Synthesis of Molybdenum Sulfide/Tellurium Hetero-Composite by a Simple One-Pot Hydrothermal Technique for High-Performance Supercapacitor Electrode Material

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Reagents

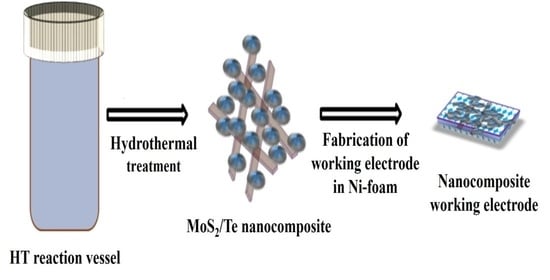

2.2. Preparation of MoS2/Te Composite

2.3. Characterization

2.4. Electrochemical Characterization

3. Results and Discussion

3.1. Morphological Analysis

3.2. Electrochemical Performances

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jiang, A.; Wang, Z.; Li, Q.; Dong, M. Ionic Liquid-Assisted Synthesis of Hierarchical One-Dimensional MoP/NPC for High-Performance Supercapacitor and Electrocatalysis. ACS Sustain. Chem. Eng. 2020, 8, 6343–6351. [Google Scholar] [CrossRef]

- Wang, M.; Han, K.; Qi, J.; Li, J.; Teng, Z.; Zhang, J. Heteroatom-Rich Porous Carbons Derived from Nontoxic Green Organic Crystals for High-Performance Symmetric and Asymmetric Supercapacitors with Aqueous/Gel Electrolyte. ACS Sustain. Chem. Eng. 2020, 8, 13634–13647. [Google Scholar] [CrossRef]

- Liu, X.; Ma, C.; Wen, Y.; Chen, X.; Zhao, X.; Tang, T.; Holze, R.; Mijowska, E. Highly efficient conversion of waste plastic into thin carbon nanosheets for superior capacitive energy storage. Carbon 2021, 171, 819–828. [Google Scholar] [CrossRef]

- Shi, X.; Zhang, S.; Chen, X.; Tang, T.; Mijowska, E. Three dimensional graphene/carbonized metal-organic frameworks based high-performance supercapacitor. Carbon 2020, 157, 55–63. [Google Scholar] [CrossRef]

- Najib, S.; Erdem, E. Current progress achieved in novel materials for supercapacitor electrodes: Mini review. Nanoscale Adv. 2019, 1, 2817–2827. [Google Scholar] [CrossRef] [Green Version]

- Yu, P.; Coll, M.; Amade, R.; AlShaikh, I.; Pantoja-Suárez, F.; Pascual, E.; Andújar, J.L.; Serra, E.B.; Bertran, E. Homogeneous Fe2O3 coatings on carbon nanotube structures for supercapacitors. Dalton Trans. 2020, 49, 4136–4145. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sridhar, D.; Yu, H.; Meunier, J.-L.; Omanovic, S. Carbon nano-fiber forest foundation for ruthenium oxide pseudo-electrochemical capacitors. Mater. Adv. 2020, 1, 215–227. [Google Scholar] [CrossRef]

- Hekmat, F.; Shahrokhian, S.; Rahimi, S. 3D flower-like binary nickel cobalt oxide decorated coiled carbon nanotubes directly grown on nickel nanocones and binder-free hydrothermal carbons for advanced asymmetric supercapacitors. Nanoscale 2019, 11, 2901–2915. [Google Scholar] [CrossRef]

- Yang, C.; Shi, M.; Tian, Y.; Yang, J.; Song, X.; Zhao, L.; Liu, J.; Zhang, P.; Gao, L. Bioinspired pomegranate-like microflowers confining core-shell binary NixSy nanobeads for efficient supercapacitors exhibiting a durable lifespan exceeding 100,000 cycles. J. Mater. Chem. A 2019, 7, 3432–3442. [Google Scholar] [CrossRef]

