3.1.1. Model Construction and Model Verification

Multivariate quadratic regression fitting was carried out on the test data to obtain the regression models of

,

,

, and

S, as shown in Equations (1)–(4).

where

is tensile strength in MPa;

is elongation at break in %;

is bending strength in MPa;

is bending deflection in mm;

A is the amount of curing agent,%;

B is the amount of toughening agent in %; and

C is the dosage of accelerator in %;

To explore the significance of the influence between the factors (independent variables) of the response surface regression model and the response values, the regression model was subjected to analysis of variance, as shown in

Table 3. The model was evaluated using the

F test. The larger the

F value is, the smaller the

p value is, which means that the probability of the invalid hypothesis of the model is also smaller, and the model is more significant [

22]. The

F values of the regression models

,

,

, and

were 66.50, 49.57, 46.32, and 40.49, respectively, and the corresponding

p values were less than 0.0001, indicating that the statistical significance of the four models was very high. The

p values, corresponding to the

F values of the four regression models, were greater than 0.05, indicating that the lack of fit caused by error was not significant. The four models could well describe the relationship between response and factors.

Table 3 shows the relationship between three independent variables (factors) and materials’ response values. It can be seen that the order of influence of the three factors

A (curing agent dosage),

B (toughening agent dosage), and

C (accelerator dosage) on the tensile strength model was

A >

B >

C, the order of influence of the three factors on the bending strength model was

A >

C >

B, and factor

A was the most significant in both models. The results show that the amount of curing agent was the main factor affecting the strength of epoxy resin adhesive.

A,

B, and

C influenced the elongation at break model in the order of

B >

C >

A and influenced the bending deflection model in the order of

B >

A >

C. Factor

B was the most significant factor in both models, which indicates that the content of toughening agent was the main factor affecting the deformation ability of epoxy resin adhesive. In the two models of tensile strength and flexural strength,

AC was significant (

p < 0.05), while

AB and

BC were not (

p > 0.05), indicating that the interaction of curing agent dosage

A and accelerator dosage

C had significant effects on tensile strength and flexural strength. The order of factor interaction significance in the elongation at break model was

AB >

BC >

AC, and the order of factor interaction significance in the bending deflection model was

BC >

AB >

AC.

Table 4 shows the statistical analysis of the fitting accuracy of the four regression models

,

,

, and

. The R

2 of the four models is close to 1, indicating that the correlation between the predicted value and the actual value of the four regression models was good. The difference between the calibration coefficient of determination (R

2Adj) and the prediction coefficient of determination (R

2Pred) of the four models was less than 0.2, and the coefficient of variation (CV) for all of them was less than 10%. The signal-to-noise ratio was far greater than 4, which further shows that the fitting error of the four regression models

,

,

, and

was small, and the model fitting effect was good [

23,

24].

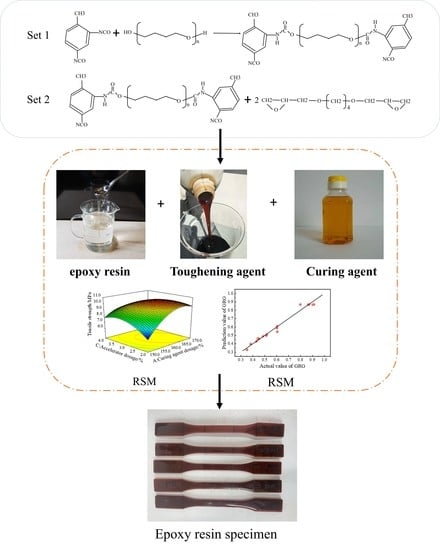

Figure 3 shows the comparison results of actual values and predicted values of models

,

,

, and

. The predicted values of the four regression models are close to the actual values, and the average deviations between the actual values and the predicted values are 1.68%, 2.23%, 2.57%, and 1.60%, respectively, indicating that the reliability of the model fitting is high. The above analysis shows that the four regression models can accurately describe the functional relationship between the response values and the factors and analyze and predict the test results.

3.1.2. Analysis of Three-Dimensional Response Surface Interaction Effect

According to the test results and the variance analysis results in

Table 3, the tensile strength

, elongation at break

, bending strength

, and bending deflection

of the epoxy resin adhesive were all affected by the interaction between the factors.

In the regression model of tensile strength

, the

F value of the interaction term

AC was the largest, and the

p value was the smallest, which indicates that the interaction of curing agent dosage

A and accelerator dosage

C had the most significant effect on the tensile strength of epoxy resin adhesive.

