A Novel Data Acquisition System for Obtaining Thermal Parameters of Building Envelopes

Abstract

:1. Introduction

2. Measurement Methodology

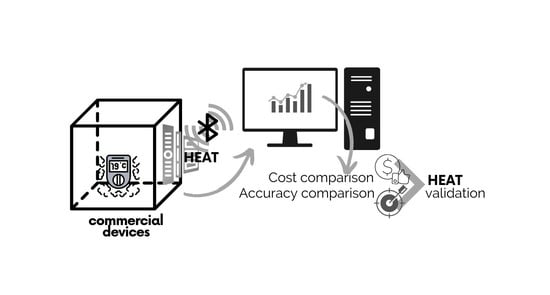

3. Establishing a Hyper-Efficient Arduino Transmittance-Meter (HEAT)

3.1. Hardware

3.2. The Developed HEATs

3.3. Measurement Methodology and Developed Algorithm

- -

- Receive the HEAT observations via the wireless Bluetooth protocol.

- -

- Calculate the mean value of the measurements of the eight sensors associated with interior temperature (), exterior temperature (), and interior surface temperature ().

- -

- Substitute the mean values of the parameters into Equation (1), determine the U-value of each HEAT, and then calculate the difference between the obtained results and those derived from the TESTO 435-1.

- Approach 1

- -

- Specify the outliers (measurements that fall below and above the 5th and 95th percentiles) and remove them from the observations.

- -

- Substitute the mean values of the parameters into Equation (1), determine the U-value, and then calculate the difference between the obtained results and those derived from the TESTO 435-1.

- Approach 2

- -

- Define the median values of the eight measurements associated with the observations of each of the three parameters (, , and ).

- -

- Substitute the median values of the parameters into Equation (1), determine the U-value, and then calculate the difference between the obtained results and those derived from the TESTO 435-1.

4. Laboratory Testing

4.1. Description of the Test

- -

- The achievement of a steady-state condition.

- -

- The outdoor temperature did not exceed ±10 °C 24 h prior to the experiment.

- -

- The indoor and outdoor temperatures were not altered by more than ±2 °C and ±5 °C, respectively, with respect to their initial values during the experiment.

- -

- Direct solar radiation was kept off the temperature-controlled box model during the test.

4.2. Sensitivity of the Infrared Sensor

5. Results and Discussion

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pi, Z.X.; Li, X.H.; Ding, Y.M.; Zhao, M.; Liu, Z.X. Demand Response Scheduling Algorithm of the Economic Energy Consumption in Buildings for Considering Comfortable Working Time and User Target Price. Energy Build. 2021, 250, 111252. [Google Scholar] [CrossRef]

- Agency, A.E. Energy Data of Andalusia; Andalusian Energy Agency: Seville, Spain. Available online: https://www.eneragen.org/en/members/andalusian-energy-agency/ (accessed on 1 February 2022).

- AIGUASOL. Barcelona Energy Improvement Plan (PMEB) and Barcelona Energy, Climate Change and Air Quality Plan (PECQ). Available online: https://aiguasol.coop/project/barcelona-energy-improvement-plan-energy-climate-change-air-quality-plan/ (accessed on 1 February 2022).

- Wagiman, K.R.; Abdullah, M.N.; Hassan, M.Y.; Mohammad Radzi, N.H. A New Metric for Optimal Visual Comfort and Energy Efficiency of Building Lighting System Considering Daylight Using Multi-Objective Particle Swarm Optimization. J. Build. Eng. 2021, 43, 102525. [Google Scholar] [CrossRef]

- Verbruggen, S.; Delghust, M.; Laverge, J.; JanssensArnold. Evaluation of the Relationship between Window Use and Physical Environmental Variables: Consistency, Seasonality and Diversity. J. Build. Perform. Simul. 2021, 14, 366–382. [Google Scholar] [CrossRef]

- Susorova, I.; Stephens, B.; Skelton, B. The Effect of Balcony Thermal Breaks on Building Thermal and Energy Performance: Field Experiments and Energy Simulations in Chicago, IL. Buildings 2019, 9, 190. [Google Scholar] [CrossRef] [Green Version]

