Alien Wood Species as a Resource for Wood-Plastic Composites

Abstract

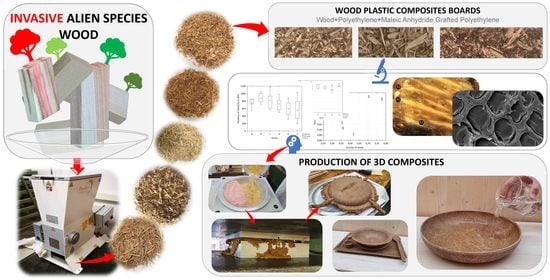

:1. Introduction

2. Materials and Methods

2.1. WPC Boards Preparation

- black locust (Robinia pseudoacacia): density 0.778 g·cm−3

- boxelder maple (Acer negundo): density 0.560 g·cm−3

- honey locust (Gleditsia triacanthos): density 0.705 g·cm−3

- horse chestnut (Aesculus hippocastanum): density 0.495 g·cm−3

- tree of heaven (Ailanthus altissima): density 0.555 g·cm−3

- thickness and density (EN 323): 50 × 50 mm2, 6 samples [28]

- flexural strength (EN ISO 178): 80 × 50 mm2, 10 samples [29]

- tensile strength (EN ISO 527-1): 165 × 13 mm2, 10 samples [30]

- thickness swelling and water absorption (EN 317): 50 × 50 mm2, 10 samples [31]

- dimensional stability due heating and cooling: 100 × 25 mm2, 2 × 5 samples

2.2. Physical and Mechanical Properties Testing

2.3. WPC Structural Analyses

2.4. Pilot Production of 3D Composites Based on the Proposed Methodology

3. Results and Discussion

3.1. Physical and Mechanical Properties of WPC Boards

3.2. Surface and Internal Structure of WPC Boards

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Buschbeck, L.; Kehr, E.; Jensen, U. Untersuchungen über die Eignung verschiedener Holzarten und sortimente zur Herstellung von Spanplatten—1. Mitteilung: Rotbuche und Kiefer. Holztechnologie 1961, 2, 99–110. [Google Scholar]

- Buschbeck, L.; Kehr, E.; Jensen, U. Untersuchungen über die Eignung verschiedener Holzarten und sortimente zur Herstellung von Spanplatten—2. Mitteilung: Kiefernreiserholz. Holztechnologie 1961, 2, 195–201. [Google Scholar]

- Kehr, E. Untersuchungen über die Eignung verschiedener Holzarten und sortimente zur Herstellung von Spanplatten—3. Mitteilung: Der Einfluß des Härteranteils auf die eigenschaften von Spanplatten aus Rotbuchen-und Kieferholz. Holztechnologie 1962, 3, 22–28. [Google Scholar]

- Niemz, P. Physik des Holzes und der Holzwerkstoffe; Leinfelden—Echterdingen, DRW—Verlag: Tübingen, Germany, 1993; pp. 27–33. ISBN 3-87181-324-9. [Google Scholar]

- Schöberl, M. Elastische Rückfederung verdichteter Spänvliese aus Siebfraktionen verschiedener Span– und Holzarten. Holz Roh Werkst 2000, 58, 46. [Google Scholar]

- Marra, A.A. Technology of Wood Bonding, Principles in Practice; Van Nostrand Reinhold: New York, NY, USA, 1992; 454p, ISBN 978-0442007973. [Google Scholar]

- Dunky, M.; Niemz, P. Holzwerkstoffe und Leime: Technologie und Einflussfaktoren; Springer: Berlin, Germany, 2002; 954p, ISBN 978-3-540-42980-7. [Google Scholar]

- Berger, M.J.; Stark, N.M. Investigations of species effects in an injection molding grade wood filled polypropylene. In Fourth International Conference on Woodfiber-Plastic Composites; Forest Products Society: Madison, WI, USA, 1997; pp. 19–25. ISBN 0935018956. [Google Scholar]

