PVB Binder System

3.2.2. PEG/PMMA Binder System

3.3. Rheological Characterization

3.3.1. PEG/PVB Binder with Constant PEG/PVB Ratio

3.3.2. PEG/PVB Binder with Different PEG/PVB Ratios

3.3.3. PEG/PMMA Binder with Constant PEG/PMMA Ratio

3.3.4. PEG/PMMA Binder with Different PEG/PMMA Ratios

3.3.5. Solid Load Variation

3.4. Material Extrusion (MEX)

3.4.1. Processing of PEG/PVB Feedstocks

3.4.2. Processing of PEG/PMMA Feedstocks

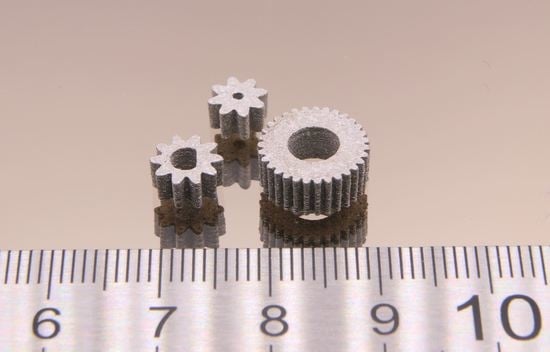

3.5. Debinding and Sintering

3.6. Sinter Part Characterization

3.6.1. Density

3.6.2. Microstructure

3.6.3. Elemental Analysis

4. Conclusions and Outlook

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kluck, S.; Hambitzer, L.; Luitz, M.; Mader, M.; Sanjaya, M.; Balster, A.; Milich, M.; Greiner, C.; Kotz-Helmer, F.; Rapp, B.E. Replicative manufacturing of metal moulds for low surface roughness polymer replication. Nat. Commun. 2022, 13, 5048. [Google Scholar] [CrossRef] [PubMed]

- Gohn, A.M.; Brown, D.; Mendis, G.; Forster, S.; Rudd, N.; Giles, M. Mold inserts for injection molding prototype applications fabricated via material extrusion additive manufacturing. Addit. Manuf. 2022, 51, 102595. [Google Scholar] [CrossRef]

- Sarabia-Vallejos, M.A.; Rodríguez-Umanzor, F.E.; González-Henríquez, C.M.; Rodríguez-Hernández, J. Innovation in Additive Manufacturing Using Polymers: A Survey on the Technological and Material Developments. Polymers 2022, 14, 1351. [Google Scholar] [CrossRef]

- Ranjan, R.; Kumar, D.; Kundu, M.; Chandra Moi, S. A critical review on Classification of materials used in 3D printing process. Mater. Today Proc. 2022, 61, 43–49. [Google Scholar] [CrossRef]

- Cramer, C.L.; Ionescu, E.; Graczyk-Zajac, M.; Nelson, A.T.; Katoh, Y.; Haslam, J.J.; Wondraczek, L.; Aguirre, T.G.; LeBlanc, S.; Wang, H.; et al. Additive manufacturing of ceramic materials for energy applications: Road map and opportunities. J. Eur. Ceram. Soc. 2022, 42, 3049–3088. [Google Scholar] [CrossRef]

- Blakey-Milner, B.; Gradl, P.; Snedden, G.; Brooks, M.; Pitot, J.; Lopez, E.; Leary, M.; Berto, F.; du Plessis, A. Metal additive manufacturing in aerospace: A review. Mater. Des. 2021, 209, 110008. [Google Scholar] [CrossRef]

- Saleh Alghamdi, S.; John, S.; Roy Choudhury, N.; Dutta, N.K. Additive Manufacturing of Polymer Materials: Progress, Promise and Challenges. Polymers 2021, 13, 753. [Google Scholar] [CrossRef]

- Lakhdar, Y.; Tuck, C.; Binner, J.; Terry, A.; Goodridge, R. Additive manufacturing of advanced ceramic materials. Prog. Mater. Sci. 2021, 116, 100736. [Google Scholar] [CrossRef]