- Roppel, P.; Lawton, M.; Norris, N. Thermal Performance of Building Envelope Details for Mid- and High-Rise Buildings. ASHRAE Trans. 2012, 118, 569–584. [Google Scholar]

- Li, T.; Xia, J.; Chin, C.S.; Song, P. Investigation of the Thermal Performance of Lightweight Assembled Exterior Wall Panel (LAEWP) with Stud Connections. Buildings 2022, 12, 473. [Google Scholar] [CrossRef]

- Currie, J.; Bros Williamson, J.; Stinson, J. Monitoring Thermal Upgrades to Ten Traditional Properties. Hist. Scotl. Tech. Pap. 2013, 19, 51. [Google Scholar] [CrossRef]

- Biler, A.; Tavil, A.U.; Su, Y.; Khan, N. A Review of Performance Specifications and Studies of Trickle Vents. Buildings 2018, 8, 152. [Google Scholar] [CrossRef] [Green Version]

- Ian, C.-S. Proposed Method for Measuring the Thermal Properties of Windows in the New BRANZ Guarded Hotbox. In Proceedings of the IPENZ Annual Conference 1997, Proceedings of: Engineering Our Nation’s Future, Wellington, New Zealand, 7–10 February 1997; pp. 95–102. [Google Scholar]

- Fang, Y.; Eames, P.C.; Norton, B.; Hyde, T.J. Experimental Validation of a Numerical Model for Heat Transfer in Vacuum Glazing. Sol. Energy 2006, 80, 564–577. [Google Scholar] [CrossRef]

- Buratti, C.; Barelli, L.; Moretti, E. Application of Artificial Neural Network to Predict Thermal Transmittance of Wooden Windows. Appl. Energy 2012, 98, 425–432. [Google Scholar] [CrossRef]

- Smith, N.; Isaacs, N.; Burgess, J.; Cox-Smith, I. Thermal Performance of Secondary Glazing as a Retrofit Alternative for Single-Glazed Windows. Energy Build. 2012, 54, 47–51. [Google Scholar] [CrossRef]

- Lechowska, A.; Schnotale, J.; Fedorczak-Cisak, M.; Paszkowski, M. Measurement of thermal transmittance of multi-layer glazing with ultrathin internal glass partitions. Czas. Tech. 2014, 2014, 273–279. [Google Scholar]

- Malvoni, M.; Baglivo, C.; Congedo, P.M.; Laforgia, D. CFD Modeling to Evaluate the Thermal Performances of Window Frames in Accordance with the ISO 10077. Energy 2016, 111, 430–438. [Google Scholar] [CrossRef]

- Mellado Mascaraque, M.Á.; Castilla Pacual, F.J.; Oteiza, I.; Aparicio Secanellas, S. Hygrothermal Assessment of a Traditional Earthen Wall in a Dry Mediterranean Climate. Build. Res. Inf. 2020, 48, 632–644. [Google Scholar] [CrossRef]

- Zhu, X.F.; Li, L.P.; Yin, X.B. An In-Situ Test Apparatus of Heat Transfer Coefficient for Building Envelope. Build. Energy Effic. 2012, 256, 57–60. [Google Scholar]

- Meng, X.; Gao, Y.; Wang, Y.; Yan, B.; Zhang, W.; Long, E. Feasibility Experiment on the Simple Hot Box-Heat Flow Meter Method and the Optimization Based on Simulation Reproduction. Appl. Therm. Eng. 2015, 83, 48–56. [Google Scholar] [CrossRef]

- Glavaš, H.; Hadzima-Nyarko, M.; Buljan, I.H.; Barić, T. Locating Hidden Elements in Walls of Cultural Heritage Buildings by Using Infrared Thermography. Buildings 2019, 9, 32. [Google Scholar] [CrossRef] [Green Version]

- Evangelisti, L.; Scorza, A.; Vollaro, R.D.L.; Sciuto, S.A. Comparison between Heat Flow Meter (HFM) and Thermometric (THM) Method for Building Wall Thermal Characterization: Latest Advances and Critical Review. Sustainability 2022, 14, 693. [Google Scholar] [CrossRef]

- Teni, M.; Krstić, H.; Kosiński, P. Review and Comparison of Current Experimental Approaches for In-Situ Measurements of Building Walls Thermal Transmittance. Energy Build. 2019, 203, 109417. [Google Scholar] [CrossRef]

