Dual-Functionalized Pesticide Nanocapsule Delivery System with Improved Spreading Behavior and Enhanced Bioactivity

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

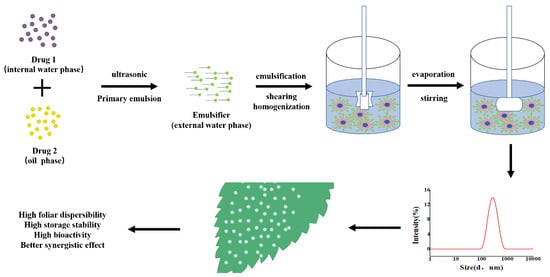

2.2.1. Preparation of Dual-Functionalized Pesticide Nanocapsules

2.2.2. Particle Size and Morphological Characterization of Dual-Functionalized Pesticide Nanocapsules

2.2.3. Determination of Dual-Functionalized Pesticide Nanocapsules’ Loading Efficiencies

2.2.4. Stability Evaluation of Dual-Functionalized Pesticide Nanocapsules

2.2.5. Foliar Spread and Contact Angle Evaluation of Dual-Functionalized Pesticide Nanocapsules

2.2.6. Bioactivity Evaluation of Dual-Functionalized Pesticide Nanocapsules

2.2.7. Statistical Analysis

3. Results and Discussion

3.1. Preparation of Dual-Functionalized Pesticide Nanocapsules

3.2. Effects of Surfactants on the Particle Size and Polydispersity of Dual-Functionalized Pesticide Nanocapsules

3.2.1. Single Surfactants

3.2.2. Complex Surfactants

3.3. Morphology of Dual-Functionalized Pesticide Nanocapsules

3.4. Stability of Dual-Functionalized Pesticide Nanocapsules

3.5. Foliar Spread and Contact Angle Evaluation of Dual-Functionalized Pesticide Nanocapsules

3.6. Bioactivity of the Dual-Functionalized Pesticide Nanocapsules

4. Conclusions

Author Contributions

Funding

Acknowledgement

Conflicts of Interest

References

- Singh, P.; Mazumdar, P.; Harikrishna, J.A.; Babu, S. Sheath blight of rice: A review and identification of priorities for future research. Planta 2019, 250, 1387–1407. [Google Scholar] [CrossRef] [Green Version]

- Swain, D.M.; Sahoo, R.K.; Chandan, R.K.; Ghosh, S.; Kumar, R.; Jha, G.; Tuteja, N. Concurrent overexpression of rice G-protein β and γ subunits provide enhanced tolerance to sheath blight disease and abiotic stress in rice. Planta 2019, 250, 1505–1520. [Google Scholar] [CrossRef]

- Peng, D.; Li, S.; Wang, J.; Chen, C.; Zhou, M. Integrated biological and chemical control of rice sheath blight by Bacillus subtilis NJ–18 and jinggangmycin. Pest. Manag. Sci. 2013, 70, 258–263. [Google Scholar] [CrossRef]

- Shu, Z.; He, D.; Yao, K.; Zhao, L.; Miao, K.; Yang, H.; Ji, M. Control effects of jinggangmycin and its compounded reagents against rice sheath blight. Plant Dis. Pests 2012, 3, 5. [Google Scholar]

- Chen, C.; Wang, Y.; Qian, Y.; Zhao, X.; Wang, Q. The synergistic toxicity of the multiple chemical mixtures: Implications for risk assessment in the terrestrial environment. Environ. Int. 2015, 77, 95–105. [Google Scholar] [CrossRef] [PubMed]

- Cycoń, M.; Mrozik, A.; Piotrowska-Seget, Z. Bioaugmentation as a strategy for the remediation of pesticide-polluted soil: A review. Chemosphere 2017, 172, 52–71. [Google Scholar] [CrossRef] [PubMed]

