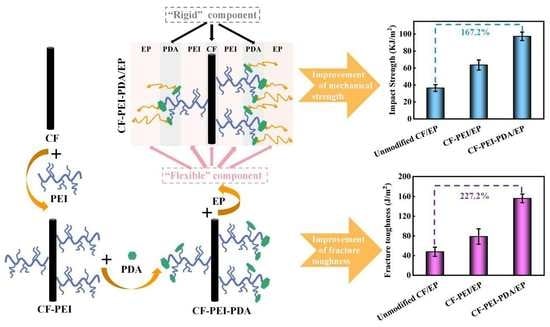

Constructing a Double Alternant “Rigid-Flexible” Structure for Simultaneously Strengthening and Toughening the Interface of Carbon Fiber/Epoxy Composites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Functionalized Fibers

2.2.1. Preparation of the CF-PEI

2.2.2. Preparation of CF-PEI-PDA

2.2.3. Preparation of Fiber/Epoxy Composite

2.3. Characterization

3. Results and Discussion

3.1. Surface Morphology of Carbon Fibers

3.2. Surface Structure and Chemical Composition of Carbon Fibers

3.3. Surface Wettability of Carbon Fibers

3.4. Interfacial Properties of CF/EP Composite

3.5. Mechanical Properties of the Composites

3.6. Dynamic Mechanical Thermal Properties of the Composites

3.7. Interface Analysis of the Composites

4. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Quan, D.; Bologna, F.; Scarselli, G.; Ivanković, A.; Murphy, N. Mode-II fracture behaviour of aerospace-grade carbon fibre/epoxy composites interleaved with thermoplastic veils. Compos. Sci. Technol. 2020, 191, 108065. [Google Scholar] [CrossRef]

- Frank, E.; Steudle, L.M.; Ingildeev, D.; Spörl, D.-C.J.M.; Buchmeiser, M.R. Carbon Fibers: Precursor Systems, Processing, Structure, and Properties. Angew. Chem. Int. Ed. 2014, 53, 5262–5298. [Google Scholar] [CrossRef]

- Wu, X.F.; Yarin, A.L. Recent progress in interfacial toughening and damage self-healing of polymer composites based on electrospun and solution-blown nanofibers: An overview. J. Appl. Polym. Sci. 2013, 130, 2225–2237. [Google Scholar] [CrossRef]

- Han, L.; Li, K.; Sun, J.; Song, Q.; Wang, Y. Reinforcing effects of carbon nanotube on carbon/carbon composites before and after heat treatment. Mater. Sci. Eng. A 2018, 735, 10–18. [Google Scholar] [CrossRef]

- Li, J.; Yang, Z.; Huang, X.; Zhao, Y.; Li, X.; Wei, W.; Li, H.; Wu, G. Interfacial reinforcement of composites by the electrostatic self-assembly of graphene oxide and NH3 plasma-treated carbon fiber. Appl. Surf. Sci. 2022, 585, 152717. [Google Scholar] [CrossRef]

- Jia, J.; Du, X.; Chen, C.; Sun, X.; Mai, Y.-W.; Kim, J.-K. 3D network graphene interlayer for excellent interlaminar toughness and strength in fiber reinforced composites. Carbon 2015, 95, 978–986. [Google Scholar] [CrossRef]

- Kessman, A.J.; Zhang, J.; Vasudevan, S.; Lou, J.; Sheldon, B.W. Carbon Nanotube Pullout, Interfacial Properties, and Toughening in Ceramic Nanocomposites: Mechanistic Insights from Single Fiber Pullout Analysis. Adv. Mater. Interfaces 2014, 2, 1400110. [Google Scholar] [CrossRef]

- De Luca, F.; Sernicola, G.; Shaffer, S.P.; Bismarck, A. “Brick-and-mortar” nanostructured interphase for glass-fiber-reinforced polymer composites. ACS Appl. Mater. Interfaces 2018, 10, 7352–7361. [Google Scholar] [CrossRef]

- Doineau, E.; Cathala, B.; Benezet, J.C.; Bras, J.; Le Moigne, N. European polysaccharide, Development of bio-inspired hierarchical fibres to tailor the fibre/matrix interphase in (bio) composites. Polymers 2021, 13, 804. [Google Scholar] [CrossRef]

