Properties of Starve-Fed Extrusion on a Material Containing a VHMWPE Fraction

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Extrusion Experiments

2.3. Experimental Overview

- Output;

- Melt temperature;

- Specific energy input (SEI);

- Degradation after extrusion;

- Residence-time distribution;

- Melting performance;

- VHMWPE particle distribution;

- Shape distribution of the VHMWPE particles.

2.4. Measurement of Melt Temperature

2.5. Specific Energy Input

2.6. Measurement of Degradation after Extrusion

2.7. Measurement of Residence Time

2.8. Melting-Performance Analysis

2.9. Analysis of Sample Homogeneity

2.10. Analysis of Particle-Size Distribution

2.11. Analysis of VHMWPE Particle-Shape Distribution

3. Results and Discussion

3.1. Influence of Feeding Rate on Output

3.2. Influence of Feeding Rate on Melt Temperature

3.3. Influence of Feeding Rate on Pressure Build-Up

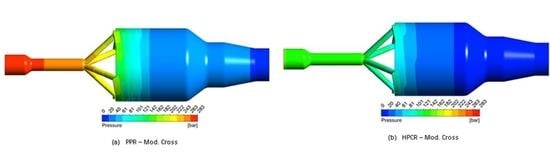

3.4. Influence of Backpressure on Pressure Build-Up at Various Feeding Rates

3.4.1. Influence of Backpressure on Pressure Build-Up at 100% Feeding Rate

3.4.2. Influence of Backpressure on Pressure Build-Up at 25% Feeding Rate

3.5. Influence of Feeding Rate on Specific Energy Input (SEI)

3.6. Analysis of Degradation by the Extrusion Process

3.7. Residence Time Distribution

3.8. Analysis of Melting Performance

3.9. Analysis of Sample Homogeneity

3.10. Particle Shape

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wilczyński, K.; Nastaj, A.; Lewandowski, A.; Wilczyński, K.J.; Buziak, K. Fundamentals of Global Modeling for Polymer Extrusion. Polymers 2019, 11, 2106. [Google Scholar] [CrossRef] [Green Version]

- Thompson, M.R.; Donoian, G.; Christiano, J.P. Melting mechanism of a starved-fed single-screw extruder for calcium carbonate filled polyethylene. Polym. Eng. Sci. 2000, 40, 2014–2026. [Google Scholar] [CrossRef]

- Lopez-Latorre, L.; McKelvey, J.M. Melting and pressurization in starve feed extrusion. Adv. Polym. Technol. 1984, 3, 355–364. [Google Scholar] [CrossRef]

- Wilczyński, K.; Nastaj, A.; Wilczyński, K.J. Melting Model for Starve Fed Single Screw Extrusion of Thermoplastics. Int. Polym. Process. J. Polym. Process. Soc. 2013, 28, 34–42. [Google Scholar] [CrossRef]

- Wilczynski, K.J.; Nastaj, A. Modeling of starve-fed single-screw extrusion of thermoplastic polyblends. Polimery 2015, 60, 199–208. [Google Scholar] [CrossRef]

- Wilczyński, K.; Lewandowski, A.; Wilczyński, K.J. Experimental study for starve-fed single screw extrusion of thermoplastics. Polym. Eng. Sci. 2012, 52, 1258–1270. [Google Scholar] [CrossRef]

- Gale, M. Compounding with single-screw extruders. Adv. Polym. Technol. 1997, 16, 251–262. [Google Scholar] [CrossRef]

- Isherwood, D.P.; Pieris, R.N.; Kassatly, J. The Effect of Metered Starve Feeding on the Performance of a Small Extruder. J. Eng. Ind. 1984, 106, 132–136. [Google Scholar] [CrossRef]

- Nastaj, A.; Wilczyński, K. Optimization for Starve Fed/Flood Fed Single Screw Extrusion of Polymeric Materials. Polymers 2020, 12, 149. [Google Scholar] [CrossRef] [Green Version]

- Mazzanti, V.; Malagutti, L.; Santoni, A.; Sbardella, F.; Calzolari, A.; Sarasini, F.; Mollica, F. Correlation between Mechanical Properties and Processing Conditions in Rubber-Toughened Wood Polymer Composites. Polymers 2020, 12, 1170. [Google Scholar] [CrossRef]

- Diop, M.F.; Burghardt, W.R.; Torkelson, J.M. Well-mixed blends of HDPE and ultrahigh molecular weight polyethylene with major improvements in impact strength achieved via solid-state shear pulverization. Polymer 2014, 55, 4948–4958. [Google Scholar] [CrossRef]

- Fu, J.; Ghali, B.W.; Lozynsky, A.J.; Oral, E.; Muratoglu, O.K. Ultra high molecular weight polyethylene with improved plasticity and toughness by high temperature melting. Polymer 2010, 51, 2721–2731. [Google Scholar] [CrossRef]

- Smith, P.; Lemstra, P.J.; Booij, H.C. Ultradrawing of high-molecular-weight polyethylene cast from solution. II. Influence of initial polymer concentration. J. Polym. Sci. Polym. Phys. Ed. 1981, 19, 877–888. [Google Scholar] [CrossRef] [Green Version]