- Kumar, S.; Bhanjana, G.; Sharma, A.; Sidhu, M.C.; Dilbaghi, N. Synthesis, characterization and on field evaluation of pesticide loaded sodium alginate nanoparticles. Carbohydr. Polym. 2014, 101, 1061–1067. [Google Scholar] [CrossRef]

- Roy, A.; Singh, S.K.; Bajpai, J.; Bajpai, A.K. Controlled pesticide release from biodegradable polymers. Cent. Eur. J. Chem. 2014, 12, 453–469. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, A.; Wang, C.; Cui, B.; Sun, C.; Zhao, X.; Zeng, Z.; Shen, Y.; Gao, F.; Liu, G.; et al. Synthesis and characterization of emamectin–benzoate slow–release microspheres with different surfactants. Sci. Rep. 2017, 7, 12761. [Google Scholar] [CrossRef] [Green Version]

- Pereira, J.L.; Antunes, S.C.; Castro, B.B.; Marques, C.R.; Gonçalves, A.M.M.; Gonçalves, F.; Pereira, R. Toxicity evaluation of three pesticides on non-target aquatic and soil organisms: Commercial formulation versus active ingredient. Ecotoxicology 2009, 18, 455–463. [Google Scholar] [CrossRef]

- Knowles, A. Recent developments of safer formulations of agrochemicals. Environmentalist 2008, 28, 35–44. [Google Scholar] [CrossRef]

- Qian, L.; Tao, L.I. Review of reproductive toxicity of environmental chemical pollutants. J. Lab. Med. 2005, 167–171. [Google Scholar]

- Bradberry, S.M.; Proudfoot, A.T.; Vale, J.A. Poisoning due to chlorophenoxy herbicides. Toxicol. Rev. 2004, 23, 65–73. [Google Scholar] [CrossRef] [PubMed]

- Mogul, M.G.; Akin, H.; Hasirci, N.; Trantolo, D.J.; Gresser, J.D.; Wise, D.L. Controlled release of biologically active agents for purposes of agricultural crop management. Resour. Conserv. Recycl. 1996, 16, 289–320. [Google Scholar] [CrossRef]

- Weber, J.; Halsall, C.J.; Muir, D.; Teixeira, C.; Small, J.; Solomon, K.; Hermanson, M.; Hung, H.; Bidleman, T. Endosulfan, a global pesticide: A review of its fate in the environment and occurrence in the Arctic. Sci. Total. Environ. 2009, 408, 2966–2984. [Google Scholar] [CrossRef] [PubMed]

- Kah, M.; Hofmann, T. Nanopesticide research: Current trends and future priorities. Environ. Int. 2014, 63, 224–235. [Google Scholar] [CrossRef]

- Xu, L.; Luo, G.; Sun, Y.; Huang, S.; Xu, D.; Xu, G.; Han, Z.; Gu, Z.; Zhang, Y. Multiple down–regulated cytochrome P450 monooxygenase genes contributed to synergistic interaction between chlorpyrifos and imidacloprid against Nilaparvata lugens. J. Asia-Pac. Entomol. 2020, 23, 44–50. [Google Scholar] [CrossRef]

- Ghormade, V.; Deshpande, M.V.; Paknikar, K.M. Perspectives for nano–biotechnology enabled protection and nutrition of plants. Biotechnol. Adv. 2011, 29, 792–803. [Google Scholar] [CrossRef]

- Feng, J.; Yang, G.; Zhang, S.; Liu, Q.; Jafari, S.M.; McClements, D.J. Fabrication and characterization of beta-cypermethrin-loaded PLA microcapsules prepared by emulsion-solvent evaporation: Loading and release properties. Environ. Sci. Pollut. Res. Int. 2018, 25, 13525–13535. [Google Scholar] [CrossRef]

- Nuruzzaman, M.; Rahman, M.M.; Liu, Y.; Naidu, R. Nanoencapsulation, nano-guard for pesticides: A new window for safe application. J. Agric. Food Chem. 2016, 64, 1447–1483. [Google Scholar] [CrossRef]

