Influence of Some Spaghetti Processing Variables on Technological Attributes and the In Vitro Digestion of Starch

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Analytical Methods

2.3. Spaghetti Preparation and Assessment

2.4. In vitro Starch Digestion of Spaghetti

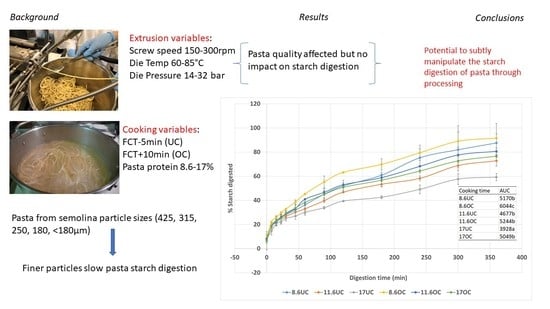

2.5. Experimental Trials

2.5.1. Effect of Transglutaminase (TG) Addition in Pasta Making on Technological Quality and Spaghetti Starch Digestion

2.5.2. Effect of Spaghetti Cooking Time on Starch Digestion

2.5.3. Effect of Spaghetti Storage Conditions after Cooking on Starch Digestion

2.5.4. Effect of Spaghetti Extrusion Conditions on Starch Digestion and Technological Quality

- (1)

- Feed rate: the dry mix was fed into the twin screw feeder at various rates 40, 44, 36, 32 g/min.

- (2)

- Screw speed: The extruder screw speed was varied 150, 200, 250 and 300 rpm (using a feed rate of 40 g/min).

- (3)

- Die temperature: 61, 70, 75 and 85 °C (using feed rate of 40g/min and screw speed 200 rpm).

- (4)

- Die pressure: 14, 22, 28 and 32 bar (using feed rate of 40 g/min, die temperature 54–60 °C and screw speed 200 rpm).

2.5.5. Effect of Semolina Particle Size on Spaghetti Technological Quality and Starch Digestion

2.6. Statistical Analyses

3. Results and Discussion

3.1. Effect of Semolina Particle Size on Spaghetti Technological Quality and Starch Digestion

3.2. Effect of Spaghetti Extrusion Conditions on Starch Digestion and Technological Quality

3.3. Effect of Transglutaminase (TG) Addition in Pasta Making on Technological Quality and Spaghetti Starch Digestion

3.4. Effect of Spaghetti Cooking Time on Starch Digestion

3.5. Effect of Spaghetti Storage Conditions after Cooking on Starch Digestion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sissons, M. Pasta. In Encyclopedia of Food Grains, 2nd ed.; Wrigley, C., Corke, H., Seetharaman, K., Faubion, J., Eds.; Academic Press: Oxford, UK, 2016; pp. 79–89. [Google Scholar]

- Di Pede, G.; Dodi, R.; Scarpa, C.; Brighenti, F.; Dall’Asta, M.; Scazzina, F. Glycemic index values of pasta products: An Overview. Foods 2021, 10, 2541. [Google Scholar] [CrossRef] [PubMed]

- Brand-Millar, J.C.; Hayne, S.; Petocz, P.; Colagiuri, S. Low-glycemic index diets in the management of diabetes A me-ta-analysis of randomized controlled trials. Diabetes Care 2003, 26, 2261–2267. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, M.; Zhu, K.-X.; Guo, X.-N.; Brijs, K.; Zhou, H.-M. Natural additives in wheat-based pasta and noodle products: Op-portunities for enhanced nutritional and functional properties. Compr. Rev. Food Sci. Food Saf. 2014, 13, 347–357. [Google Scholar] [CrossRef] [PubMed]

- Sissons, M. Development of Novel Pasta Products with Evidence Based Impacts on Health—A Review. Foods 2022, 11, 123. [Google Scholar] [CrossRef] [PubMed]