- Mallick, S.; Samanta, A.; Raj, C.R. Mesoporous carbon-supported manganese tungstate nanostructures for the development of zinc–air battery powered long lifespan asymmetric supercapacitor. Sustain. Energy Fuels 2020, 4, 4008–4017. [Google Scholar] [CrossRef]

- Ouyang, M.; Bertei, A.; Cooper, S.J.; Wu, Y.; Boldrin, P.; Liu, X.; Kishimoto, M.; Wang, H.; Marlow, M.N.; Chen, J.; et al. Model-guided design of a high performance and durability Ni nanofiber/ceria matrix solid oxide fuel cell electrode. J. Energy Chem. 2021, 56, 98–112. [Google Scholar] [CrossRef]

- Valdez-Resendiz, J.E.; Rosas-Caro, J.C.; Mayo-Maldonado, J.C.; Claudio-Sanchez, A.; Ruiz-Martinez, O.; Sanchez, V.M. Improvement of ultracapacitors-energy usage in fuel cell based hybrid electric vehicle. Int. J. Hydrog. Energy 2020, 45, 13746–13756. [Google Scholar] [CrossRef]

- Zhang, P.; Wang, F.; Yu, M.; Zhuang, X.; Feng, X. Two-dimensional materials for miniaturized energy storage devices: From individual devices to smart integrated systems. Chem. Soc. Rev. 2018, 47, 7426–7451. [Google Scholar] [CrossRef] [Green Version]

- Yu, F.; Zhang, C.; Wang, F.; Gu, Y.; Zhang, P.; Waclawik, E.R.; Du, A.; Ostrikov, K.; Wang, H. A zinc bromine “supercapattery” system combining triple functions of capacitive, pseudocapacitive and battery-type charge storage. Mater. Horiz. 2020, 7, 495–503. [Google Scholar] [CrossRef]

- Chen, G.Z. Supercapattery: Merit merge of capacitive and Nernstian charge storage mechanisms. Curr. Opin. Electrochem. 2020, 21, 358–367. [Google Scholar] [CrossRef]

- He, Y.; Hamann, T.; Wang, D. Thin film photoelectrodes for solar water splitting. Chem. Soc. Rev. 2019, 48, 2182–2215. [Google Scholar] [CrossRef]

- Poudel, M.B.; Karki, H.P.; Kim, H.J. Silver nanoparticles decorated molybdenum sulfide/tungstate oxide nanorods as high performance supercapacitor electrode. J. Energy Storage 2020, 32, 101693. [Google Scholar] [CrossRef]

- Roger, I.; Moca, R.; Miras, H.N.; Crawford, K.G.; Moran, D.; Ganin, A.Y.; Symes, M.D. The direct hydrothermal deposition of cobalt-doped MoS2 onto fluorine-doped SnO2 substrates for catalysis of the electrochemical hydrogen evolution reaction. J. Mater. Chem. A 2016, 5, 1472–1480. [Google Scholar] [CrossRef] [Green Version]

- Neetika; Sanger, A.; Malik, V.K.; Chandra, R. One step sputtered grown MoS2 nanoworms binder free electrodes for high performance supercapacitor application. Int. J. Hydrog. Energy 2018, 43, 11141–11149. [Google Scholar] [CrossRef]

- Wang, W.; Jiang, B.; Qian, C.; Lv, F.; Feng, J.; Zhou, J.; Wang, K.; Yang, C.; Yang, Y.; Guo, S. Pistachio-Shuck-Like MoSe2/C Core/Shell Nanostructures for High-Performance Potassium-Ion Storage. Adv. Mater. 2018, 30, e1801812. [Google Scholar] [CrossRef] [PubMed]

- Yu, M.; Zhao, S.; Feng, H.; Hu, L.; Zhang, X.; Zeng, Y.; Tong, Y.; Lu, X. Engineering Thin MoS2 Nanosheets on TiN Nanorods: Advanced Electrochemical Capacitor Electrode and Hydrogen Evolution Electrocatalyst. ACS Energy Lett. 2017, 2, 1862–1868. [Google Scholar] [CrossRef]