- Jansen, B.J.P.; Rastogi, S.; Meijer, H.E.H.; Lemstra, P.J. Rubber-Modified Glassy Amorphous Polymers Prepared via Chemically Induced Phase Separation. 1. Morphology Development and Mechanical Properties. Macromolecules 2001, 34, 3998–4006. [Google Scholar] [CrossRef] [Green Version]

- Ronca, S.; Forte, G.; Tjaden, H.; Yao, Y.; Rastogi, S. Tailoring molecular structure via nanoparticles for solvent-free processing of ultra-high molecular weight polyethylene composites. Polymer 2012, 53, 2897–2907. [Google Scholar] [CrossRef]

- Kurtz, S. Advances in the processing, sterilization, and crosslinking of ultra-high molecular weight polyethylene for total joint arthroplasty. Biomaterials 1999, 20, 1659–1688. [Google Scholar] [CrossRef]

- Baena, J.; Wu, J.; Peng, Z. Wear Performance of UHMWPE and Reinforced UHMWPE Composites in Arthroplasty Applications: A Review. Lubricants 2015, 3, 413–436. [Google Scholar] [CrossRef] [Green Version]

- Khasraghi, S.S.; Rezaei, M. Preparation and characterization of UHMWPE/HDPE/MWCNT melt-blended nanocomposites. J. Thermoplast. Compos. Mater. 2015, 28, 305–326. [Google Scholar] [CrossRef]

- Li, Y.-M.; Wang, Y.; Bai, L.; Zhou, H.-L.-Z.; Yang, W.; Yang, M.-B. Dynamic Rheological Behavior of HDPE/UHMWPE Blends. J. Macromol. Sci. Part B 2011, 50, 1249–1259. [Google Scholar] [CrossRef]

- Li, Y.; He, H.; Ma, Y.; Geng, Y.; Tan, J. Rheological and mechanical properties of ultrahigh molecular weight polyethylene/high density polyethylene/polyethylene glycol blends. Adv. Ind. Eng. Polym. Res. 2019, 2, 51–60. [Google Scholar] [CrossRef]

- Liang, J.Z.; Yang, Q.Q. Mechanical Properties of Carbon Black-Filled High-Density Polyethylene Antistatic Composites. J. Reinf. Plast. Compos. 2009, 28, 295–304. [Google Scholar] [CrossRef]

- Aiello, R.; La Mantia, F.P. On the Improvement of the Processability of UHMW-HDPE by Adding a Liquid Crystalline Polymer and a Fluoroelastomer. Macromol. Mater. Eng. 2001, 286, 176–178. [Google Scholar] [CrossRef]

- Liu, G.; Chen, Y.; Li, H. Study on processing of ultrahigh molecular weight polyethylene/polypropylene blends. J. Appl. Polym. Sci. 2004, 94, 977–985. [Google Scholar] [CrossRef]

- Zuo, J.-D.; Zhu, Y.-M.; Liu, S.-M.; Jiang, Z.-J.; Zhao, J.-Q. Preparation of HDPE/UHMWPE/MMWPE blends by two-step processing way and properties of blown films. Polym. Bull. 2007, 58, 711–722. [Google Scholar] [CrossRef]

- Gerstorfer, G.; Lepschi, A.; Miethlinger, J.; Zagar, B.G. An optical system for measuring the residence time distribution in co-rotating twin-screw extruders. J. Polym. Eng. 2013, 33, 683–690. [Google Scholar] [CrossRef]

- Takashimizu, Y.; Iiyoshi, M. New parameter of roundness R: Circularity corrected by aspect ratio. Prog. Earth Planet. Sci. 2016, 3, 2. [Google Scholar] [CrossRef] [Green Version]

- Preedy, E.C.; Perni, S.; Prokopovich, P. Nanomechanical and surface properties of rMSCs post-exposure to CAP treated UHMWPE wear particles. Nanomedicine 2016, 12, 723–734. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bracco, P.; Bellare, A.; Bistolfi, A.; Affatato, S. Ultra-High Molecular Weight Polyethylene: Influence of the Chemical, Physical and Mechanical Properties on the Wear Behavior. A Review. Materials 2017, 10, 791. [Google Scholar] [CrossRef] [PubMed]