- Edwards, C.H.; Cochetel, N.; Setterfield, L.; Perez-Moral, N.; Warren, F.J. A single-enzyme system for starch digestibility screening and its relevance to understanding and predicting the glycaemic index of food products. Food Funct. 2019, 10, 4751–4760. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gruber, W.; Sarkar, A. Durum wheat milling. In Durum Wheat Chemistry and Technology, 2nd ed.; Sissons, M., Abecassis, J., Marchylo, B., Carcea, M., Eds.; AACC International Press: St. Paul, MN, USA, 2012; pp. 139–160. [Google Scholar]

- Abecassis, J.; Abbou, R.; Chaurand, M.; Morel, M.H.; Vernoux, P. Influence of extrusion conditions on extrusion speed, temperature, and pressure in the extruder and on pasta quality. Cereal Chem. 1994, 71, 247–253. [Google Scholar]

- Petitot, M.; Abecassis, J.; Micard, V. Structuring of pasta components during processing: Impact on starch and protein digestibility and allergenicity. Trends Food Sci. 2009, 20, 521–532. [Google Scholar] [CrossRef]

- Zou, W.; Sissons, M.; Gidley, M.; Gilbert, R.; Warren, F. Combined techniques for characterising pasta structure reveals how the gluten network slows enzymic digestion rate. Food Chem. 2015, 188, 559–568. [Google Scholar] [CrossRef] [Green Version]

- Singh, J.; Dartois, A.; Kaur, L. Starch digestibility in food matrix: A review. Trends in Journal Food Science. Technology 2010, 21, 168–180. [Google Scholar]

- Cunin, C.; Handschin, S.; Walther, P.; Escher, F. Structural changes of starch during cooking of durum wheat pasta. Le-Bensmittel-Wiss. Und-Technol. 1995, 28, 323–328. [Google Scholar] [CrossRef]

- Sissons, M.J.; Gianibelli, M.C.; Batey, I.L. Small-scale reconstitution of durum Semolina components. Cereal Chem. 2002, 79, 675–680. [Google Scholar] [CrossRef]

- American Association of Cereal Chemists. Approved Methods of the AACCI Methods 44-15A, 66-51.01, 66-52.01, 11th ed.; American Association of Cereal Chemists: St. Paul, MN, USA, 2010. [Google Scholar]

- Sissons, M.; Ovenden, B.; Adorada, D.; Milgate, A. Durum wheat quality in high input irrigation systems in south eastern Australia. Crop Pasture Sci. 2014, 65, 411–422. [Google Scholar] [CrossRef]

- Alzuwaid, N.T.; Pleming, D.; Fellows, C.M.; Sissons, M. Fortification of durum wheat spaghetti and common wheat bread with wheat bran protein concentrate-impacts on nutrition and technological properties. Food Chem. 2021, 334, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Sissons, M.J.; Aravind, N.; Fellows, C.M. Quality of fibre-enriched spaghetti containing microbial transglutaminase. Cereal Chem. 2010, 87, 57–64. [Google Scholar] [CrossRef]

- Sissons, M.; Cutillo, S.; Marcotuli, I.; Gadaleta, A. Impact of durum wheat protein content on spaghetti in vitro starch digestion and technological properties. J. Cereal Sci. 2021, 98, 103156. [Google Scholar] [CrossRef]

- Cañas, S.; Perez-Morala, N.; Edwards, C.H. Effect of cooking, 24 h cold storage, microwave reheating, and particle size on in vitro starch digestibility of dry and fresh pasta. Food Funct. 2020, 11, 6265–6272. [Google Scholar] [CrossRef]

- Aravind, N.; Sissons, M.; Fellows, C.M. Can variation in durum wheat pasta protein and starch composition affect in vitro starch hydrolysis? Food Chem. 2010, 124, 816–821. [Google Scholar] [CrossRef]