Figure 4 is a three-dimensional response surface showing the effect of the interaction between the curing agent dosage

A and the accelerator dosage

C on the tensile strength (

), with the toughening agent dosage

B of 15%. When the amount of accelerator was constant, the tensile strength increased first and then decreased with the increase in the amount of curing agent. The main reason is that when the amount of curing agent is too small, the proportion of epoxy is too high, and a large number of ether bonds are formed in the reaction process, resulting in many irreversible cross-linking points. Thus, the transesterification reaction does not occur easily in the curing system. When the cross-linking density and uniformity of the curing system were reduced, strength decreased [

25,

26]. When the amount of curing agent was constant, the tensile strength of epoxy resin binder increased first and then decreased with the increase in the amount of accelerator, which is consistent with the research results of Liang Ming et al. [

19]. The reason is that a proper amount of DMP-30 accelerator can catalyze the anhydride group, promote the curing and cross-linking of epoxy resin, and relatively improve its mechanical properties. However, the excessive amount of accelerator will make the curing system release too much heat in unit time, resulting in phase separation of the curing system, reducing the cross-linking density, and, thus, reducing the mechanical properties of the resin [

27,

28,

29]. In summary, simultaneously increasing the amount of curing agent and accelerator within a certain range can effectively improve the tensile strength of epoxy resin binder.

Figure 5a is a three-dimensional response surface, showing the effect of the interaction between the curing agent dosage

A and the toughening agent dosage

B on the elongation at break (

), with the accelerator dosage

C of 3%.

Figure 5b is a three-dimensional response surface of the effect of the interaction between the toughening agent content

B and the accelerator content

C on the elongation at break (

), with a curing agent content of 160%. When the dosage of toughening agent

B was constant, the elongation at break increased first and then decreased with the increase in the dosage of curing agent

A or the dosage of accelerator

C. When the dosage of curing agent

A or accelerator

C was constant, the elongation at break increased with the increase in the dosage of the toughening agent. The variance analysis of the model

results from

Table 3 obtained the

p values of 0.0036 and 0.0037 for

AB and

BC, respectively, indicating that the interaction of toughening agent B and curing agent

A, as well as the interaction between toughening agent

B and accelerator

C, had significant effects on the elongation at break. The interaction between toughening agent dosage

B and curing agent dosage

A had the most significant effect on the elongation at break.

A and

B, as well as

B and

C interactions, had significant effects on elongation at break, which may be due to the decrease in cross-link density of the curing system when the toughening agent is used, but the increase in cross-link density can be caused by the addition of proper amounts of curing agent and accelerator. The interactions between the amount of toughening agent and the amount of curing agent, and between the amount of toughening agent and the accelerator, significantly affected the elongation at break [

30,

31]. Thus, in summary, to improve the elongation at break of epoxy resin adhesive, it is necessary to comprehensively consider the effects of the interaction of the amounts of toughening agent and curing agent, as well as the quantities of toughening agent and accelerator on the elongation at break of epoxy resin adhesive in the process of ratio optimization.

Figure 6 is a three-dimensional response surface with the effect of the interaction of the curing agent dosage

A and the accelerator dosage

C on the flexural strength (

), with the toughening agent dosage

B of 15%. It can be seen from

Figure 6 that, with the increase in the amount of curing agent or accelerator, the bending strength of the epoxy resin binder increased first and then decreased. According to the variance analysis results of the

model in

Table 3, the

AC term was significant (

p = 0.0002 < 0.05), and the response surface was steep when the curing agent dosage

A and the accelerator dosage

C changed at the same time, indicating that the interaction of the curing agent dosage

A and the accelerator dosage

C had a significant effect on the bending strength. The reason is that the tertiary amine produced by the decomposition of the DMP-30 accelerator can react with the anhydride group in the anhydride curing agent to produce carboxylate anion, which can catalyze the anhydride curing agent and make the system more easily cross-linked and cured. However, the excessive accelerator will quickly cross-link and cure the system, resulting in the unreacted chain segment that cannot continue participating in the reaction. Macroscopically, the interaction between the amount of DMP-30 accelerator and the amount of anhydride curing agent affects the mechanical properties of epoxy resin adhesive [

19,

27,

28].

Figure 7 is a three-dimensional response surface with the effect of the interaction of the toughening agent dosage

B and the accelerator dosage

C on the bending deflection (

) of the epoxy resin adhesive with the curing agent dosage

A of 160%. With the increase in the content of toughening agent, the range of change in bending deflection was greater when the content of accelerator was 2% than when it was 4%, indicating that the sensitivity of bending deflection of epoxy resin adhesive to the amount of toughening agent decreased with the increase in the amount of accelerator. According to the variance analysis results of the bending deflection

model in

Table 3, the

BC term was significant (

p = 0.001 < 0.05), indicating that the interaction of the toughening agent B and the accelerator C had a significant effect on the bending deflection.

3.1.3. Single-Objective Optimization Results

The single-objective response was optimized by Design-Expert 8.0 software. The maximum tensile strength of epoxy resin adhesive was 10.61 MPa, the corresponding amount of curing agent was 163.1%, the amount of toughening agent was 14.3%, and the amount of accelerator was 2.8%. The maximum elongation at break of the epoxy resin adhesive was 24.60%, and the corresponding amounts of curing agent, toughening agent, and accelerator were 156.9%, 18.8%, and 3.1%, respectively. The maximum bending strength of the epoxy resin adhesive was 6.17 MPa, and the amounts of curing agent, toughening agent, and accelerator were 162.5%, 14.9%, and 3.1%, respectively. The maximum bending deflection of epoxy resin adhesive was 7.42 mm, the corresponding amount of curing agent was 159.0%, the amount of toughening agent was 20.0%, and the amount of accelerator was 2.8%.