- Song, Q.; Li, K.-Z.; Zhang, L.-L.; Qi, L.-H.; Li, H.-J.; Fu, Q.-G.; Deng, H.-L. Increasing mechanical strength retention rate of car-bon/carbon composites after graphitization by grafting straight carbon nanotubes radially onto carbon fibers. Mater. Sci. Eng. 2013, 560, 831–836. [Google Scholar] [CrossRef]

- Zhu, C.; Su, Y.; Zhang, D.; Ouyang, Q. Effect of Al2O3 coating thickness on microstructural characterization and mechanical properties of continuous carbon fiber reinforced aluminum matrix composites. Mater. Sci. Eng. A 2020, 793, 139839. [Google Scholar] [CrossRef]

- Wang, C.; Li, J.; Sun, S.; Li, X.; Zhao, F.; Jiang, B.; Huang, Y. Electrophoretic deposition of graphene oxide on continuous carbon fibers for reinforcement of both tensile and interfacial strength. Compos. Sci. Technol. 2016, 135, 46–53. [Google Scholar] [CrossRef]

- Tang, Z.; Kotov, N.; Magonov, S.N.; Ozturk, B. Nanostructured artificial nacre. Nat. Mater. 2003, 2, 413–418. [Google Scholar] [CrossRef] [PubMed]

- Feng, P.; Ma, L.; Wu, G.; Li, X.; Zhao, M.; Shi, L.; Wang, M.; Wang, X.; Song, G. Establishment of multistage gradient modulus intermediate layer between fiber and matrix via designing double “rigid-flexible” structure to improve interfacial and mechanical properties of carbon fiber/resin composites. Compos. Sci. Technol. 2020, 200, 108336. [Google Scholar] [CrossRef]

- Wu, Q.; Wan, Q.Q.; Liu, Q.L.; He, J.Q.; Zhao, R.Y.; Yang, X.; Wang, F.; Guo, J.; Zhu, J.F. Synergistic strengthening and toughening the interphase of composites by constructing alternating “rigid-and-soft” structure on carbon fiber surface. Adv. Mater. Interfaces 2019, 6, 1900970. [Google Scholar] [CrossRef]

- Yang, H.C.; Pi, J.K.; Liao, K.J.; Huang, H.; Wu, Q.Y.; Huang, X.J.; Xu, Z.K. Silica-decorated polypropylene microfiltration mem-branes with a mussel-inspired intermediate layer for oil-in-water emulsion separation. ACS Appl. Mater. Interfaces 2014, 6, 12566–12572. [Google Scholar] [CrossRef]

- Hong, S.; Schaber, C.F.; Dening, K.; Appel, E.; Gorb, S.N.; Lee, H. Air/Water Interfacial Formation of Freestanding, Stimuli-Responsive, Self-Healing Catecholamine Janus-Faced Microfilms. Adv. Mater. 2014, 26, 7581–7587. [Google Scholar] [CrossRef]

- Sun, T.; Li, M.X.; Zhou, S.T.; Liang, M.; Chen, Y.; Zou, H.W. Multi-scale structure construction of carbon fiber surface by electrophoretic deposition and electropolymerization to enhance the interfacial strength of epoxy resin composites. Appl. Surf. Sci. 2020, 499, 143929. [Google Scholar] [CrossRef]

- Barclay, T.G.; Hegab, H.M.; Clarke, S.R.; Ginic-Markovic, M. Versatile Surface Modification Using Polydopamine and Related Polycatecholamines: Chemistry, Structure, and Applications. Adv. Mater. Interfaces 2017, 4, 1601192. [Google Scholar] [CrossRef]

- Gao, B.; Du, W.; Hao, Z.; Zhou, H.; Zou, D.; Zhang, R. Bioinspired Modification via Green Synthesis of Mussel-Inspired Nanoparticles on Carbon Fiber Surface for Advanced Composite Materials. ACS Sustain. Chem. Eng. 2018, 7, 5638–5648. [Google Scholar] [CrossRef]

- Jin, L.; He, Y.L.; Shang, L.; Liu, L.; Zhang, M.J.; Li, M.; Ao, Y.H. Superior and versatile interface transition layer with a sand-wich-like multiscale rigid-soft dual-locked structure for high performance composites. Appl. Surf. Sci. 2020, 508, 145238. [Google Scholar] [CrossRef]

