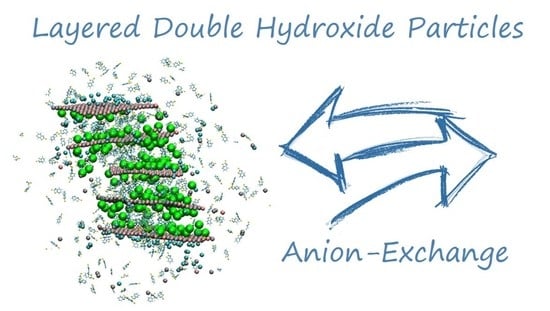

Molecular Dynamics Model to Explore the Initial Stages of Anion Exchange involving Layered Double Hydroxide Particles

Abstract

:1. Introduction

2. Computational Methodology

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Galvão, T.L.P.; Wilhelm, M.; Gomes, J.R.B.; Tedim, J. Emerging trends in smart nanocontainers for corrosion applications. Smart Nanocontainers 2020, 22, 385–398. [Google Scholar] [CrossRef]

- Thyveetil, M.-A.; Coveney, P.V.; Greenwell, H.C.; Suter, J.L. Role of host layer flexibility in DNA guest intercalation revealed by computer simulation of layered nanomaterials. J. Am. Chem. Soc. 2008, 130, 12485–12495. [Google Scholar] [CrossRef] [PubMed]

- Evans, D.G.; Slade, R.C.T. Structural Aspects of Layered Double Hydroxides. Struct. Bond. 2006, 119, 1–87. [Google Scholar] [CrossRef]

- Galvão, T.L.P.; Neves, C.S.; Caetano, A.P.F.; Maia, F.; Mata, D.; Malheiro, E.; Ferreira, M.J.; Bastos, A.C.; Salak, A.N.; Gomes, J.R.B.; et al. Control of crystallite and particle size in the synthesis of layered double hydroxides: Macromolecular insights and a complementary modeling tool. J. Colloid Interface Sci. 2016, 468, 86–94. [Google Scholar] [CrossRef] [PubMed]

- Galvão, T.L.P.; Neves, C.S.; Zheludkevich, M.L.; Gomes, J.R.B.; Tedim, J.; Ferreira, M.G.S. How Density Functional Theory Surface Energies May Explain the Morphology of Particles, Nanosheets, and Conversion Films Based on Layered Double Hydroxides. J. Phys. Chem. C 2017, 121, 2211–2220. [Google Scholar] [CrossRef] [Green Version]

- Pérez-Sánchez, G.; Galvão, T.L.P.; Tedim, J.; Gomes, J.R.B. A molecular dynamics framework to explore the structure and dynamics of layered double hydroxides. Appl. Clay Sci. 2018, 163, 164–177. [Google Scholar] [CrossRef]

- Novell-Leruth, G.; Pérez-Sánchez, G.; Galvão, T.L.P.; Boiba, D.; Poznyak, S.; Carneiro, J.; Tedim, J.; Gomes, J.R.B. Unveiling the local structure of 2-mercaptobenzothiazole intercalated in (Zn2Al) layered double hydroxides. Appl. Clay Sci. 2020, 198, 105842. [Google Scholar] [CrossRef]

- Lu, Z.; Qian, L.; Tian, Y.; Li, Y.; Sun, X.; Duan, X. Ternary NiFeMn layered double hydroxides as highly-efficient oxygen evolution catalysts. Chem. Commun. 2016, 52, 908–911. [Google Scholar] [CrossRef]

- Lu, Y.; Jiang, B.; Fang, L.; Ling, F.; Gao, J.; Wu, F.; Zhang, X. High performance NiFe layered double hydroxide for methyl orange dye and Cr(VI) adsorption. Chemosphere 2016, 152, 415–422. [Google Scholar] [CrossRef]