- Sarlak, N.; Taherifar, A.; Salehi, F. Synthesis of nanopesticides by encapsulating pesticide nanoparticles using functionalized carbon nanotubes and application of new nanocomposite for plant disease treatment. J. Agric. Food Chem. 2014, 62, 4833–4838. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Sun, Y.; Ding, G.; Geng, Q.; Zhu, J.; Guo, M.; Duan, Y.; Wang, B.; Cao, Y. Synthesis, characterization, and application of microbe–triggered controlled-release kasugamycin-pectin conjugate. J. Agric. Food Chem. 2015, 63, 4263–42688. [Google Scholar] [CrossRef] [PubMed]

- Yan, Y.; Hou, H.; Ren, T.; Xu, Y.; Wang, Q.; Xu, W. Utilization of environmental waste cyanobacteria as a pesticide carrier: Studies on controlled release and photostability of avermectin. Colloid Surf. B-Biointerfaces 2013, 102, 341–347. [Google Scholar] [CrossRef] [PubMed]

- Liang, J.; Tang, S.; Cheke, R.A.; Wu, J. Models for determining how many natural enemies to release inoculatively in combinations of biological and chemical control with pesticide resistance. J. Math. Anal. Appl. 2015, 422. [Google Scholar] [CrossRef]

- Li, Z.-Z.; Xu, S.-A.; Wen, L.-X.; Liu, F.; Liu, A.-Q.; Wang, Q.; Sun, H.-Y.; Yu, W.; Chen, J.-F. Controlled release of avermectin from porous hollow silica nanoparticles: Influence of shell thickness on loading efficiency, UV–shielding property and release. J. Control. Release 2005, 111, 81–88. [Google Scholar] [CrossRef] [PubMed]

- Campos, E.V.R.; Oliveira, J.L.; Fraceto, L.F.; Singh, B. Polysaccharides as safer release systems for agrochemicals. Agron. Sustain. Dev. 2015, 35, 47–66. [Google Scholar] [CrossRef]

- Campos, E.V.R.; de Oliveira, J.L.; Fraceto, L.F. Applications of controlled release systems for fungicides, herbicides, acaricides, nutrients, and plant growth hormones: A review. Adv. Sci. Eng. Med. 2014, 6, 373–387. [Google Scholar] [CrossRef]

- Cao, L.; Zhang, H.; Cao, C.; Zhang, J.; Li, F.; Huang, Q. Quaternized chitosan–capped mesoporous silica nanoparticles as nanocarriers for controlled pesticide release. Nanomaterials 2016, 6, 126. [Google Scholar] [CrossRef] [Green Version]

- Fu, Q.; Sun, J.; Zhang, D.; Li, M.; Wang, Y.; Ling, G.; Liu, X.; Sun, Y.; Sui, X.; Luo, C. Nimodipine nanocrystals for oral bioavailability improvement: Preparation, characterization and pharmacokinetic studies. Colloid Surf. B-Biointerfaces 2013, 109, 161–166. [Google Scholar] [CrossRef]

- Liu, B.; Wang, Y.; Yang, F.; Wang, X.; Shen, H.; Cui, H.; Wu, D. Construction of a controlled–release delivery system for pesticides using biodegradable PLA–based microcapsules. Colloid. Surf. B-Biointerfaces 2016, 144, 38–45. [Google Scholar] [CrossRef]

- Chen, C.; Zhang, G.; Dai, Z.; Xiang, Y.; Liu, B.; Bian, P.; Kang, Z.; Wu, Z.; Cai, D. Fabrication of light–responsively controlled–release herbicide using a nanocomposite. Chem. Eng. J. 2018, 349, 101–110. [Google Scholar] [CrossRef]