- Soares, N.; Martins, C.; Gonçalves, M.; Santos, P.; da Silva, L.S.; Costa, J.J. Laboratory and In-Situ Non-Destructive Methods to Evaluate the Thermal Transmittance and Behavior of Walls, Windows, and Construction Elements with Innovative Materials: A Review. Energy Build. 2019, 182, 88–110. [Google Scholar] [CrossRef]

- Bienvenido-Huertas, D.; Moyano, J.; Marín, D.; Fresco-Contreras, R. Review of in Situ Methods for Assessing the Thermal Transmittance of Walls. Renew. Sustain. Energy Rev. 2019, 102, 356–371. [Google Scholar] [CrossRef]

- Gaši, M.; Milovanović, B.; Gumbarević, S. Comparison of Infrared Thermography and Heat Flux Method for Dynamic Thermal Transmittance Determination. Buildings 2019, 9, 132. [Google Scholar] [CrossRef] [Green Version]

- Komarizadehasl, S.; Khanmohammadi, M. Novel Plastic Hinge Modification Factors for Damaged RC Shear Walls with Bending Performance. Adv. Concr. Constr. 2021, 12, 355–365. [Google Scholar] [CrossRef]

- Esfandiari, M.; Zaid, S.M.; Ismail, M.A.; Hafezi, M.R.; Asadi, I.; Mohammadi, S. A Field Study on Thermal Comfort and Cooling Load Demand Optimization in a Tropical Climate. Sustainability 2021, 13, 12425. [Google Scholar] [CrossRef]

- Kim, S.H.; Kim, J.H.; Jeong, H.G.; Song, K.D. Reliability Field Test of the Air-Surface Temperature Ratio Method for in Situ Measurement of U-Values. Energies 2018, 11, 1. [Google Scholar] [CrossRef] [Green Version]

- TESTO. TESTO. Available online: https://www.testo.com/es-MX/testo-435-1/p/0560-4351 (accessed on 1 February 2022).

- Vučićević, B.; Turanjanin, V.; Bakić, V.; Jovanović, M.; Stevanović, Ž. Experimental and Numerical Modelling of Thermal Performance of a Residential Building in Belgrade. Therm. Sci. 2009, 13, 245–252. [Google Scholar] [CrossRef]

- Andargie, M.S.; Azar, E. An Applied Framework to Evaluate the Impact of Indoor Office Environmental Factors on Occupants’ Comfort and Working Conditions. Sustain. Cities Soc. 2019, 46, 101447. [Google Scholar] [CrossRef]

- Evangelisti, L.; Guattari, C.; Gori, P.; de Lieto Vollaro, R.; Asdrubali, F. Experimental Investigation of the Influence of Convective and Radiative Heat Transfers on Thermal Transmittance Measurements. Int. Commun. Heat Mass Transf. 2016, 78, 214–223. [Google Scholar] [CrossRef]

- Komarizadehasl, S.; Mobaraki, B.; Lozano-Galant, J.A.; Turmo, J. Development of a Low-Cost System for the Accurate Measurement of Structural Vibrations. Sensors 2021, 21, 6191. [Google Scholar] [CrossRef]

- Porras Soriano, R.; Mobaraki, B.; Lozano-Galant, J.A.; Sanchez-Cambronero, S.; Prieto Muñoz, F.; Gutierrez, J.J. New Image Recognition Technique for Intuitive Understanding in Class of the Dynamic Response of High-Rise Buildings. Sustainability 2021, 13, 3695. [Google Scholar] [CrossRef]

- Mobaraki, B.; Lozano-Galant, F.; Soriano, R.P.; Pascual, F.J.C. Application of Low-Cost Sensors for Building Monitoring: A Systematic Literature Review. Buildings 2021, 11, 336. [Google Scholar] [CrossRef]

- Scislo, L.; Szczepanik-Scislo, N. Air Quality Sensor Data Collection and Analytics with IoT for an Apartment with Mechanical Ventilation. In Proceedings of the 2021 11th IEEE International Conference on Intelligent Data Acquisition and Advanced Computing Systems: Technology and Applications (IDAACS), Cracow, Poland, 22–25 September 2021; Volume 2, pp. 932–936. [Google Scholar] [CrossRef]

