Improvement in the Output Power of Near-Ultraviolet LEDs of p-GaN Nanorods through SiO2 Nanosphere Mask Lithography with the Dip-Coating Method

Abstract

:1. Introduction

2. Materials and Methods

2.1. Preparation of SiO2 Nanosphere Arrays by the Dip-Coating Method

- (a)

- Modification of the SiO2 ball solution: The density of SiO2 spheres is 2.2~2.66 g/cm3, which is higher than that of water. Additionally, it is necessary to add a diffusion agent, generally alcohol solvent, to modify the surface of SiO2 spheres so that the spheres float on the surface of water and do not sink when they diffuse at the gas-liquid interface.

- (b)

- Cleaning and hydrophilic treatment of the substrate: After ultrasonic treatment for 10 min in deionized water, acetone and absolute ethanol, the particles are cleaned by a cleaning machine for 5 min, dried by nitrogen, and then put into a plasma degumming machine for 15 min. Hydrophilic treatment is carried out on the surface of the substrate so that the particles can better adhere to the surface of the substrate. The rest of the glassware is cleaned in a cleaning machine.

- (c)

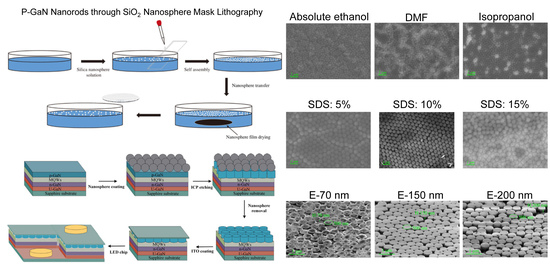

- Self-assembly and transfer of SiO2 balls: As shown in the schematic diagram in Figure 1, a pipette gun is used to obtain an appropriate amount of ultrasonic suspension, and then a glass slide is inserted into the culture dish for drainage. The suspension is dripped onto the glass slides, and the drops slowly flow into the gas-liquid interface from the glass slide to form a floating oil film. Then, the surfactant sodium dodecyl sulfate (SDS) is used to change the surface tension of the liquid surface such that the oil film of loosely arranged SiO2 spheres becomes densely arranged, Next, tweezers are used to put the treated substrate in the water parallel to the oil film, and then the tweezers are extended under the liquid surface at an angle suitable for transferring the tightly arranged SiO2 spherical film to the substrate.

- (d)

- Drying of the SiO2 spherical film: The substrate covered with SiO2 spherical film is placed in a clean culture dish, which is then placed into a 100 ℃ incubator for drying. All the residual water stains and solvents on the surface of the substrate volatilize within a certain period of time, leaving only the self-assembled SiO2 spherical film on the surface of the substrate.

- (e)

- Self-assembly test: The self-assembly effect of the sample was preliminarily tested under an optical microscope. The test parameters can be adjusted quickly according to the test results, and the experimental results can be further confirmed by SEM.

2.2. Dip-Coating Method Condition Optimization

2.3. p-Type GaN Nanopillar LED

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Würtele, M.; Kolbe, T.; Lipsz, M.; Külberg, A.; Weyers, M.; Kneissl, M.; Jekel, M. Application of GaN-based ultraviolet-C light emitting diodes–UV LEDs–for water disinfection. Water Res. 2011, 45, 1481–1489. [Google Scholar] [CrossRef]

- Anyaogu, K.C.; Ermoshkin, A.A.; Neckers, D.C.; Mejiritski, A.; Grinevich, O.; Fedorov, A.V. Performance of the light emitting diodes versus conventional light sources in the UV light cured formulations. J. Appl. Polym. Sci. 2007, 105, 803–808. [Google Scholar] [CrossRef]

- Zhang, Z.-H.; Zhang, Y.; Bi, W.; Geng, C.; Xu, S.; Demir, H.V.; Sun, X.W. A charge inverter for III-nitride light-emitting diodes. Appl. Phys. Lett. 2016, 108, 133502. [Google Scholar] [CrossRef] [Green Version]

- Reich, C.; Guttmann, M.; Feneberg, M.; Wernicke, T.; Mehnke, F.; Kuhn, C.; Rass, J.; Lapeyrade, M.; Einfeldt, S.; Knauer, A. Strongly transverse-electric-polarized emission from deep ultraviolet AlGaN quantum well light emitting diodes. Appl. Phys. Lett. 2015, 107, 142101. [Google Scholar] [CrossRef]

- Lobo, N.; Rodriguez, H.; Knauer, A.; Hoppe, M.; Einfeldt, S.; Vogt, P.; Weyers, M.; Kneissl, M. Enhancement of light extraction in ultraviolet light-emitting diodes using nanopixel contact design with Al reflector. Appl. Phys. Lett. 2010, 96, 081109. [Google Scholar] [CrossRef]

- Kim, J.-Y.; Kwon, M.-K.; Kim, J.-P.; Park, S.-J. Enhanced light extraction from triangular GaN-based light-emitting diodes. IEEE Photonics Technol. Lett. 2007, 19, 1865–1867. [Google Scholar] [CrossRef] [Green Version]

- Tsuzuki, H.; Mori, F.; Takeda, K.; Ichikawa, T.; Iwaya, M.; Kamiyama, S.; Amano, H.; Akasaki, I.; Yoshida, H.; Kuwabara, M. High-performance UV emitter grown on high-crystalline-quality AlGaN underlying layer. Phys. Status Solidi (a) 2009, 206, 1199–1204. [Google Scholar] [CrossRef]

- Kikuchi, A.; Tada, M.; Miwa, K.; Kishino, K. Growth and characterization of InGaN/GaN nanocolumn LED. In Proceedings of Quantum Dots, Particles, and Nanoclusters III; International Society for Optics and Photonics: San Jose, CA, USA; p. 612905.