- Yan, Z.; Zhu, B.; Yu, J.; Xu, Z. Effect of calcination on adsorption performance of Mg–Al layered double hydroxide prepared by a water-in-oil microemulsion method. RSC Adv. 2016, 6, 50128–50137. [Google Scholar] [CrossRef]

- Li, L.; Gu, Z.; Gu, W.; Liu, J.; Xu, Z.P. Efficient drug delivery using SiO 2 -layered double hydroxide nanocomposites. J. Colloid Interface Sci. 2016, 470, 47–55. [Google Scholar] [CrossRef] [Green Version]

- Senapati, S.; Thakur, R.; Verma, S.P.; Duggal, S.; Mishra, D.P.; Das, P.; Shripathi, T.; Kumar, M.; Rana, D.; Maiti, P. Layered double hydroxides as effective carrier for anticancer drugs and tailoring of release rate through interlayer anions. J. Control. Release 2016, 224, 186–198. [Google Scholar] [CrossRef]

- Yokoi, T.; Hara, M.; Seki, T.; Terasaka, S.; Kamitakahara, M.; Matsubara, H. Synthesis of layered double hydroxide coatings with an oriented structure and controllable thickness on aluminium substrates. CrystEngComm 2016, 18, 1207–1214. [Google Scholar] [CrossRef]

- Wilhelm, M.; Quevedo, M.C.; Sushkova, A.; Galvão, T.L.P.; Bastos, A.; Ferreira, M.; Tedim, J. Hexacyanoferrate-Intercalated Layered Double Hydroxides as Nanoadditives for the Detection of Early-Stage Corrosion of Steel: The Revival of Prussian blue. Eur. J. Inorg. Chem. 2020, 2020, 2063–2073. [Google Scholar] [CrossRef]

- Tedim, J.; Zheludkevich, M.L.; Salak, A.N.; Lisenkov, A.; Ferreira, M.G.S. Nanostructured LDH-container layer with active protection functionality. J. Mater. Chem. 2011, 21, 15464–15470. [Google Scholar] [CrossRef]

- Tedim, J.; Kuznetsova, A.; Salak, A.N.; Montemor, F.; Snihirova, D.; Pilz, M.; Zheludkevich, M.L.; Ferreira, M.G.S. Zn–Al layered double hydroxides as chloride nanotraps in active protective coatings. Corros. Sci. 2012, 55, 1–4. [Google Scholar] [CrossRef]

- Kang, H.; Kim, H.-J.; Yang, J.-H.; Kim, T.-H.; Choi, G.; Paek, S.-M.; Choi, A.-J.; Choy, J.-H.; Oh, J.-M. Intracrystalline structure and release pattern of ferulic acid intercalated into layered double hydroxide through various synthesis routes. Appl. Clay Sci. 2015, 112–113, 32–39. [Google Scholar] [CrossRef]

- Tedim, J.; Poznyak, S.K.; Kuznetsova, A.; Raps, D.; Hack, T.; Zheludkevich, M.L.; Ferreira, M.G.S. Enhancement of Active Corrosion Protection via Combination of Inhibitor-Loaded Nanocontainers. ACS Appl. Mater. Interfaces 2010, 2, 1528–1535. [Google Scholar] [CrossRef]

- Ma, L.; Qiang, Y.; Zhao, W. Designing novel organic inhibitor loaded MgAl-LDHs nanocontainer for enhanced corrosion resistance. Chem. Eng. J. 2021, 408, 127367. [Google Scholar] [CrossRef]

- Zhu, F.; Wang, L.; Liao, S.; Zhu, Y.; Luo, W.; Huang, X.; Jiao, F.; Chen, X. Co-assembly of exfoliated Mg/Al layered double hydroxides nanosheets with sulfobutyl ether-β-cyclodextrin for enantioseparation of racemic propranolol. Appl. Clay Sci. 2018, 162, 138–145. [Google Scholar] [CrossRef]