- Khot, L.R.; Sankaran, S.; Maja, J.M.; Ehsani, R.; Schuster, E.W. Applications of nanomaterials in agricultural production and crop protection: A review. Crop Prot. 2012, 35, 64–70. [Google Scholar] [CrossRef]

- Wang, H.-C.; Yan, Z.-R.; Deng, L.; Dong, H.; Jia, Y.-H.; Ma, N.; He, J.; Yu, G.-H. Synthesis and surface modification of cobalt nanoparticles and electromagnetic property of Co/PPy nanocomposites. Rare Met. 2015, 34, 223–228. [Google Scholar] [CrossRef]

- Qian, K.; Shi, T.; He, S.; Luo, L.; Liu, X.; Cao, Y. Release kinetics of tebuconazole from porous hollow silica nanospheres prepared by miniemulsion method. Micropor. Mesopor. Mater. 2013, 169, 1–6. [Google Scholar] [CrossRef]

- Zhao, X.; Cui, H.; Wang, Y.; Sun, C.; Cui, B.; Zeng, Z. Development strategies and prospects of nano–based smart pesticide formulation. J. Agric. Food Chem. 2018, 66, 6504–6512. [Google Scholar] [CrossRef]

- Sharma, P.; Zujovic, Z.D.; Bowmaker, G.A.; Marshall, A.J.; Denny, W.A.; Garg, S. Corrigendum to ‘Evaluation of a crystalline nanosuspension: Polymorphism, process induced transformation and in vivo studies. Int. J. Pharm. 2011, 408, 138–151. [Google Scholar] [CrossRef]

- Pignatello, R.; Ricupero, N.; Bucolo, C.; Maugeri, F.; Maltese, A.; Puglisi, G. Preparation and characterization of eudragit retard nanosuspensions for the ocular delivery of cloricromene. AAPS Pharmscitech. 2006, 7, E192–E198. [Google Scholar] [CrossRef]

- Talekar, M.; Kendall, J.; Denny, W.; Jamieson, S.; Garg, S. Development and evaluation of PIK75 nanosuspension, a phosphatidylinositol-3-kinase inhibitor. Eur. J. Pharm. Sci. 2012, 47, 824–833. [Google Scholar] [CrossRef]

- Mishra, P.R.; Shaal, L.A.; Müller, R.H.; Keck, C.M. Production and characterization of Hesperetin nanosuspensions for dermal delivery. Int. J. Pharm. 2008, 371, 182–189. [Google Scholar] [CrossRef]

- Yang, Y.; Qi, S.; Wang, D.; Wang, K.; Wang, C. Toxic effects of thifluzamide on zebrafish (Danio rerio). J. Hazard. Mater. 2016, 307, 127–136. [Google Scholar] [CrossRef]

- Zhang, Y.; Lu, J.; Wang, J.; Zhou, M.G.; Chen, C. Baseline sensitivity and resistance risk assessmemt of Rhizoctonia cerealis to thifluzamide, a succinate dehydrogenase inhibitor. Pestic. Biochem. Phys. 2015, 124, 97–102. [Google Scholar] [CrossRef] [PubMed]

- Wei, L.N.; Wu, P.; Wang, F.R.; Yang, H. Dissipation and degradation dynamics of thifluzamide in rice field. Water Air Soil. Pollut. 2015, 226, 130–143. [Google Scholar] [CrossRef]

- Tang, Q.-Y.; Zhang, C.-X. Data Processing System (DPS) software with experimental design, statistical analysis and data mining developed for use in entomological research. Insect Sci. 2013, 20, 254–260. [Google Scholar] [CrossRef] [PubMed]

- Agricultural Industry Standard of the People’s Republic of China—Laboratory Pesticide Testing Standard for Pesticides, Standard, Fungicides Part 6: Determination of Combined Action of Mixtures: NT / T1156. 6–2006 [S.]; Ministry of Agriculture of the People’s Republic of China: Beijing, China, 2006.