- Saini, J.; Dutta, M.; Marques, G. Indoor Air Quality Monitoring Systems Based on Internet of Things: A Systematic Review. Int. J. Environ. Res. Public Health 2020, 17, 4942. [Google Scholar] [CrossRef] [PubMed]

- Pierleoni, P.; Conti, M.; Belli, A.; Palma, L.; Incipini, L.; Sabatini, L.; Valento, S.; Mercuri, M.; Concetti, R. IoT Solution Based on MQTT Protocol for Real-Time Building Monitoring. In Proceedings of the IoT Solution Based on MQTT Protocol for Real-Time Building Monitoring, Ancona, Italy, 19–21 June 2019; pp. 57–62. [Google Scholar]

- Mitro, N.; Krommyda, M.; Amditis, A. Smart Tags: IoT Sensors for Monitoring the Micro-Climate of Cultural Heritage Monuments. Appl. Sci. 2022, 12, 2315. [Google Scholar] [CrossRef]

- Giusto, E.; Gandino, F.; Greco, M.L.; Grosso, M.; Montrucchio, B.; Rinaudo, S. An Investigation on Pervasive Technologies for IoT-Based Thermal Monitoring. Sensors 2019, 19, 663. [Google Scholar] [CrossRef] [Green Version]

- Oztemel, E.; Gursev, S. Literature Review of Industry 4.0 and Related Technologies. J. Intell. Manuf. 2020, 31, 127–182. [Google Scholar] [CrossRef]

- Ghosh, A.; Edwards, D.J.; Hosseini, M.R.; Al-Ameri, R.; Abawajy, J.; Thwala, W.D. Real-Time Structural Health Monitoring for Concrete Beams: A Cost-Effective ‘Industry 4.0′ Solution Using Piezo Sensors. Int. J. Build. Pathol. Adapt. 2021, 39, 283–311. [Google Scholar] [CrossRef]

- Alarcón, M.; Martínez-García, F.M.; Gómez de León Hijes, F.C. Energy and Maintenance Management Systems in the Context of Industry 4.0. Implementation in a Real Case. Renew. Sustain. Energy Rev. 2021, 142, 110841. [Google Scholar] [CrossRef]

- Aheleroff, S.; Xu, X.; Lu, Y.; Aristizabal, M.; Pablo Velásquez, J.; Joa, B.; Valencia, Y. IoT-Enabled Smart Appliances under Industry 4.0: A Case Study. Adv. Eng. Informatics 2020, 43, 101043. [Google Scholar] [CrossRef]

- Martín-Garín, A.; Millán-García, J.A.; Baïri, A.; Millán-Medel, J.; Sala-Lizarraga, J.M. Environmental Monitoring System Based on an Open Source Platform and the Internet of Things for a Building Energy Retrofit. Autom. Constr. 2018, 87, 201–214. [Google Scholar] [CrossRef]

- Ali, A.S.; Cote, C.; Heidarnejad, M.; Stephens, B. Elemental: An Open-Source Wireless Hardware and Software Platform for Building Energy and Indoor Environmental Monitoring and Control. Sensors 2019, 19, 4017. [Google Scholar] [CrossRef] [Green Version]

- Mesas-Carrascosa, F.J.; Verdú Santano, D.; de Larriva, J.E.M.; Ortíz Cordero, R.; Hidalgo Fernández, R.E.; García-Ferrer, A. Monitoring Heritage Buildings with Open Source Hardware Sensors: A Case Study of the Mosque-Cathedral of Córdoba. Sensors 2016, 16, 1620. [Google Scholar] [CrossRef] [PubMed]

- Echarri, V.; Espinosa, A.; Rizo, C. Thermal Transmission through Existing Building Enclosures: Destructive Monitoring in Intermediate Layers versus Non-Destructive Monitoring with Sensors on Surfaces. Sensors 2017, 17, 2848. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Andújar Márquez, J.M.; Martínez Bohórquez, M.Á.; Gómez Melgar, S. A New Metre for Cheap, Quick, Reliable and Simple Thermal Transmittance (U-Value) Measurements in Buildings. Sensors 2017, 17, 2017. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Serroni, S.; Arnesano, M.; Pandarese, G.; Martarelli, M.; Marco Revel, G. IoT Infrared Sensor for Continuous Monitoring of Building Envelope Thermal Performances. In Proceedings of the 2021 6th International Conference on Smart and Sustainable Technologies (SpliTech), Bol and Split, Croatia, 8–11 September 2021; pp. 1–6. [Google Scholar] [CrossRef]

- Melexis. MLX90614. Available online: https://www.mouser.es/new/melexis/melexis-mlx90640-fir-sensor/ (accessed on 1 February 2022).