- Klyosov, A.A. Wood-Plastic Composites; John Wiley & Sons, Inc. Publication: Hoboken, NJ, USA, 2008; 702p, ISBN 978-0-470-14891-4. [Google Scholar]

- Oksman Niska, K.; Sain, M. Wood-Polymere Composites; Woodhead Publishing, Ltd: Cambridge, UK, 2008; 384p, ISBN 978-1-84569-457-9. [Google Scholar]

- Kim, J.W.; Harper, D.P.; Taylor, A.M. Effect of wood species on the mechanical properties of wood-plastic composites. J. Appl. Polym. Sci. 2009, 112, 1378–1385. [Google Scholar] [CrossRef]

- Migneault, S.; Koubaa, A.; Erchiqui, F.; Chaala, A.; Englund, K.; Wolcott, M.P. Effect of processing method and fiber size on the structure and properties of wood-plastic composites. Compos. Part A Appl. Sci. 2009, 40, 80–85. [Google Scholar] [CrossRef]

- Tisserat, B.; Reifschneider, L.; Gravett, A.; Peterson, S.C. Wood-plastic Composites Utilizing Wood Flours Derived from Fast-growing Trees Common to the Midwest. BioResources 2017, 12, 7898–7916. [Google Scholar] [CrossRef]

- Shebani, A.N.; Van Reenen, A.J.; Meincken, M. The Effect of Wood Species on the Mechanical and Thermal Properties of Wood–LLDPE Composites. J. Compos. Mater. 2009, 43, 1305–1318. [Google Scholar] [CrossRef]

- Gardner, D.J.; Han, Y.; Wang, L. Wood-Plastic Composite Technology. Curr. For. Rep. 2015, 1, 139–150. [Google Scholar] [CrossRef] [Green Version]

- Merela, M.; Thaler, N.; Balzano, A.; Plavčak, D. Optimal Surface Preparation for Wood Anatomy Research of Invasive Species by Scanning Electron Microscopy. Drv. Ind. 2020, 71, 117–127. [Google Scholar] [CrossRef]

- Merhar, M.; Gornik Bučar, D.; Merela, M. Machinability Research of the Most Common Invasive Tree Species in Slovenia. Forests 2020, 11, 752. [Google Scholar] [CrossRef]

- Findlay, G.W.D.; Levy, J.F. Scanning electron microscopy as an aid to the study of wood anatomy and decay. J. Inst. Wood Sci. 1969, 5, 57–63. [Google Scholar]

- Jansen, S.; Piesschaert, F.; Smets, E. Wood anatomy of Elaeagnaceae, with comments on vestured pits, helical thickenings, and systematic relationships. Am. J. Bot. 2000, 87, 20–28. [Google Scholar] [CrossRef] [PubMed]

- Jansen, S.; Pletsers, A.; Sano, Y. The effect of preparation techniques on SEM-imaging of pit membranes. IAWA J. 2008, 29, 161–178. [Google Scholar] [CrossRef]

- Collett, B.M. Scanning electron microscopy: A review and report of research in wood science. Wood Fiber Sci. 2007, 2, 113–133. [Google Scholar]

- Vek, V.; Balzano, A.; Poljanšek, I.; Humar, M.; Oven, P. Improving Fungal Decay Resistance of Less Durable Sapwood by Impregnation with Scots Pine Knotwood and Black Locust Heartwood Hydrophilic Extractives with Antifungal or Antioxidant Properties. Forests 2020, 11, 1024. [Google Scholar] [CrossRef]

- Chun, K.S.; Fahamy, N.M.Y.; Yeng, C.Y.; Choo, H.L.; Ming, P.M.; Tshai, K.Y. Wood plastic composites made from corn husk fiber and recycled polystyrene foam. J. Eng. Sci. Technol. 2018, 13, 3445–3456. [Google Scholar]

- Kallakas, H.; Shamim, M.A.; Olutubo, T.; Poltimäe, T.; Süld, T.M.; Krumme, A.; Kers, J. Effect of chemical modification of wood flour on the mechanical properties of wood-plastic composites. Agron. Res. 2015, 13, 639–653. [Google Scholar]