- Wu, L.; Zhang, J.; Watanabe, W. Physical and chemical stability of drug nanoparticles. Adv. Drug Deliv. Rev. 2011, 63, 456–469. [Google Scholar] [CrossRef]

- Wang, X.J.; Li, X.; Yang, S. Influence of pH and SDBS on the stability and thermal conductivity of nanofluids. Energy Fuel 2009, 23, 270–278. [Google Scholar] [CrossRef]

- Chin, C.P.; Lan, C.W.; Wu, H.S. Study on the performance of lambda cyhalothrin microemulsion with biodiesel as an alternative solvent. Ind. Eng. Chem. Res. 2012, 51, 4710–4718. [Google Scholar] [CrossRef]

- Feng, L.; Cui, B.; Yang, D.; Wang, C.; Zeng, Z.; Wang, Y.; Sun, C.; Zhao, X.; Cui, H. Preparation and evaluation of emamectin benzoate solid microemulsion. J. Nanomater. 2016, 1–7. [Google Scholar] [CrossRef] [Green Version]

- Wang, C.; Cui, B.; Guo, L.; Wang, A.; Zhao, X.; Wang, Y.; Sun, C.; Zeng, Z.; Zhi, H.; Chen, H.; et al. Fabrication and evaluation of lambda-cyhalothrin nanosuspension by one-step melt emulsification technique. Nanomaterials 2019, 9, 145. [Google Scholar] [CrossRef] [Green Version]

- Shen, Y.; Zhu, H.; Cui, J.; Wang, A.; Zhao, X.; Cui, B.; Wang, Y.; Cui, H. Construction of lambda-cyhalothrin nano-delivery system with a high loading content and controlled–release property. Nanomaterials 2018, 8, 1016. [Google Scholar] [CrossRef] [Green Version]

- Ahuja, B.K.; Jena, S.K.; Paidi, S.K.; Bagri, S.; Suresh, S. Formulation, optimization and in vitro-in vivo evaluation of febuxostat nanosuspension. Int. J. Pharm. 2015, 478, 540–552. [Google Scholar] [CrossRef]

- Wang, C.; Cui, B.; Zhao, X.; Wang, Y.; Zeng, Z.; Sun, C.; Yang, D.; Liu, G.; Cui, H. Optimization and characterization of lambda–cyhalothrin solid nanodispersion by self-dispersing method. Pest. Manag. Sci. 2019, 75, 380–389. [Google Scholar] [CrossRef] [PubMed]

- Ali, H.S.M.; York, P.; Blagden, N. Preparation of hydrocortisone nanosuspension through a bottom-up nanoprecipitation technique using microfluidic reactors. Int. J. Pharm. 2009, 375, 107–113. [Google Scholar] [CrossRef] [PubMed]

- Yu, M.; Yao, J.; Liang, J.; Zeng, Z.; Cui, B.; Zhao, X.; Sun, C.; Wang, Y.; Liu, G.; Cui, H. Development of functionalized abamectin poly(lactic acid) nanoparticles with regulatable adhesion to enhance foliar retention. RSC Adv. 2017, 7, 11271–11280. [Google Scholar] [CrossRef] [Green Version]

- Pandey, S.K.; Ghosh, S.; Maiti, P.; Haldar, C. Therapeutic efficacy and toxicity of tamoxifen loaded PLA nanoparticles for breast cancer. Int. J. Biol. Macromol. 2015, 72, 309–319. [Google Scholar] [CrossRef]

- Wang, C.; Guo, L.; Yao, J.; Wang, A.; Gao, F.; Zhao, X.; Zeng, Z.; Wang, Y.; Sun, C.; Cui, H.; et al. Preparation, characterization and antifungal activity of pyraclostrobin solid nanodispersion by self-emulsifying technique. Pest. Manag. Sci. 2019, 75, 2785–2793. [Google Scholar] [CrossRef]