- Maxim. MAX30205. Available online: https://www.maximintegrated.com/en/products/sensors/MAX30205.html?s_kwcid=AL!8732!3!517495051369!!!g!!&utm_source=google&utm_campaign=corp-sensors&gclid=Cj0KCQjwpv2TBhDoARIsALBnVnm_amL18iRn8n5HNoSnv1S72xQDIcsQ3LC3Uu9jJ-5eyE4J6pXtiZYaAoBJEALw_wcB (accessed on 1 February 2022).

- FocuSens. DS18B20. Available online: https://www.focusensing.com/digital-temperature-sensor-assembly_c27?gclid=Cj0KCQjwpv2TBhDoARIsALBnVnlly-N0z4pRiU80aYE2_utq7vwTNh6VUg3m_SN4mfYsA_hex9Mb7wcaApiYEALw_wcB (accessed on 1 February 2022).

- Nepomuceno, M.C.S.; Martins, A.M.T.; Pinto, H.A.S. A Comparison between On-Site Measured and Estimated Based Adjustment Factor Values Used to Calculate Heat Losses to Unconditioned Spaces in Dwellings. Buildings 2022, 12, 146. [Google Scholar] [CrossRef]

- ISO. ISO 6946:2017. Available online: https://www.iso.org/standard/65708.html (accessed on 1 February 2022).

- ISO. ISO 9869:2014. Available online: https://www.iso.org/standard/59697.html#:~:text=ISO 9869-1%3A2014 describes,no significant lateral heat flow (accessed on 1 February 2022).

- ISO. ISO 14813-1:2015. Available online: https://www.iso.org/standard/57393.html (accessed on 1 February 2022).

- ISO. ISO 10456:2007. Available online: https://www.iso.org/standard/40966.html (accessed on 1 February 2022).

- Afsar, M.M.; Tayarani-N, M.H. Clustering in Sensor Networks: A Literature Survey. J. Netw. Comput. Appl. 2014, 46, 198–226. [Google Scholar] [CrossRef]

- Karagulian, F.; Barbiere, M.; Kotsev, A.; Spinelle, L.; Gerboles, M.; Lagler, F.; Redon, N.; Crunaire, S.; Borowiak, A. Review of the Performance of Low-Cost Sensors for Air Quality Monitoring. Atmosphere 2019, 10, 506. [Google Scholar] [CrossRef] [Green Version]

- Lee, M.; Yoo, M. Characteristic of Thin-Film NTC Thermal Sensors. Proc. IEEE Sensors 2002, 1, 56–61. [Google Scholar] [CrossRef]

- Tejero-Gómez, J.A.; Bayod-Rújula, A.A. Energy Management System Design Oriented for Energy Cost Optimization in Electric Water Heaters. Energy Build. 2021, 243, 111012. [Google Scholar] [CrossRef]

- Abu Bakar, A.; Rahim, S.S.A.; Razali, A.R.; Noorsal, E.; Radzali, R.; Abd Rahim, A.F. Wearable Heart Rate and Body Temperature Monitoring Device for Healthcare. J. Phys. Conf. Ser. 2020, 1535, 012002. [Google Scholar] [CrossRef]

- Enkhzul, D.; Erdenechimeg, D.; Amartuvshin, T.; Chuluunbaatar, N.; Enkhbaatar, T. Implementation of Early Diagnostic Device for Diabetic Foot Using the Thermal Sensor; University of Orléans: Orléans, France, 2016. [Google Scholar]

- Wu, Y.; Liu, H.; Li, B.; Kosonen, R. Prediction of Thermal Sensation Using Low-Cost Infrared Array Sensors Monitoring System. In IOP Conference Series: Materials Science and Engineering; Institute of Physics Publishing: Bristol, UK, 2019; Volume 609. [Google Scholar] [CrossRef]