- Zhu, S.; Khan, M.A.; Kameda, T.; Xu, H.; Wang, F.; Xia, M.; Yoshioka, T. New insights into the capture performance and mechanism of hazardous metals Cr3+ and Cd2+ onto an effective layered double hydroxide based material. J. Hazard. Mater. 2022, 426, 128062. [Google Scholar] [CrossRef] [PubMed]

- Tavares, S.R.; Haddad, J.F.S.; Moraes, P.I.; Leitão, A.A. Computational exploration of the anion exchange on the basal surface of layered double hydroxides by molecular dynamics. Appl. Surf. Sci. 2020, 513, 145743. [Google Scholar] [CrossRef]

- Pšenička, M.; Škoda, J.; Pospíšil, M. Structural arrangement and properties of layered double hydroxide drug nanocarrier intercalated by sulindac and mefenamic acid solved by molecular simulation methods. Appl. Clay Sci. 2020, 189, 105560. [Google Scholar] [CrossRef]

- Li, X.; Würger, T.; Feiler, C.; Meißner, R.H.; Serdechnova, M.; Blawert, C.; Zheludkevich, M.L. Atomistic Insight into the Hydration States of Layered Double Hydroxides. ACS Omega 2022, 7, 12412–12423. [Google Scholar] [CrossRef]

- Galvão, T.L.P.; Sousa, I.; Wilhelm, M.; Carneiro, J.; Opršal, J.; Kukačková, H.; Špaček, V.; Maia, F.; Gomes, J.R.B.; Tedim, J.; et al. Improving the Functionality and Performance of AA2024 Corrosion Sensing Coatings with Nanocontainers. Chem. Eng. J. 2018, 341, 526–538. [Google Scholar] [CrossRef] [Green Version]

- Galvão, T.L.P.; Kuznetsova, A.; Gomes, J.R.B.; Zheludkevich, M.L.; Tedim, J.; Ferreira, M.G.S. A computational UV–Vis spectroscopic study of the chemical speciation of 2-mercaptobenzothiazole corrosion inhibitor in aqueous solution. Theor. Chem. Acc. 2016, 135, 78. [Google Scholar] [CrossRef] [Green Version]

- Abraham, M.J.; Murtola, T.; Schulz, R.; Páll, S.; Smith, J.C.; Hess, B.; Lindahl, E. GROMACS: High performance molecular simulations through multi-level parallelism from laptops to supercomputers. SoftwareX 2015, 1–2, 19–25. [Google Scholar] [CrossRef] [Green Version]

- Hockney, R.; Goel, S.; Eastwood, J. Quiet high-resolution computer models of a plasma. J. Comput. Phys. 1974, 14, 148–158. [Google Scholar] [CrossRef]

- Essmann, U.; Perera, L.; Berkowitz, M.L.; Darden, T.; Lee, H.; Pedersen, L.G. A smooth particle mesh Ewald method. J. Chem. Phys. 1995, 103, 8577–8593. [Google Scholar] [CrossRef] [Green Version]

- Hess, B.; Bekker, H.; Berendsen, H.J.C.; Fraaije, J.G.E.M. LINCS: A linear constraint solver for molecular simulations. J. Comput. Chem. 1997, 18, 1463–1472. [Google Scholar] [CrossRef]

- Hoover, W.G. Canonical dynamics: Equilibrium phase-space distributions. Phys. Rev. A 1985, 31, 1695–1697. [Google Scholar] [CrossRef] [Green Version]

- Nosé, S. A unified formulation of the constant temperature molecular dynamics methods. J. Chem. Phys. 1984, 81, 511–519. [Google Scholar] [CrossRef] [Green Version]

- Berendsen, H.J.C.; Postma, J.P.M.; van Gunsteren, W.F.; DiNola, A.; Haak, J.R. Molecular dynamics with coupling to an external bath. J. Chem. Phys. 1984, 81, 3684–3690. [Google Scholar] [CrossRef] [Green Version]