- Piotter, V.; Hanemann, T.; Heldele, R.; Mueller, T.; Plewa, K.; Ruh, A. Metal and Ceramic Parts fabricated by Microminiature powder injection molding. Int. J. Powder Metall. 2010, 43, 21–28. [Google Scholar]

- Clemens, F.J.; Kerber, A. FDM/FFF an Alternative to CIM Manufacturing of Prototype and Small Quantities of Ceramic Part? Ceram Appl. 2020, 8, 27–31. [Google Scholar]

- Noetzel, D.; Eickhoff, R.; Hanemann, T. Fused Filament Fabrication of Small Ceramic Components. Materials 2018, 11, 1463. [Google Scholar] [CrossRef]

- Noetzel, D.; Hanemann, T. New Feedstock System for Fused Filament Fabrication of Sintered Alumina Parts. Materials 2020, 13, 4461. [Google Scholar] [CrossRef] [PubMed]

- Eickenscheidt, M.; Langenmair, M.; Dbouk, A.; Noetzel, D.; Hanemann, T.; Stieglitz, T. 3D-Printed Hermetic Alumina Housings. Materials 2021, 14, 200. [Google Scholar] [CrossRef]

- Cano, S.; Gonzalez-Gutierrez, J.; Sapkota, J.; Spoerk, M.; Arbeiter, F.; Schuschnigg, S.; Holzer, C.; Kukla, C. Additive manufacturing of zirconia parts by fused filament fabrication and solvent debinding: Selection of binder formulation. Addit. Manuf. 2019, 26, 117–128. [Google Scholar] [CrossRef]

- Kataoka, Y.; Yokota, K. Fabrication of Three-dimensional Zirconia Ceramics by Material Extrusion. J. Soc. Powder Technol. Jpn. 2020, 57, 520–525. [Google Scholar] [CrossRef]

- He, Q.; Jiang, J.; Yang, X.; Zhang, L.; Zhou, Z.; Zhong, Y.; Shen, Z. Additive manufacturing of dense zirconia ceramics by fused deposition modeling via screw extrusion. J. Eur. Ceram. Soc. 2021, 41, 1033–1040. [Google Scholar] [CrossRef]

- Hadian, A.; Koch, L.; Koberg, P.; Sarraf, F.; Liersch, A.; Sebastian, T.; Clemens, F. Material Extrusion Based Additive Manufacturing of Large Zirconia Structures Using Filaments with Ethylene Vinyl Acetate Based Binder Composition. Addit. Manuf. 2021, 47, 102227. [Google Scholar] [CrossRef]

- Noetzel, D.; Eickhoff, E.; Pfeifer, C.; Hanemann, T. Printing of Zirconia Parts via Fused Filament Fabrication. Materials 2021, 14, 5467. [Google Scholar] [CrossRef]

- Kukla, C.; Cano, S.; Moritz, T.; Müller-Köhn, A.; Courtney, P.; Hampel, S.; Holzer, C. Multimaterial Components by Material Extrusion-Fused Filament Fabrication (ME-FFF)—Production of an Infrared Heater. Ceram. Forum Int. 2019, 96, 22–27. [Google Scholar]

- Lieberwirth, C.; Harder, A.; Seitz, H. Extrusion Based Additive Manufacturing of Metal Parts. J. Mech. Eng. Autom. 2017, 7, 79–83. [Google Scholar] [CrossRef]

- Masood, S.H.; Song, W.Q. Development of new metal/polymer materials for rapid tooling using Fused deposition modelling. Mater. Des. 2004, 25, 587–594. [Google Scholar] [CrossRef]

- Gonzalez-Gutierrez, J.; Cano, S.; Schuschnigg, S.; Kukla, C.; Sapkota, J.; Holzer, C. Additive Manufacturing of Metallic and Ceramic Components by the Material Extrusion of Highly-Filled Polymers: A Review and Future Perspectives. Materials 2018, 11, 840. [Google Scholar] [CrossRef]

- Singh, G.; Missiaen, J.-M.; Bouvard, D.; Chaix, J.-M. Copper extrusion 3D printing using metal injection moulding feedstock: Analysis of process parameters for green density and surface roughness optimization. Addit. Manuf. 2021, 38, 101778. [Google Scholar] [CrossRef]