- Wu, Q.; Wan, Q.; Yang, X.; Wang, F.; Zhu, J. Effects of chain length of polyether amine on interfacial adhesion of carbon fiber/epoxy composite in the absence or presence of polydopamine bridging platform. Appl. Surf. Sci. 2021, 547, 149162. [Google Scholar] [CrossRef]

- Han, P.; Ma, L.; Song, G.; Shi, L.; Gu, Z.; Li, X.; Yang, C.; Wang, G. Strengthening and Modulating Interphases in Carbon Fiber/Epoxy Composites by Grafting Dendritic Polyetheramine With Different Molecular Weights Onto Carbon Fiber. Polym. Compos. 2018, 40, e1525–e1536. [Google Scholar] [CrossRef]

- Yang, X.; Du, H.; Li, S.; Wang, Z.X.; Shao, L. Codepositing Mussel-Inspired Nanohybrids onto One-Dimensional Fibers under “Green” Conditions for Significantly Enhanced Surface/Interfacial Properties. ACS Sustain. Chem. Eng. 2018, 6, 4412–4420. [Google Scholar] [CrossRef]

- Zhang, L.; Li, Z.; Pan, Y.-T.; Yáñez, A.P.; Hu, S.; Zhang, X.-Q.; Wang, R.; Wang, D.-Y. Polydopamine induced natural fiber surface functionalization: A way towards flame retardancy of flax/poly(lactic acid) biocomposites. Compos. Part B Eng. 2018, 154, 56–63. [Google Scholar] [CrossRef]

- Hao, R.T.; Jiao, X.W.; Zhang, X.J.; Tian, Y.H. Fe3O4/graphene modified waterborne polyimide sizing agent for high modulus carbon fiber. Appl. Surf. Sci. 2019, 485, 304–313. [Google Scholar] [CrossRef]

- Gu, B.; Pu, G.; Ding, B.; Zhang, K.; He, R.; Fan, J.; Xing, T.; Wu, J.; Yang, W. Improved interfacial bonding strength of silicone rubber/carbon fiber modified by dopamine. Polym. Compos. 2022, 11, 1639. [Google Scholar] [CrossRef]

- Rosenthal, D.; Ruta, M.; Schlögl, R.; Kiwi-Minsker, L. Combined XPS and TPD study of oxygen-functionalized carbon nanofibers grown on sintered metal fibers. Carbon 2010, 48, 1835–1843. [Google Scholar] [CrossRef]

- Zhao, M.; Meng, L.; Ma, L.; Wu, G.; Xie, F.; Ma, L.; Wang, W.; Jiang, B.; Huang, Y. Stepwise growth of melamine-based dendrimers onto carbon fibers and the effects on interfacial properties of epoxy composites. Compos. Sci. Technol. 2016, 138, 144–150. [Google Scholar] [CrossRef]

- Ma, L.; Meng, L.; Wu, G.; Wang, Y.; Zhao, M.; Zhang, C.; Huang, Y. Improving the interfacial properties of carbon fiber-reinforced epoxy composites by grafting of branched polyethyleneimine on carbon fiber surface in supercritical methanol. Compos. Sci. Technol. 2015, 114, 64–71. [Google Scholar] [CrossRef]

- Xu, N.; Li, Y.; Zheng, T.; Xiao, L.; Liu, Y.; Chen, S.; Zhang, D. A mussel-inspired strategy for CNT/carbon fiber reinforced epoxy composite by hierarchical surface modification. Colloids Surf. A Physicochem. Eng. Asp. 2021, 635, 128085. [Google Scholar] [CrossRef]

- Liu, S.; Yao, F.; Oderinde, O.K.; Li, K.; Wang, H.; Zhang, Z.; Fu, G. Zinc ions enhanced nacre-like chitosan/graphene oxide composite film with superior mechanical and shape memory properties. Chem. Eng. J. 2017, 321, 502–509. [Google Scholar] [CrossRef]

- Song, P.G.; Xu, Z.G.; Wu, Y.P.; Cheng, Q.F.; Guo, Q.P.; Wang, H. Super-tough artificial nacre based on graphene oxide via synergistic interface interactions of π-π stacking and hydrogen bonding. Carbon 2017, 111, 807–812. [Google Scholar] [CrossRef]