- Granfeldt, Y.; Bjorck, I.; Hagander, B. On the importance of processing conditions, product thickness and egg addition for the glycemic and hormonal responses to pasta e a comparison with bread made from pasta ingredients. Eur. J. Clin. Nutr. 1991, 45, 489–499. [Google Scholar]

- Ma, S.; Wang, C.; Li, L.; Wang, X. Effects of particle size on the quality attributes of wheat flour made by the milling process. Cereal Chem. 2020, 97, 172–182. [Google Scholar] [CrossRef]

- Hatcher, D.W.; Edwards, N.M.; Dexter, J.E. Effects of particle size and starch damage of flour and alkaline reagent on yellow alkaline noodle characteristics. Cereal Chem. 2008, 85, 425–532. [Google Scholar] [CrossRef]

- Niu, M.; Hou, G.G.; Wang, L.; Chen, Z. Effects of superfine grinding on the quality characteristics of whole-wheat flour and its raw noodle product. J. Cereal Sci. 2014, 60, 382–388. [Google Scholar] [CrossRef]

- Sacchettia, G.; Cocco, G.; Cocco, D.; Neri, L.; Mastrocola, D. Effect of semolina particle size on the cooking kinetics and quality of spaghetti. Procedia Food Sci. 2011, 1, 1740–1745. [Google Scholar] [CrossRef] [Green Version]

- Fu, B.X.; Wang, K.; Dupuis, B.; Taylor, D.; Nam, S. Kernel vitreousness and protein content: Relationship, interaction and synergistic effects on durum wheat quality. J. Cereal Sci. 2018, 79, 210–217. [Google Scholar] [CrossRef]

- Rakhesh, N.; Fellows, C.F.; Sissons, M. Evaluation of the technological and sensory properties of durum wheat spaghetti enriched with different dietary fibres. J. Sci. Food Agric. 2014, 95, 2–11. [Google Scholar] [CrossRef]

- Debbouz, A.; Doetkott, C. Effect of process variables on spaghetti quality. Cereal Chem. 1996, 73, 672–676. [Google Scholar]

- Cutillo, S.; Farahnaky, A.; Marcotuli, I.; Gadaleta, A.; Sissons, M. In vitro starch digestion and technological properties of spaghetti fortified with lupin protein isolate. Int. J. Food Sci. Technol. 2021, 56, 3567–3577. [Google Scholar] [CrossRef]

- Fardet, A.; Abecassis, J.; Hoebler, C.; Baldwin, P.M.; Buleon, A.; Berot, S.; Barry, J.-L. Influence of technological modifications of the protein network from pasta on in vitro starch degradation. J. Cereal Sci. 1999, 30, 133–145. [Google Scholar] [CrossRef]

- Gharibzahedi, S.M.T.; Yousefi, S.; Chronakis, I.S. Microbial transglutaminase in noodle and pasta processing. Crit. Rev. Food Sci. Nutr. 2017, 59, 313–327. [Google Scholar] [CrossRef]

- Aalami, M.; Leelavathi, K. Effect of microbial transglutaminase on spaghetti quality. J. Food Sci. 2008, 73, C306–C312. [Google Scholar] [CrossRef]

- D’Egidio, M.G.; De Stefanis, E.; Fortini, S.; Galterio, G.; Nardi, S.; Sgrulletta, D.; Bozzini, A. Standardization of cooking quality analysis in macaroni and pasta products. Cereal Foods World 1982, 27, 367–368. [Google Scholar]

- Li, L.-Y.; Tan, T.-C.; Liong, M.-T.; Easa, A.M. Preparation and evaluation of chili powder-enriched layered noodles. LWT Food Sci. Technol. 2014, 59, 566–571. [Google Scholar] [CrossRef]

- Holm, J.; Bjoerck, I.; Eliasson, A.C. Effects of thermal processing of wheat on starch. I. Physico-chemical and functional properties. J. Cereal Sci. 1988, 8, 249–260. [Google Scholar] [CrossRef]