- Kukla, C.; Gonzalez-Gutierrez, J.; Burkhardt, C.; Holzer, C. The Production of Magnets by FFF-Fused Filament Fabrication. In Proceedings of the Euro PM2017, Milano, Italy, 1–5 October 2017. [Google Scholar]

- Parenti, P.; Puccio, D.; Colosimo, B.M.; Semeraro, Q. A new solution for assessing the printability of 17-4 PH gyroids produced via extrusion-based metal AM. J. Manuf. Process. 2022, 74, 557–572. [Google Scholar] [CrossRef]

- Riaz, A.; Töllner, P.; Ahrend, A.; Springer, A.; Milkereit, B.; Seitz, H. Optimization of composite extrusion modeling process parameters for 3D printing of low-alloy steel AISI 8740 using metal injection moulding feedstock. Mater. Des. 2022, 219, 110814. [Google Scholar] [CrossRef]

- ASTM F2885-17; Standard Specification for Metal Injection Molded Titanium-6Aluminum-4Vanadium Components for Surgical Implant Applications. American Society for Testing and Materials International: West Conshohocken, PA, USA, 2017.

- Zhang, G.; Lu, X.; Li, J.; Chen, J.; Lin, X.; Wang, M.; Tan, H.; Huang, W. In-situ grain structure control in directed energy deposition of Ti6Al4V. Addit. Manuf. 2022, 55, 102865. [Google Scholar] [CrossRef]

- Li, H.; Yu, Y.; Li, Y.; Lin, F. Effects of the higher accelerating voltage on electron beam powder-bed based additive manufacturing of Ti6Al4V alloy. Addit. Manuf. 2022, 50, 102579. [Google Scholar] [CrossRef]

- Damon, J.; Czink, S.; Schüßler, P.; Antusch, S.; Klein, A.; Send, S.; Dapprich, D.; Dietrich, S.; Schulze, V. Mechanical surface treatment of EBM Ti6Al4V components: Effects of the resulting surface layer state on fatigue mechanisms and service life. Mater. Sci. Eng. A 2022, 849, 143422. [Google Scholar] [CrossRef]

- Zhang, F.; Wang, K.; Li, Y.; Chen, Y.; Yang, M.; Wang, M.; Clare, A.T. Composition fine-tuning for directed energy deposition of Ti-6Al-4V. J. Mater. Process. Technol. 2022, 299, 117321. [Google Scholar] [CrossRef]

- Thompson, Y.; Polzer, M.; Gonzalez-Gutierrez, J.; Kasian, O.; Heckl, J.P.; Dalbauer, V.; Kukla, C.; Felfer, P.J. Fused Filament Fabrication-Based Additive Manufacturing of Commercially Pure Titanium. Adv. Eng. Mater. 2021, 23, 2100380. [Google Scholar] [CrossRef]

- Singh, P.; Balla, V.K.; Atre, S.V.; German, R.M.; Kate, K.H. Factors affecting properties of Ti-6Al-4V alloy additive manufactured by metal fused filament fabrication. Powder Technol. 2021, 386, 9–19. [Google Scholar] [CrossRef]

- Singh, P.; Balla, V.K.; Tofangchi, A.; Atre, S.V.; Kate, K.H. Printability studies of Ti-6Al-4V by metal fused filament fabrication (MF3). Int. J. Refract. Met. Hard Mater. 2020, 91, 105249. [Google Scholar] [CrossRef]

- Gloeckle, C.; Konkol, T.; Jacobs, O.; Limberg, W.; Ebel, T.; Handge, U.A. Processing of Highly Filled Polymer-Metal Feedstocks for Fused Filament Fabrication and the Production of Metallic Implants. Materials 2020, 13, 4413. [Google Scholar] [CrossRef]

- Eickhoff, R.; Antusch, S.; Baumgärtner, S.; Nötzel, D.; Hanemann, T. Feedstock Development for Material Extrusion-Based Printing of Ti6Al4V Parts. Materials 2022, 15, 6442. [Google Scholar] [CrossRef]