- Wang, P.-P.; Sun, H.; Ji, Y.; Li, W.; Wang, X. Three-Dimensional Assembly of Single-Layered MoS2. Adv. Mater. 2014, 26, 964–969. [Google Scholar] [CrossRef] [PubMed]

- Wu, K.; Ma, H.; Gao, Y.; Hu, W.; Yang, J. Highly-efficient heterojunction solar cells based on two-dimensional tellurene and transition metal dichalcogenides. J. Mater. Chem. A 2019, 7, 7430–7436. [Google Scholar] [CrossRef]

- He, Z.; Yang, Y.; Liu, J.-W.; Yu, S.-H. Emerging tellurium nanostructures: Controllable synthesis and their applications. Chem. Soc. Rev. 2017, 46, 2732–2753. [Google Scholar] [CrossRef]

- Wang, Y.; Qiu, G.; Wang, R.; Huang, S.; Wang, Q.; Liu, Y.; Du, Y.; Iii, W.A.G.; Kim, M.J.; Xu, X.; et al. Field-effect transistors made from solution-grown two-dimensional tellurene. Nat. Electron. 2018, 1, 228–236. [Google Scholar] [CrossRef]

- Liu, Y.; Wu, W.; Goddard, W.A. Tellurium: Fast Electrical and Atomic Transport along the Weak Interaction Direction. J. Am. Chem. Soc. 2018, 140, 550–553. [Google Scholar] [CrossRef] [Green Version]

- He, J.; Chen, Y.; Lv, W.; Wen, K.; Wang, Z.; Zhang, W.; Li, Y.; Qin, W.; He, W. Three-Dimensional Hierarchical Reduced Graphene Oxide/Tellurium Nanowires: A High-Performance Freestanding Cathode for Li–Te Batteries. ACS Nano 2016, 10, 8837–8842. [Google Scholar] [CrossRef]

- Tsai, H.-W.; Yaghoubi, A.; Chan, T.-C.; Wang, C.-C.; Liu, W.-T.; Liao, C.-N.; Lu, S.-Y.; Tsung-Cheng, C.; Chueh, Y.-L. Electrochemical synthesis of ultrafast and gram-scale surfactant-free tellurium nanowires by gas–solid transformation and their applications as supercapacitor electrodes for p-doping of graphene transistors. Nanoscale 2015, 7, 7535–7539. [Google Scholar] [CrossRef]

- Wang, X.; Fang, Y.; Shi, B.; Huang, F.; Rong, F.; Que, R. Three-dimensional NiCo2O4@NiCo2O4 core–shell nanocones arrays for high-performance supercapacitors. Chem. Eng. J. 2018, 344, 311–319. [Google Scholar] [CrossRef]

- Poudel, M.B.; Shinb, M.; Kim, H.J. Polyaniline-silver-manganese dioxide nanorod ternary composite for asymmetric supercapacitor with remarkable electrochemical performance. Int. J. Hydrog. Energy 2021, 46, 474–485. [Google Scholar] [CrossRef]

- Li, H.B.; Yu, M.; Wang, F.X.; Liu, P.; Liang, Y.; Xiao, J.; Tong, Y.X.; Yang, G.W. Amorphous nickel hydroxide nanospheres with ultrahigh capacitance and energy density as electrochemical pseudocapacitor materials. Nat. Commun. 2013, 4, 1894. [Google Scholar] [CrossRef] [Green Version]

- Wu, W.; Qi, W.; Zhao, Y.; Tang, X.; Qiu, Y.; Su, D.; Fan, H.; Wang, G. Hollow CeO2 spheres conformally coated with graphitic carbon for high-performance supercapacitor electrodes. Appl. Surf. Sci. 2019, 463, 244–252. [Google Scholar] [CrossRef]