- Fares, C.; Codianni, P.; Nigro, F.; Platani, C.; Scazzina, F.; Pellegrini, N. Processing and cooking effects on chemical, nu-tritional and functional properties of pasta obtained from selected emmer genotypes. J. Sci. Food Agric. 2008, 88, 2435–2444. [Google Scholar] [CrossRef]

- Dhital, S.; Katawal, S.B.; Shrestha, A.K. Formation of resistant starch during processing and storage of instant noodles. Int. J. Food Propuls. 2010, 13, 454–463. [Google Scholar] [CrossRef] [Green Version]

- Garcia-Alonso, A.; Jimenez-Escrig, A.; Martin-Carron, N.; Bravo, L.; Saura-Calixto, F. Assessment of some parameters involved in the gelatinization and retrogradation of starch. Food Chem. 1999, 66, 181–187. [Google Scholar] [CrossRef]

- Colonna, P.; Barry, J.L.; Cloarec, D.; Bornet, F.; Gouilloud, S.; Galmiche, J.P. Enzymatic susceptibility of starch from pasta. J. Cereal Sci. 1990, 11, 59–70. [Google Scholar] [CrossRef] [Green Version]

- Wang, S.; Copeland, L. Molecular disassembly of starch granules during gelatinization and its effect on starch digestibility: A review. Food Funct. 2013, 4, 1564–1580. [Google Scholar] [CrossRef]

- Frei, M.; Siddhuraju, P.; Becker, K. Studies on the in vitro starch digestibility and the glycemic index of six different in-digenous rice cultivars from the Philippines. Food Chem. 2003, 83, 395–402. [Google Scholar] [CrossRef]

- Alzaabi, A.; Fielding, B.; Robertson, M. Effect of starchmeal chilling and reheating on postprandial glycaemia in overweight and obese individuals. Proceedings. Nutr. Soc. 2018, 77, E168. [Google Scholar] [CrossRef]

- Lu, L.W.; Venn, B.; Lu, J.; Monro, J.; Rush, E. Effect of cold storage and reheating of parboiled rice on postprandial gly-caemic response, satiety, palatability and chewed particle size distribution. Nutrients 2017, 9, 475. [Google Scholar] [CrossRef]

| Fraction | Semolina | Farinograph | ||

|---|---|---|---|---|

| Protein (14% mb) | FWA% (14% mb) | DDT (min) | Softness at 5 min | |

| <180 μm | 14.51 f | 65.95 f | 3.89 de | 74.75 f |

| 180 μm | 13.93 e | 61.55 e | 2.69 b | 57.15 e |

| 250 μm | 13.27 d | 57.9 d | 2.34 a | 34.40 d |

| 315 μm | 12.61 b | 54.55 b | 3.27 c | 11.25 b |

| 425 μm | 12.32 a | 53.25 a | 4.18 e | 0.25 a |

| Control | 13.11 c | 57.1 c | 3.93 de | 19.65 c |

| LSD (av.) | 0.09 | 0.38 | 0.38 | 7.44 |

| p | <0.001 | <0.001 | <0.001 | <0.001 |

| Pasta | FCT (min) | F-PH (g) | F-Area (g/s) | Overcook Tolerance | CL% | WABS% | S-PH (g) | S-Area (g/s) | DPL* | DPa* | DPb* |

|---|---|---|---|---|---|---|---|---|---|---|---|

| <180 μm | 10.5 | 867 c | 382 c | 31.0 bc | 6.0 b | 123.9 a | 20.9 a | 10.1 ab | 58.80 a | 5.24 | 31.25 a |

| 180 μm | 11 | 926 d | 384 c | 32.3 c | 5.2 a | 131.1 b | 21.2 a | 9.6 a | 63.05 bc | 3.22 | 35.29 c |

| 250 μm | 12 | 820 b | 339 b | 26.3 a | 5.4 ab | 141.8 c | 21.0 a | 10.6 ab | 65.26 cd | 1.84 | 34.98 b |