- Parrinello, M.; Rahman, A. Polymorphic transitions in single crystals: A new molecular dynamics method. J. Appl. Phys. 1981, 52, 7182–7190. [Google Scholar] [CrossRef]

- Cygan, R.T.; Liang, J.-J.; Kalinichev, A.G. Molecular Models of Hydroxide, Oxyhydroxide, and Clay Phases and the Development of a General Force Field. J. Phys. Chem. B 2004, 108, 1255–1266. [Google Scholar] [CrossRef]

- Berendsen, H.J.C.; Grigera, J.R.; Straatsma, T.P. The missing term in effective pair potentials. J. Phys. Chem. 1987, 91, 6269–6271. [Google Scholar] [CrossRef]

- Mark, P.; Nilsson, L. Structure and Dynamics of the TIP3P, SPC, and SPC/E Water Models at 298 K. J. Phys. Chem. A 2001, 105, 9954–9960. [Google Scholar] [CrossRef]

- Malde, A.K.; Zuo, L.; Breeze, M.; Stroet, M.; Poger, D.; Nair, P.C.; Oostenbrink, C.; Mark, A.E. An Automated Force Field Topology Builder (ATB) and Repository: Version 1.0. J. Chem. Theory Comput. 2011, 7, 4026–4037. [Google Scholar] [CrossRef]

- Schmid, N.; Eichenberger, A.P.; Choutko, A.; Riniker, S.; Winger, M.; Mark, A.E.; van Gunsteren, W.F. Definition and testing of the GROMOS force-field versions 54A7 and 54B7. Eur. Biophys. J. 2011, 40, 843–856. [Google Scholar] [CrossRef]

- Debye, P. Zerstreuung von Röntgenstrahlen. Ann. Phys. 1915, 351, 809–823. [Google Scholar] [CrossRef]

- Iwasa, T.; Nobusada, K. Theoretical Investigation of Optimized Structures of Thiolated Gold Cluster [Au25 (SCH3)18]+. Phys. Chem. C 2007, 25, 45–49. [Google Scholar] [CrossRef]

- Pedregosa, F.; Varoquaux, G.; Gramfort, A.; Michel, V.; Thirion, B.; Grisel, O.; Blondel, M.; Prettenhofer, P.; Weiss, R.; Dubourg, V.; et al. Scikit-learn: Machine Learning in Python. J. Mach. Learn. Res. 2011, 12, 2825–2830. [Google Scholar]

- Virtanen, P.; Gommers, R.; Oliphant, T.E.; Haberland, M.; Reddy, T.; Cournapeau, D.; Burovski, E.; Peterson, P.; Weckesser, W.; Bright, J.; et al. SciPy 1.0: Fundamental algorithms for scientific computing in Python. Nat. Methods 2020, 17, 261–272. [Google Scholar] [CrossRef] [Green Version]

- Barber, C.B.; Dobkin, D.P.; Huhdanpaa, H. The quickhull algorithm for convex hulls. ACM Trans. Math. Softw. 1996, 22, 469–483. [Google Scholar] [CrossRef] [Green Version]

- Dellostritto, M.J.; Thenuwara, A.C.; Klein, M.L.; Strongin, D.R. Effect of Interlayer Co2+ on Structure and Charge Transfer in NiFe Layered Double Hydroxides. J. Phys. Chem. C 2019, 123, 13593–13599. [Google Scholar] [CrossRef]

- Thyveetil, M.-A.; Coveney, P.V.; Suter, J.L.; Greenwell, H.C. Emergence of Undulations and Determination of Materials Properties in Large-Scale Molecular Dynamics Simulation of Layered Double Hydroxides. Chem. Mater. 2007, 19, 5510–5523. [Google Scholar] [CrossRef]

- Hibino, T.; Jones, W. New approach to the delamination of layered double hydroxides. J. Mater. Chem. 2001, 11, 1321–1323. [Google Scholar] [CrossRef]