- Bek, M.; Gonzalez-Gutierrez, J.; Kukla, C.; Pušnik Črešnar, K.; Maroh, B.; Slemenik Perše, L. Rheological Behaviour of Highly Filled Materials for Injection Moulding and Additive Manufacturing: Effect of Particle Material and Loading. Appl. Sci. 2020, 10, 7993. [Google Scholar] [CrossRef]

- Mezger, T.G. The Rheology Handbook, 4th ed.; Vincentz Network: Hanover, Germany, 2014; ISBN 3-86630-650-4. [Google Scholar]

- Basir, A.; Sulong, A.B.; Jamadon, N.H.; Muhamad, N.; Emeka, U.B. Process Parameters Used in Macro/Micro Powder Injection Molding: An Overview. Met. Mater. Int. 2020, 27, 2023. [Google Scholar] [CrossRef]

- Metal Powder Ti6Al4V, Data Sheet, Heraeus. Available online: https://www.heraeus.com/media/media/group/doc_group/products_1/additivemanufacturing/datasheets_en/Ti6Al4V.pdf (accessed on 18 July 2022).

- Medesi, A.J.; Noetzel, D.; Hanemann, T. PVB/PEG-Based Feedstocks for Injection Molding of Alumina Microreactor Components. Materials 2019, 12, 1219. [Google Scholar] [CrossRef]

- Medesi, A.J.; Noetzel, D.; Wohlgemuth, J.; Franzreb, M.; Hanemann, T. Ceramic Injection Moulding using 3D-Printed Mould Inserts. Ceram. Mod. Technol. 2019, 1, 104–110. [Google Scholar] [CrossRef]

- Weber, O.; Hanemann, T. Green-conscious ceramic injection moulding. In Advanced Processing and Manufacturing Technologies for Structural and Multifunctional Materials VI; Ihji, T., Singh, M., Halbig, M., Mathur, S., Eds.; John Wiley & Sons: Hoboken, NJ, USA, 2013; pp. 63–71. [Google Scholar]

- Weber, O.; Hanemann, T. Ceramic injection moulding using a partially water-soluble binder system: Effect of back-bone polymers on the process. In Advanced Processing and Manufacturing Technologies for Structural and Multifunctional Materials VI; Ihji, T., Singh, M., Halbig, M., Mathur, S., Eds.; John Wiley & Sons: Hoboken, NJ, USA, 2013; pp. 52–61. [Google Scholar]

- Hanemann, T.; Heldele, R. Modern Alchemy: Ceramic Feedstock Optimization by Surfactant Screening. CFI/Ber. DKG 2010, 87, E38–E40. [Google Scholar]

- Hanemann, T.; Weber, O. Thermoplastic PMMA/PEG binder system for micro ceramic injection moulding. In Proceedings of the 10th International Conference on Multi-Material Micro Manufacture, San Sebastian, Spain, 8–10 October 2013; pp. 231–234. [Google Scholar]

- Chuankrerkkul, N.; Messer, P.F.; Davies, H.A. Flow and void formation in powder injection moulding feedstocks made with PEG/PMMA binders Part 1—Experimental observations. Powder Metall. 2013, 51, 66–71. [Google Scholar] [CrossRef]

- Chen, G.; Cao, P.; Wen, G.; Edmonds, N. Debinding behaviour of a water soluble PEG/PMMA binder for Ti metal injection moulding. Mater. Chem. Phys. 2013, 139, 557–565. [Google Scholar] [CrossRef]

- Hayat, M.D.; Wen, G.; Zulkifli, M.F.; Cao, P. Effect of PEG molecular weight on rheological properties of Ti-MIM feedstocks and water debinding behaviour. Powder Technol. 2015, 270, 293–301. [Google Scholar] [CrossRef]

- Available online: https://spool-database.info/pvb-filament-was-ist-das (accessed on 1 February 2023).