| 315 μm | 12 | 780 a | 317 a | 26.4 a | 5.4 ab | 147.9 d | 22.6 a | 12.0 abc | 66.46 d | −0.48 | 39.01 f |

| 425 μm | 12.5 | 792 ab | 323 a | 27.0 ab | 5.5 ab | 150.2 d | 25.6 b | 13.8 c | 63.23 bc | −0.41 | 37.43 e |

| Control | 12 | 883 c | 371 c | 29.8 abc | 4.9 a | 140.4 c | 22.5 a | 12.2 bc | 61.95 b | 1.63 | 36.46 d |

| LSD | 34.43 | 14.4 | 4.011 | 0.6794 | 2.329 | 2.83 | 2.503 | 2.486 | 0.4006 | 0.013 | |

| p | <0.001 | <0.001 | <0.05 | 0.07 NS | <0.001 | <0.05 | <0.05 | <0.001 | <0.001 | <0.001 |

| Variable | Firmness | Overcook Tolerance | Dry Pasta Colour | Stickiness | Cooking Quality | Starch Digestibility | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Screw Speed (rpm) | F-PH (g) | F-Area (g/s) | DPL* | DPa* | DPb* | S-PH(g) | S-Area (g/s) | CL(%) | WABS(%) | AUC | |

| 150 | 2068 c | 1582 c | ND | 58.96 a | 0.77 a | 10.02 a | 14.3 b | 6.5 b | 6.8 a | 114.5 a | 4160 a |

| 200 | 1817 b | 1362 b | 40.11 b | 60.93 b | 1.03 b | 10.37 a | 10.4 a | 4.8 a | 7.6 ab | 120.0 a | 4453 a |

| 250 | 1380 a | 974 a | 27.26 a | 61.79 c | 1.38 c | 11.30 b | 10.4 a | 3.7 a | 8.5 b | 120.1 a | 4234 a |

| 300 | 1325 a | 955 a | 29.89 a | 62.41 d | 1.61 c | 12.60 c | 10.0 a | 4.3 a | 10.2 c | 123.9 a | 4212 a |

| LSD | 82.1 | 74.1 | 9.105 | 0.585 | 0.28 | 0.79 | 2.55 | 1.29 | 1.02 | 16.06 | 1031 |

| p | <0.001 | <0.001 | <0.05 | <0.05 | <0.05 | <0.05 | <0.05 | <0.05 | <0.05 | 0.45 NS | 0.81 NS |

| Die Temp. (°C) | |||||||||||

| 60 | 1652 b | 1275 b | 33.7 b | 60.46 b | 1.31 b | 11.64 a | 11.7 ab | 4.9 a | 6.8 a | 130.5 b | 4907 a |

| 70 | 1660 b | 1181 b | 37.8 bc | 59.39 a | 1.12 a | 12.95 b | 14.2 b | 8.0 b | 9.2 ab | 133.8 b | 5078 a |

| 75 | 1356 a | 778 a | 11.1 a | 58.54 a | 1.38 c | 13.71 c | 10.8 ab | 5.2 a | 10.1 ab | 130.9 b | 5601 a |

| 85 | 2282 c | 1476 c | 42.2 c | 58.61 a | 1.44 c | 16.05 d | 9.9 a | 4.9 a | 11.9 b | 111.6 a | 4596 a |

| LSD | 91.7 | 138.7 | 5.754 | 0.91 | 0.07 | 0.29 | 3.76 | 1.91 | 4.97 | 11.52 | 1956 |

| p | <0.001 | <0.001 | <0.001 | <0.05 | 0.001 | <0.001 | 0.12 NS | <0.05 | 0.16 NS | <0.05 | 0.52 NS |

| Die Pressure (bar) | |||||||||||

| 14 | 1151 a | 892 a | 27.8 ab | 58.78 a | 2.09 b | 13.02 b | 9.3 a | 3.2 a | 7.0 a | 131.5 a | 4858 a |