- Kashima, Y.; Maeda, N.; Matsuura, E.; Jo, M.; Iwai, T.; Morita, T.; Kokubo, M.; Tashiro, T.; Kamimura, R.; Osada, Y. High external quantum efficiency (10%) AlGaN-based deep-ultraviolet light-emitting diodes achieved by using highly reflective photonic crystal on p-AlGaN contact layer. Appl. Phys. Express 2017, 11, 012101. [Google Scholar] [CrossRef]

- Inoue, S.I.; Tamari, N.; Taniguchi, M. 150 mW deep-ultraviolet light-emitting diodes with large-area AlN nanophotonic light-extraction structure emitting at 265 nm. Appl. Phys. Lett. 2017, 110, 141106. [Google Scholar] [CrossRef] [Green Version]

- Pernot, C.; Kim, M.; Fukahori, S.; Inazu, T.; Fujita, T.; Nagasawa, Y.; Hirano, A.; Ippommatsu, M.; Iwaya, M.; Kamiyama, S. Improved efficiency of 255–280 nm AlGaN-based light-emitting diodes. Appl. Phys. Express 2010, 3, 061004. [Google Scholar] [CrossRef]

- Wu, Q.; Hu, Z.; Wang, X.; Lu, Y.; Huo, K.; Deng, S.; Xu, N.; Shen, B.; Zhang, R.; Chen, Y. Extended vapor–liquid–solid growth and field emission properties of aluminium nitride nanowires. J. Mater. Chem. 2003, 13, 2024–2027. [Google Scholar] [CrossRef]

- Chen, L.Y.; Huang, Y.Y.; Chang, C.H.; Sun, Y.H.; Cheng, Y.W.; Ke, M.Y.; Chen, C.P.; Huang, J. High performance InGaN/GaN nanorod light emitting diode arrays fabricated by nanosphere lithography and chemical mechanical polishing processes. Opt. Express 2010, 18, 7664–7669. [Google Scholar] [CrossRef]

- Hsieh, M.Y.; Wang, C.Y.; Chen, L.Y.; Ke, M.Y.; Huang, J.J. InGaN–GaN nanorod light emitting arrays fabricated by silica nanomasks. IEEE J. Quantum Electron. 2008, 44, 468–472. [Google Scholar] [CrossRef]

- Liu, H.; Siron, M.; Gao, M.; Lu, D.; Bekenstein, Y.; Zhang, D.; Dou, L.; Alivisatos, A.P.; Yang, P. Lead halide perovskite nanowires stabilized by block copolymers for langmuir-blodgett assembly. Nano Res. 2020, 13, 1453–1458. [Google Scholar] [CrossRef]

- Ariga, K. Don’t Forget Langmuir–Blodgett Films 2020: Interfacial Nanoarchitectonics with Molecules, Materials, and Living Objects. Langmuir 2020, 36, 7158–7180. [Google Scholar] [CrossRef]

- Li, Z.; Wang, J.; Song, Y. Self-assembly of latex particles for colloidal crystals. Particuology 2011, 9, 559–565. [Google Scholar] [CrossRef]

- Çam, Ş.U.; Serïn, T.; Yazıcı, A.N. Effect of Sn doping concentration on structural, optical and electrical properties of ZnS/p-Si (111) diodes fabricated by sol-gel dip-coating method. Mater. Sci. Semicond. Process. 2021, 127, 105693. [Google Scholar] [CrossRef]

- Guo, Y.N.; Liang, L.Y.; Bao, S.X.; Du, F.P.; Wen, X. Excellent oil/water separation performance of poly (styrene-alt-maleic anhydride)/fluorocarbon surfactant membrane filter with functionalized multiwalled carbon nanotubes. J. Appl. Polym. Sci. 2020, 137, 48977. [Google Scholar] [CrossRef]

- Ly, P.-M.T.; Mitas, K.D.J.; Thiele, U.; Gurevich, S.V. Two-dimensional patterns in dip coating-first steps on the continuation path. Phys. D Nonlinear Phenom. 2020, 409, 132485. [Google Scholar] [CrossRef] [Green Version]

- Dundas, A.A.; Cuzzucoli Crucitti, V.; Haas, S.; Dubern, J.F.; Latif, A.; Romero, M.; Sanni, O.; Ghaemmaghami, A.M.; Williams, P.; Alexander, M.R. Achieving microparticles with cell-instructive surface chemistry by using tunable co-polymer surfactants. Adv. Funct. Mater. 2020, 30, 2001821. [Google Scholar] [CrossRef]