- Pratheep, V.G.; Priyanka, E.B.; Thangavel, S.; Gousanal, J.J.; Antony, P.B.; Kavin, E.D. Investigation and analysis of corn cob, coir pith with wood plastic composites. Mater. Today Proc. 2020, 7. [Google Scholar] [CrossRef]

- Segerholm, B.K.; Ibach, R.E.; Wålinder, M.E. Moisture sorption in artificially aged wood-plastic composites. BioResources 2012, 7, 1283–1293. [Google Scholar]

- Leu, S.-Y.; Yang, T.-H.; Lo, S.-F.; Yang, T.-H. Optimized material composition to improve physical and mechanical properties of extruded wood-plastic composites (WPCs). Constr. Build. Mater. 2012, 29, 120–127. [Google Scholar] [CrossRef]

- EN 323. Wood-Based Panels—Determination of Density; CEN: Brussels, Belgium, 1993; p. 7. [Google Scholar]

- EN ISO 178. Plastics—Determination of Flexural Properties; CEN: Brussels, Belgium, 2019; p. 25. [Google Scholar]

- EN ISO 527-1. Plastics—Determination of Tensile Properties—Part 1: General Principles; CEN: Brussels, Belgium, 2019; p. 26. [Google Scholar]

- EN 317. Particleboards and Fibreboards—Determination of Swelling in Thickness after Immersion in Water; CEN: Brussels, Belgium, 1993; p. 12. [Google Scholar]

- Wheeler, E.A. Inside Wood–A web resource for hardwood anatomy. IAWA J. 2011, 32, 199–211. [Google Scholar] [CrossRef]

- Medved, S.; Vilamn, G.; Merela, M. Alien wood species for particleboards. In Proceedings of the International Conference “Wood Science and Engineering in the Third Millennium”, Braşov, Romania, 7–9 November 2019; pp. 321–328. [Google Scholar]

- Callister, D.W., Jr. Materials Science and Engineering: An Introduction; John Wiley & Sons, Inc. Publication: Hoboken, NJ, USA, 2007; 201p, ISBN-13: 978-0-471-73696-7. [Google Scholar]

- Schwarzkopf, M.; Muszynski, L. Strain distribution and load transfer in the polymer-wood particle bond in wood plastic composites. Holzforschung 2015, 69, 53–60. [Google Scholar] [CrossRef]

- Sretenovic, A.; Müller, U.; Gindl, W. Mechanism of stress transfer in a single wood fibre-LDPE composites by means of electronic laser speckle interferometry. Compos. Part A-Appl. Sci. Manuf. 2006, 37, 1406–1412. [Google Scholar] [CrossRef]

- IAPWS home page. Why does Water Expand When It Freezes? Why does Liquid Water have a Density Maximum? Available online: http://www.iapws.org/faq1/freeze.html (accessed on 10 October 2020).

- Wimmer, R.; Steyrer, B.; Woess, J.; Koddenberg, T.; Mundigler, N. 3D printing and wood. Pro Ligno 2015, 11, 144–149. [Google Scholar]

| Physical Property | Value |

|---|---|

| Density | 0.935 g·cm−3 |

| Melt index, 190 °C/2.16 kg | 7 g/10 min |

| Melting point | 124 °C |

| Vicat softening point A120 | 115 °C |

| Deflection temperature under load HDT B | 52 °C |

| Series | Wood Species Used |

|---|---|

| A | Boxelder maple (Acer negundo) |

| B | Horse chestnut (Aesculus hippocastanum) |

| C | Tree of heaven (Ailanthus altissima) |

| D | Black locust (Robinia pseudoacacia) |

| E | Honey locust (Gleditsia triacanthos) |

| F | Mixture |

| Size Class | A Boxelder Maple | B Horse Chestnut | C Tree of Heaven | D Black Locust | E Honey Locust |