- Rahman, M.M.; Zainuddin, S.; Hosur, M.V.; Malone, J.E.; Salam, M.B.A.; Kumar, A. Improvements in mechanical and thermo-mechanical properties of e-glass/epoxy composites using amino functionalized MWCNTs. Compos. Struct. 2012, 94, 2397–2406. [Google Scholar] [CrossRef]

- Wan, Y.-J.; Gong, L.-X.; Tang, L.-C.; Wu, L.-B.; Jiang, J.-X. Mechanical properties of epoxy composites filled with silane-functionalized graphene oxide. Compos. Part A Appl. Sci. Manuf. 2014, 64, 79–89. [Google Scholar] [CrossRef]

- Wu, D.; Yao, Z.; Sun, X.; Liu, X.; Liu, L.; Zhang, R.; Wang, C. Mussel-tailored carbon fiber/carbon nanotubes interface for elevated interfacial properties of carbon fiber/epoxy composites. Chem. Eng. J. 2021, 429, 132449. [Google Scholar] [CrossRef]

- Wu, Q.; Yang, X.; Wan, Q.; Zhao, R.; He, J.; Zhu, J. Layer-by-layer assembled nacre-like polyether amine/GO hierarchical structure on carbon fiber surface toward composites with excellent interfacial strength and toughness. Compos. Sci. Technol. 2020, 198, 108296. [Google Scholar] [CrossRef]

- Han, W.; Zhang, H.-P.; Tavakoli, J.; Campbell, J.; Tang, Y. Polydopamine as sizing on carbon fiber surfaces for enhancement of epoxy laminated composites. Compos. Part A Appl. Sci. Manuf. 2018, 107, 626–632. [Google Scholar] [CrossRef]

- Wu, Q.; He, J.; Wang, F.; Yang, X.; Zhu, J. Constructing a simple anti-sandwich structure on carbon fiber surface for simultaneously strengthening and toughening the interphase of epoxy composites. Compos. Struct. 2020, 240, 112075. [Google Scholar] [CrossRef]

| Samples | D | G | A | ID/IG | IA/IG |

|---|---|---|---|---|---|

| W (cm−1) | W (cm−1) | W (cm−1) | |||

| Unmodified CF | 1360 | 1600 | 1505 | 1.65 | 0.21 |

| CF-COOH | 1360 | 1600 | 1524 | 1.76 | 0.24 |

| CF-PEI | 1358 | 1596 | 1524 | 1.82 | 0.25 |

| CF-PEI-PDA | 1374 | 1603 | 1524 | 1.93 | 0.33 |

| Scheme | Element Composition (%) | ||||

|---|---|---|---|---|---|

| C1s | O1s | N1s | N/C | O/C | |

| Unmodified CF | 93.71 | 4.49 | 1.80 | 1.92 | 4.79 |

| CF-PEI | 73.22 | 17.68 | 9.10 | 12.43 | 24.15 |

| CF-PEI-PDA | 67.84 | 21.79 | 10.37 | 15.29 | 32.12 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, S.; Han, P.; Yang, L.; Hu, S.; Wang, J.; Gu, Z. Constructing a Double Alternant “Rigid-Flexible” Structure for Simultaneously Strengthening and Toughening the Interface of Carbon Fiber/Epoxy Composites. Nanomaterials 2022, 12, 3056. https://doi.org/10.3390/nano12173056

Zhang S, Han P, Yang L, Hu S, Wang J, Gu Z. Constructing a Double Alternant “Rigid-Flexible” Structure for Simultaneously Strengthening and Toughening the Interface of Carbon Fiber/Epoxy Composites. Nanomaterials. 2022; 12(17):3056. https://doi.org/10.3390/nano12173056

Chicago/Turabian StyleZhang, Susu, Ping Han, Lina Yang, Shaokai Hu, Jianfa Wang, and Zheng Gu. 2022. "Constructing a Double Alternant “Rigid-Flexible” Structure for Simultaneously Strengthening and Toughening the Interface of Carbon Fiber/Epoxy Composites" Nanomaterials 12, no. 17: 3056. https://doi.org/10.3390/nano12173056

APA StyleZhang, S., Han, P., Yang, L., Hu, S., Wang, J., & Gu, Z. (2022). Constructing a Double Alternant “Rigid-Flexible” Structure for Simultaneously Strengthening and Toughening the Interface of Carbon Fiber/Epoxy Composites. Nanomaterials, 12(17), 3056. https://doi.org/10.3390/nano12173056