| Pressure Sensor | Position (D) |

|---|---|

| P1 | 8.2 |

| P2 | 14.0 |

| P3 | 19.7 |

| P4 | 25.4 |

| P5 | 31.2 |

| P6 | 38.5 |

| P7 (backpressure) | 42.5 |

| Zone | Temperature [°C] |

|---|---|

| F0 | 40 |

| Z1 | 220 |

| Z2 | 215 |

| Z3 | 210 |

| Z4 | 200 |

| Z5 | 200 |

| Z6 | 200 |

| Tool | 200 |

| Screw Speed (rpm) | Feeding Rate (%) |

|---|---|

| 50 | 25 |

| 50 | 50 |

| 50 | 75 |

| 50 | 100 |

| 200 | 25 |

| 200 | 50 |

| 200 | 75 |

| 200 | 100 |

| Screw Speed (rpm) | Feeding Rate | |

|---|---|---|

| 50 | 25 | 0.95 |

| 50 | 50 | 0.99 |

| 50 | 75 | 0.93 |

| 50 | 100 | 0.93 |

| 200 | 25 | 0.85 |

| 200 | 50 | 0.96 |

| 200 | 75 | 0.99 |

| 200 | 100 | 0.98 |

| Feeding Rate | 50 rpm | 200 rpm |

|---|---|---|

| 25% | 877 s | 189 s |

| 50% | 450 s | 141 s |

| 75% | 281 s | 102 s |

| 100% | 224 s | 67 s |

| Percentage of Particles | 50 rpm, 100% Feeding Rate | 200 rpm, 100% Feeding Rate |

|---|---|---|

| 10% | 141 s | 41 s |

| 30% | 171 s | 50.5 s |

| 50% | 207 s | 65.5 s |

| 75% | 269 s | 105.5 s |

| 100% | 412,5 s | 216 s |

| Percentage of Particles | 50 rpm, 100% Feeding Rate | 200 rpm, 100% Feeding Rate |

|---|---|---|

| 10% | 512 s | 127.5 s |

| 30% | 713 s | 231 s |

| 50% | 920 s | 369.5 s |

| 75% | 1197 s | 577 s |

| 100% | 1658 s | 912.5 s |

| Feeding Rate | 50 rpm | 200 rpm |

|---|---|---|

| 25% | 920 s | 369.5 s |

| 50% | 452.5 s | 155.5 s |

| 75% | 300 s | 87 s |

| 100% | 207 s | 65.5 s |

| Sample | Number of Particles | Mean Particle Area (µm2) | Median Particle Size (µm) | Area Covered by All Particles (µm2) |

|---|---|---|---|---|

| Pellet | 353 | 686.6 | 361.0 | 73,170 |

| 25% Feeding rate | 141 | 532.5 | 352.0 | 22,665 |

| 50% Feeding rate | 148 | 678.1 | 390.5 | 30,297 |

| 75% Feeding rate | 158 | 575.2 | 355.5 | 27,434 |

| 100% Feeding rate | 129 | 686.5 | 330.0 | 26,738 |

| Sample | Number of Particles | Mean Particle Area (µm2) | Median Particle Size (µm) | Area Covered by All Particles (µm2) |

|---|---|---|---|---|

| Pellet | 353 | 686.6 | 361.0 | 73,170 |

| 25% Feeding rate | 84 | 678.4 | 426.5 | 17,202 |

| 50% Feeding rate | 76 | 807.7 | 449.5 | 18,533 |

| 75% Feeding rate | 120 | 659.7 | 332.5 | 23,899 |

| 100% Feeding rate | 162 | 704.1 | 356.0 | 34,433 |

| Sample | Number of Particles | Mean Value of Circularity | Median Value of Circularity |

|---|---|---|---|

| Pellet | 353 | 0.6142 | 0.66 |

| 25% Feeding rate | 141 | 0.2753 | 0.25 |

| 50% Feeding rate | 148 | 0.3219 | 0.27 |

| 75% Feeding rate | 158 | 0.5737 | 0.59 |

| 100% Feeding rate | 129 | 0.6003 | 0.612 |

| Sample | Number of Particles | Mean Value of Circularity | Median Value of Circularity |

|---|---|---|---|

| Pellet | 353 | 0.6142 | 0.66 |

| 25% Feeding rate | 84 | 0.5326 | 0.55 |

| 50% Feeding rate | 76 | 0.6227 | 0.65 |

| 75% Feeding rate | 120 | 0.5934 | 0.63 |

| 100% Feeding rate | 162 | 0.5863 | 0.61 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rathner, R.; Tranchida, D.; Roland, W.; Ruemer, F.; Buchmann, K.; Amsüss, P.; Steinbichler, G. Properties of Starve-Fed Extrusion on a Material Containing a VHMWPE Fraction. Polymers 2021, 13, 944. https://doi.org/10.3390/polym13060944

Rathner R, Tranchida D, Roland W, Ruemer F, Buchmann K, Amsüss P, Steinbichler G. Properties of Starve-Fed Extrusion on a Material Containing a VHMWPE Fraction. Polymers. 2021; 13(6):944. https://doi.org/10.3390/polym13060944

Chicago/Turabian StyleRathner, Raffael, Davide Tranchida, Wolfgang Roland, Franz Ruemer, Klaus Buchmann, Philipp Amsüss, and Georg Steinbichler. 2021. "Properties of Starve-Fed Extrusion on a Material Containing a VHMWPE Fraction" Polymers 13, no. 6: 944. https://doi.org/10.3390/polym13060944

APA StyleRathner, R., Tranchida, D., Roland, W., Ruemer, F., Buchmann, K., Amsüss, P., & Steinbichler, G. (2021). Properties of Starve-Fed Extrusion on a Material Containing a VHMWPE Fraction. Polymers, 13(6), 944. https://doi.org/10.3390/polym13060944