|---|---|---|---|---|---|

| Dust | 9% | 6% | 6% | 7% | 7% |

| 0.237 | 11% | 10% | 13% | 12% | 14% |

| 0.6 | 12% | 12% | 13% | 13% | 14% |

| 1.0 | 9% | 9% | 9% | 10% | 9% |

| 1.27 | 9% | 9% | 9% | 8% | 8% |

| 1.5 | 18% | 19% | 17% | 17% | 16% |

| 2.0 | 27% | 30% | 26% | 27% | 27% |

| 4.0 | 5% | 5% | 6% | 5% | 7% |

| Series | Thickness | Density | Flexural Strength | Modulus of Elasticity | Tensile Strength |

|---|---|---|---|---|---|

| mm | g·cm−3 | MPa | MPa | MPa | |

| A | 4.23 | 0.901 (a) | 15.04 (a,b) | 759 (a,b) | 6.46 (a) |

| B | 4.36 | 0.929 (c) | 15.14 (a,b) | 876 (a) | 7.03 (a,b,c) |

| C | 4.33 | 0.912 (b,c) | 15.21 (a,b) | 812 (a) | 7.29 (b,c) |

| D | 4.15 | 0.956 (d) | 15.60 (b) | 721 (a,b) | 7.10 (a,b,c) |

| E | 4.07 | 0.961 (d) | 14.57 (a,b) | 594 (b,c) | 6.48 (a,b) |

| F | 3.80 | 0.889 (a) | 13.69 (a,b) | 550 (c) | 7.52 (c) |

| Series | TS2 | WA2 | TS24 | WA24 | Length | Thickness | ||

|---|---|---|---|---|---|---|---|---|

| δ + 65 | δ − 25 | δ + 65 | δ − 25 | |||||

| % | % | % | % | % | % | % | % | |

| A | 3.39 (b) | 4.12 (b) | 7.01 (c) | 41.69 (a) | −0.05 | 0.13 | −2.18 | −1.23 |

| B | 1.42 (c) | 3.83 (a) | 3.24 (a) | 42.72 (a,b) | −0.02 | 0.10 | −0.53 | −1.32 |

| C | 2.51 (a,b) | 4.12 (b) | 5.02 (b) | 43.15 (a,b) | −0.07 | 0.05 | −0.51 | −0.61 |

| D | 2.24 (a,c) | 2.06 (a) | 3.91 (a,b) | 38.72 (c) | −0.04 | 0.02 | −0.74 | −0.74 |

| E | 2.35 (a,b,c) | 2.23 (a) | 3.51 (a) | 42.32 (a) | −0.07 | 0.05 | −1.09 | −2.27 |

| F | 2.82 (a,b) | 4.81 (b) | 4.92 (a,b) | 45.15 (b) | 0.14 | −0.09 | −2.07 | −2.65 |

| Property | Spruce | Alien |

|---|---|---|

| % | % | |

| Density in g·cm−3 | 0.946 | 0.871–0.963 |

| Flexural strength in MPa | 15.98 | 13.69–15.60 |

| Modulus of elasticity in MPa | 807 | 550–876 |

| Tensile strength in MPa | 7.18 | 6.46–7.52 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Medved, S.; Tomec, D.K.; Balzano, A.; Merela, M. Alien Wood Species as a Resource for Wood-Plastic Composites. Appl. Sci. 2021, 11, 44. https://doi.org/10.3390/app11010044

Medved S, Tomec DK, Balzano A, Merela M. Alien Wood Species as a Resource for Wood-Plastic Composites. Applied Sciences. 2021; 11(1):44. https://doi.org/10.3390/app11010044

Chicago/Turabian StyleMedved, Sergej, Daša Krapež Tomec, Angela Balzano, and Maks Merela. 2021. "Alien Wood Species as a Resource for Wood-Plastic Composites" Applied Sciences 11, no. 1: 44. https://doi.org/10.3390/app11010044

APA StyleMedved, S., Tomec, D. K., Balzano, A., & Merela, M. (2021). Alien Wood Species as a Resource for Wood-Plastic Composites. Applied Sciences, 11(1), 44. https://doi.org/10.3390/app11010044