- Kampezidou, S.I.; Ray, A.T.; Duncan, S.; Balchanos, M.G.; Mavris, D.N. Real-Time Occupancy Detection with Physics-Informed Pattern-Recognition Machines Based on Limited CO2 and Temperature Sensors. Energy Build. 2021, 242, 110863. [Google Scholar] [CrossRef]

- Mobaraki, B.; Komarizadehasl, S.; Castilla, F.J.; Lozano-Galant, J.A. Open Source Platforms for Monitoring Thermal Parameters of Structures. In Bridge Maintenance, Safety, Management, Life-Cycle Sustainability and Innovations; CRC Press: Boca Raton, FL, USA, 2019; pp. 3892–3896. [Google Scholar]

- Wu, L.H.; Yao, J.Y.; Lin, X.R.; Zhang, H.Y. Design of Acquisition and Control System of Granary Supervisory Control and Data Acquisition System. Int. J. Multimed. Ubiquitous Eng. 2015, 10, 1–8. [Google Scholar] [CrossRef]

- Zhan, Q.; Pungercar, V.; Musso, F.; Ni, H.; Xiao, Y. Hygrothermal Investigation of Lightweight Steel-Framed Wall Assemblies in Hot-Humid Climates: Measurement and Simulation Validation. J. Build. Eng. 2021, 42, 103044. [Google Scholar] [CrossRef]

- Ibrahim, M.; Moselhi, O. Inertial Measurement Unit Based Indoor Localization for Construction Applications. Autom. Constr. 2016, 71, 13–20. [Google Scholar] [CrossRef]

- Moschevikin, A.P.; Sikora, A.; Lunkov, P.V.; Fedorov, A.A.; Maslennikov, E.I. Hardware and Software Architecture of Multi Mems Sensor Inertial Module. In Proceedings of the 2017 24th Saint Petersburg International Conference on Integrated Navigation Systems (ICINS), St. Petersburg, Russia, 29–31 May 2017; pp. 7–9. [Google Scholar] [CrossRef]

- Nuhu, B.K.; Aliyu, I.; Adegboye, M.A.; Ryu, J.K.; Olaniyi, O.M.; Lim, C.G. Distributed Network-Based Structural Health Monitoring Expert System. Build. Res. Inf. 2021, 49, 144–159. [Google Scholar] [CrossRef]

- Scietec. TNP006. Available online: https://scitec.uk.com/irsources/index?ppc_keyword=ir (accessed on 1 February 2022).

- Sensirion. SHT35. Available online: https://sensirion.com/products/catalog/SHT35-DIS-F/ (accessed on 1 February 2022).

- Arduino.cc. Arduino MEGA. Available online: http://store.arduino.cc/products/arduino-mega-2560-rev3 (accessed on 1 February 2022).

- Komarizadehasl, S.; Mobaraki, B.; Ma, H.; Lozano-Galant, J.-A.; Turmo, J. Low-Cost Sensors Accuracy Study and Enhancement Strategy. Appl. Sci. 2022, 12, 3186. [Google Scholar] [CrossRef]

- Instrument, T. TCA9548A. Available online: https://www.ti.com/product/TCA9548A?utm_source=google&utm_medium=cpc&utm_campaign=asc-int-null-prodfolderdynamic-cpc-pf-google-wwe&utm_content=prodfolddynamic&ds_k=DYNAMIC+SEARCH+ADS&DCM=yes&gclid=Cj0KCQjwpv2TBhDoARIsALBnVnmCDY4fUb5wjVwsB2l-XinVxE2ofvGlqBtLYe5vFUIZwikHZjzrzosaAiJGEALw_wcB&gclsrc=aw.ds (accessed on 1 February 2022).

- Last Minute Engineer. DS3231. Available online: https://www.focusensing.com/digital-temperature-sensor-assembly_c27?gclid=Cj0KCQjwpv2TBhDoARIsALBnVnlly-N0z4pRiU80aYE2_utq7vwTNh6VUg3m_SN4mfYsA_hex9Mb7wcaApiYEALw_wcB (accessed on 1 February 2022).