- Adachi-Pagano, M.; Forano, C.; Besse, J.P. Delamination of layered double hydroxides by use of surfactants. Chem. Commun. 2000, 1, 91–92. [Google Scholar] [CrossRef]

- Salak, A.N.; Tedim, J.; Kuznetsova, A.I.; Zheludkevich, M.L.; Ferreira, M.G.S. Anion exchange in Zn–Al layered double hydroxides: In situ X-ray diffraction study. Chem. Phys. Lett. 2010, 495, 73–76. [Google Scholar] [CrossRef]

- Carneiro, J.; Caetano, A.F.; Kuznetsova, A.; Maia, F.; Salak, A.N.; Tedim, J.; Scharnagl, N.; Zheludkevich, M.L.; Ferreira, M.G.S. Polyelectrolyte-modified layered double hydroxide nanocontainers as vehicles for combined inhibitors. RSC Adv. 2015, 5, 39916–39929. [Google Scholar] [CrossRef] [Green Version]

- Ghazanfari, S.; Faisal, H.M.N.; Katti, K.S.; Katti, D.R.; Xia, W. A Coarse-Grained Model for the Mechanical Behavior of Na-Montmorillonite Clay. Langmuir 2022, 38, 4859–4869. [Google Scholar] [CrossRef]

- Iuzviuk, M.H.; Bouali, A.C.; Serdechnova, M.; Yasakau, K.A.; Wieland, D.C.F.; Dovzhenko, G.; Mikhailau, A.; Blawert, C.; Zobkalo, I.A.; Ferreira, M.G.S.; et al. In situ kinetics studies of Zn–Al LDH intercalation with corrosion related species. Phys. Chem. Chem. Phys. 2020, 22, 17574–17586. [Google Scholar] [CrossRef]

- Alibakhshi, E.; Ghasemi, E.; Mahdavian, M.; Ramezanzadeh, B.; Yasaei, M. The effect of interlayer spacing on the inhibitor release capability of layered double hydroxide based nanocontainers. J. Clean. Prod. 2020, 251, 119676. [Google Scholar] [CrossRef]

| Model | Zn(2)Al-NO3 | Zn(2)Al-MBT |

|---|---|---|

| LDH | 500 | 500 |

| NO3− | 400 | |

| MBT− | 400 | |

| Water * | 800/80,252 | 1800/79,252 |

| Cl- | 500 | 500 |

| Na+ | 400 | 400 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Novell Leruth, G.; Kuznetsova, A.; Tedim, J.; Gomes, J.R.B.; Galvão, T.L.P. Molecular Dynamics Model to Explore the Initial Stages of Anion Exchange involving Layered Double Hydroxide Particles. Nanomaterials 2022, 12, 4039. https://doi.org/10.3390/nano12224039

Novell Leruth G, Kuznetsova A, Tedim J, Gomes JRB, Galvão TLP. Molecular Dynamics Model to Explore the Initial Stages of Anion Exchange involving Layered Double Hydroxide Particles. Nanomaterials. 2022; 12(22):4039. https://doi.org/10.3390/nano12224039

Chicago/Turabian StyleNovell Leruth, Gerard, Alena Kuznetsova, João Tedim, José R. B. Gomes, and Tiago L. P. Galvão. 2022. "Molecular Dynamics Model to Explore the Initial Stages of Anion Exchange involving Layered Double Hydroxide Particles" Nanomaterials 12, no. 22: 4039. https://doi.org/10.3390/nano12224039

APA StyleNovell Leruth, G., Kuznetsova, A., Tedim, J., Gomes, J. R. B., & Galvão, T. L. P. (2022). Molecular Dynamics Model to Explore the Initial Stages of Anion Exchange involving Layered Double Hydroxide Particles. Nanomaterials, 12(22), 4039. https://doi.org/10.3390/nano12224039