| 22 | 1293 b | 947 a | 30.6 b | 60.79 c | 1.54 a | 11.33 a | 9.5 a | 3.0 a | 8.0 a | 124.2 a | 5089 a |

| 28 | 1587 c | 1220 b | 28 ab | 60.76 c | 12 c | 11.11 a | 9.7 a | 3.1 a | 7.5 a | 123.1 a | 5224 a |

| 32 | 1561 c | 1228 b | 14.6 a | 59.81 b | 1.57 a | 12.62 b | 10.0 a | 3.7 a | 7.2 a | 121 a | 5304 a |

| LSD | 112.2 | 68.8 | 15.2 | 0.27 | 0.19 | 0.85 | 1.30 | 1.03 | 3.01 | 21.64 | 1713 |

| p | <0.001 | <0.001 | 0.14 NS | <0.001 | <0.05 | <0.05 | 0.68 NS | 0.40 NS | 0.71 NS | 0.53 NS | 0.84 NS |

| Pasta | FCT (min:s) | F-PH (g) | F-Area (g/s) | Overcooking Tolerance | S-PH (g) | S-Area (g/s) | Cooking Loss (%) | WABS | AUC |

|---|---|---|---|---|---|---|---|---|---|

| Commercial semolina | 12:30 | 795 c | 350 e | 25.9 ab | 19.8 abc | 9.0 ab | 5.6 a | 144 a | 4464 a |

| Commercial + TG | 13:00 | 774 c | 341 d | 28.6 bc | 16.7 a | 8.0 a | 6.5 b | 148 ab | 4810 a |

| Low protein | 12:30 | 638 b | 259 b | 31.7 c | 23.1 cd | 11.9 b | 7.2 c | 161 c | 4612 a |

| Low protein + TG | 12:30 | 536 a | 211 a | 24.3 a | 23.3 d | 15.1 c | 9.4 d | 162 c | 4700 a |

| High protein | 13:00 | 823 d | 330 c | 24.6 a | 19.3 ab | 9.5 ab | 5.7 a | 152 b | 4121 a |

| High protein + TG | 14:00 | 931 e | 379 e | 26.6 ab | 22.3 bcd | 8.6 a | 5.3 a | 152 b | 4200 a |

| Sample LSD | 21.40 | 10.53 | 3.29 | 3.46 | 3.16 | 0.47 | 4.4920 | 1006 | |

| p | <0.001 | <0.001 | <0.05 | <0.05 | <0.05 | <0.001 | <0.001 | NS |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sissons, M.; Cutillo, S.; Egan, N.; Farahnaky, A.; Gadaleta, A. Influence of Some Spaghetti Processing Variables on Technological Attributes and the In Vitro Digestion of Starch. Foods 2022, 11, 3650. https://doi.org/10.3390/foods11223650

Sissons M, Cutillo S, Egan N, Farahnaky A, Gadaleta A. Influence of Some Spaghetti Processing Variables on Technological Attributes and the In Vitro Digestion of Starch. Foods. 2022; 11(22):3650. https://doi.org/10.3390/foods11223650

Chicago/Turabian StyleSissons, Mike, Silvia Cutillo, Narelle Egan, Asgar Farahnaky, and Agata Gadaleta. 2022. "Influence of Some Spaghetti Processing Variables on Technological Attributes and the In Vitro Digestion of Starch" Foods 11, no. 22: 3650. https://doi.org/10.3390/foods11223650

APA StyleSissons, M., Cutillo, S., Egan, N., Farahnaky, A., & Gadaleta, A. (2022). Influence of Some Spaghetti Processing Variables on Technological Attributes and the In Vitro Digestion of Starch. Foods, 11(22), 3650. https://doi.org/10.3390/foods11223650