- Matworks. MatLab. Available online: https://www.mathworks.com/ (accessed on 1 February 2022).

| Application | Method/Sensor | Number of Sensors | Reference |

|---|---|---|---|

| Windows and built- up panels | GHB 1 | 2 | [11] |

| Window | GHB and FEM 2 | 16 | [12] |

| Wooden windows | ANN 3 | - | [13] |

| Single window glazing | GHB | 5 | [14] |

| Window (steel frame) | CHB 4 | 3 | [15] |

| Window frames | ANSYS CFD/GAMBIT | - | [16] |

| Model | Operation | Application | Detection Range (°C) | Accuracy (°C) | Cost (EUR) | Ref. |

|---|---|---|---|---|---|---|

| NTC | Contact | Environmental and structural | (−55 to 200) | 1 | 1 | [61] |

| DS18B20 | (−55 to 125) | 0.5 | 4.9 | [62] | ||

| MAX30205 | fitness | (0 to 70) | 0.1 | 12.9 | [63] | |

| TMP006 | Infrared | Environmental and structural | (−40 to 125) | 1 | 6 | [64] |

| MLX90614 | Medical | (−40 to 125) | 0.5 | 29.6 | [65] | |

| DHT11 | Contactless | Environmental | (0 to 50) | 2 | 1.56 | [66] |

| DHT22 | (−40 to 80) | 0.5 | 5.40 | [67] | ||

| SHT10 | (−40 to 125) | 0.5 | 4.57 | [68] | ||

| SHT21 | (−40 to 125) | 0.3 | 4.61 | [45] | ||

| SHT35 | (−40 to 125) | 0.2 | 5.76 | [69] | ||

| BMP180 | (−40 to 85) | 2 | 3.72 | [70] | ||

| BMP280 | (−40 to 85) | 1 | 3.59 | [71] | ||

| LM35 | (−55 to 125) | 1 | 2.80 | [72] |

| HEAT MLX90614 | HEAT MAX30205 | HEAT DS18B20 | TESTO 435-1 | ||||

|---|---|---|---|---|---|---|---|

| Components | Price (EUR) | Number | Price (EUR) | Number | Price (EUR) | Number | |

| Sensors | 29.6 | 8 | 12.9 | 8 | 4.95 | 8 | |

| Breadboard | 3.5 | 1 | 3.5 | 1 | 3.5 | 1 | |

| Arduino | 35.5 | 1 | 35.5 | 1 | 35.5 | 1 | |

| Multiplexer | 1.2 | 2 | 1.2 | 2 | - | - | |

| Clock sensor | 1.3 | 1 | 1.3 | 1 | 1.3 | 1 | |

| Bluetooth sensor | 4.5 | 1 | 4.5 | 1 | 4.5 | 1 | |

| Resistor | - | - | - | - | 0.2 | 8 | |

| SHT35 set () | 92 | 1 | 92 | 1 | 92 | 1 | |

| Total Cost (EUR) | 380 | 246 | 181 | 1032 | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mobaraki, B.; Komarizadehasl, S.; Castilla Pascual, F.J.; Lozano-Galant, J.A.; Porras Soriano, R. A Novel Data Acquisition System for Obtaining Thermal Parameters of Building Envelopes. Buildings 2022, 12, 670. https://doi.org/10.3390/buildings12050670

Mobaraki B, Komarizadehasl S, Castilla Pascual FJ, Lozano-Galant JA, Porras Soriano R. A Novel Data Acquisition System for Obtaining Thermal Parameters of Building Envelopes. Buildings. 2022; 12(5):670. https://doi.org/10.3390/buildings12050670

Chicago/Turabian StyleMobaraki, Behnam, Seyedmilad Komarizadehasl, Francisco Javier Castilla Pascual, José Antonio Lozano-Galant, and Rocio Porras Soriano. 2022. "A Novel Data Acquisition System for Obtaining Thermal Parameters of Building Envelopes" Buildings 12, no. 5: 670. https://doi.org/10.3390/buildings12050670

APA StyleMobaraki, B., Komarizadehasl, S., Castilla Pascual, F. J., Lozano-Galant, J. A., & Porras Soriano, R. (2022). A Novel Data Acquisition System for Obtaining Thermal Parameters of Building Envelopes. Buildings, 12(5), 670. https://doi.org/10.3390/buildings12050670