- Zhang, X.; Ding, P.; Sun, Y.; Wang, Y.; Wu, Y.; Guo, J. Shell-core MoS2 nanosheets@Fe3O4 sphere heterostructure with exposed active edges for efficient electrocatalytic hydrogen production. J. Alloy. Compd. 2017, 715, 53–59. [Google Scholar] [CrossRef]

- Zambonino, M.; Quizhpe, E.; Jaramillo, F.; Rahman, A.; Vispo, N.S.; Jeffryes, C.; Dahoumane, S. Green Synthesis of Selenium and Tellurium Nanoparticles: Current Trends, Biological Properties and Biomedical Applications. Int. J. Mol. Sci. 2021, 22, 989. [Google Scholar] [CrossRef]

- Amani, M.; Tan, C.; Zhang, G.; Zhao, C.; Bullock, J.; Song, X.; Kim, H.; Shrestha, V.R.; Gao, Y.; Crozier, K.B.; et al. Solution-Synthesized High-Mobility Tellurium Nanoflakes for Short-Wave Infrared Photodetectors. ACS Nano 2018, 12, 7253–7263. [Google Scholar] [CrossRef] [PubMed]

- Feng, W.; Chen, L.; Qin, M.; Zhou, X.; Zhang, Q.; Miao, Y.; Qiu, K.; Zhang, Y.; He, C. Flower-like PEGylated MoS2 nanoflakes for near-infrared photothermal cancer therapy. Sci. Rep. 2015, 5, 17422. [Google Scholar] [CrossRef] [Green Version]

- Yi, M.; Zhang, C. The synthesis of two-dimensional MoS2 nanosheets with enhanced tribological properties as oil additives. RSC Adv. 2018, 8, 9564–9573. [Google Scholar] [CrossRef] [Green Version]

- Alegaonkar, A.P.; Pardeshi, S.K.; Alegaonkar, P.S. Tellurium-reduced graphene oxide two-dimensional (2D) architecture for efficient photo-catalytic effluent: Solution for industrial water waste. Diam. Relat. Mater. 2020, 108, 107994. [Google Scholar] [CrossRef]

- Eda, G.; Yamaguchi, H.; Voiry, D.; Fujita, T.; Chen, M.; Chhowalla, M. Photoluminescence from Chemically Exfoliated MoS2. Nano Lett. 2011, 11, 5111–5116. [Google Scholar] [CrossRef]

- Lee, Y.-K.; Lee, M.; Lee, G.W.; Eom, K.; Lee, M.-H.; Lee, S.; Joh, H.-I. Amorphous MoSx embedded within edges of modified graphite as fast-charging anode material for rechargeable batteries. Appl. Surf. Sci. 2020, 509, 145352. [Google Scholar] [CrossRef]

- Thommes, M.; Kaneko, K.; Neimark, A.V.; Olivier, J.P.; Rodriguez-Reinoso, F.; Rouquerol, J.; Sing, K.S.W. Physisorption of gases, with special reference to the evaluation of surface area and pore size distribution (IUPAC Technical Report). Pure Appl. Chem. 2015, 87, 1051–1069. [Google Scholar] [CrossRef] [Green Version]

- Manikandan, M.; Subramani, K.; Sathish, M.; Dhanuskodi, S. Hydrothermal synthesis of cobalt telluride nanorods for a high performance hybrid asymmetric supercapacitor. RSC Adv. 2020, 10, 13632–13641. [Google Scholar] [CrossRef] [Green Version]

- Ward, K.R.; Lawrence, N.S.; Hartshorne, R.S.; Compton, R.G. The theory of cyclic voltammetry of electrochemically heterogeneous surfaces: Comparison of different models for surface geometry and applications to highly ordered pyrolytic graphite. Phys. Chem. Chem. Phys. 2012, 14, 7264–7275. [Google Scholar] [CrossRef]