- Weber, O. Wasserlösliche Bindersysteme zum Minimieren von Pulver-Binder-Segregationseffekten im Mikropulverspritzguss. Ph.D. Thesis, University of Freiburg, Freiburg, Germany, 2015. [Google Scholar]

- DIN EN ISO 5832-3:2020-11; Implants for Surgery—Metallic Materials—Part 3: Wrought Titanium 6-Aluminium 4-Vanadium Alloy (ISO/DIS 5832-3:2020-11). DIN: Berlin, Germany, 2020.

| Component | Density (g/cm³) | MW (g/mol) | TS (°C) | TD (°C) |

|---|---|---|---|---|

| PEG 2000 | 1.22 M | 1800–2200 V | 52 V | n.a. |

| PEG 4000 | 1.22 M | 3500–4500 V | 58 V | n.a. |

| PEG 6000 | 1.22 M | 5000–7000 V | 60 V | n.a. |

| PEG 8000 | 1.22 M | 7300–9000 V | 60 V | n.a. |

| PEG 20,000 | 1.22 M | 20,000 V | 60 V | n.a. |

| PVB 30 H | 1.11 M | 32,000–35,000 V | 68 V | 206 M |

| PMMA Degalan 7 E | 1.18 M | 159,000 M | 96–109 M | 240 M |

| Stearic acid | 0.92 M | 284 V | 69–85 V | 170 M |

| PAT-77 P | 0.97 M | n.a. | 85–95 V | n.a. |

| PAT-659/CB | 0.96 M | n.a | 45–75 V | n.a. |

| Feedstock | Extrusion Temperature (°C) | Filament Diameter (mm) |

|---|---|---|

| PEG 2000/PVB | 90 | 2.82 ± 0.02 |

| PEG 8000/PVB | 90 | 2.80 ± 0.01 |

| PEG 20,000/PVB | 90 | 2.86 ± 0.01 |

| FFF Printing Parameter | PEG 2000/PVB | PEG 8000/PVB | PEG 20,000/PVB |

|---|---|---|---|

| Temperature (°C) | 230 | 230 | 180 |

| Platform temperature (°C) | 55 | 55 | 60 |

| Printing speed (mm/s) | 5 | 5 | 5 |

| Printing speed first layer (mm/s) | 5 | 5 | 2.5 |

| Nozzle diameter (mm) | 0.3 | 0.3 | 0.3 |

| Infill (%) | 105 | 105 | 105 |

| Overlap contour lines with infill (mm) | 0.2 | 0.2 | 0.2 |

| Feedstock | Extrusion Temperature (°C) | Filament Diameter (mm) |

|---|---|---|

| SA | 106 | 2.81 ± 0.04 |

| PAT77P | 70 | 2.87 ± 0.02 |

| PAT659/CB | n.a. | n.a. |

| Printing Parameter | FFF (X350Pro) | FFD (150H) |

|---|---|---|

| Temperature (°C) | 210 | 220 |

| Platform temperature (°C) | 50 | 60 |

| Printing speed (mm/s) | 5–10 | 5 |

| Printing speed first layer (mm/s) | 3 | 3 |

| Nozzle diameter (mm) | 0.15/0.3/0.4 | 0.4 |

| Infill (%) | 105 | 105 |

| Overlap contour lines with infill (mm) | 0.2 | 0.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Eickhoff, R.; Antusch, S.; Nötzel, D.; Hanemann, T. New Partially Water-Soluble Feedstocks for Additive Manufacturing of Ti6Al4V Parts by Material Extrusion. Materials 2023, 16, 3162. https://doi.org/10.3390/ma16083162

Eickhoff R, Antusch S, Nötzel D, Hanemann T. New Partially Water-Soluble Feedstocks for Additive Manufacturing of Ti6Al4V Parts by Material Extrusion. Materials. 2023; 16(8):3162. https://doi.org/10.3390/ma16083162

Chicago/Turabian StyleEickhoff, Ralf, Steffen Antusch, Dorit Nötzel, and Thomas Hanemann. 2023. "New Partially Water-Soluble Feedstocks for Additive Manufacturing of Ti6Al4V Parts by Material Extrusion" Materials 16, no. 8: 3162. https://doi.org/10.3390/ma16083162

APA StyleEickhoff, R., Antusch, S., Nötzel, D., & Hanemann, T. (2023). New Partially Water-Soluble Feedstocks for Additive Manufacturing of Ti6Al4V Parts by Material Extrusion. Materials, 16(8), 3162. https://doi.org/10.3390/ma16083162