- Song, J.H.; Kim, H.J.; Ann, B.J.; Dong, Y.; Hong, S.; Song, J.H.; Moon, Y.; Yuh, H.K.; Choi, S.C.; Shee, S. Role of photovoltaic effects on characterizing emission properties of InGaN/GaN light emitting diodes. Appl. Phys. Lett. 2009, 95, 183507. [Google Scholar] [CrossRef]

- Chen, H.S.; Yeh, D.M.; Lu, Y.C.; Chen, C.Y.; Huang, C.; Tang, T.Y.; Yang, C.C.; Wu, C.S.; Chen, C.D. Strain relaxation and quantum confinement in InGaN/GaN nanoposts. Nanotechnology 2006, 17, 1454–1458. [Google Scholar] [CrossRef]

- Ma, B.; Tang, M.; Ueno, K.; Kobayashi, A.; Morita, K.; Fujioka, H.; Ishitani, Y. Combined infrared reflectance and Raman spectroscopy analysis of Si-doping limit of GaN. Appl. Phys. Lett. 2020, 117, 192103. [Google Scholar] [CrossRef]

- Tripathy, S.; Chua, S.J.; Chen, P.; Miao, Z.L. Micro-Raman investigation of strain in GaN and AlxGa1xN/GaN heterostructures grown on Si(111). J. Appl. Phys. 2002, 92, 3503–3510. [Google Scholar] [CrossRef]

- Kuball, M.; Hayes, J.M.; Shi, Y.; Edgar, J.H. Phonon lifetimes in bulk AlN and their temperature dependence. Appl. Phys. Lett. 2000, 77, 1958–1960. [Google Scholar] [CrossRef]

- Chierchia, R.; Böttcher, T.; Heinke, H.; Einfeldt, S.; Hommel, D. Microstructure of heteroepitaxial GaN revealed by x-ray diffraction. J. Appl. Phys. 2003, 93, 8918–8925. [Google Scholar] [CrossRef]

- Zeng, Y.; Ning, J.; Zhang, J.; Jia, Y.; Yan, C.; Wang, B.; Wang, D. Raman analysis of E2 (high) and A1 (LO) phonon to the stress-free GaN grown on sputtered AlN/graphene buffer layer. Appl. Sci. 2020, 10, 8814. [Google Scholar] [CrossRef]

- Park, J.Y.; Baker, L.R.; Somorjai, G.A. Role of Hot Electrons and Metal–Oxide Interfaces in Surface Chemistry and Catalytic Reactions. Chem. Rev. 2015, 115, 2781–2817. [Google Scholar] [CrossRef] [PubMed]

- Bao, W.; Su, Z.; Zheng, C.; Ning, J.; Xu, S. Carrier localization effects in InGaN/GaN multiple-quantum-wells LED nanowires: Luminescence quantum efficiency improvement and “negative” thermal activation energy. Sci. Rep. 2016, 6, 34545. [Google Scholar] [CrossRef] [Green Version]

| Sample | Nanospheres | Absolute Ethanol | DMF | Isopropanol | SDS |

|---|---|---|---|---|---|

| μL | μL | μL | μL | % | |

| A | 60 | 0 | 0 | 0 | 0 |

| B | 60 | 60 | 0 | 0 | 0 |

| C | 60 | 0 | 60 | 0 | 0 |

| D | 60 | 0 | 0 | 60 | 0 |

| E | 60 | 0 | 0 | 60 | 5 |

| F | 60 | 0 | 0 | 60 | 10 |

| G | 60 | 0 | 0 | 60 | 15 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yue, W.; Li, P.; Zhou, X.; Wang, Y.; Wu, J.; Bai, J. Improvement in the Output Power of Near-Ultraviolet LEDs of p-GaN Nanorods through SiO2 Nanosphere Mask Lithography with the Dip-Coating Method. Nanomaterials 2021, 11, 2009. https://doi.org/10.3390/nano11082009

Yue W, Li P, Zhou X, Wang Y, Wu J, Bai J. Improvement in the Output Power of Near-Ultraviolet LEDs of p-GaN Nanorods through SiO2 Nanosphere Mask Lithography with the Dip-Coating Method. Nanomaterials. 2021; 11(8):2009. https://doi.org/10.3390/nano11082009

Chicago/Turabian StyleYue, Wenkai, Peixian Li, Xiaowei Zhou, Yanli Wang, Jinxing Wu, and Junchun Bai. 2021. "Improvement in the Output Power of Near-Ultraviolet LEDs of p-GaN Nanorods through SiO2 Nanosphere Mask Lithography with the Dip-Coating Method" Nanomaterials 11, no. 8: 2009. https://doi.org/10.3390/nano11082009

APA StyleYue, W., Li, P., Zhou, X., Wang, Y., Wu, J., & Bai, J. (2021). Improvement in the Output Power of Near-Ultraviolet LEDs of p-GaN Nanorods through SiO2 Nanosphere Mask Lithography with the Dip-Coating Method. Nanomaterials, 11(8), 2009. https://doi.org/10.3390/nano11082009