- Wu, C.; Cai, J.; Zhang, Q.; Zhou, X.; Zhu, Y.; Li, L.; Shen, P.K.; Zhang, K. Direct growth of urchin-like ZnCo2O4 microspheres assembled from nanowires on nickel foam as high-performance electrodes for supercapacitors. Electrochim. Acta 2015, 169, 202–209. [Google Scholar] [CrossRef]

- Gong, C.; Huang, M.; Zhou, P.; Sun, Z.; Fan, L.; Lin, J.; Wu, J. Mesoporous Co0.85Se nanosheets supported on Ni foam as a positive electrode material for asymmetric supercapacitor. Appl. Surf. Sci. 2016, 362, 469–476. [Google Scholar] [CrossRef]

- Quan, Y.; Zhang, M.; Wang, G.; Lu, L.; Wang, Z.; Xu, H.; Liu, S.; Min, Q. 3D hierarchical porous CuS flower-dispersed CNT arrays on nickel foam as a binder-free electrode for supercapacitors. New J. Chem. 2019, 43, 10906–10914. [Google Scholar] [CrossRef]

- Ji, H.; Luan, A.-L.; Dai, C.-C.; Li, M.; Yang, G.; Hou, W.-H. Highly active free-standing and flexible MoS2/rGO sandwich-structured films for supercapacitor applications. Solid State Commun. 2019, 297, 45–49. [Google Scholar] [CrossRef]

- Peng, W.; Wang, W.; Han, G.; Huang, Y.; Zhang, Y. Fabrication of 3D flower-like MoS2/graphene composite as high-performance electrode for capacitive deionization. Desalination 2020, 473, 114191. [Google Scholar] [CrossRef]

- Askari, M.; Salarizadeh, P.; Seifi, M.; Rozati, S.M.; Beheshti-Marnani, A. Binary mixed molybdenum cobalt sulfide nanosheets decorated on rGO as a high-performance supercapacitor electrode. Nanotechnology 2020, 31, 275406. [Google Scholar] [CrossRef]

- Numan, A.; Duraisamy, N.; Omar, F.S.; Mahipal, Y.K.; Ramesh, K.; Ramesh, S. Enhanced electrochemical performance of cobalt oxide nanocube intercalated reduced graphene oxide for supercapacitor application. RSC Adv. 2016, 6, 34894–34902. [Google Scholar] [CrossRef]

- Lim, E.; Jo, C.; Kim, M.S.; Kim, M.-H.; Chun, J.; Kim, H.; Park, J.; Roh, K.C.; Kang, K.; Yoon, S.; et al. High-Performance Sodium-Ion Hybrid Supercapacitor Based on Nb2O5@Carbon Core-Shell Nanoparticles and Reduced Graphene Oxide Nanocomposites. Adv. Funct. Mater. 2016, 26, 3711–3719. [Google Scholar] [CrossRef]

- Yoon, Y.; Lee, M.; Kim, S.K.; Bae, G.; Song, W.; Myung, S.; Lim, J.; Lee, S.S.; Zyung, T.; An, K.-S. A Strategy for Synthesis of Carbon Nitride Induced Chemically Doped 2D MXene for High-Performance Supercapacitor Electrodes. Adv. Energy Mater. 2018, 8, 1703173. [Google Scholar] [CrossRef]

- Arul, N.S.; Han, J.I. Facile hydrothermal synthesis of hexapod-like two dimensional dichalcogenide NiSe2 for supercapacitor. Mater. Lett. 2016, 181, 345–349. [Google Scholar] [CrossRef]

- Zhao, J.; Jiang, Y.; Fan, H.; Liu, M.; Zhuo, O.; Wang, X.; Wu, Q.; Yang, L.; Ma, Y.; Hu, Z. Porous 3D Few-Layer Graphene-like Carbon for Ultrahigh-Power Supercapacitors with Well-Defined Structure-Performance Relationship. Adv. Mater. 2017, 29, 1604569. [Google Scholar] [CrossRef] [PubMed]