- Horst, A.M.; Vukanti, R.; Priester, J.H.; Holden, P.A. An Assessment of fluorescence–and absorbance–based assays to study metal–oxide nanoparticle ROS production and effects on bacterial membranes. Small 2013, 9, 1753–1764. [Google Scholar] [CrossRef]

- Yao, J.; Cui, B.; Zhao, X.; Zhi, H.; Zeng, Z.; Wang, Y.; Sun, C.; Liu, G.; Gao, J.; Cui, H. Antagonistic effect of zzoxystrobin poly (Lactic Acid) microspheres with controllable particle size on Colletotrichum higginsianum Sacc. Nanomaterials 2018, 8, 857. [Google Scholar] [CrossRef] [Green Version]

| PVA:PC | MPS (d.nm) | D90 (nm) | PDI |

|---|---|---|---|

| 1:1 | 287.4 ± 0.7 | 373.3 ± 26.3 | 0.051 ± 0.046 |

| 1:2 | 265.3 ± 0.8 | 330.7 ± 6.0 | 0.034 ± 0.030 |

| 2:1 | 279.7 ± 0.2 | 359.7 ± 14.5 | 0.042 ± 0.002 |

| 1:3 | 282.4 ± 2.7 | 378.7 ± 8.0 | 0.043 ± 0.018 |

| 3:1 | 288.2 ± 3.7 | 355.7 ± 8.7 | 0.025 ± 0.017 |

| Treatments | Toxicity Regression Equation | Correlation Coefficient (R2) | 36-h EC50 (μg/mL) (95% CI) | EC50 (μg/mL) (Theoretical) | Synergistic Ratio |

|---|---|---|---|---|---|

| VWP | Y = 0.8485x + 3.0276 | 0.9716 | 227.5372 (135.8436–339.1162) | – | – |

| TSC | Y = 0.5736x + 6.1966 | 0.9802 | 0.0107 (0.0050–0.0222) | – | – |

| Dual–functionalized pesticide nanocapsules | Y = 0.5736x + 6.1966 | 0.9974 | 0.0082 (0.0062–0.0110) | 0.01712 | 2.088 |

| VTSC | Y = 0.5654x + 5.8325 | 0.9683 | 0.0350 (0.0176–0.0992) | 0.03210 | 0.917 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cui, J.; Sun, C.; Wang, A.; Wang, Y.; Zhu, H.; Shen, Y.; Li, N.; Zhao, X.; Cui, B.; Wang, C.; et al. Dual-Functionalized Pesticide Nanocapsule Delivery System with Improved Spreading Behavior and Enhanced Bioactivity. Nanomaterials 2020, 10, 220. https://doi.org/10.3390/nano10020220

Cui J, Sun C, Wang A, Wang Y, Zhu H, Shen Y, Li N, Zhao X, Cui B, Wang C, et al. Dual-Functionalized Pesticide Nanocapsule Delivery System with Improved Spreading Behavior and Enhanced Bioactivity. Nanomaterials. 2020; 10(2):220. https://doi.org/10.3390/nano10020220

Chicago/Turabian StyleCui, Jianxia, Changjiao Sun, Anqi Wang, Yan Wang, Huaxin Zhu, Yue Shen, Ningjun Li, Xiang Zhao, Bo Cui, Chong Wang, and et al. 2020. "Dual-Functionalized Pesticide Nanocapsule Delivery System with Improved Spreading Behavior and Enhanced Bioactivity" Nanomaterials 10, no. 2: 220. https://doi.org/10.3390/nano10020220

APA StyleCui, J., Sun, C., Wang, A., Wang, Y., Zhu, H., Shen, Y., Li, N., Zhao, X., Cui, B., Wang, C., Gao, F., Zeng, Z., & Cui, H. (2020). Dual-Functionalized Pesticide Nanocapsule Delivery System with Improved Spreading Behavior and Enhanced Bioactivity. Nanomaterials, 10(2), 220. https://doi.org/10.3390/nano10020220