- Liu, T.; Zhang, L.; Cheng, B.; You, W.; Yu, J. Fabrication of a hierarchical NiO/C hollow sphere composite and its enhanced supercapacitor performance. Chem. Commun. 2018, 54, 3731–3734. [Google Scholar] [CrossRef] [PubMed]

- Liu, B.; Yang, M.; Chen, H.; Liu, Y.; Yang, D.; Li, H. Graphene-like porous carbon nanosheets derived from salvia splendens for high-rate performance supercapacitors. J. Power Sources 2018, 397, 1–10. [Google Scholar] [CrossRef]

| Samples | BET Specific Surface Area (m2 g−1) | Total Pore Volume (VT, cm3 g−1) | Mean Pore Diameter (nm) |

|---|---|---|---|

| MoS2 | 6.992 | 0.049 | 28.538 |

| Te | 10.513 | 0.027 | 10.426 |

| MoS2/Te | 18.212 | 0.110 | 24.286 |

| Composite Electrode | Electrolyte | Test Condition | Specific Capacitance | Capacitance Retention | Ref. |

|---|---|---|---|---|---|

| MoS2/rGO | 1 M H2SO4 | 0.5 A g−1 | 365 F g−1 | 83% after 5000 cycles | [47] |

| MoS2/rGO | 1 M Na2SO4 | 1 A g−1 | 198.6 F g−1 | – | [48] |

| MoS2/CoS2/rGO | 2 M KOH | 0.5 mA cm−2 | 190 mF cm−2 | 88.6% after 5000 cycles | [49] |

| rGO-Co3O4 | 1 M KOH | 200 mA g−1 | 278 F g−1 | 91.6% after 2000 cycles | [50] |

| Nb2O5@C/rGO | 1 M NaPF6 | 0.025 A g−1 | 285 mA h g−1 | 92% after 1000 cycles | [51] |

| MoS2 | 1 M Na2SO4 | 1 A g−1 | 138 F g−1 | 86% after 5000 cycles | [19] |

| p-C3N4-Ti2CTx | 6 M KOH | 1 A g−1 | 327 F g−1 | 96.2% after 5000 cycles | [52] |

| V2CTxMXene | Seawater | 0.2 A g−1 | 181.1 F g−1 | 89.1% after 5000 cycles | [49] |

| NiSe2 | 1 M KOH | 1 mA cm−2 | 75 F g−1 | 94% after 5000 cycles | [53] |

| MoS2/Te | 2 M KOH | 1 A g−1 | 402 F g−1 | 92.30% after 4000 cycles | This work |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Karki, H.P.; Kim, H.; Jung, J.; Oh, J. Synthesis of Molybdenum Sulfide/Tellurium Hetero-Composite by a Simple One-Pot Hydrothermal Technique for High-Performance Supercapacitor Electrode Material. Nanomaterials 2021, 11, 2346. https://doi.org/10.3390/nano11092346

Karki HP, Kim H, Jung J, Oh J. Synthesis of Molybdenum Sulfide/Tellurium Hetero-Composite by a Simple One-Pot Hydrothermal Technique for High-Performance Supercapacitor Electrode Material. Nanomaterials. 2021; 11(9):2346. https://doi.org/10.3390/nano11092346

Chicago/Turabian StyleKarki, Hem Prakash, Hyojae Kim, Jinmu Jung, and Jonghyun Oh. 2021. "Synthesis of Molybdenum Sulfide/Tellurium Hetero-Composite by a Simple One-Pot Hydrothermal Technique for High-Performance Supercapacitor Electrode Material" Nanomaterials 11, no. 9: 2346. https://doi.org/10.3390/nano11092346

APA StyleKarki, H. P., Kim, H., Jung, J., & Oh, J. (2021). Synthesis of Molybdenum Sulfide/Tellurium Hetero-Composite by a Simple One-Pot Hydrothermal Technique for High-Performance Supercapacitor Electrode Material. Nanomaterials, 11(9), 2346. https://doi.org/10.3390/nano11092346